A kind of preparation method of atractylodes lactone II

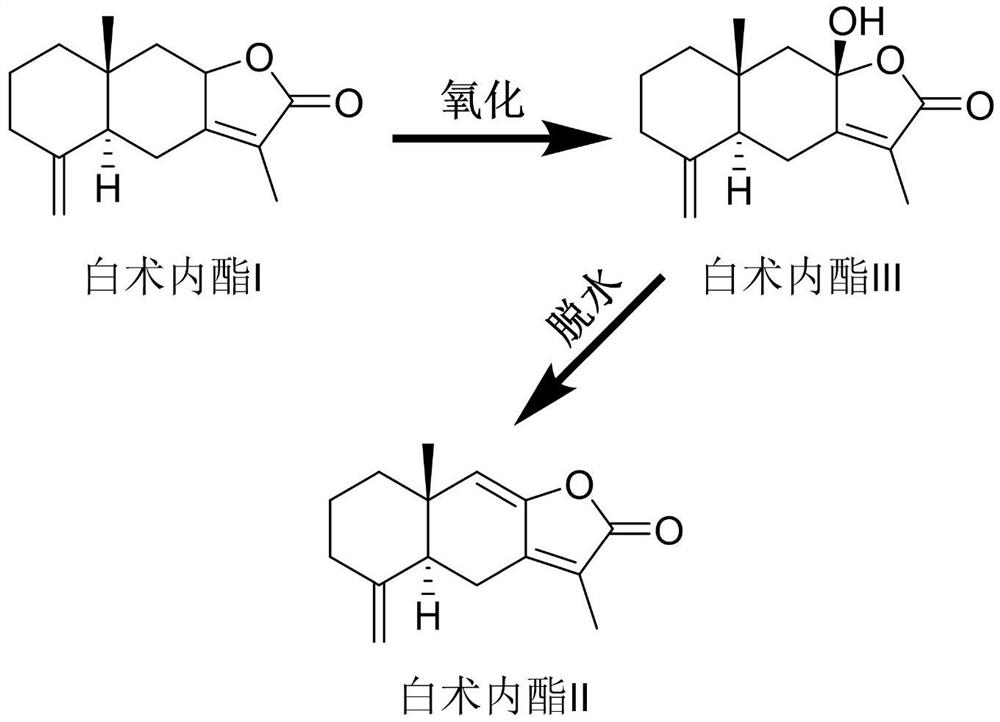

A technology of Atractylodes lactone and Atractylodes atractylodes, applied in the chemical field, can solve the problems of low efficiency, low content of Atractylodes lactone II, and high preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. Experimental equipment

