Automatic calibration apparatus of fully automatic portable eddy current displacement sensor

A displacement sensor, automatic calibration technology, applied in the direction of using electrical devices, measuring devices, instruments, etc., can solve the problems of low calibration efficiency, inability to automatically calculate sensor coefficients, and no data storage function. Conducive to on-site calibration, easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings.

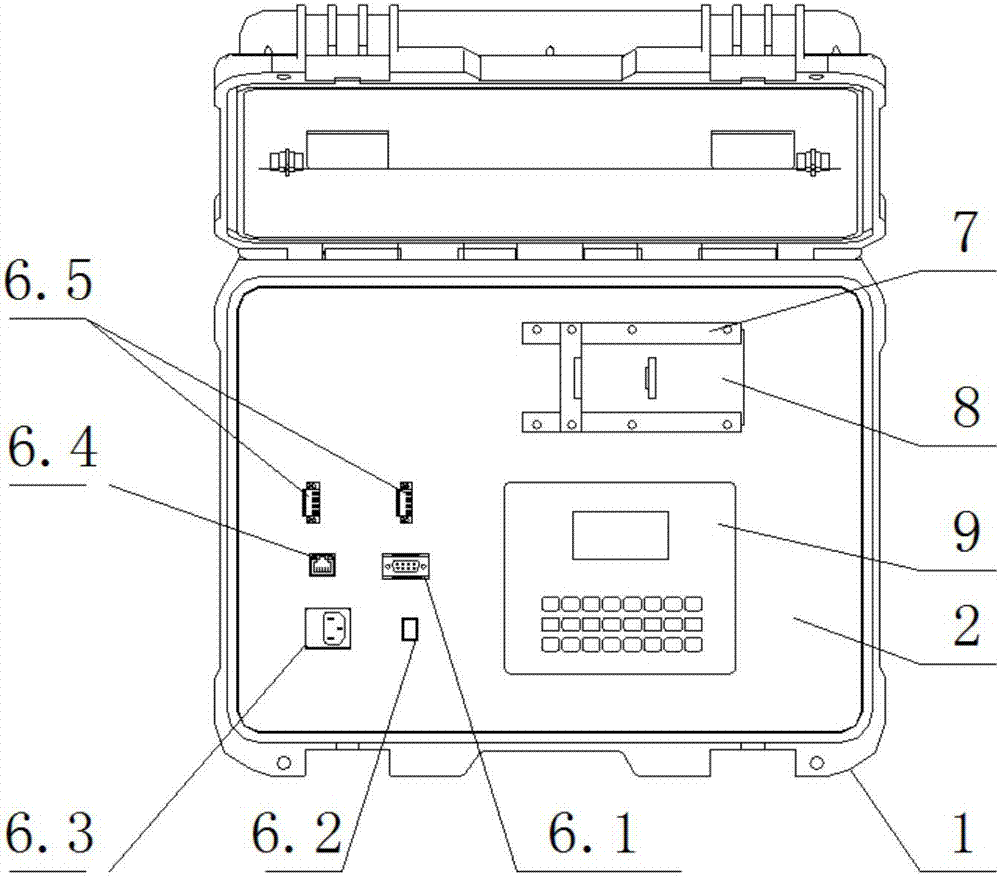

[0042] In order to clearly describe the connection relationship of each component of the device, the assembly connection relationship of the device is divided into three areas and explained separately. The three assembly areas of the device are: the outer box area, the installation floor area, and the installation panel area.

[0043] External box area:

[0044] The main component is the box body 1, and the installation base plate 2 and the installation panel 5 are directly assembled with it. The installation bottom plate 2 is fixed on the inner bottom of the box body 1 by bolts. The mounting panel 5 is fixed on the top of the cavity of the casing 1 by bolts.

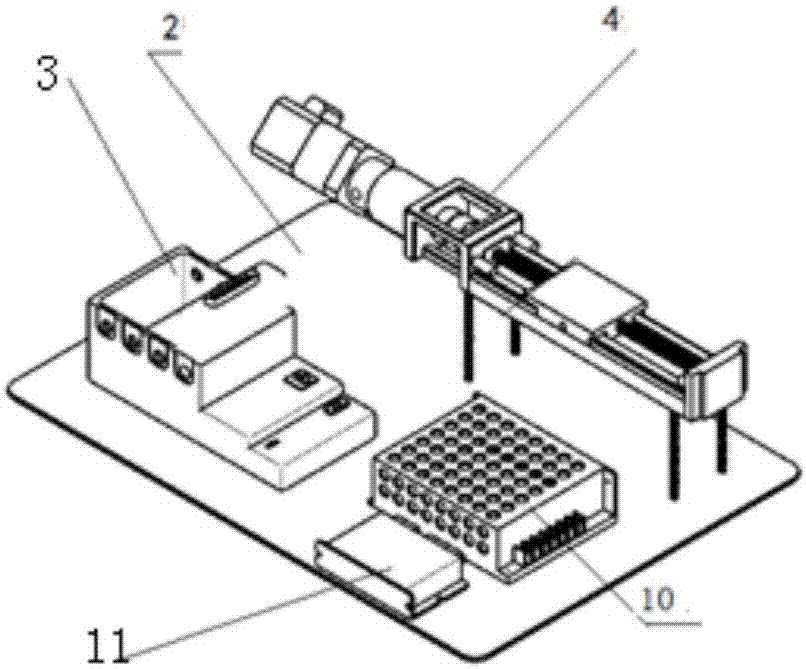

[0045] Such as image 3 Shown, mount the chassis area:

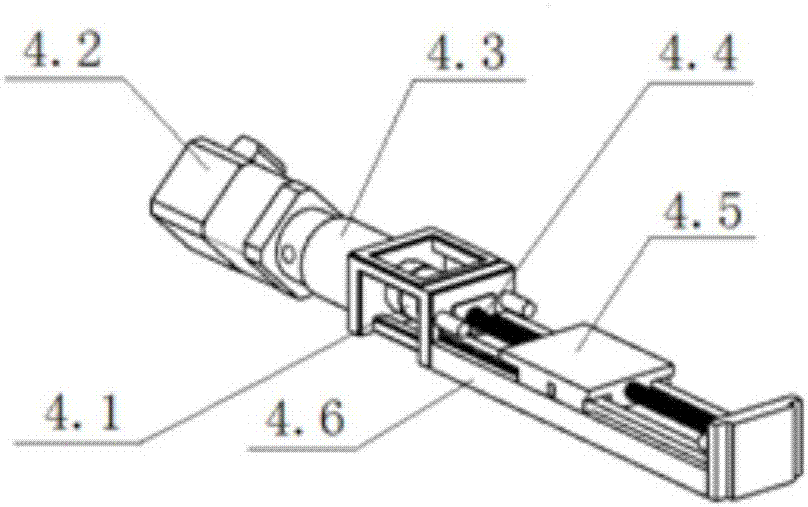

[0046] The following components are installed and fixed on the installation base plate 2 : signal acquisition device 3 , transmission device assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com