Continuous flue gas purification liquid mixing mechanism

A flue gas purification and liquid medicine technology, applied in mixers, fluid mixers, chemical instruments and methods, etc., can solve problems such as uneven local concentration, and achieve improved flue gas purification effect, simple structure, and uniform mixing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

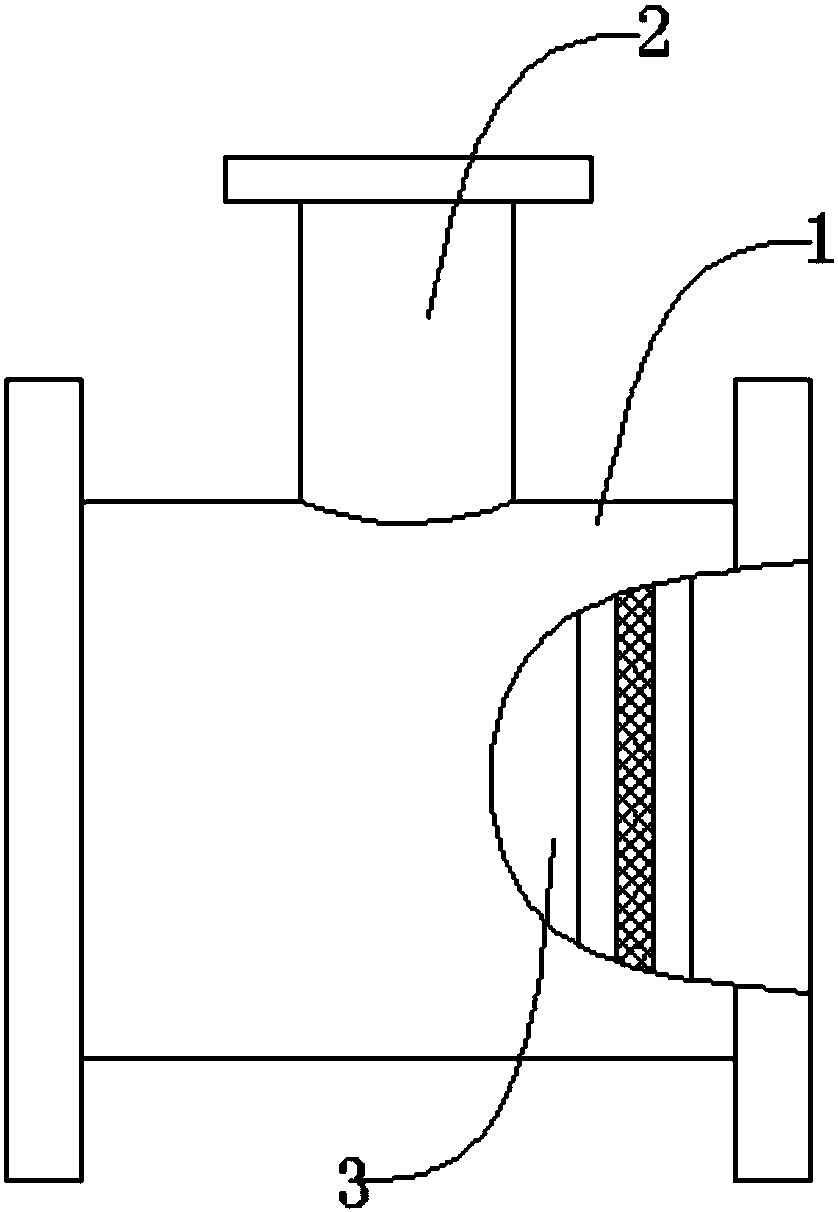

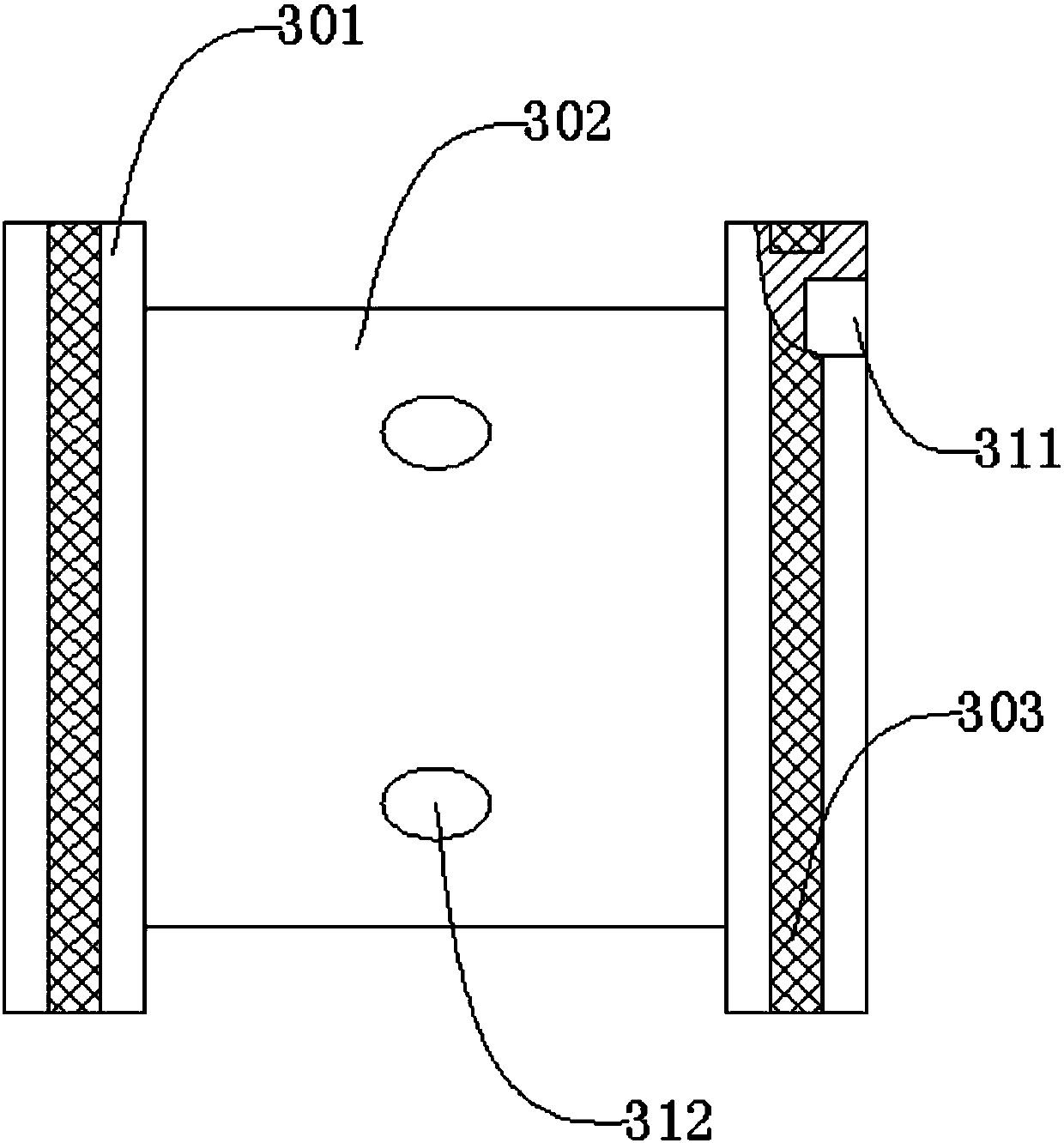

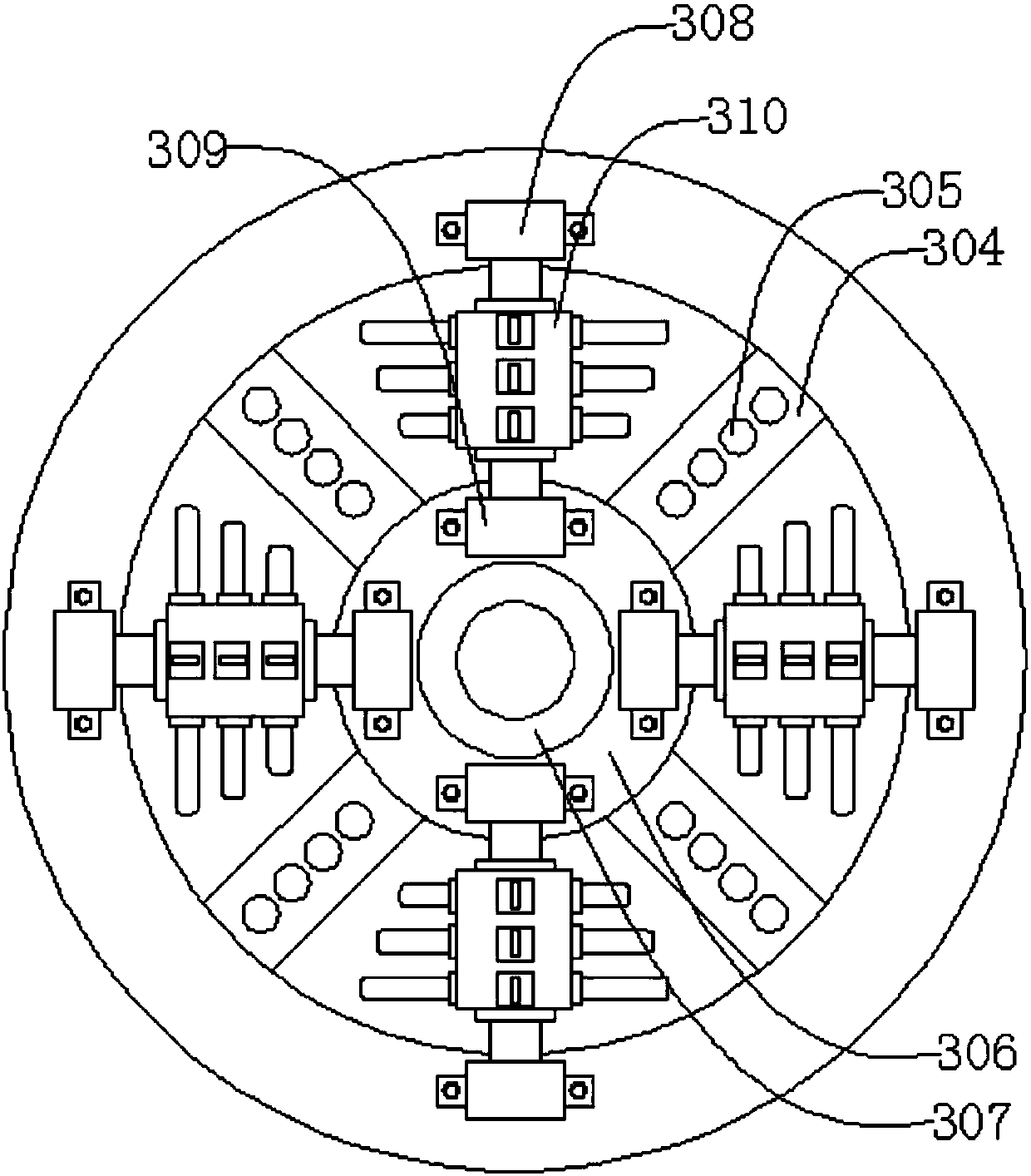

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6As shown, a continuous mixing mechanism for flue gas purification medicinal liquid includes an outer tube 1, a medicinal liquid inlet pipe 2, and a dispensing mixing mechanism 3. The medicinal liquid inlet pipe 2 is located outside the outer pipe 1, and the medicinal liquid mixing mechanism 3 is located inside the outer tube 1, and the drug dispensing and mixing mechanism 3 is connected to the outer tube 1 by welding; the drug dispensing and mixing mechanism 3 also includes two vertical rings 301 and a cylinder body 302 arranged in parallel along the outer tube 1 , sealing ring 303, liquid distribution pipe 304, liquid spray hole 305, confluence block 306, liquid distribution ring 307, first pressing block 308, second pressing block 309 distributed along the cylinder body 302 with no less than 2 pieces of liquid distribution pipe 304 . Mixing mechanism 310, the vertical ring 301 is located i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com