Cylinder-type upright agitator with adjustable height

A mixer and drum type technology, which is applied to mixer accessories, mixers with rotating agitation devices, mixers, etc., can solve the problems of inflexible and convenient use, and the inability to freely adjust the height of the barrel, so as to achieve reasonable structural design and easy maintenance. And rest, the effect of usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

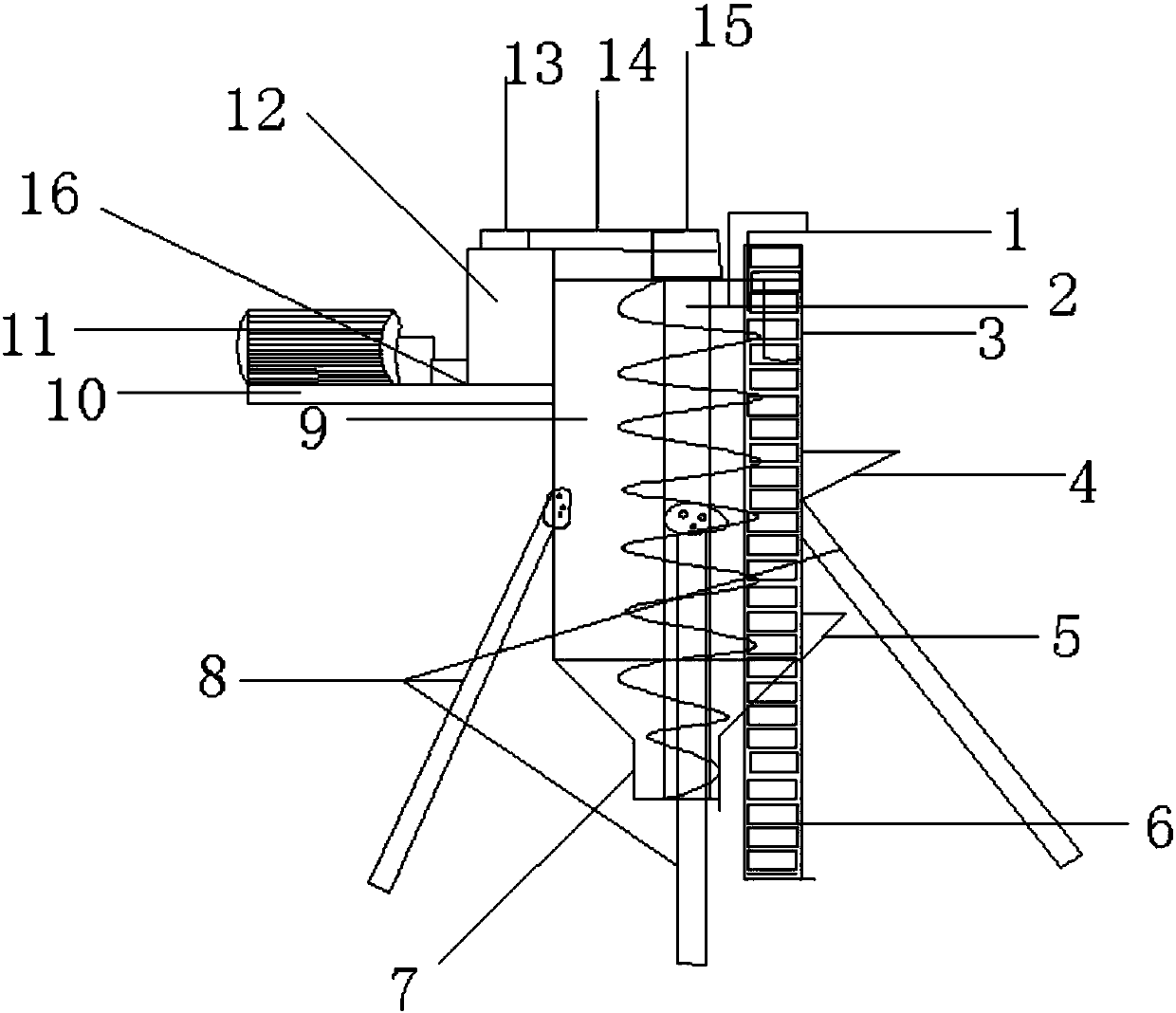

[0013] refer to figure 1 , a height-adjustable cylindrical vertical mixer, its structure includes an exhaust port 1, a spiral stirring rod 2, a perspective window 3, a first feed port 4, a second feed port 5, a telescopic man ladder 6, Discharge port 7, triangular support 8, mixing bucket 9, power unit 16, driving wheel device 13, belt 14, driven wheel device 15, the top of described air outlet 1 and mixing bucket 9 is connected by welding, and described spiral stirring The rod 2 is located in the middle of the mixing bucket 9, the upper end is connected with the driven wheel device 15 by a gear, and the lower end is connected with the discharge port 7, the tripod 8 is connected with the outer wall of the mixing bucket 9 by a rotating shaft and a nut, and the power unit 16 is composed of Motor 11, power bracket 10, reduction gear 12 are made up of, and described motor 11 and reduction gear 12 are connected with power bracket 10 through nut, and described motor 11 and reduction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com