Adhesive, foam double-sided adhesive, and preparation methods of adhesive and foam double-sided adhesive

A technology of adhesives and foams, applied in the direction of adhesives, adhesive types, ester copolymer adhesives, etc., can solve the problems of insufficient waterproof performance, insufficient strength, and insufficient bonding performance, etc., and achieve good impact resistance And docile effect, good adhesion durability, superior waterproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

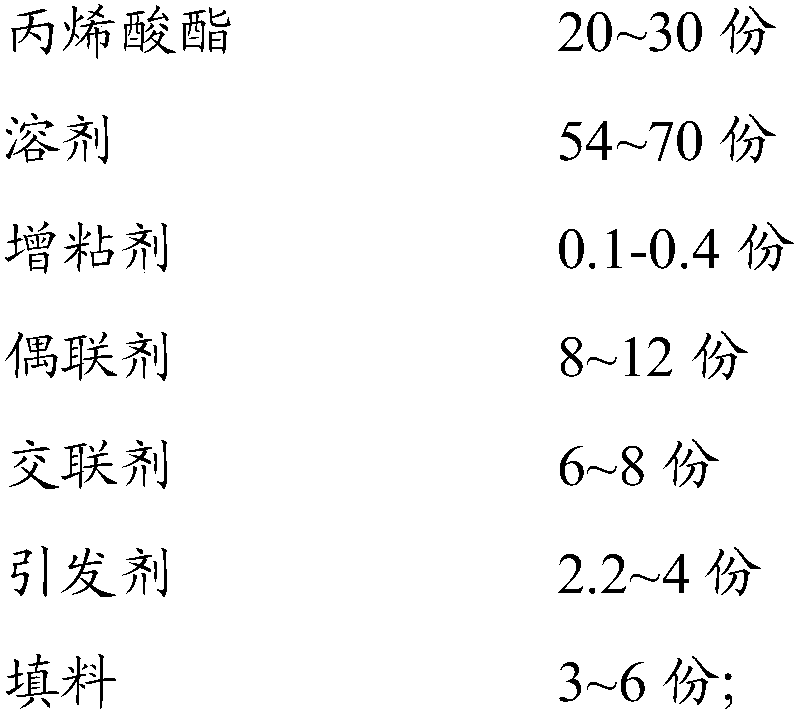

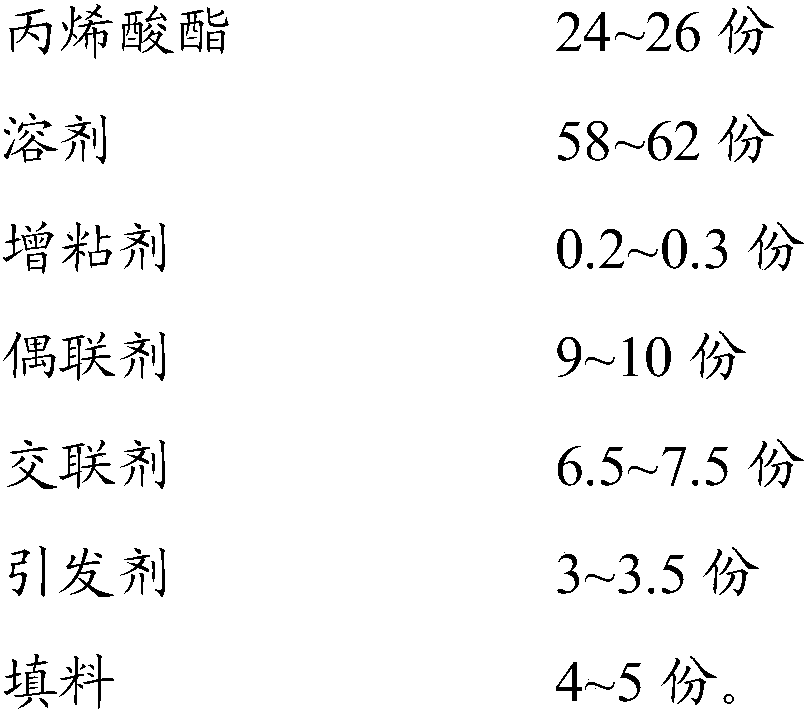

Method used

Image

Examples

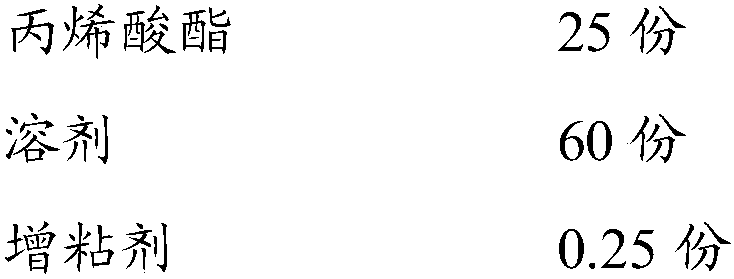

Embodiment 1

[0035] A kind of adhesive and double-sided foam adhesive tape of this embodiment are prepared by the following method:

[0036] (1) Weigh 60 parts of xylene into the reaction kettle, replace the air in the reaction kettle with nitrogen, heat to 70±5°C, drop 25 parts of sec-butyl acrylate into the reaction kettle within 0.5 to 1 hour, and keep warm After 0.5 hours, add 3.2 parts of tert-butyl peroxy-3,5,5-trimethylhexanoate into the reaction kettle, keep warm for another 0.5 hours, cool down, and discharge; then add 0.25 parts of C5 petroleum resin, 9.5 parts of iso Propyl tris (dioctyl phosphate acyloxy) titanate, 7 parts of triethylenetetramine, stirring and dispersing evenly to obtain a semi-finished base material;

[0037] (2) Add 4.5 parts of wood flour to the semi-finished base material prepared in step (1), stir and disperse evenly, filter (through 800-900 mesh), and then add the obtained slurry to the defoaming machine for degassing for 8 minutes, That is, the adhesive...

Embodiment 2

[0040] A kind of adhesive and double-sided foam adhesive tape of this embodiment are prepared by the following method:

