Motor noise-reducing structure of dust collector

A vacuum cleaner and noise reduction technology, which is applied in the field of noise reduction, can solve problems such as high noise of vacuum cleaners, and achieve the effects of extending the transmission path, reducing noise, and reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below with reference to the pictures in conjunction with the embodiments, so that those skilled in the art can implement it with reference to the description.

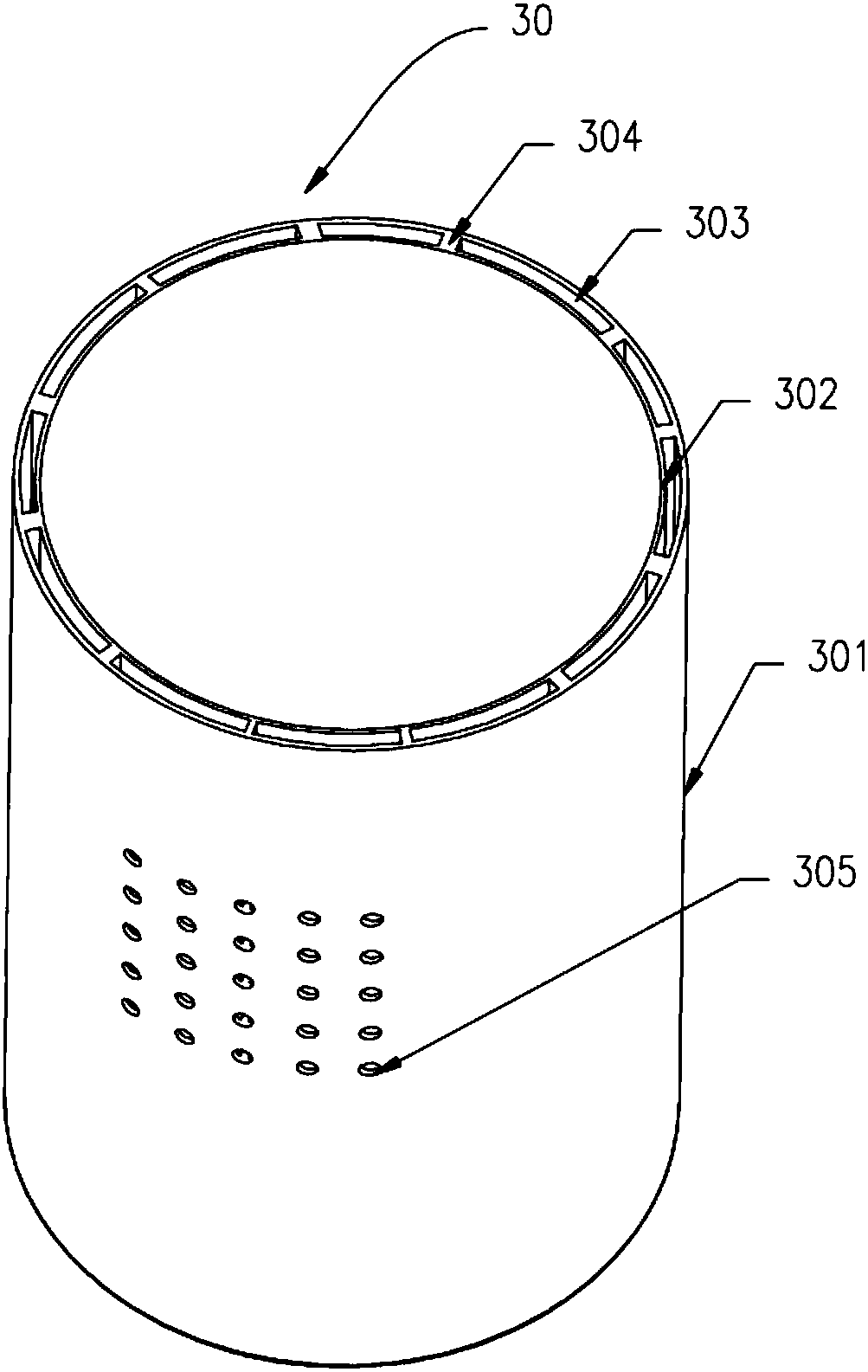

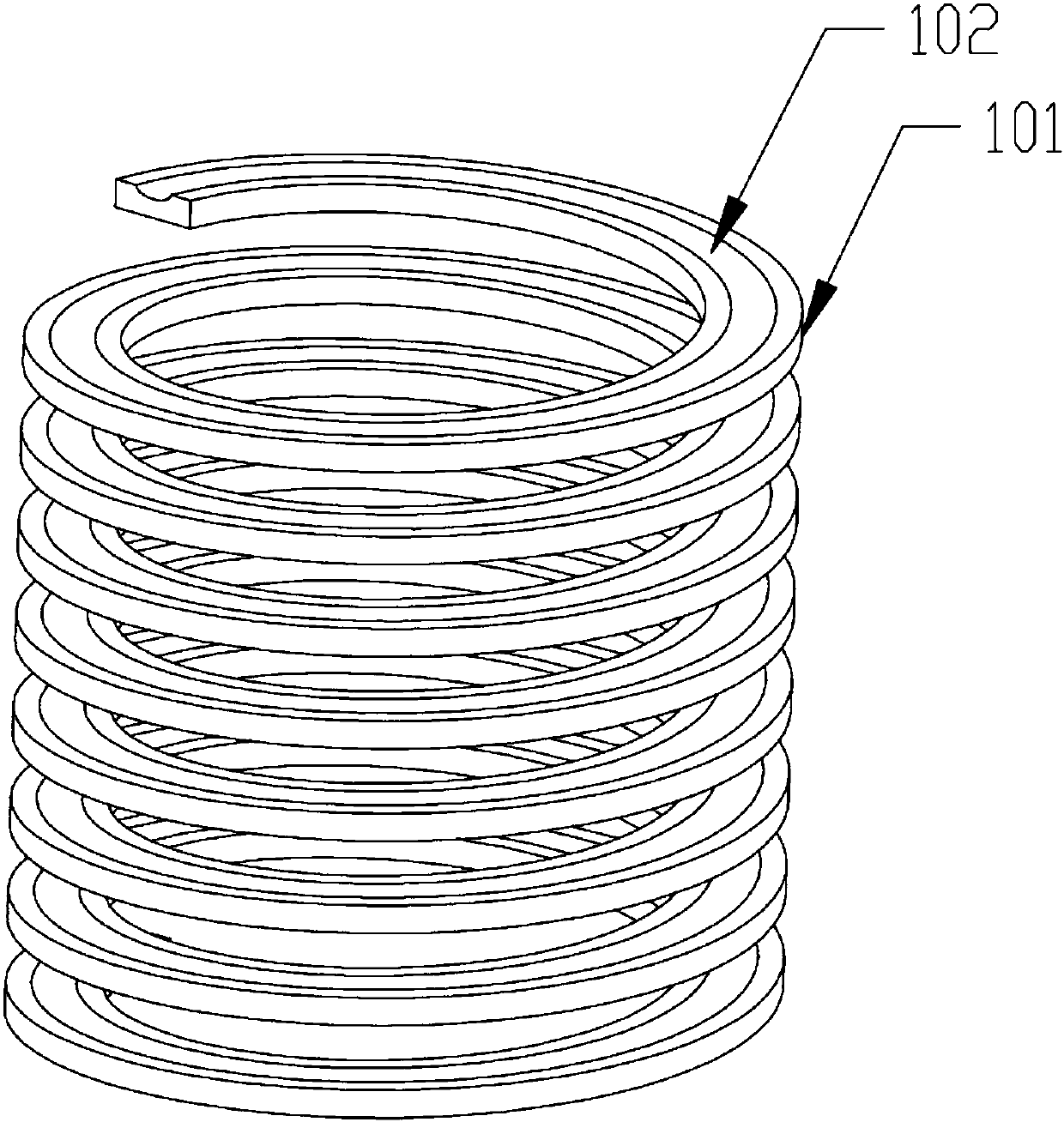

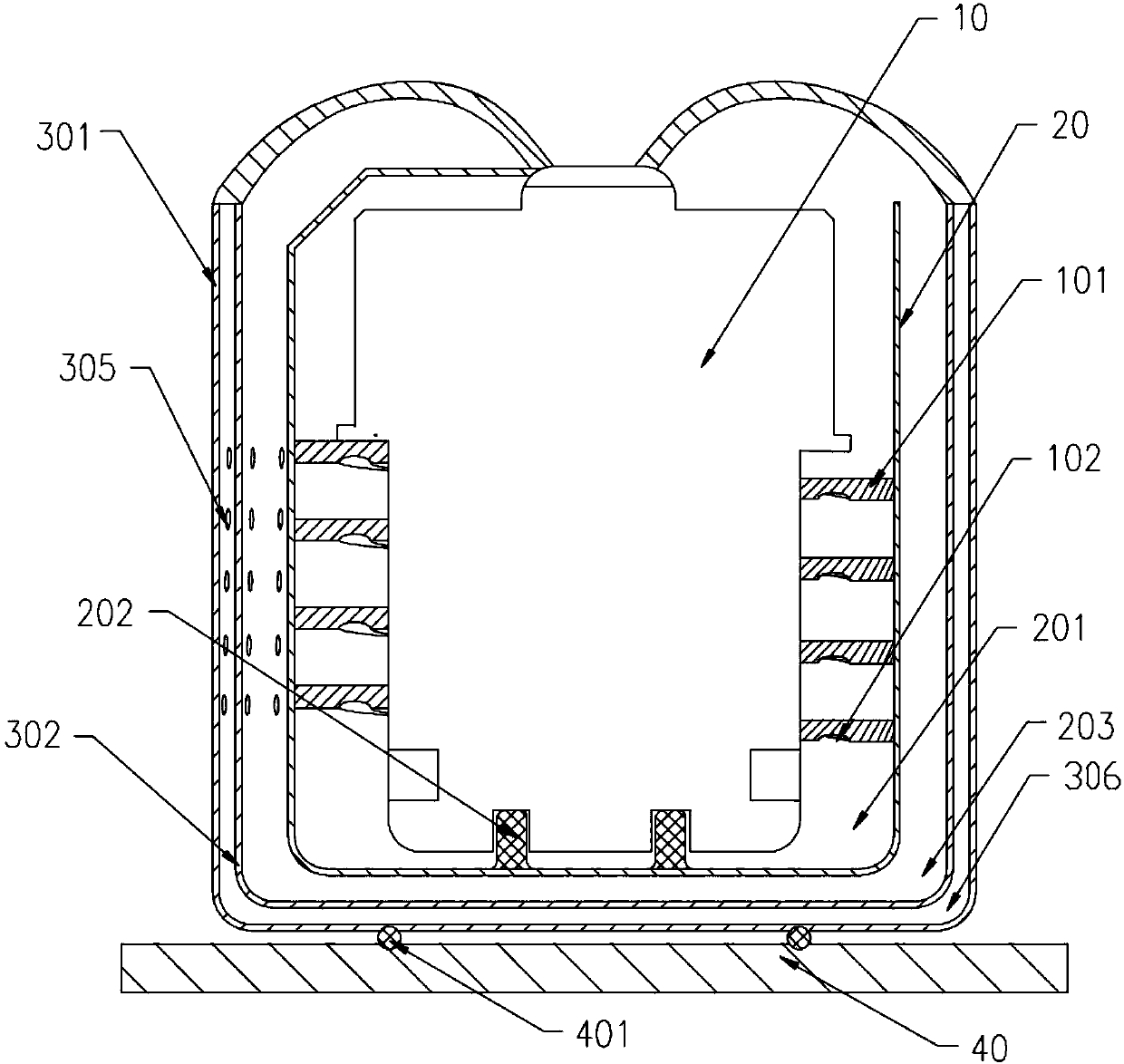

[0021] Such as Figure 1-3 As shown, this case lists a motor noise reduction structure for a vacuum cleaner, which overall includes: an inner motor cover 20 ; a deflector 101 ; a shock-absorbing column 202 ;

[0022] Motor inner cover 20, which is arranged on the outside of the vacuum cleaner motor 10, a first air flow chamber 201 is formed between the motor inner cover 20 and the vacuum cleaner motor 10, and a spiral deflector 101 is arranged in the first air flow chamber 201 , the deflector 101 increases the movement path of the airflow, so that the transmission path of the airflow noise is extended together, and the deflector 101 is also provided with a deflector groove 102, and the deflector 102 helps the air flow along the deflector 101 Get some exe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com