Car door assembly fixture and movable car door assembly fixture assembly

A technology for assembling tooling and doors, applied in auxiliary devices, manufacturing tools, metal processing equipment and other directions, can solve the problems of unsatisfactory body appearance quality, affecting production rhythm, affecting the improvement of door assembly accuracy, etc., to improve assembly accuracy and assembly. Quality, reduce debugging workload, and save the effect of manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments described below with reference to the accompanying drawings are exemplary, and are only used to explain the present invention, and cannot be construed as limiting the present invention.

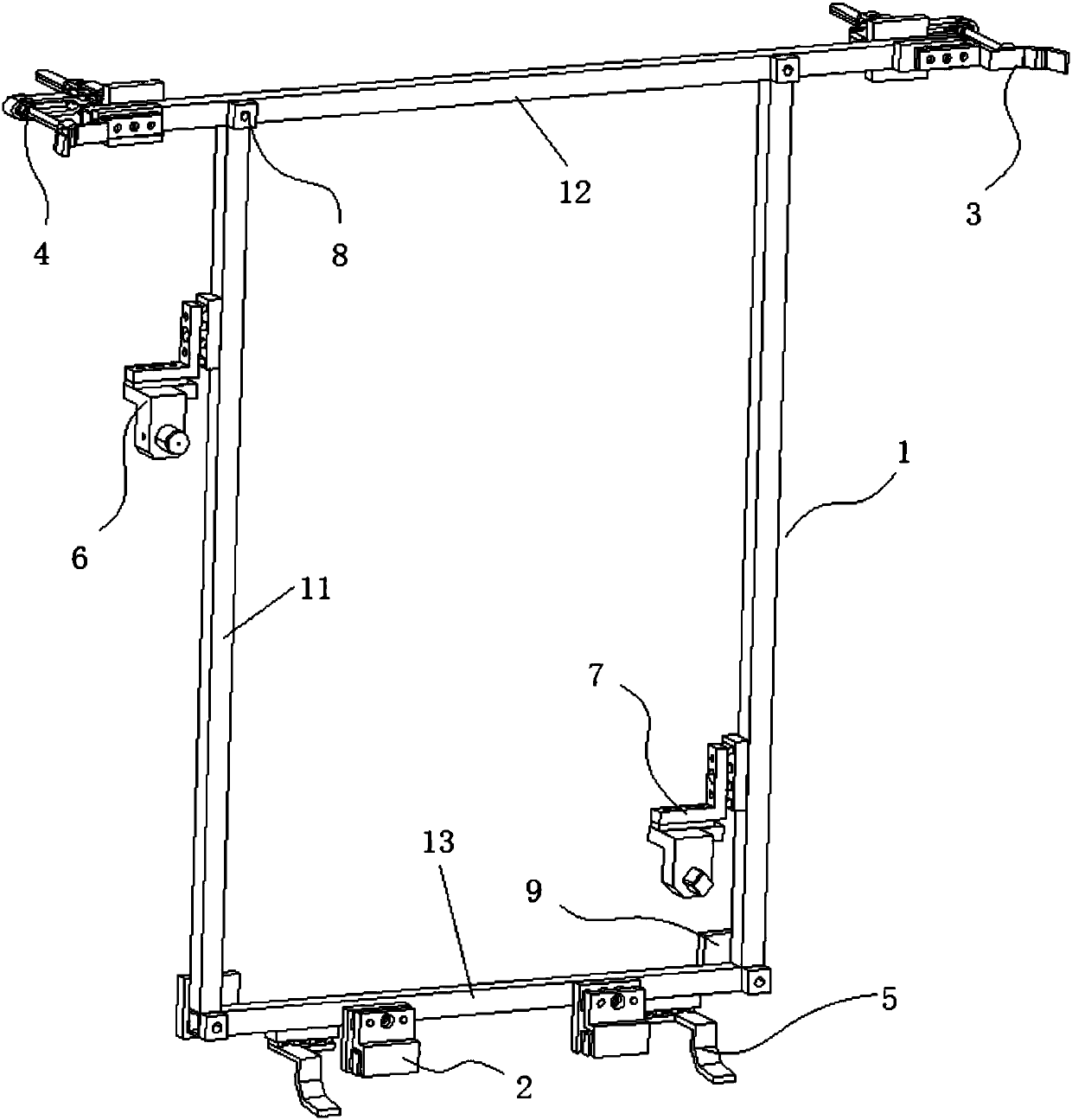

[0045] Such as figure 1 As shown, the embodiment of the present invention provides a vehicle door assembly tool, including:

[0046] The frame 1, which is a vertically arranged quadrilateral frame structure, has a first surface and a second surface that are arranged oppositely; the first surface is the front of the frame 1 in the figure, and the second surface is the back of the frame 1 in the figure.

