Manufacturing method of protective jacket for protecting respirator

A production method and technology of protective cover, which are applied in the manufacture of inductors/transformers/magnets, cooling of transformers/inductors, electrical components, etc., can solve the problems of small cracks and difficult to observe, premature failure of desiccant, frequent replacement of desiccant, etc. Achieve the effect of simple structure, convenient processing and convenient disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

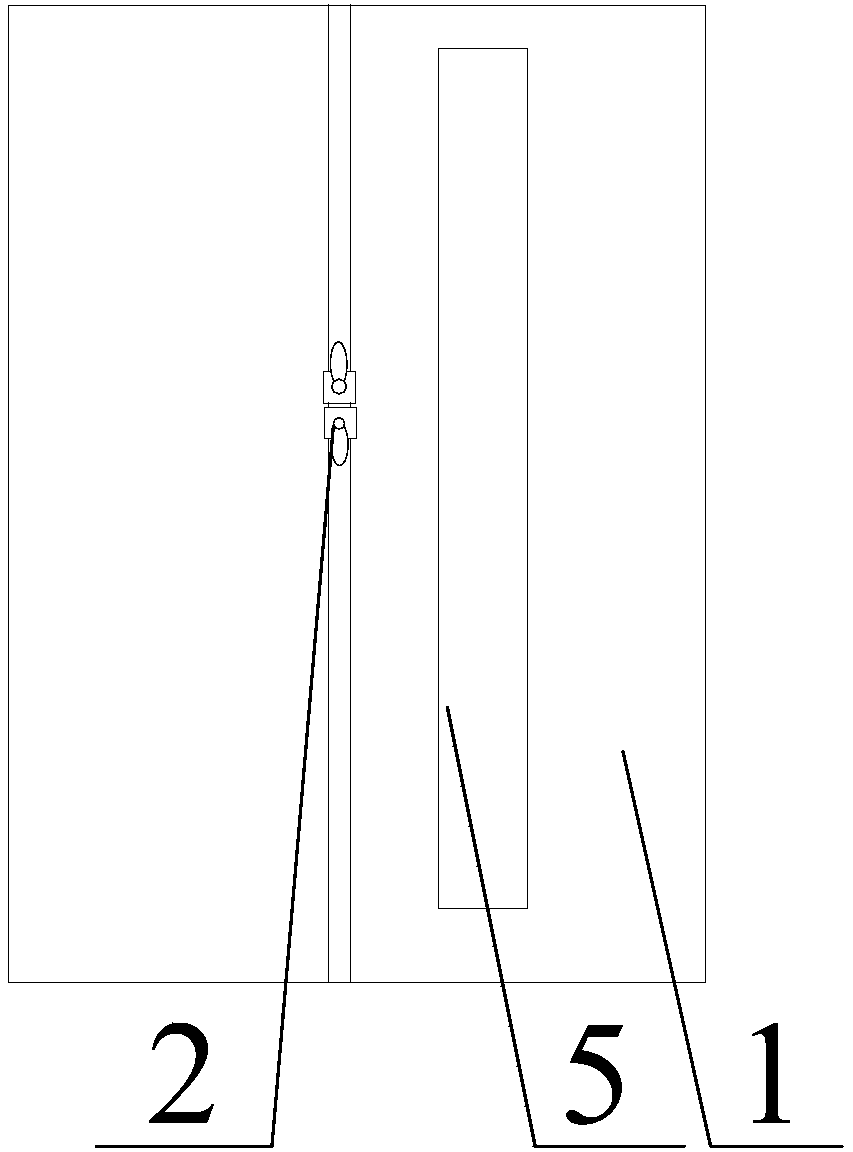

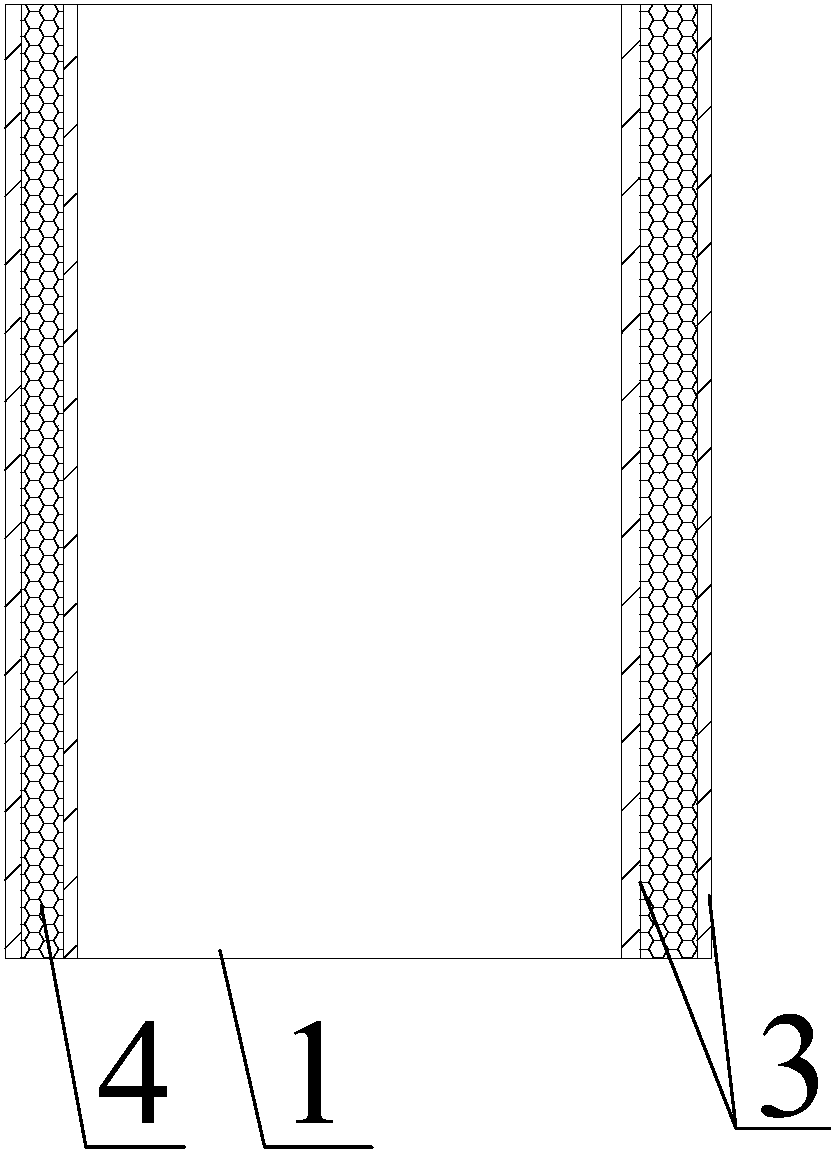

[0020] Such as figure 1 , 2 As shown, the present invention is aimed at the manufacture method of respirator protective cover, comprises the following steps:

[0021] A: Prepare the waterproof cloth 3 and the double-head zipper 2, cut the waterproof cloth 3 into two rectangles of equal size, and then spread polyethylene foam cotton 4 between the two waterproof cloth 3, and use the sealant to seal the polyethylene foam. The foam 4 is fixed to the two waterproof cloths 3, and then the edges of the waterproof cloths 3 are sequentially sewed with silk threads to complete the production of the protective cover body;

[0022] B: Open a liquid level observation port 5 on the protective cover body, and suture the surroundings of the liquid level observation port 5 with silk thread;

[0023] C: Then fix the side cloths on both sides of the double-ended zipper 2 and the two ends of the sewed protective cover body respectively. When the double-ended zipper 2 is sealed and locked, the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com