Revolving drum type beet transferring soil-removing machine

A technology for soil remover and sugar beet, applied in the direction of loaders, agricultural machinery and implements, applications, etc., can solve the problems of difficult to purchase parts, high procurement cost, poor universality of parts, etc., to achieve flexible transition and strong environmental adaptability , the effect of reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

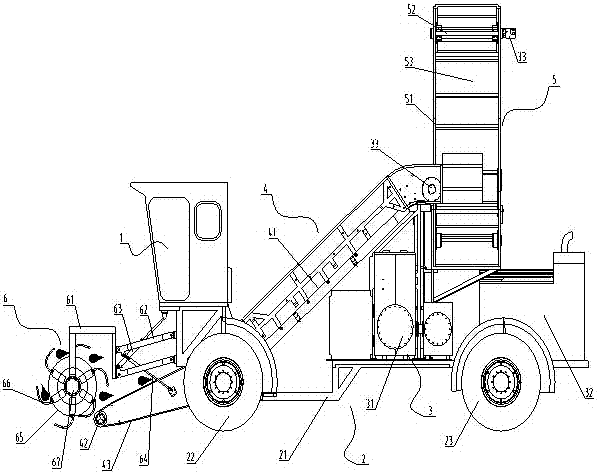

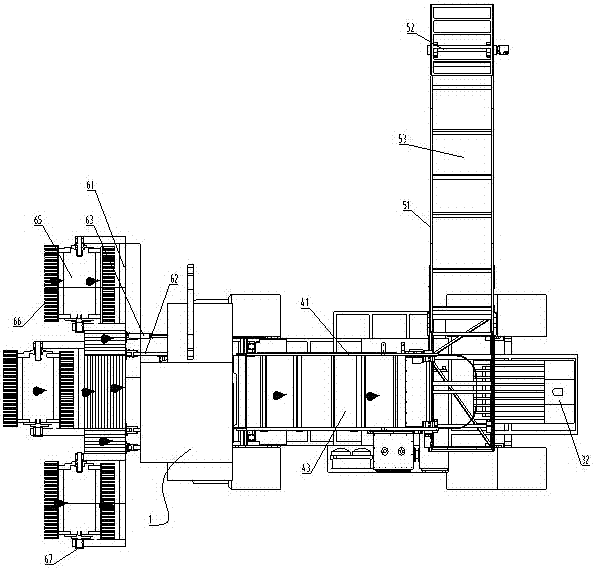

[0018] refer to Figure 1-Figure 2 , a kind of drum type sugar beet reload soil remover of the present invention, comprises driver's cab 1, walking part 2, power part 3, first conveying part 4, second conveying part 5 and pick-up part 6, and described walking part 2 comprises Vehicle frame 21, front wheel 22 and rear steering wheel 23, described front wheel 22 is installed on the front portion of vehicle frame 21, and described rear steering wheel 23 is installed on the rear portion of vehicle frame 21, and described rear steering wheel 23 is used for controlling walking The displacement direction of the part 2, the cab 1 is installed on the upper part of the vehicle frame 21, and the first conveying part 4 is installed on the lower part of the cab 1, and the first conveying part 4 includes a first conveying frame 41, a first conveying shaft 42 and the first conveyor belt 43, the first conveyor frame 41 and the vehicle frame 21 are fixedly connected by bolts, the angle between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com