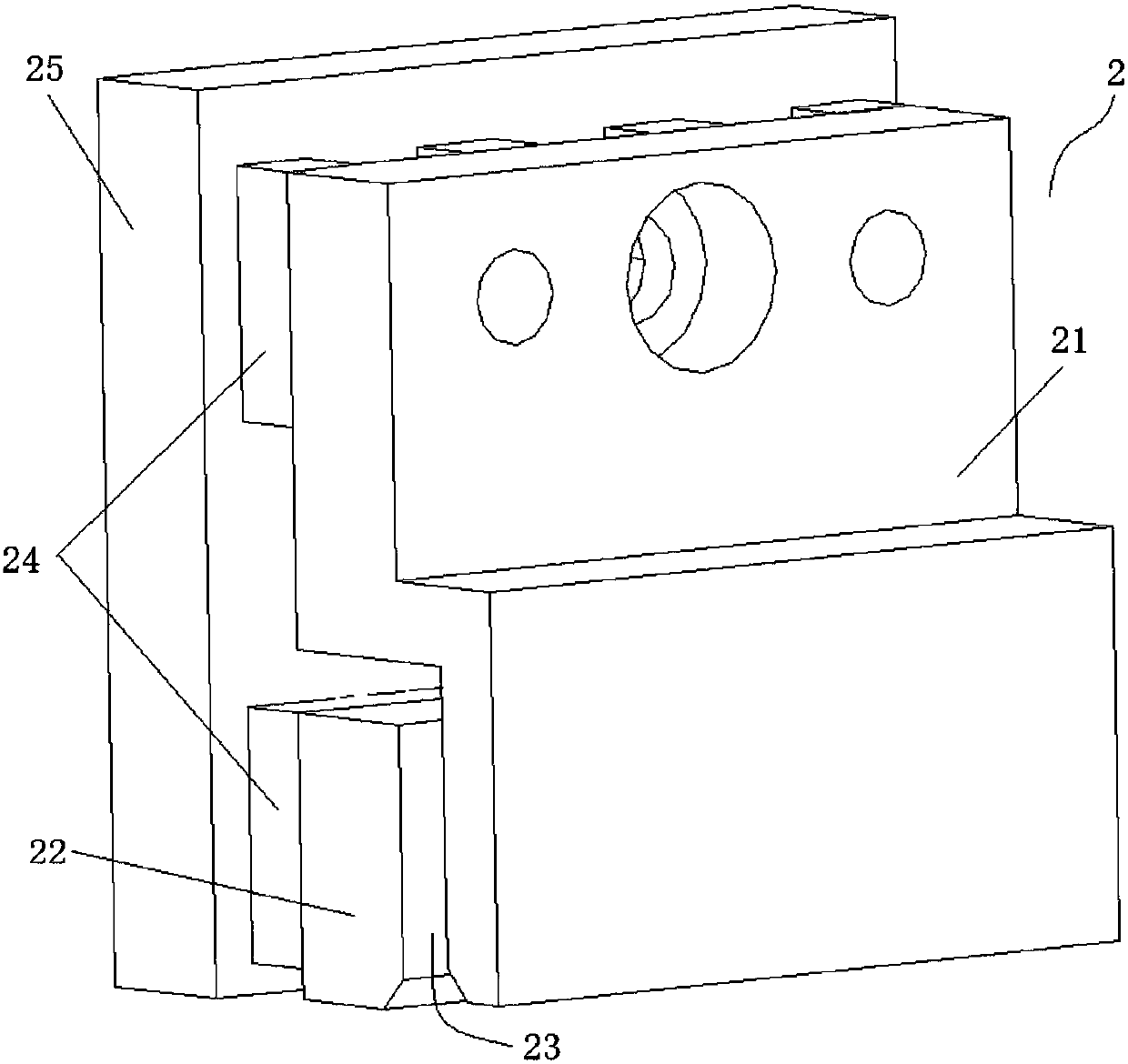

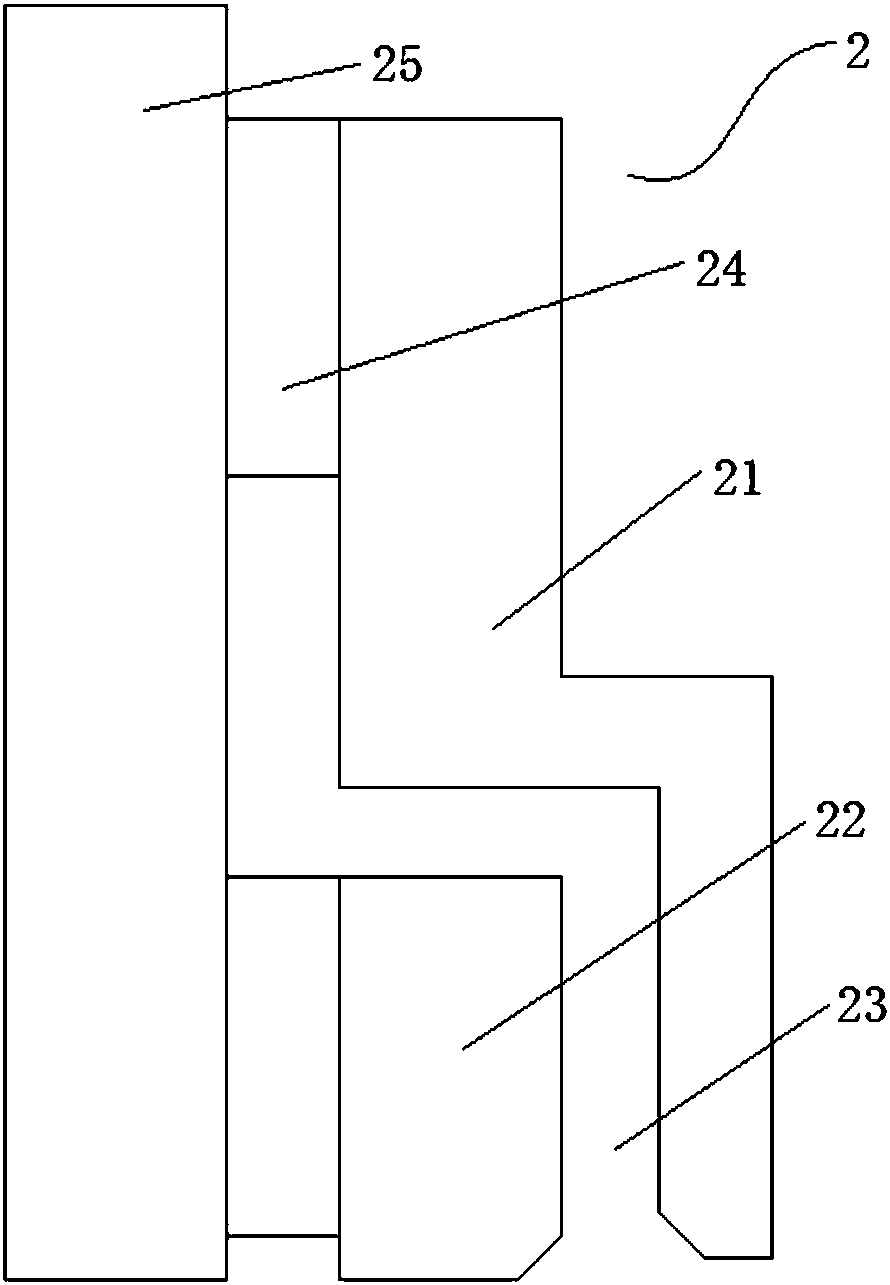

[0047] The door sill flanging positioning mechanism 2 is fixedly arranged at the bottom end of the first surface of the frame 1; it is used for clamping with the flanging structure at the door sill, thereby limiting the position of the bottom of the frame 1 relative to the door sill.

[0048] The bottom support mechanism 5 is fixedly arranged on the lower surface of the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com