Graphene oxide standard leak and graphene oxide helium permeating component

A standard leakage hole and graphene technology, applied in the testing of machines/structural components, measuring devices, instruments, etc., can solve the problems that the upper and lower limits of the leakage rate cannot be met, the controllability of the leakage rate is poor, and it is unfavorable for industrial production. Effect of Uncertainty Reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The following is a specific implementation manner of the content of the present invention, and the content of the present invention will be further clarified through the specific implementation mode below. Of course, the following specific embodiments are described only to illustrate different aspects of the present invention, and should not be construed as limiting the scope of the present invention.

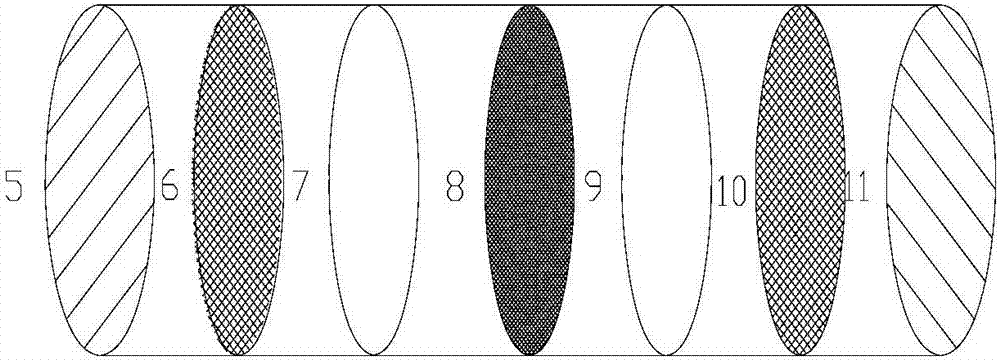

[0029] see figure 1 As shown, the graphene oxide film helium-infiltrating component of the present invention consists of a front discharge support structure 5, a front filter screen 6, an O-shaped sealing ring 7, a graphene oxide film assembly 8, an O-shaped sealing ring 9, a rear filter screen 10, and a rear filter screen 10. The discharge support structure 11 is composed of a symmetrical structure centered on the graphene oxide film assembly, wherein the front discharge support structure 5 and the rear discharge support structure 11 are connected together by screwing o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com