Spray equipment for nano-coating of lamps

A technology of nano-coating and spraying equipment, which is applied in coatings, devices for coating liquid on the surface, spraying devices, etc., which can solve the problems of affecting workers' operation and easy spraying of nano-coatings to hands, so as to avoid escape, Guaranteed stable rotation and accelerated drying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below by means of specific embodiments:

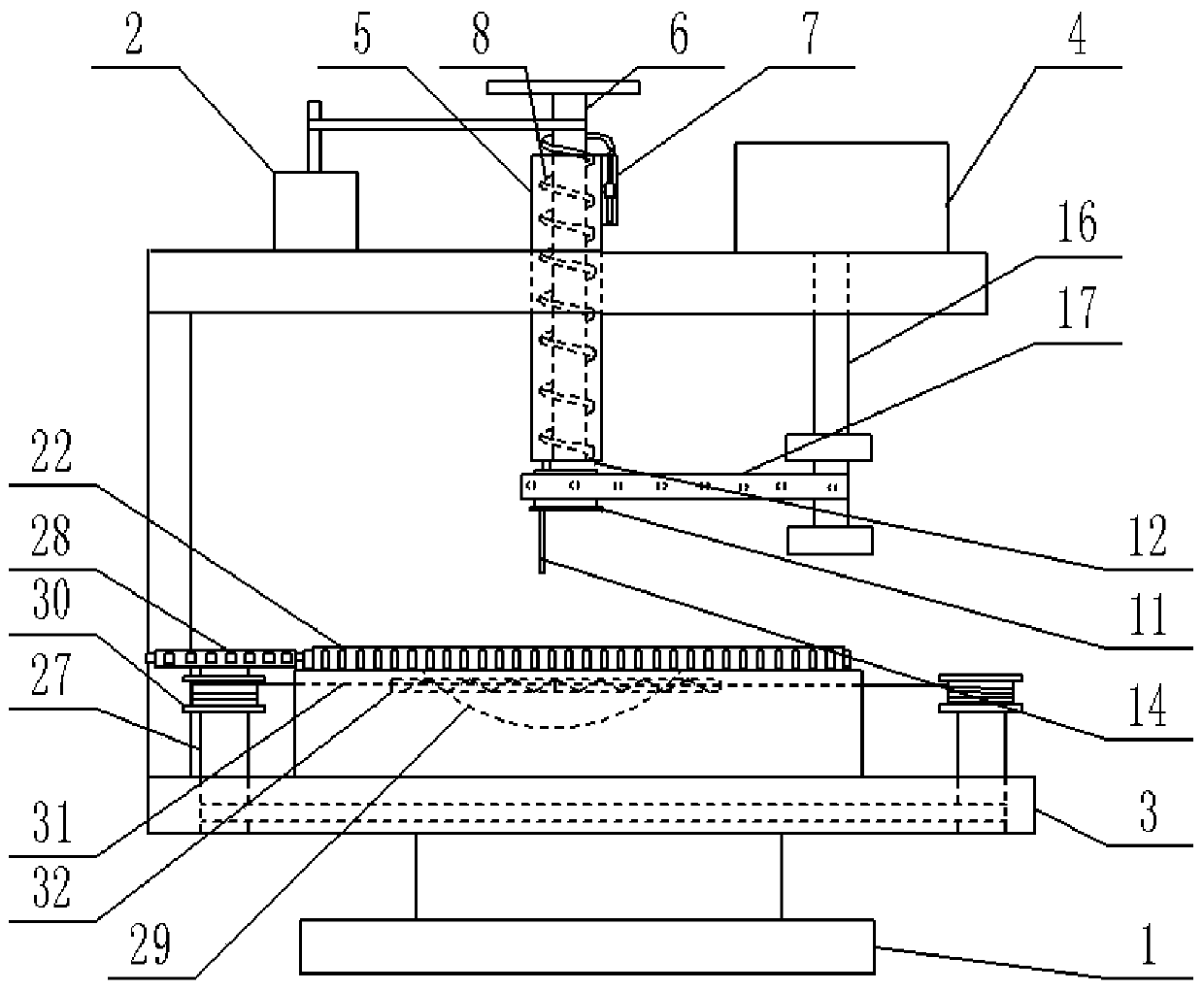

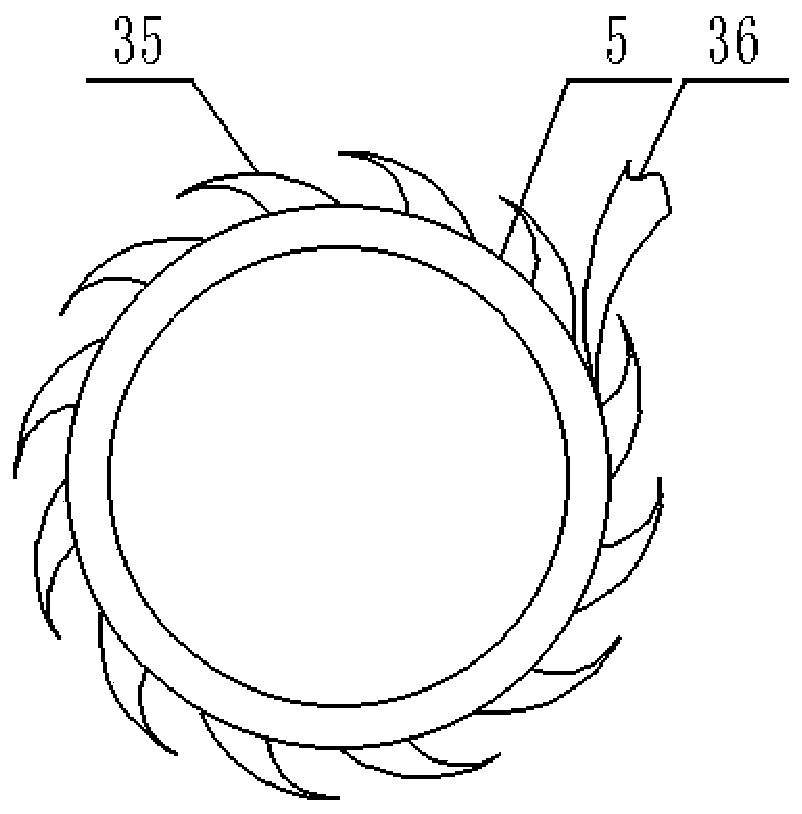

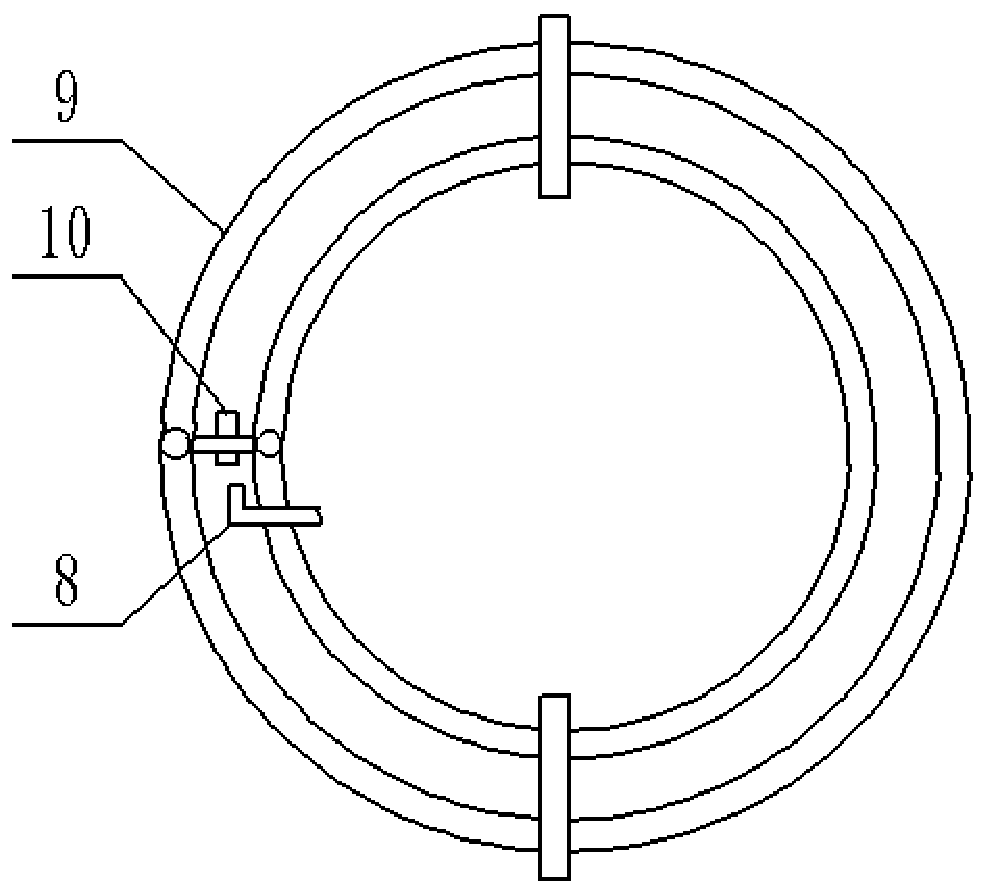

[0021] The reference signs in the drawings of the description include: frame 1, motor 2, processing table 3, spraying box 4, rotating cylinder 5, shaft 6, fan 7, air blowing pipe 8, track 9, sliding head 10, feeding head 11 , gap 12, material cavity 13, nozzle 14, first protruding pipe 15, discharge pipe 16, feeding belt 17, interlayer 18, feeding pipe 19, blocking block 20, pipe body 21, ring gear 22, inner Teeth 23, external teeth 24, shaft body 25, friction teeth 26, column 27, booster gear 28, processing groove 29, runner 30, iron wire 31, folding plate 32, baffle plate 33, perforation 34, ratchet 35, ratchet Claw 36.

[0022] The embodiment is basically as figure 1 Shown: Spraying equipment for nano-coating of lamps, including frame 1, spraying box 4 and motor 2 are installed on the top of frame 1, reducer is installed on motor 2, motor 2 includes a power shaft, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com