A liquid distributor for horizontal separator

A technology of horizontal separator and liquid distributor, which is applied in the direction of cyclone axial reversal device, cyclone device, etc., can solve the problem of uneven liquid distribution, eliminate liquid cyclone, avoid excessive liquid flow, etc. The effect of large shock perturbations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

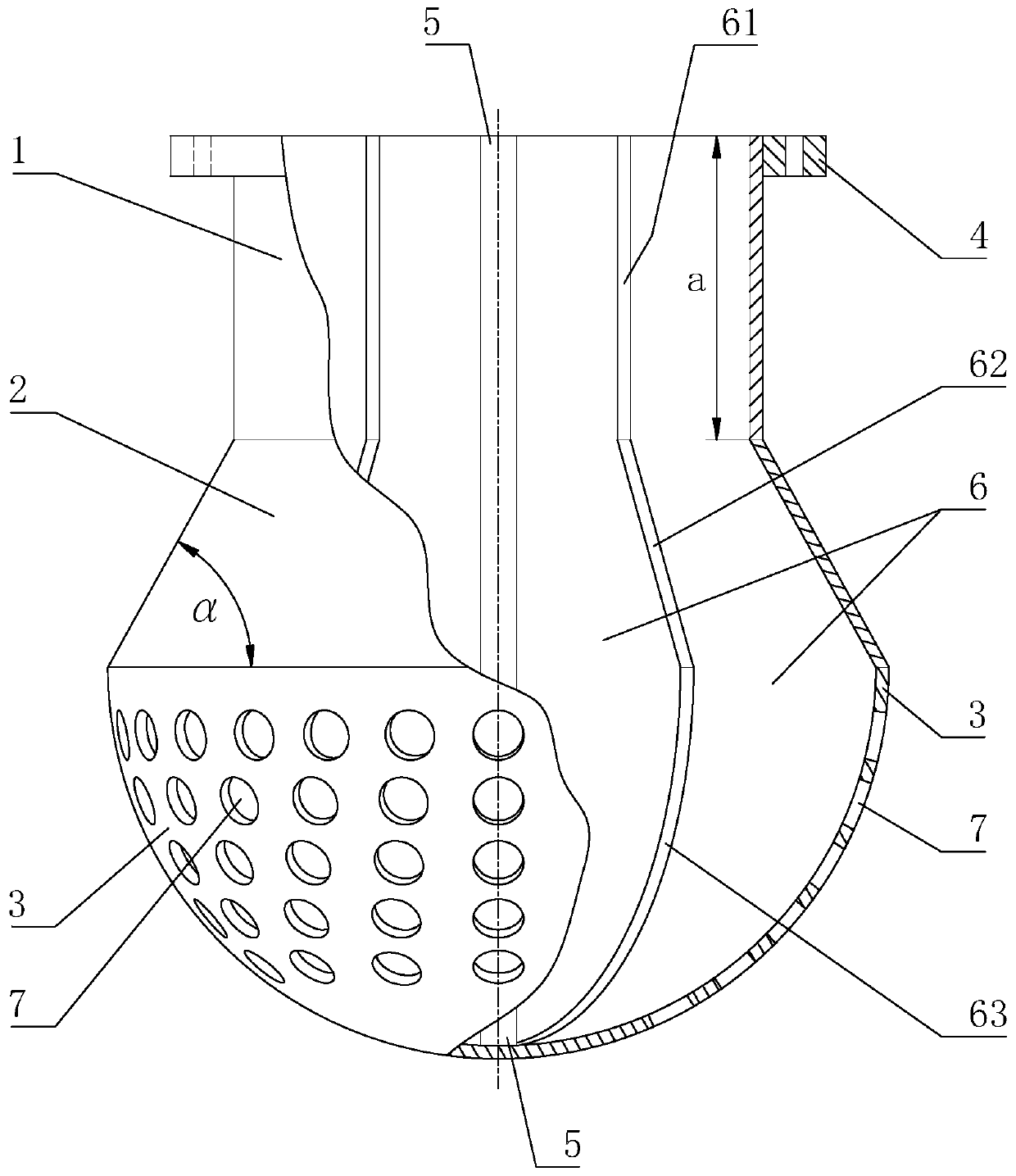

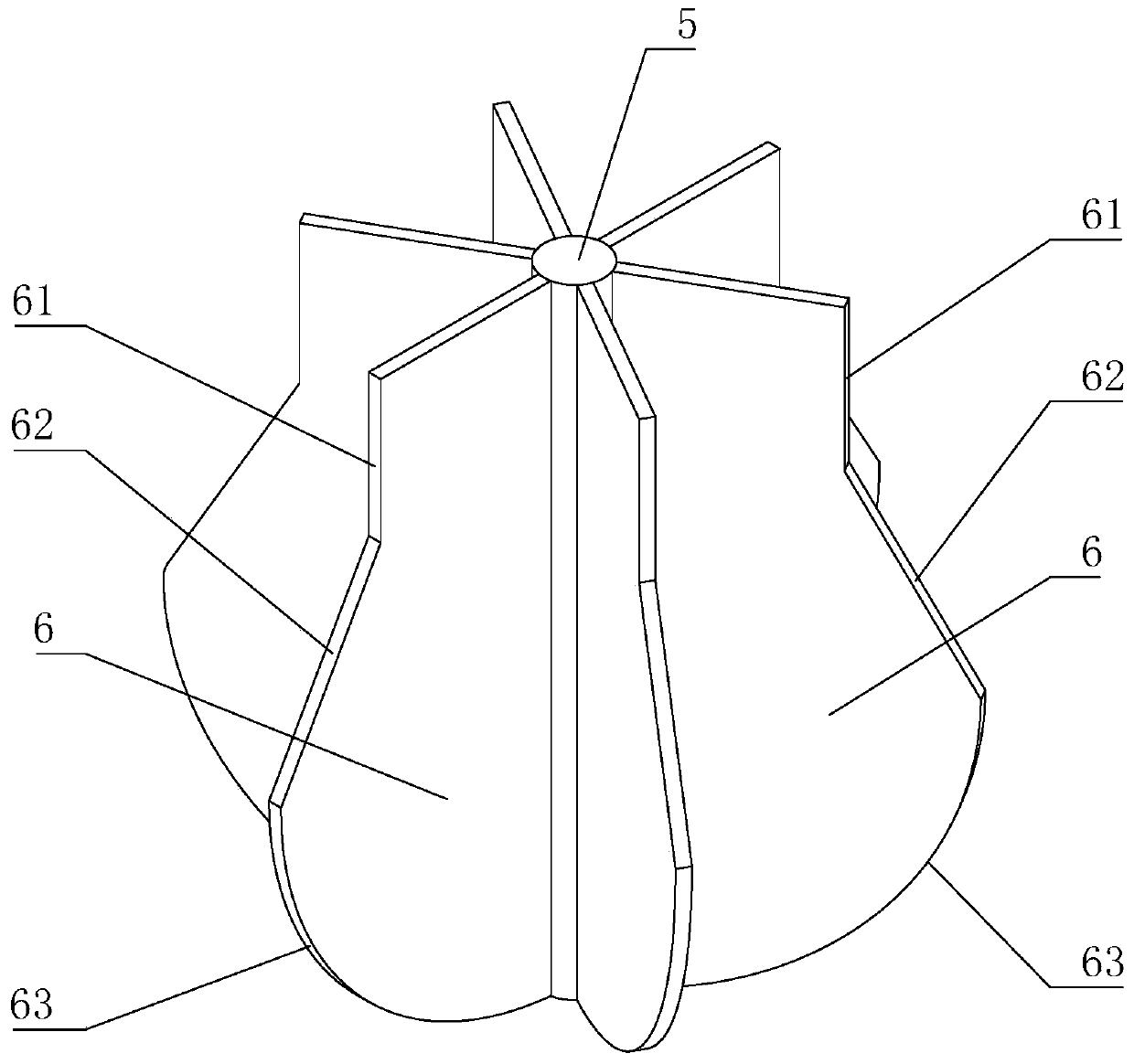

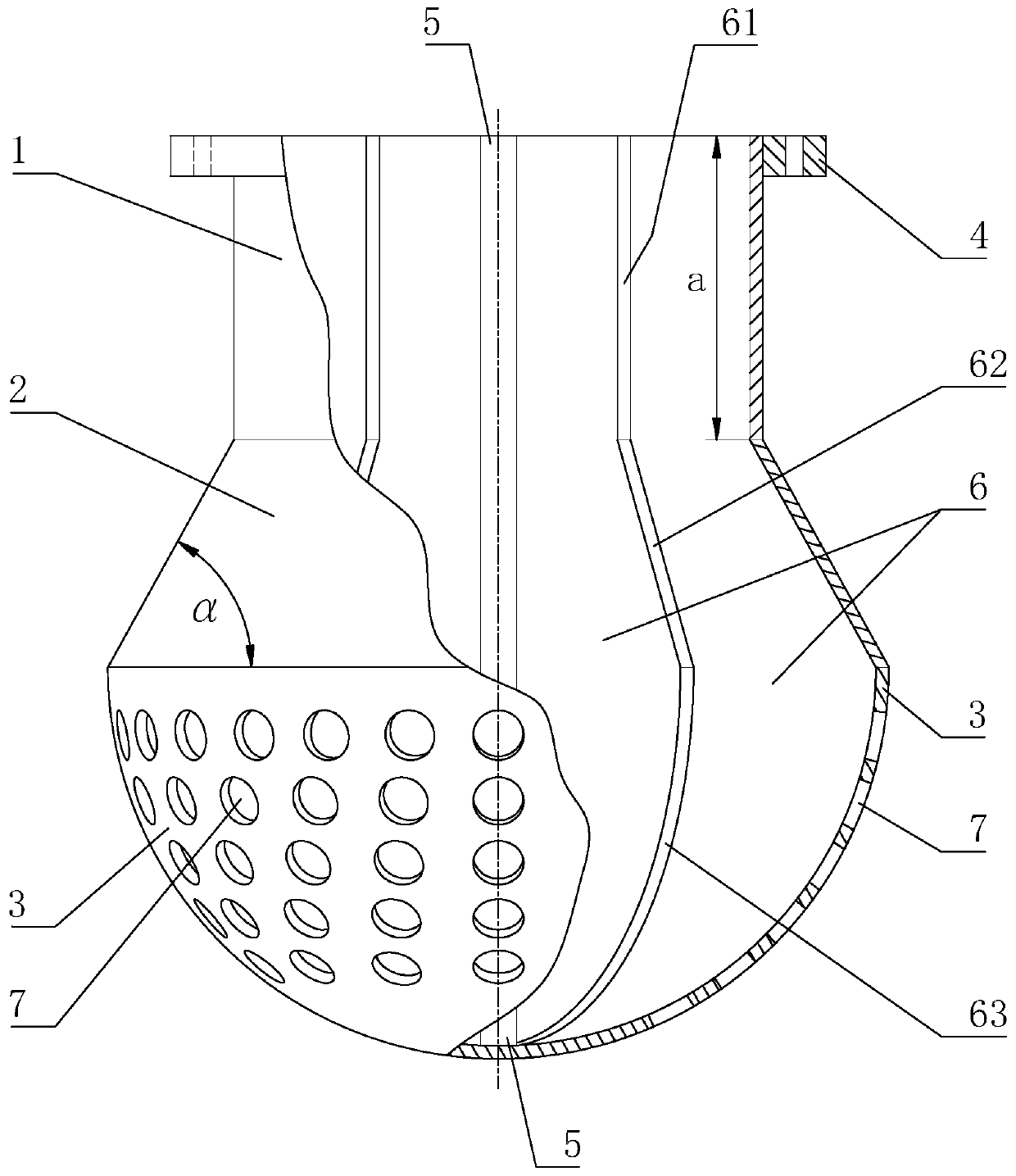

[0011] see figure 1 with figure 2 , The liquid distributor (abbreviated as the liquid distributor) used in the horizontal separator of the present invention is provided with a straight pipe 1, a circular table-shaped expanded diameter pipe 2 and a spherical crown-shaped liquid distribution plate 3 from top to bottom. The cross-sectional shape of the straight pipe 1 is circular. The top of the straight pipe 1 is provided with a flange 4 to connect with the outlet pipe (not shown in the figure) of the cyclone separation section. The bottom of the liquid distribution plate 3 is a non-perforated area, and the rest is an open area, and the open area is uniformly provided with a plurality of liquid distribution holes 7 . The opening area is roughly in the shape of a spherical band.

[0012] The straight pipe 1, the diameter-expanding pipe 2 and the liquid distribution plate 3 form the liquid distributor shell, and the liquid distributor shell is provided with a column 5 and a ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com