A new type of crane slider device

A sliding block and crane technology, which is applied in the directions of transportation and packaging, load hanging components, cleaning methods and utensils, etc., can solve the problem of poor contact between the sliding block and the sliding line, the maintenance difficulty of the sliding line and the sliding block, and reduce the operation of the crane. rate and other issues, to achieve the effect of good comprehensive use performance, less maintenance time, and improved power supply stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

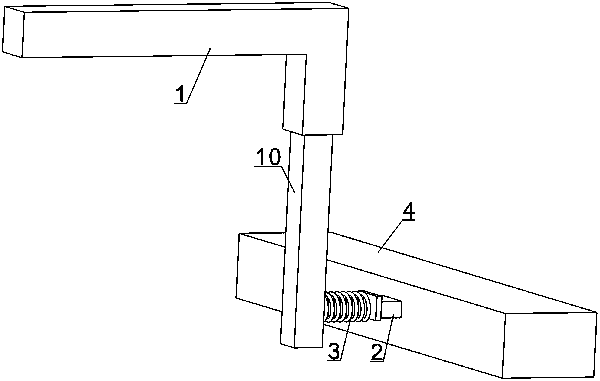

[0030] The novel crown block slider device of the present invention includes a bracket 1, a slider fixing frame and a slider 2, and the specific structure is as follows figure 1 shown. Wherein the slider 2 is arranged on the slider fixing frame, and the slider fixing frame is fixedly connected with the bracket 1, and the bracket 1 is fixedly arranged on one side of the crane, and the bracket provides support for the slider fixing frame. The slider 2 is in contact with the side of the slide wire 4 to take power, and the slider 2 slides along the side of the slide wire 4 . One side of slide block 2 fits and contacts with the side of slide wire 4 and the opposite side is fixedly connected with hold-down spring-3, and the other end of hold-down spring-3 is fixedly connected with slide block holder, so that hold-down spring-1 Under the action of 3, the slider 2 is compressed to fit closely with the slide wire 4. In this embodiment, the slider fixing frame can directly use the con...

Embodiment 2

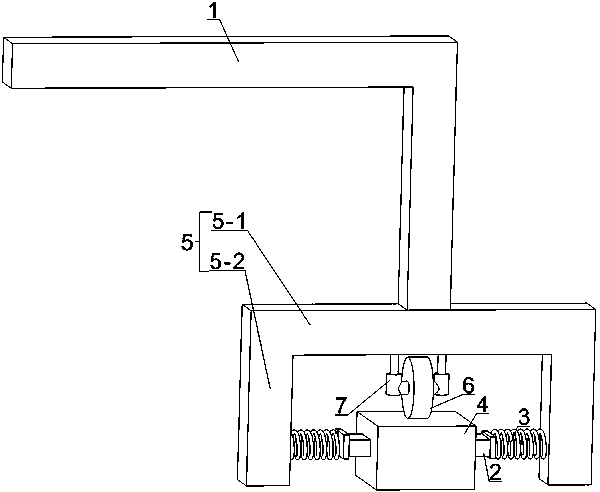

[0033] This embodiment is improved on the basis of Embodiment 1, and the main improvement lies in the improvement of the slider fixing frame. In this embodiment, the slider fixing frame is an inverted U-shaped bracket 5, and the U-shaped bracket 5 includes two vertical beams and a cross beam 5-1 integrally formed, wherein the cross beam 5-1 is located above the slide wire 4, The two vertical beams 5-2 are located on both sides of the slide line 4, the U-shaped support 5 surrounds the three sides of the slide line 4, and the beam 5-1 of the U-shaped support 5 is connected with the support 5. In this embodiment, two sliders 2 are set, and the two sliders 2 are symmetrically arranged on both sides of the slide line 4, and one end of the slider 2 is connected to the vertical beam 5- The other end of the inner side of 2 is in contact with the side of slide wire 4 . That is, a slide block 2 is arranged on the inner side of the two vertical beams 5-2, and the two slide blocks 2 are ...

Embodiment 3

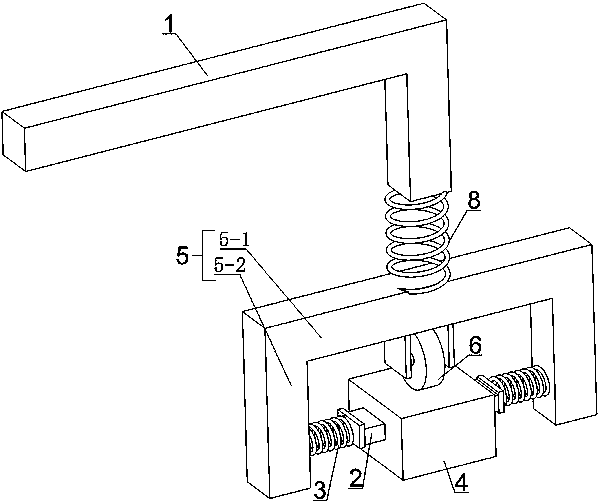

[0038] This embodiment is modified on the basis of Embodiment 2, and the modification lies in the connection method between the U-shaped bracket and the bracket. In this embodiment, the U-shaped bracket 5 and the bracket 1 are connected by a compression spring 2 8, and a pressure wheel 6 is set at the middle of the lower end surface of the crossbeam 5-1 of the U-shaped bracket 5. Adjust the position of the U-shaped support by adjusting the compression spring 2 8 to ensure that the device is not subject to partial wear of the slide block due to incorrect slide lines. For specific adjustment, it is advisable for the slider 2 to be located in the middle of the side of the slide wire 4, while ensuring that the pressure roller 6 is located on the upper end surface of the slide wire 6. The distance between compression spring two 8 and the connection point of crossbeam 5-1 and crossbeam 5-1 two ends is the same, that is, the connection point of compression spring two 8 and crossbeam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com