A small and medium-sized environment-friendly garbage incinerator

A waste incinerator, an environmentally friendly technology, applied in incinerators, combustion types, combustion methods, etc., can solve the problems of air pollution, difficult to fully combust, uneven distribution of garbage, etc., to reduce harmful gases and ensure the effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

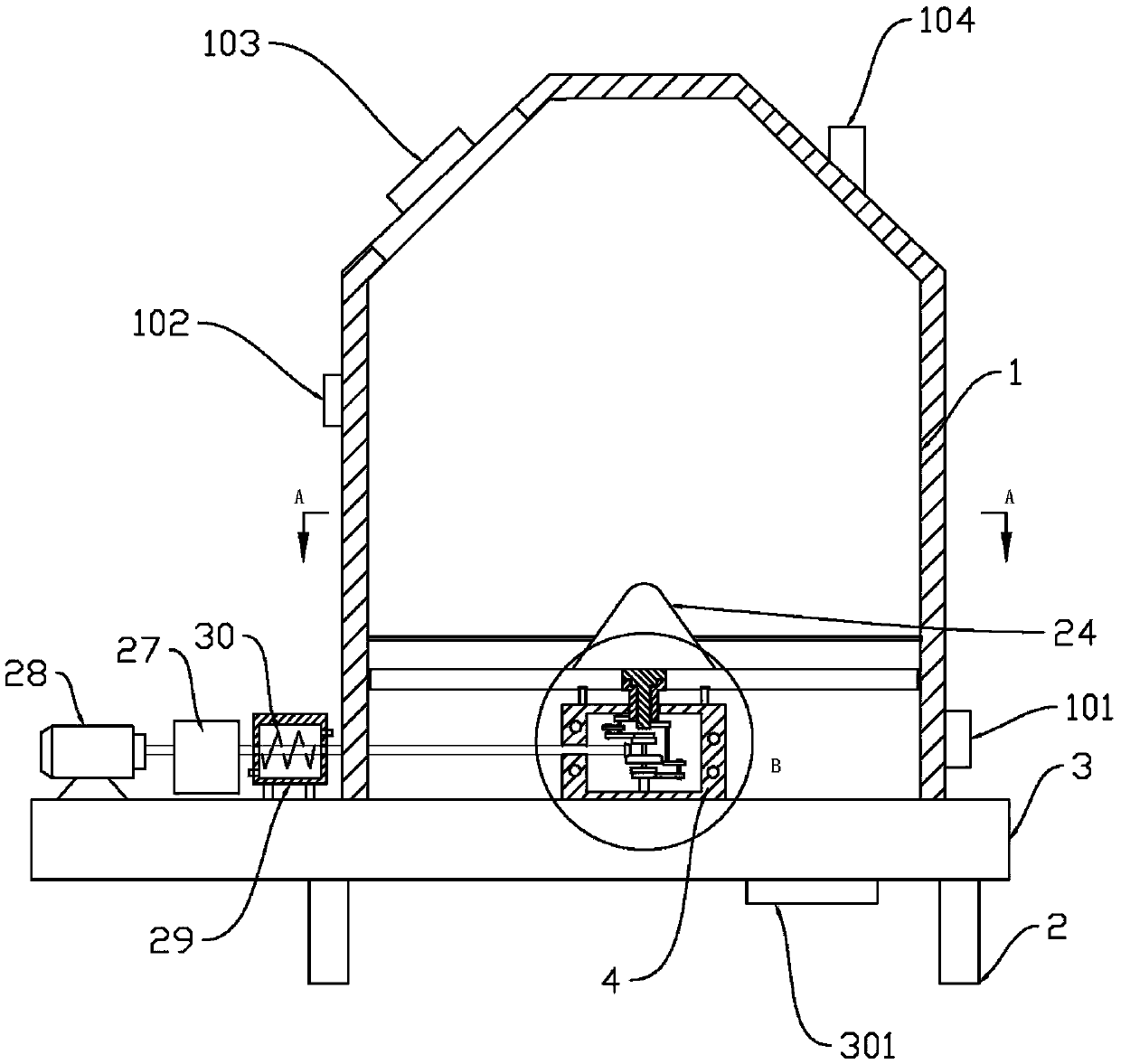

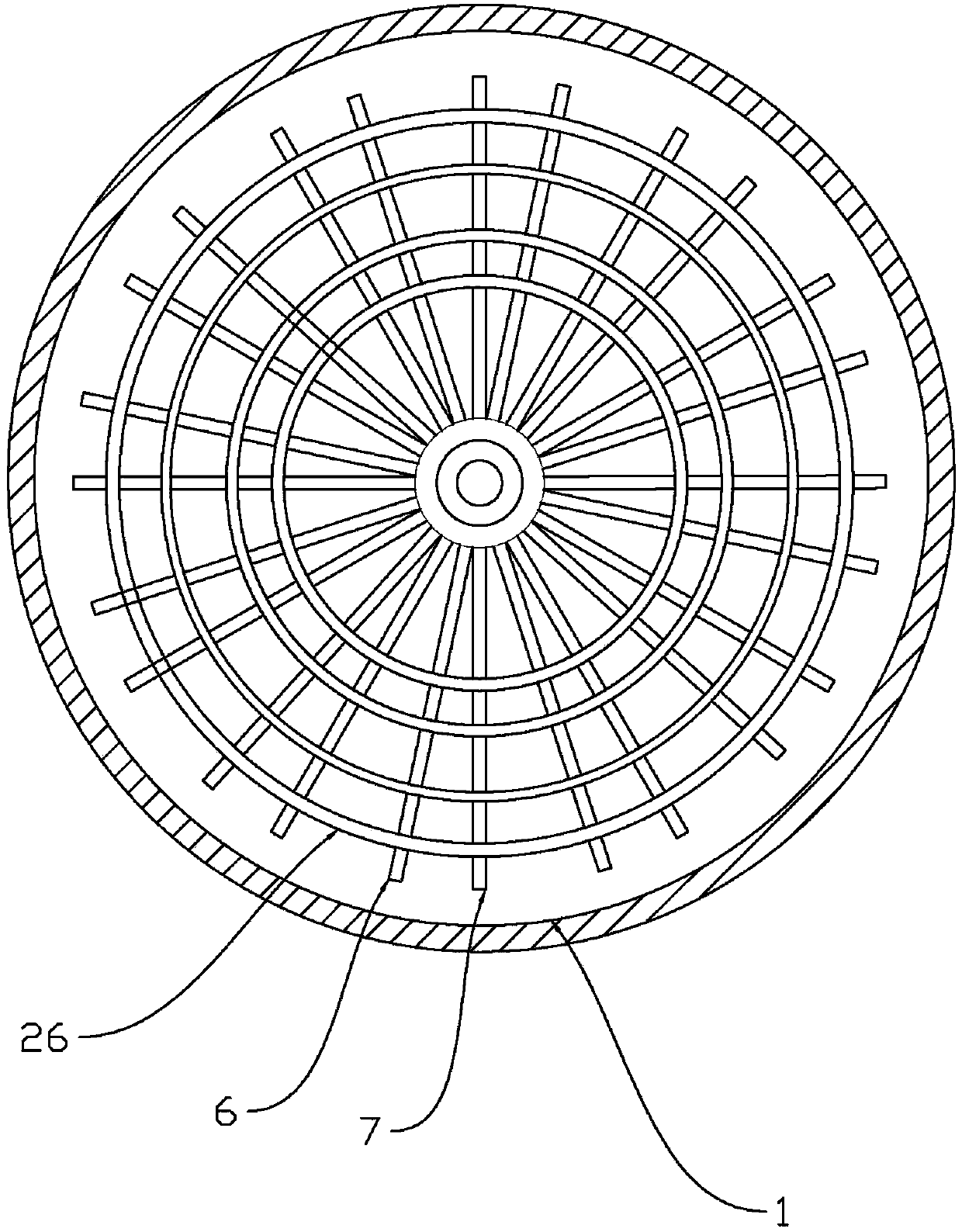

