Denoising cup cover and wall breaker

A technology of noise reduction and cup cover, which is applied in home appliances, applications, kitchen appliances, etc., can solve the problems affecting the user experience, etc., and achieve the effect of simple structure and manufacturing process and noise elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

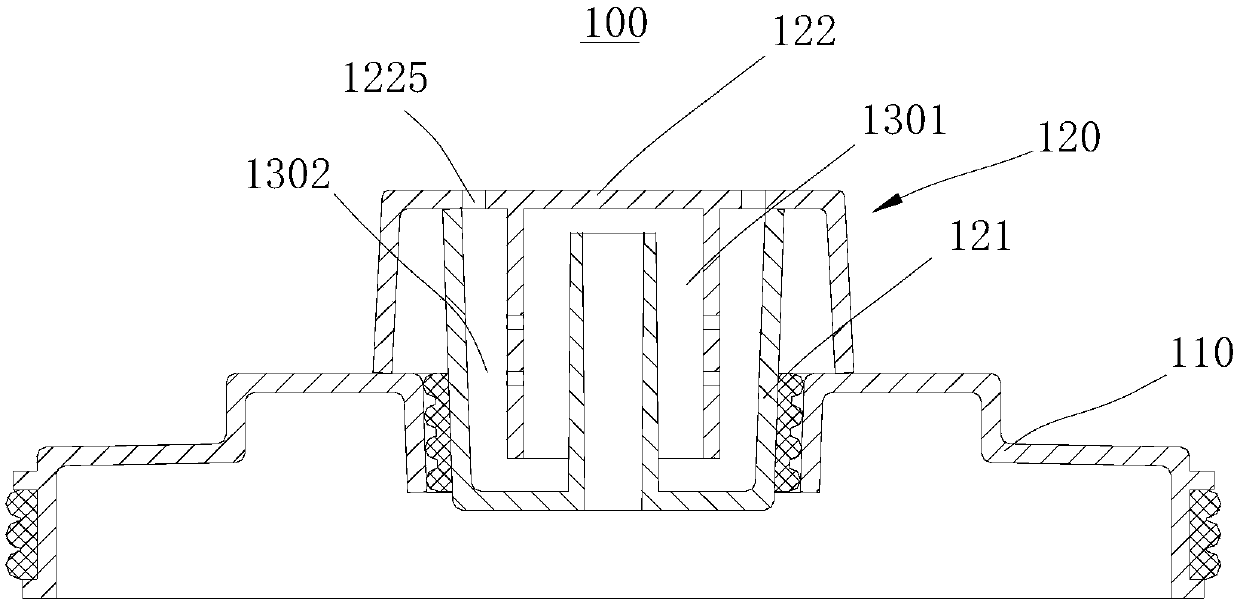

[0059] Such as figure 1 , this embodiment provides a noise-reducing cup cover 100, which is used to cooperate with the cup body of the broken wall machine. It mainly includes a cup cover body 110 and a feeding cover 120. .

