Special sampling equipment for liquid foods

A liquid food and equipment technology, applied in the field of special sampling equipment for liquid food, can solve the same problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

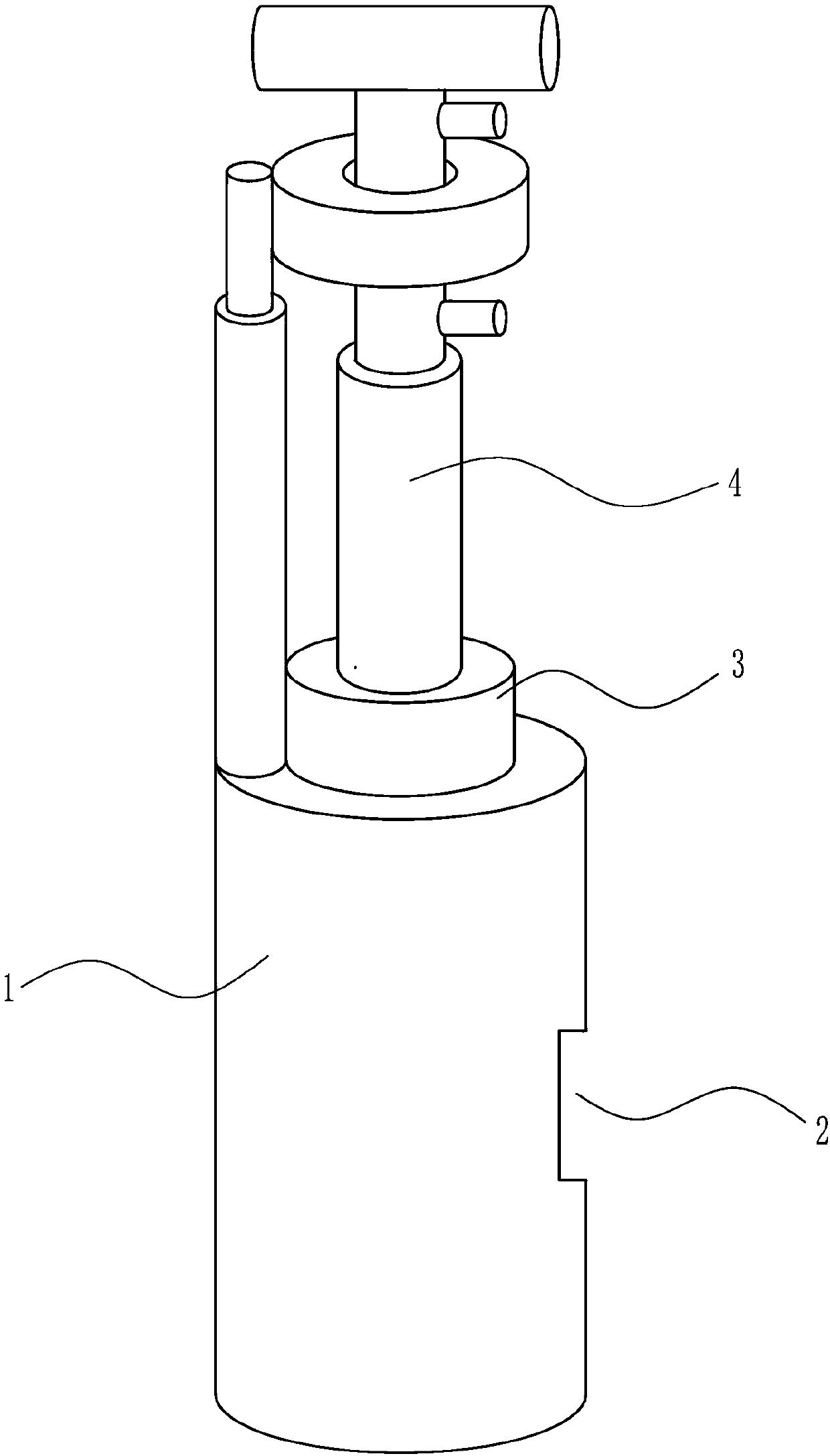

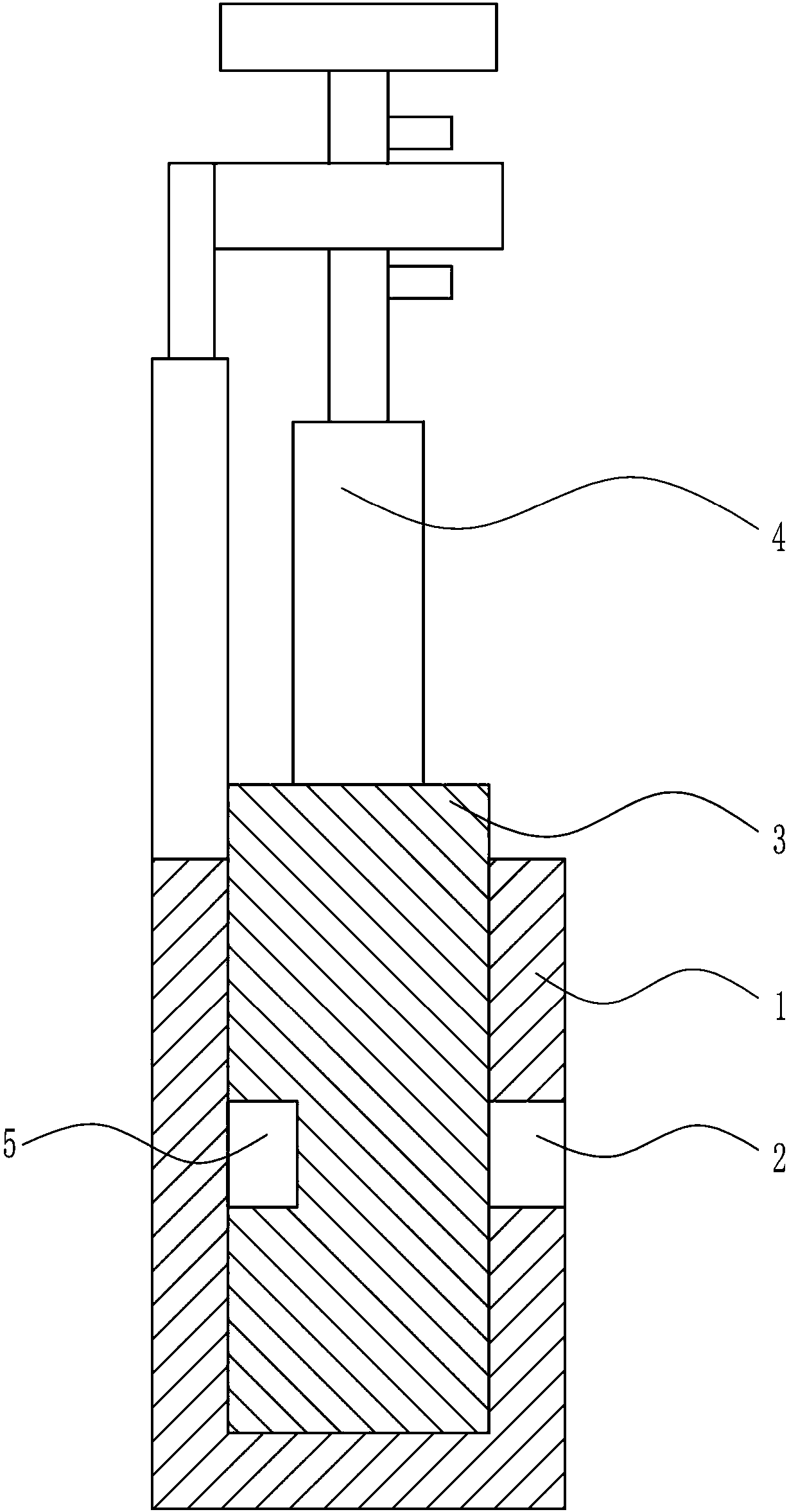

[0027] A special sampling equipment for liquid food, such as Figure 1-5 As shown, it includes a cylinder 1, a piston 3 and a telescopic device 4, a through hole 2 is opened in the middle of the right wall of the cylinder 1, a piston 3 is arranged in the cylinder 1, the piston 3 cooperates with the cylinder 1, and the lower part of the left side of the piston 3 A first groove 5 is formed, and the first groove 5 is at the same level as the through hole 2 , and the top of the piston 3 is provided with a telescoping device 4 .

Embodiment 2

[0029] A special sampling equipment for liquid food, such as Figure 1-5 As shown, it includes a cylinder 1, a piston 3 and a telescopic device 4, a through hole 2 is opened in the middle of the right wall of the cylinder 1, a piston 3 is arranged in the cylinder 1, the piston 3 cooperates with the cylinder 1, and the lower part of the left side of the piston 3 A first groove 5 is formed, and the first groove 5 is at the same level as the through hole 2 , and the top of the piston 3 is provided with a telescoping device 4 .