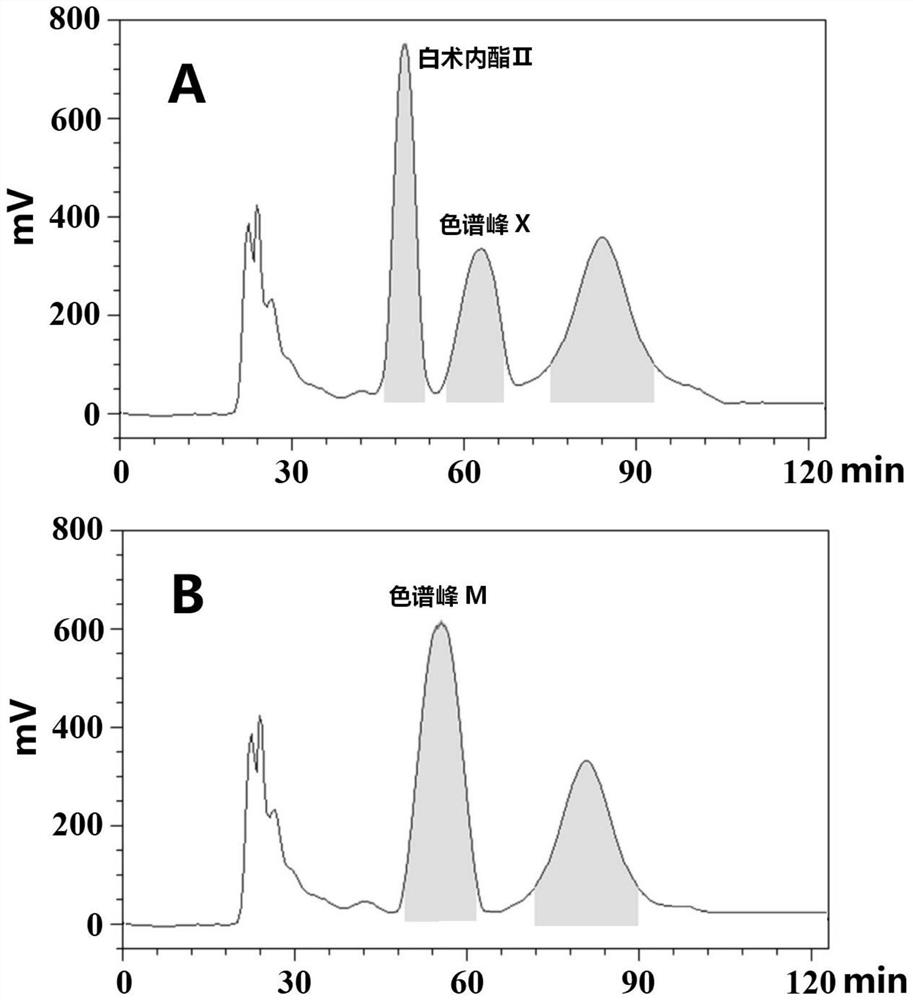

[0027] TBE-300A high-speed countercurrent chromatograph, China Shanghai Tongtian Biochemical Technology Co., Ltd.: equipped with TBE-2000 ultraviolet detector (polytetrafluoroethylene column, inner diameter 1.6mm, column volume 280mL), TBP-50 pump.

[0028] 2. Experimental methods and results

[0029] A preparation method of atractyloid II, comprising the steps of:

[0030] Step S1, adding acid to rot: Atractylodes macrocephala is crushed through a 40-mesh sieve, and dilute hydrochloric acid is sprayed while stirring. The concentration of dilute hydrochloric acid is 0.3mol / L. After the medicinal powder is wet, it is stacked overnight at 55°C;

[0031] Step S2, ethanol extraction: extract the above-mentioned decomposed medicinal powder with an ethanol solution with a concentration of 75% by volume, the solid-to-liquid ratio is 1:40, the extraction method is cold soaking for 48 hours, the extract is collected, and the ethanol in the extract is...

Embodiment 2

[0044] A preparation method of atractyloid II, comprising the steps of:

[0045] Step S1, adding acid to rot: Atractylodes macrocephala is crushed through a 40-mesh sieve, and dilute hydrochloric acid is sprayed while stirring. The concentration of dilute hydrochloric acid is 0.2mol / L. After the powder is wet, it is stacked overnight at 60°C;

[0046] Step S2, ethanol extraction: extract the above-mentioned decomposed medicinal powder with an ethanol solution with a concentration of 60% by volume, the solid-to-liquid ratio is 1:40, the extraction method is cold soaking for 48 hours, the extract is collected, and the ethanol in the extract is recovered to obtain Concentrate;

[0047] Step S3, macroporous resin enrichment: dilute the concentrated solution with water to a density of 2.5 g / mL, adjust the pH value to 5.2, load the sample on XDA-6 macroporous adsorption resin, and use volume percent concentrations of 25%, 45%, 65%, and 85% ethanol solutions were eluted for 6 column...

Embodiment 3

[0050] A preparation method of atractyloid II, comprising the steps of:

[0051]Step S1, adding acid to rot: Atractylodes macrocephala is crushed through a 40-mesh sieve, and dilute hydrochloric acid is sprayed while stirring. The concentration of dilute hydrochloric acid is 0.4mol / L. After the powder is wet, it is stacked overnight at 50°C;

[0052] Step S2, ethanol extraction: extract the above-mentioned decomposed medicinal powder with an ethanol solution with a concentration of 90% by volume, the solid-to-liquid ratio is 1:40, the extraction method is cold soaking for 48 hours, the extract is collected, and the ethanol in the extract is recovered to obtain Concentrate;

[0053] Step S3, macroporous resin enrichment: dilute the concentrated solution with water to a density of 2.5 g / mL, adjust the pH value to 6.4, load the sample on XDA-6 macroporous adsorption resin, and use volume percent concentration of 25%, 45%, 65%, and 85% ethanol solutions were eluted with 10 column...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com