Hydraulic bracket transferring equipment

A hydraulic support and equipment technology, applied in mining equipment, mine roof supports, earthwork drilling and mining, etc., can solve problems such as potential safety hazards, increased pressure on working face safety, and occupation of mine production time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

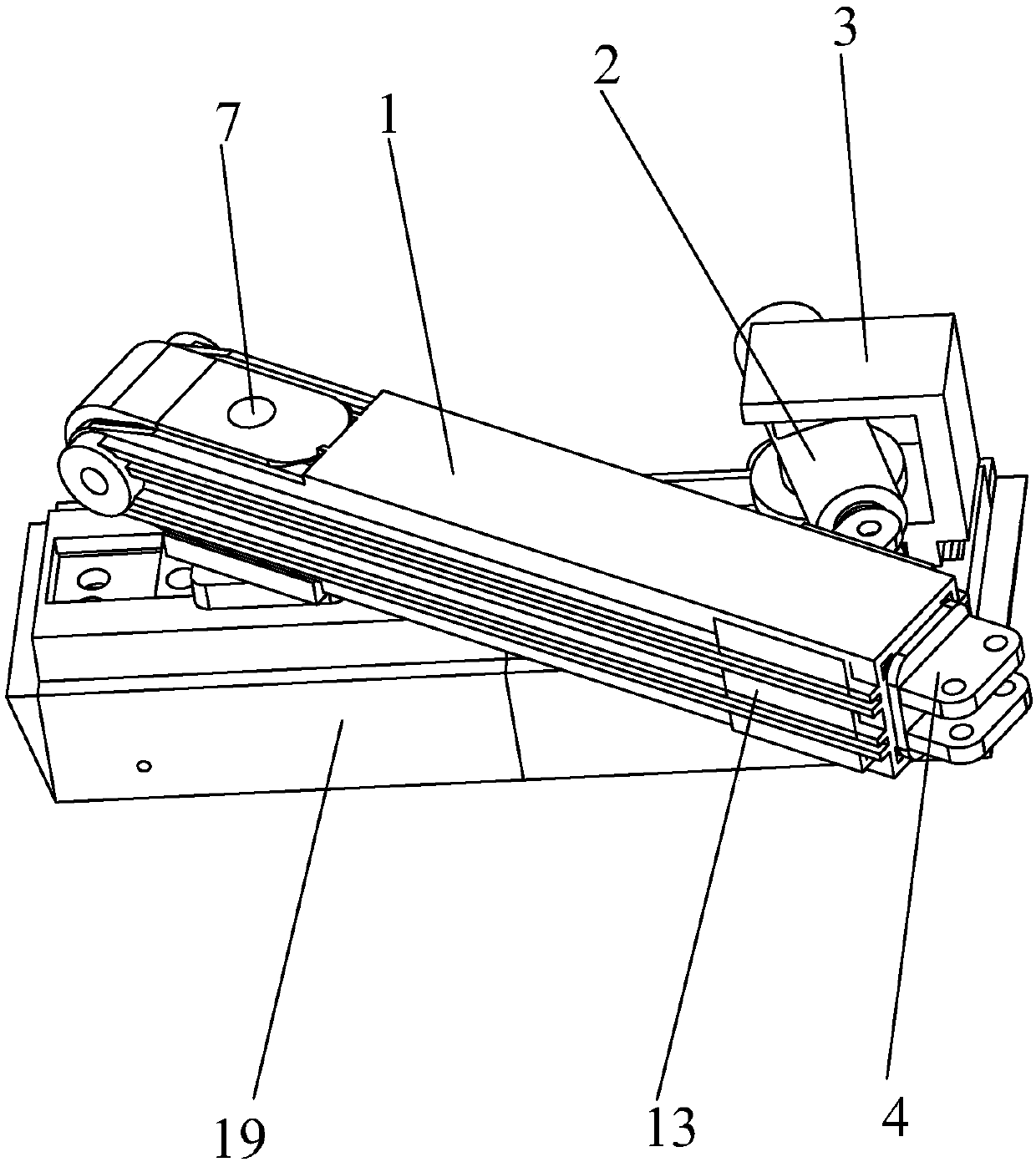

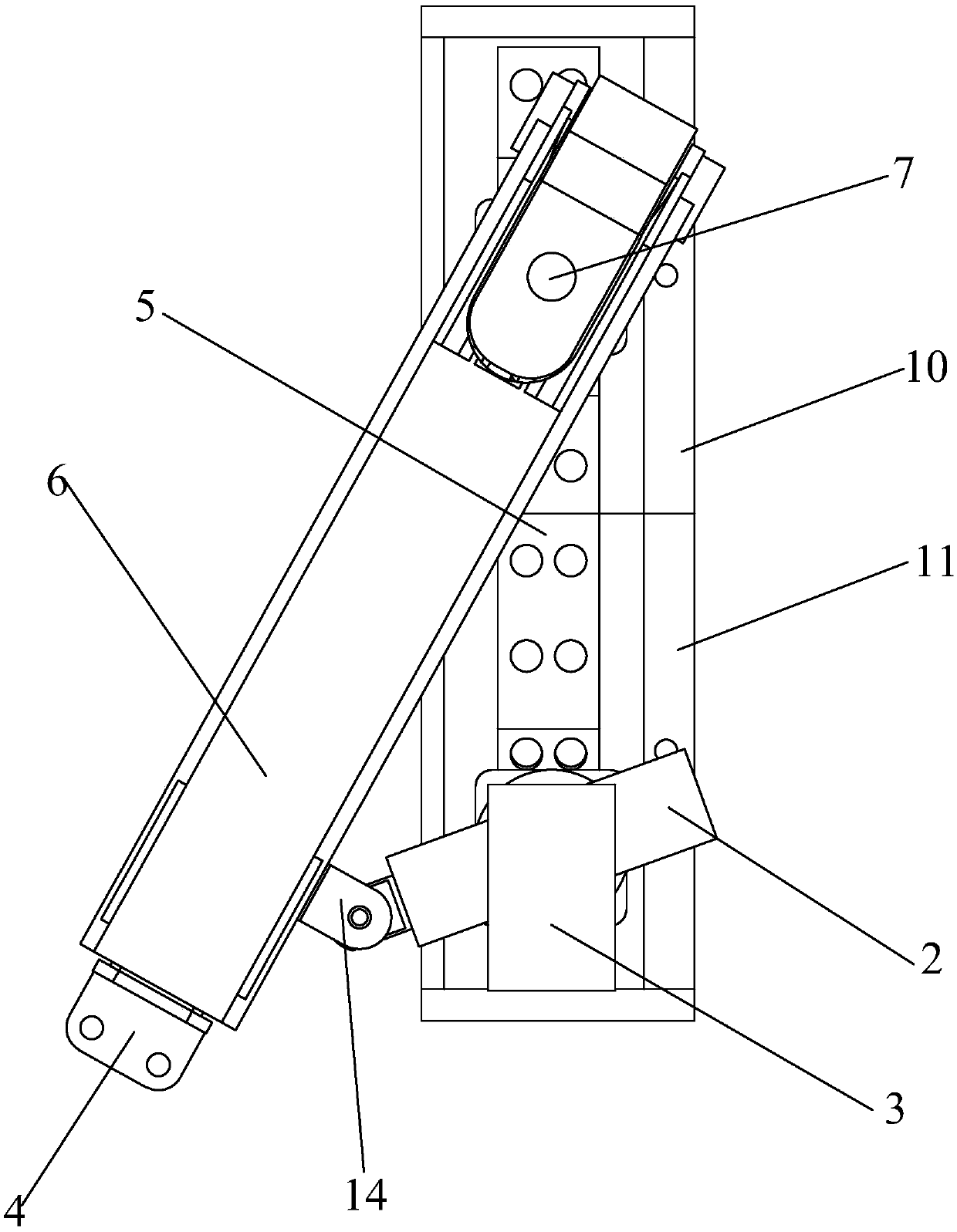

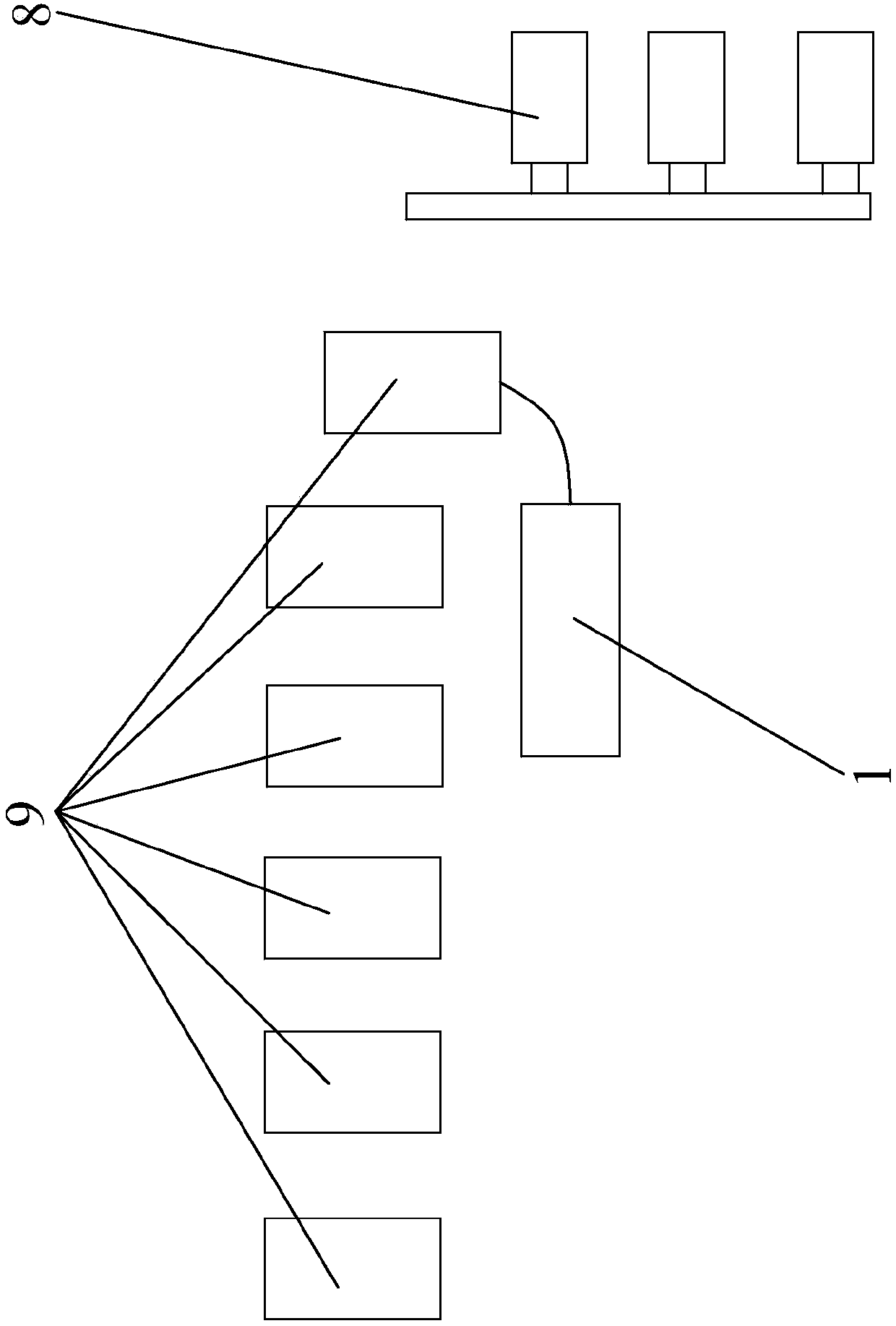

[0026] combine Figure 1-Figure 7 As shown, the hydraulic support transfer equipment of the present invention includes a self-moving device 19, a transfer device 1 and a coupling device 5, the self-moving device 19 is arranged on the ground, and the self-moving device 19 supports the coupling device 5 and the transfer device 1, and the connection The device 5 is detachably and fixedly connected to the self-moving device 19, the self-moving device 19 is connected with a driving device, and the driving device drives the self-moving device 19 to move, so as to realize the movement of the hydraulic support transfer equipment of the present invention, which can be adjusted by itself without external force Angle and move position.

[0027] The transfer device 1 is single-point connected or multi-point connected to the coupling device 5 . The transfer device 1 is single-point connected, that is, the transfer device 1 is fixedly connected to the coupling device 5, and the fixed conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com