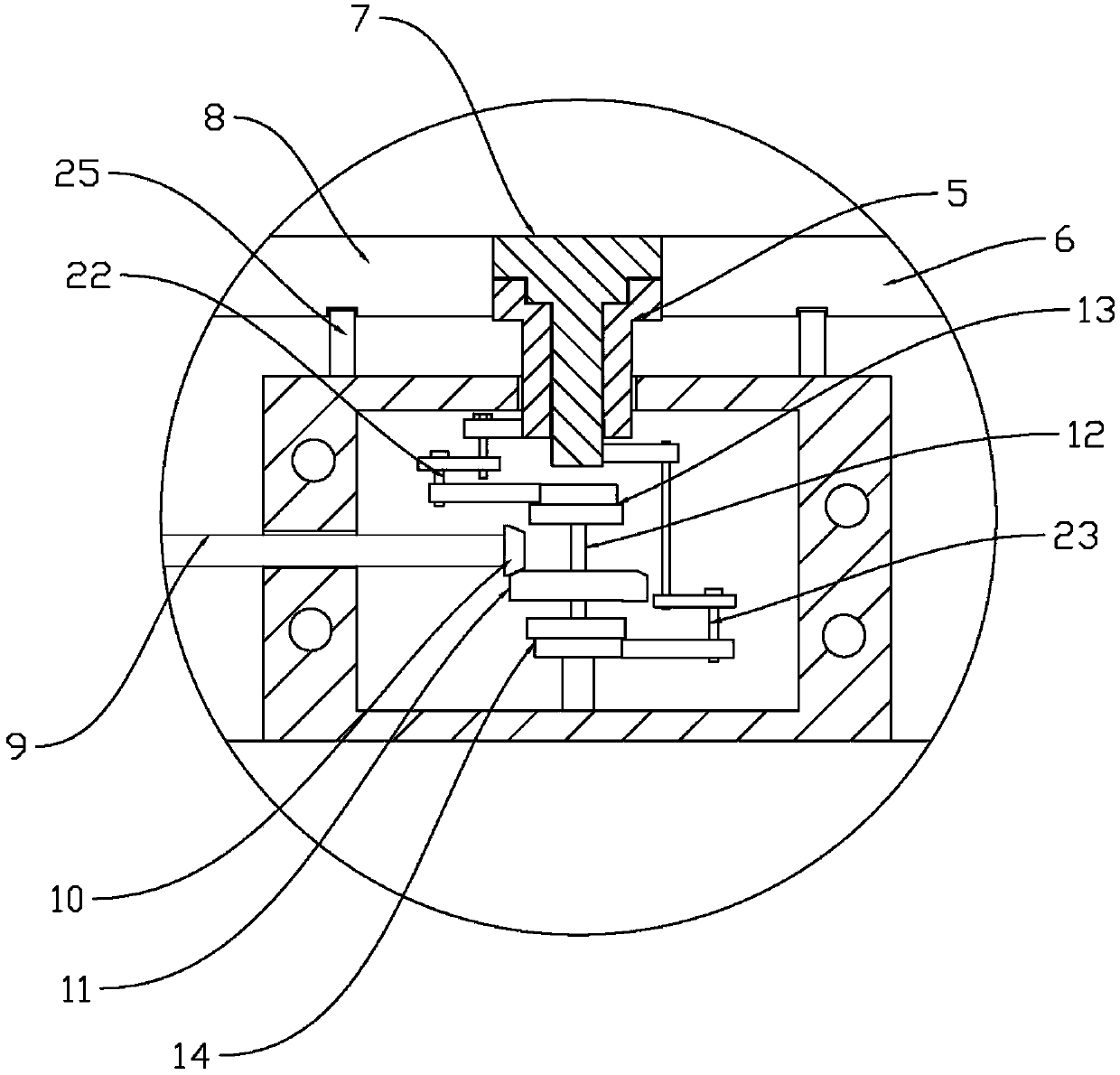

[0023] Depend on Figure 1 to Figure 6 Given, a small and medium-sized environment-friendly garbage incinerator, including a furnace body 1, a bracket 2, and a base plate 3, is characterized in that the interior of the furnace body 1 is a cylindrical cavity with an open lower end, and the furnace body 1 is placed on the base plate 3 so that the bottom of the furnace body 1 is closed, the lower part of the base plate 3 is fixedly connected with the bracket 2, the upper part of the base plate 3 is fixed with a housing 4 located in the middle of the lower part of the furnace body 1, and the upper part of the housing 4 is rotatably connected with a lower rotating shaft 5 , the lower rotating shaft 5 is a stepped shaft with a thick upper end and a thinner end, the upper thick end of the lower rotating shaft 5 is a first conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com