A Centrifugal Gas Compressor Desuperheater with Central Nozzle Structure

A technology of gas compressors and central nozzles, which is applied in the direction of machines/engines, liquid fuel engines, mechanical equipment, etc., can solve the problems of inability to effectively reach the cooling mainstream, insufficient liquid cooling evaporation time, and large impact of cooling liquid droplets, etc., to achieve Avoid impact water erosion, improve the effect, increase the effect of evaporation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0019] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The specific implementations of the present invention will be further described in detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

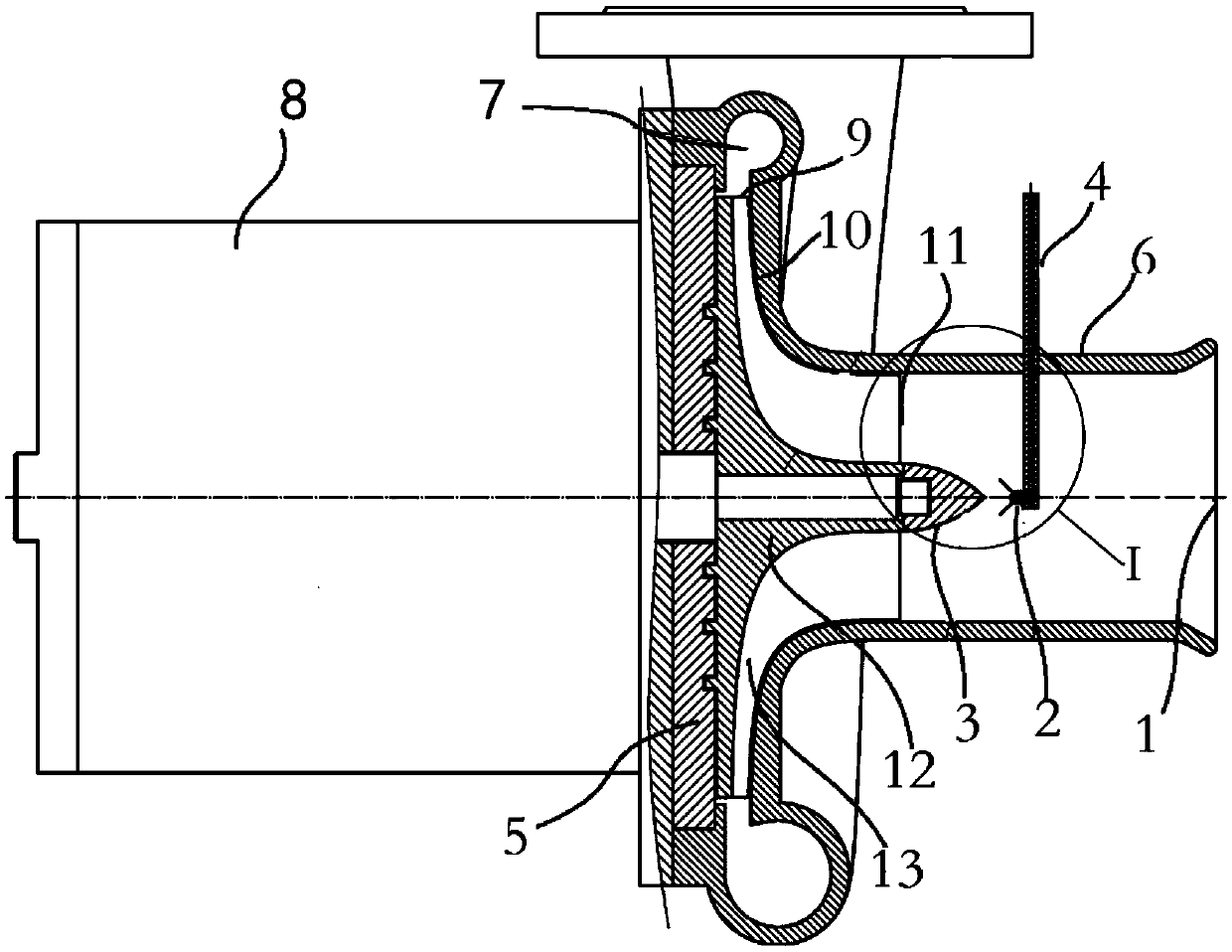

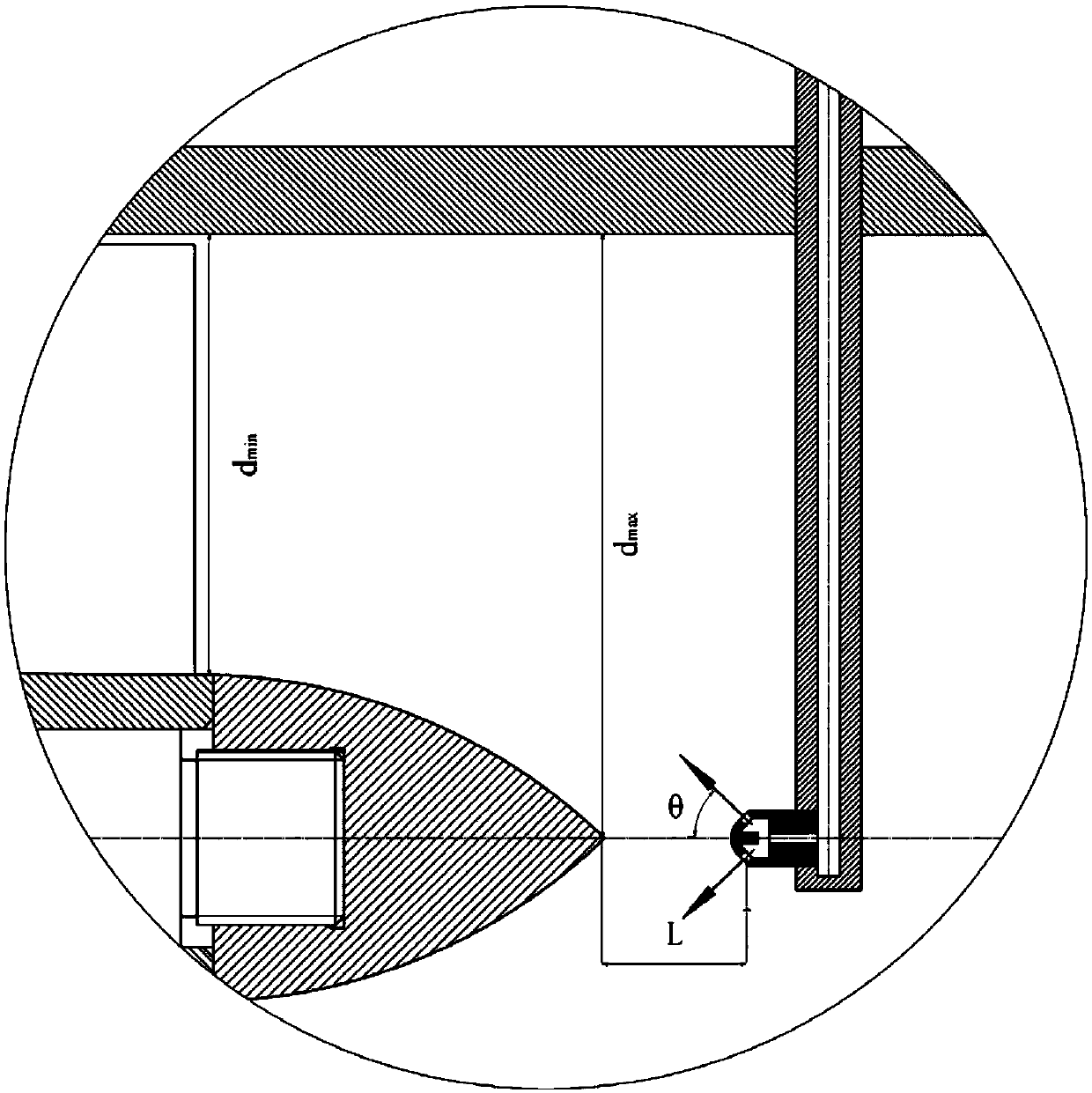

[0020] Such as figure 1 As shown in the figure, a gas compressor desuperheater with a central nozzle structure is shown, the gas compressor includes a compressor casing 6, and the compressor casing 6 includes an opening to the direction of the compressor rotation axis The air inlet 1 and the air inlet passage connected to the air inlet also include a compressor impeller 5, which is rotatably supported in the compressor housing 6 around the rotation axis of the rotating shaft , the rotating shaft is driven by a high-speed motor 8, and the side of the compressor impeller 5 close to the gas compressor inlet 1 is provided with a diversion cone 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com