Adjustable large-torque device used for mounting and dismounting lens pressing ring

A lens press ring and high torque technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of inconvenient installation of the lens barrel press ring, affecting product assembly efficiency, and difficult disassembly of the press ring, so as to reduce scratches and breakage , solve the problem of disassembly, and reduce the effect of scrapping the pressure ring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

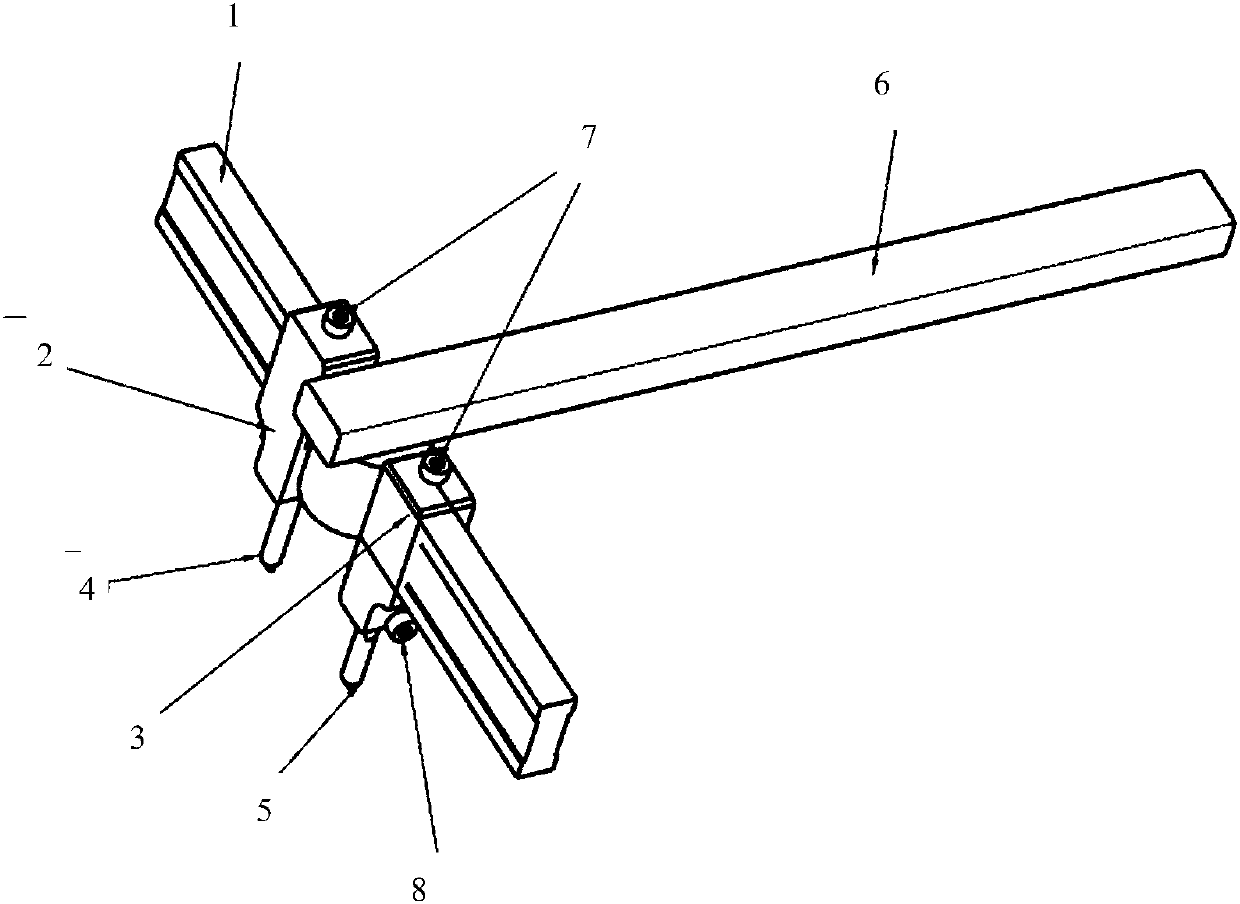

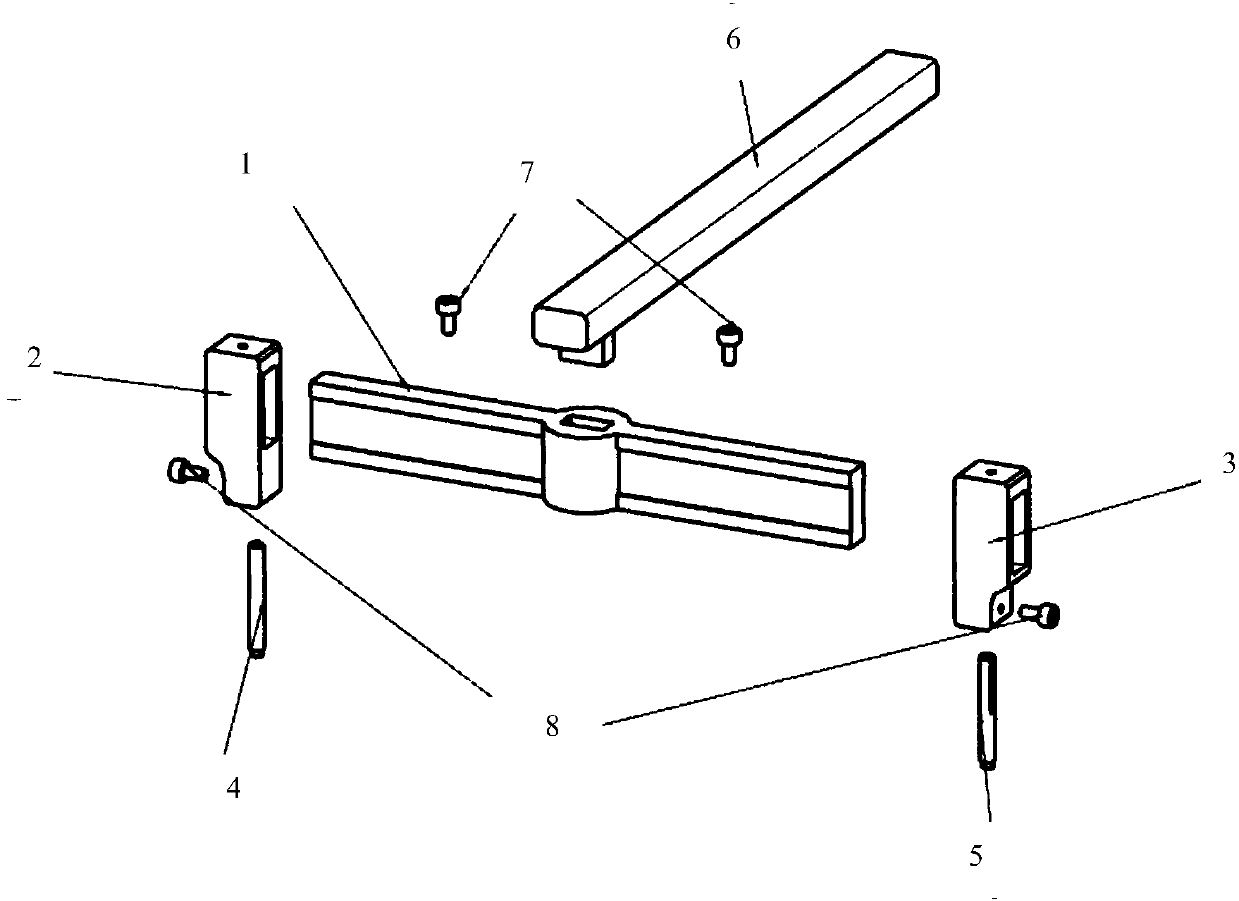

[0017] The adjustable high-torque device for mounting and disassembling the lens holder in this embodiment is characterized by comprising a support guide rail 1 , a left slider 2 , a right slider 3 , a left wrench 4 , a right wrench 5 and a long rod 6 .

[0018] A rectangular hole is provided at the center of the support guide rail 1, and a rectangular boss matching the rectangular hole is provided on the long rod 6; the rectangular boss at one end of the long rod 6 is inserted into the rectangular hole at the center of the support guide rail 1 to realize high-torque rotation.

[0019] The central through holes of the left slider 2 and the right slider 3 are slidably installed on the support rail 1, located on both sides of the long rod 6; the left wrench 4 is inserted into the hole at one end of the left slider 2 and fixed by screws, and the right wrench 5 is ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com