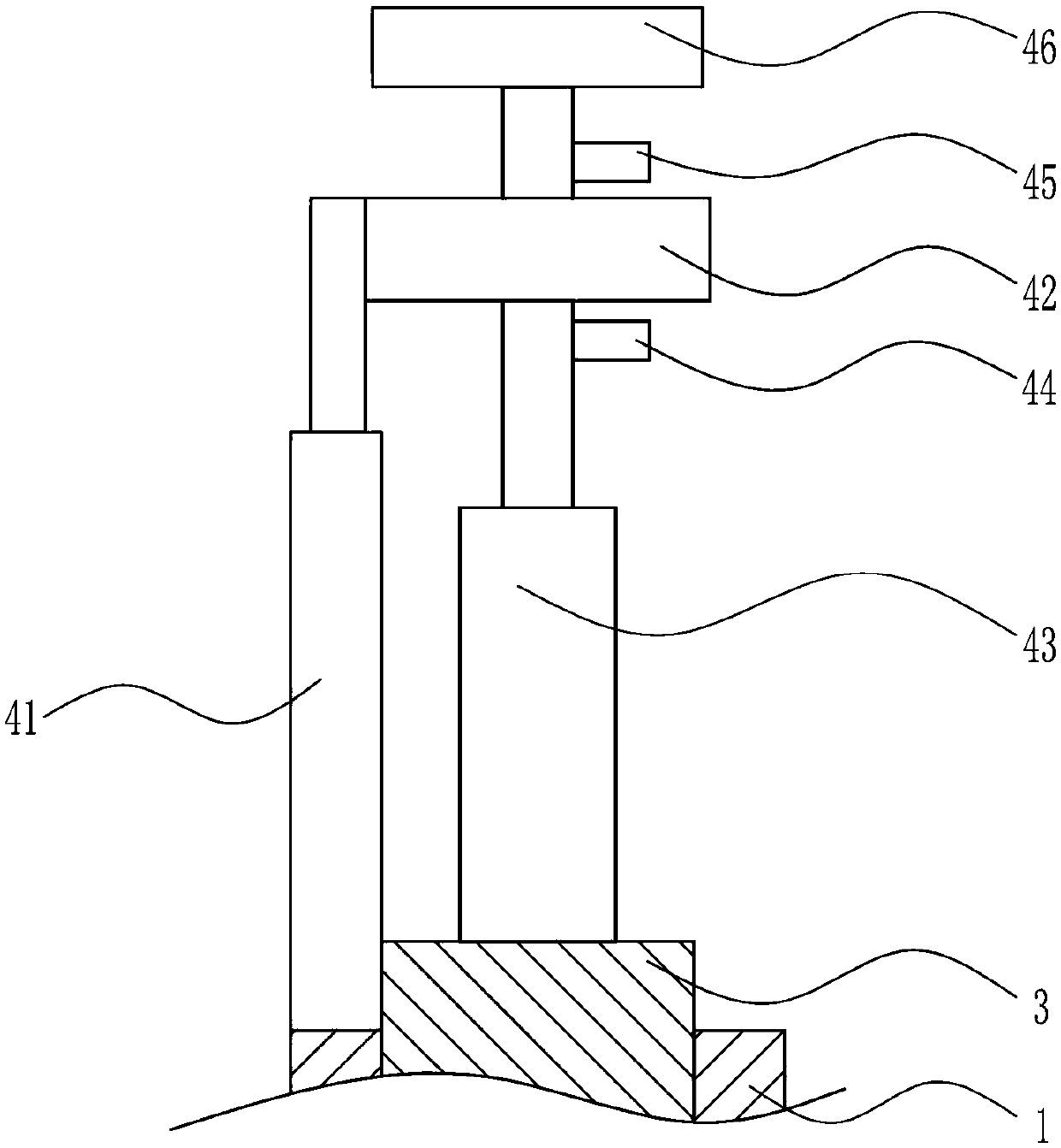

[0030] The telescopic device 4 includes a first telescopic rod 41, a guide sleeve 42, a second telescopic rod 43, a first block 44, a second block 45 and a rotating rod 46, and the left side of the top of the cylinder body 1 is provided with a first telescopic rod 41. , the upper part of the right side of the first telescopic rod 41 is provided with a guide sleeve 42, the center of the top of the piston 3 is provided with a second telescopic rod 43, the s...

Embodiment 3

[0032] A special sampling equipment for liquid food, such as Figure 1-5 As shown, it includes a cylinder 1, a piston 3 and a telescopic device 4, a through hole 2 is opened in the middle of the right wall of the cylinder 1, a piston 3 is arranged in the cylinder 1, the piston 3 cooperates with the cylinder 1, and the lower part of the left side of the piston 3 A first groove 5 is formed, and the first groove 5 is at the same level as the through hole 2 , and the top of the piston 3 is provided with a telescoping device 4 .

[0033] The telescopic device 4 includes a first telescopic rod 41, a guide sleeve 42, a second telescopic rod 43, a first block 44, a second block 45 and a rotating rod 46, and the left side of the top of the cylinder body 1 is provided with a first telescopic rod 41. , the upper part of the right side of the first telescopic rod 41 is provided with a guide sleeve 42, the center of the top of the piston 3 is provided with a second telescopic rod 43, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com