[0041] (1) Weigh 52 parts of xylene and put it into the reaction kettle, replace the air in the reaction kettle with nitrogen, heat to 70±5°C, drop 20 parts of sec-butyl acrylate into the reaction kettle within 0.5 to 1 hour, keep warm After 0.5 hours, add 2.5 parts of tert-butyl peroxy-3,5,5-trimethylhexanoate to the reaction kettle, keep warm for another 0.5 hours, cool down, and discharge; then add 0.1 parts of C5 petroleum resin, 8.2 parts of iso Propyl tris (dioctyl phosphate acyloxy) titanate, 6 parts of triethylenetetramine, stirring and dispersing evenly to obtain a semi-finished base material;

[0042] (2) Add 3.2 parts of wood flour to the semi-finished base material prepared in step (1), stir and disperse evenly, filter (through 800-900 mesh), and then add the obtained slurry to the defoamer for 8 minutes, That is, the adhesive is obtained.

[0...

Embodiment 3

[0045] A kind of adhesive and double-sided foam adhesive tape of this embodiment are prepared by the following method:

[0046] (1) Weigh 68 parts of xylene and put them into the reaction kettle, replace the air in the reaction kettle with nitrogen, heat to 70±5°C, drop 28 parts of sec-butyl acrylate into the reaction kettle within 0.5 to 1 hour, and keep warm After 0.5 hours, add 3.8 parts of tert-butyl peroxy-3,5,5-trimethylhexanoate into the reaction kettle, keep warm for another 0.5 hours, cool down, and discharge; then add 0.4 parts of C5 petroleum resin, 11.8 parts of iso Propyl tris (dioctyl phosphate acyloxy) titanate, 7 parts of triethylenetetramine, stirring and dispersing evenly to obtain a semi-finished base material;

[0047] (2) Add 5.8 parts of wood flour to the semi-finished base material prepared in step (1), stir and disperse evenly, filter (over 800-900 mesh), and then add the obtained slurry to the defoaming machine for degassing for 8 minutes, That is, th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap