Dust removal device for bridge construction at night

A dust removal device and bridge construction technology, applied in the direction of using liquid separation agent, dispersed particle separation, earth mover/shovel, etc., can solve the problems of blocking searchlights and large construction dust, so as to increase the spraying area and reduce dust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

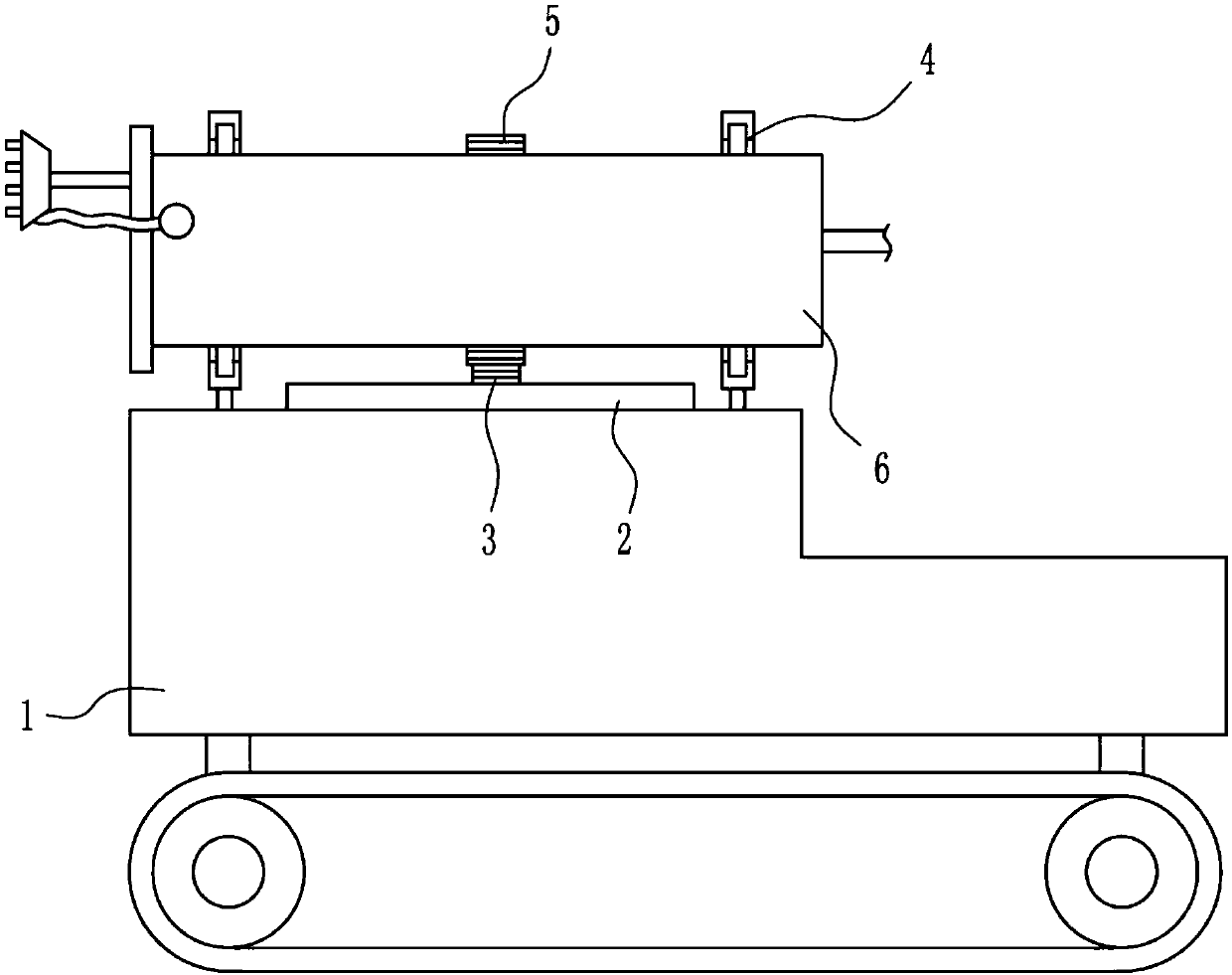

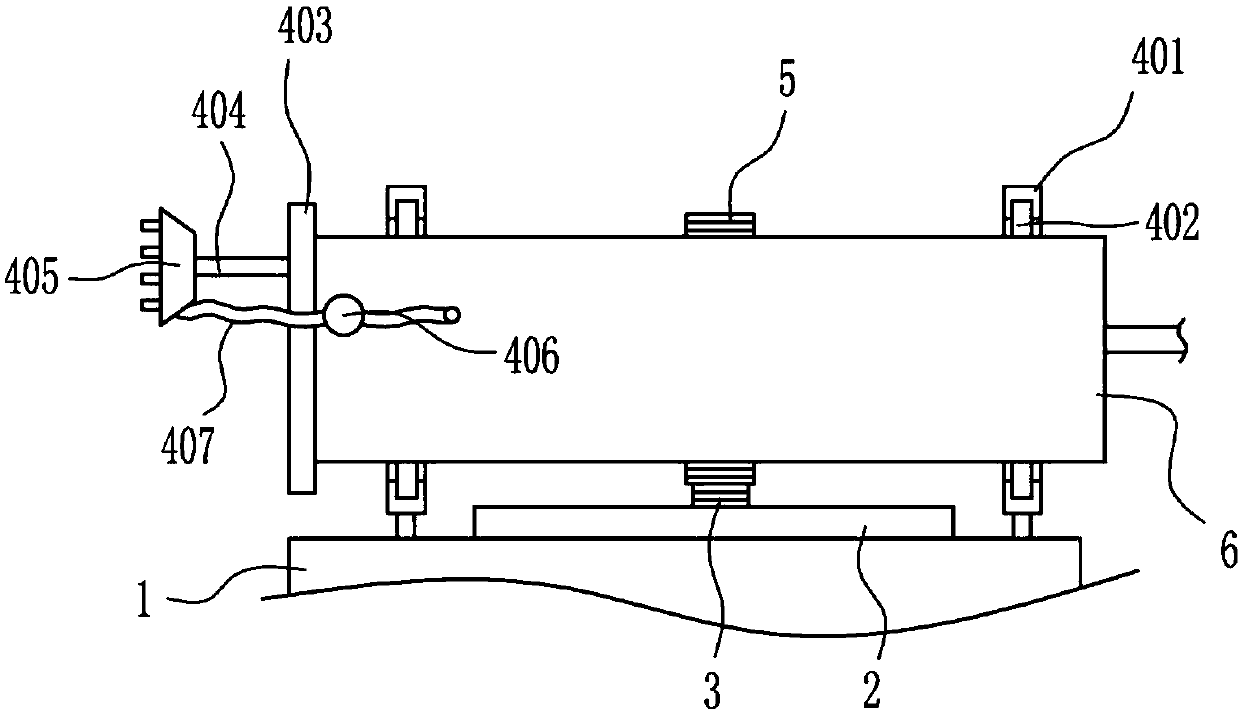

[0028] A kind of dust removal device for night construction of bridge construction, such as Figure 1-5 As shown, it includes an excavator 1, a moving mechanism 2, a second rack 3, a mounting mechanism 4, an outer ring gear 5 and a water storage bucket 6, the top of the excavator 1 is connected with a moving mechanism 2, and the top of the moving mechanism 2 is connected with a second Two racks 3, the top of the excavator 1 is connected to the installation mechanism 4, the installation mechanism 4 is connected to the water storage bucket 6, the middle part of the outer wall of the water storage bucket 6 is connected to the outer gear ring 5, the outer gear gear 5 meshes with the second rack 3 .

Embodiment 2

[0030] A kind of dust removal device for night construction of bridge construction, such as Figure 1-5As shown, it includes an excavator 1, a moving mechanism 2, a second rack 3, a mounting mechanism 4, an outer ring gear 5 and a water storage bucket 6, the top of the excavator 1 is connected with a moving mechanism 2, and the top of the moving mechanism 2 is connected with a second Two racks 3, the top of the excavator 1 is connected to the installation mechanism 4, the installation mechanism 4 is connected to the water storage bucket 6, the middle part of the outer wall of the water storage bucket 6 is connected to the outer gear ring 5, the outer gear gear 5 meshes with the second rack 3 .

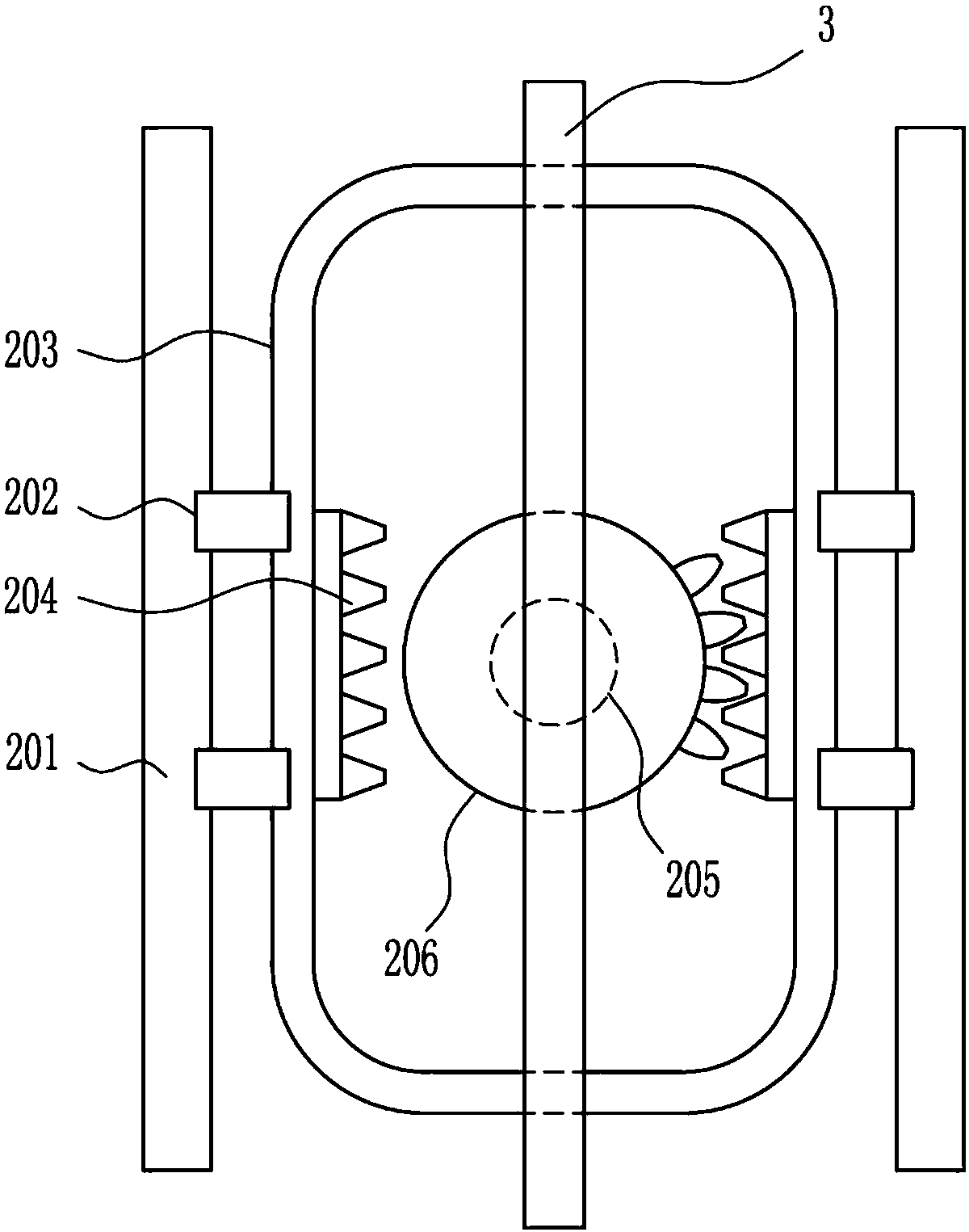

[0031] The moving mechanism 2 includes a straight slide rail 201, a first slide block 202, a moving frame 203, a first rack 204, a motor 205 and a missing gear 206, and the top left and right sides of the excavator 1 are connected with a straight slide rail 201. The rail 201 is slidin...

Embodiment 3

[0033] A kind of dust removal device for night construction of bridge construction, such as Figure 1-5 As shown, it includes an excavator 1, a moving mechanism 2, a second rack 3, a mounting mechanism 4, an outer ring gear 5 and a water storage bucket 6, the top of the excavator 1 is connected with a moving mechanism 2, and the top of the moving mechanism 2 is connected with a second Two racks 3, the top of the excavator 1 is connected to the installation mechanism 4, the installation mechanism 4 is connected to the water storage bucket 6, the middle part of the outer wall of the water storage bucket 6 is connected to the outer gear ring 5, the outer gear gear 5 meshes with the second rack 3 .

[0034] The moving mechanism 2 includes a straight slide rail 201, a first slide block 202, a moving frame 203, a first rack 204, a motor 205 and a missing gear 206, and the top left and right sides of the excavator 1 are connected with a straight slide rail 201. The rail 201 is slidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com