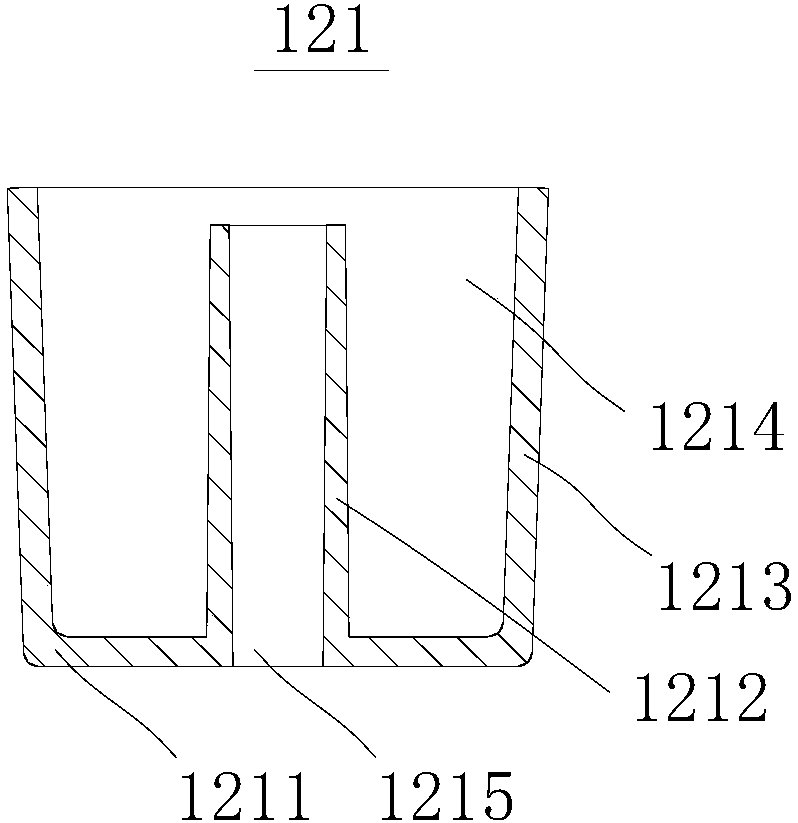

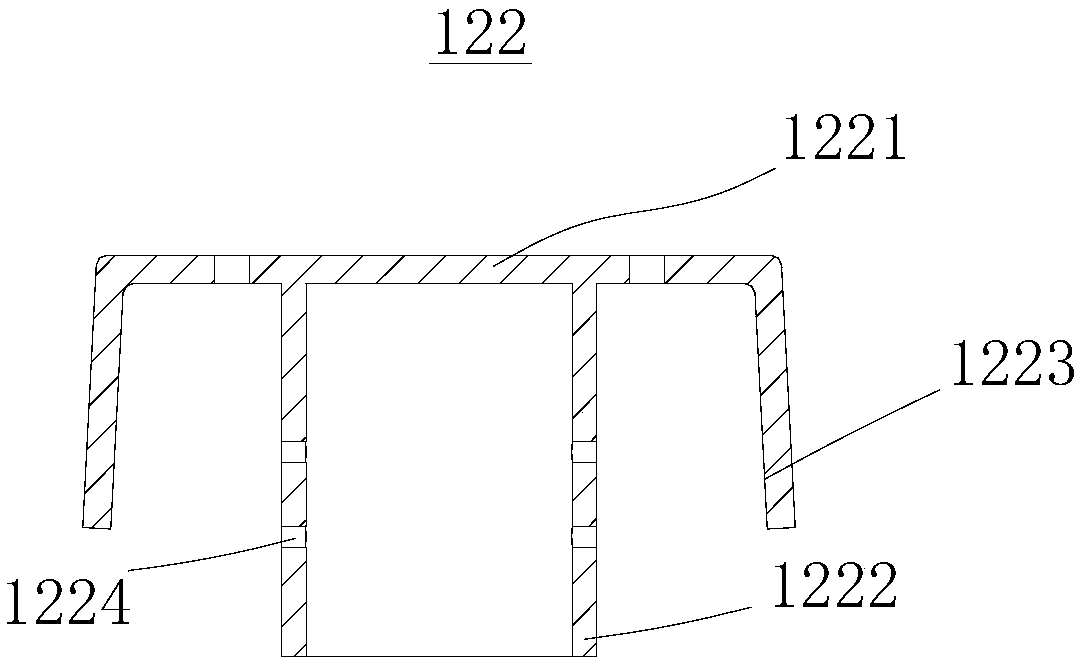

[0060] Specifically, such as figure 1 , figure 2 and image 3 , the feeding cover 120 includes a noise reduction component 121 and an upper noise reduction component 122 . The noise reduction assembly 121 includes a lower cover plate 1211, an inner cylinder 1212 and an outer cylinder 1213. One end of the inner cylinder 1212 and one end of the outer cylinder 1213 are respectively connected to the lower cover plate 1211. The outer cylinder 1213 is sleeved on the inner cylinder 1212. An accommodating space 1214 is formed between the cylinder 1213 and the inner cylinder 1212 ; the lower cover 1211 is also provided with a first through hole, and the first through hole communicates with the inner cylinder 1212 . The upper noise reduction assembly 122 inclu...

Embodiment 2

[0070] Such as Figure 4 As shown, this embodiment provides another noise-reducing cup cover 200 for a wall breaker, which is different from Embodiment 1 in that a conical barrel 210 and a water adding device 230 are added.

[0071] The conical cylinder 210 includes a large end and a small end, the large end is connected to the free end of the inner cylinder 1212; the wall of the conical cylinder 210 is provided with a through hole; the water adding device 230 is used to automatically add water to the accommodating space 1214 to form water seal.

[0072] Such as Figure 5 , the water adding device 230 comprises a water adding box 234, a first connecting rod 231, a second connecting rod 232, a third connecting rod 233, a rubber sheet 236 and a water adding valve 235, and the edge of the rubber sheet 236 is connected with the conical cylinder 210; and the rubber sheet 236 is recessed toward the inside of the tapered barrel 210 . One end of the first connecting rod 231 is conn...

Embodiment 3

[0079] Such as Figure 6 , in order to further increase the noise reduction, an auxiliary noise reduction device is added on the outer wall of the inner cylinder 1212 . Multiple noise reduction rings 310 are placed on the inner cylinder 1212. The noise reduction ring 310 is composed of a cone and a cylinder. The inner wall of the cylinder of the noise reduction ring 310 matches the outer wall of the inner cylinder 1212. . The inner wall of the tapered cylinder of the noise reduction ring 310 faces the propagation direction of the noise, and plays the role of hysteresis and reflection on the propagation of the noise; The outer wall of 1212 and the outer wall of the previous cone form a semi-closed anechoic chamber 320, which increases the number of anechoic chambers 320, further expands and concentrates the noise, and hysteresis occurs in the anechoic chamber, increasing the attenuation of the noise.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com