Mechanical lubrication device for toner cartridge scraping knife

A mechanical lubrication and scraper technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of arm fatigue, uncontrollable quantity, and influence on product quality, and achieve the protection of body safety, prevention of drifting, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

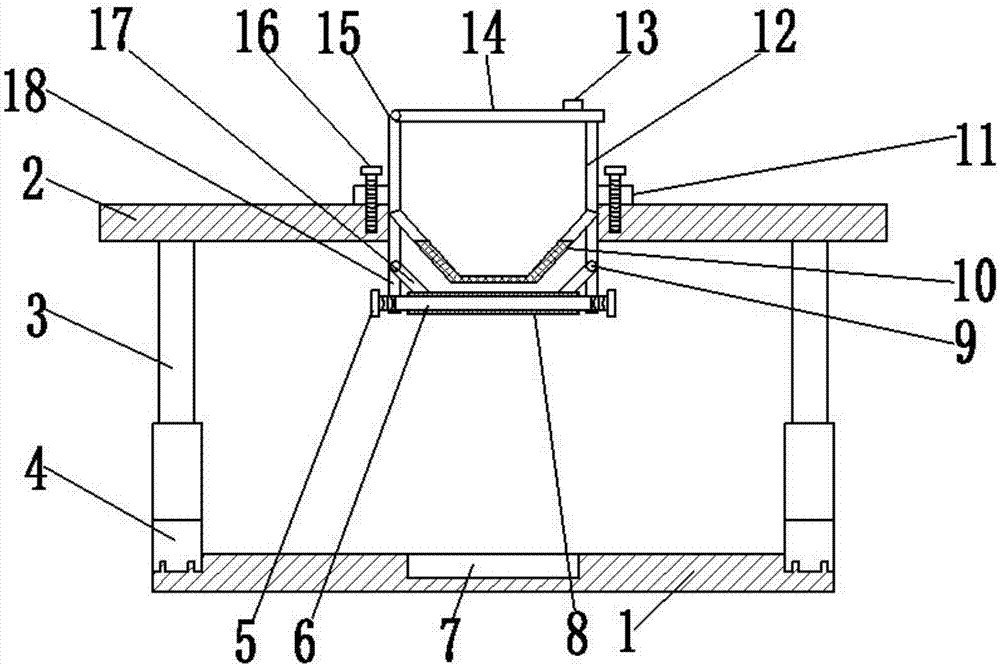

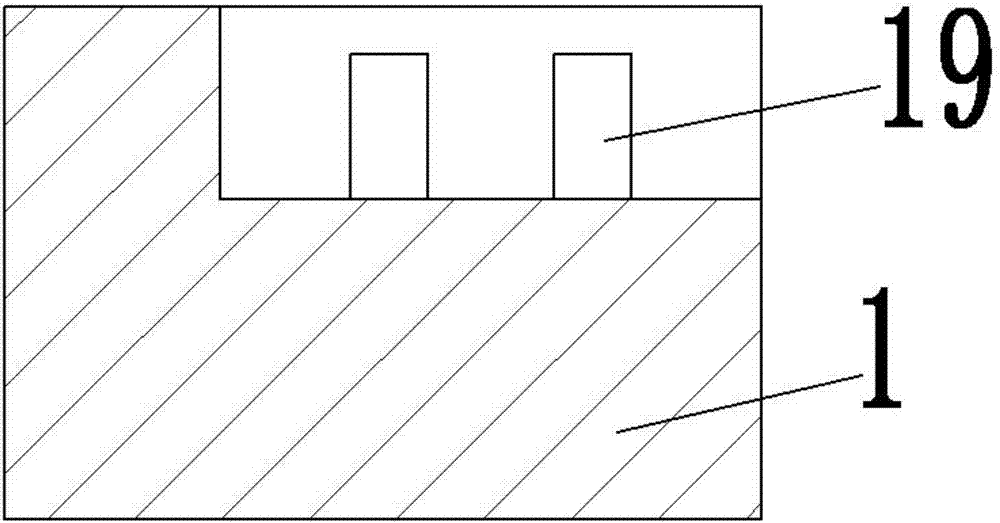

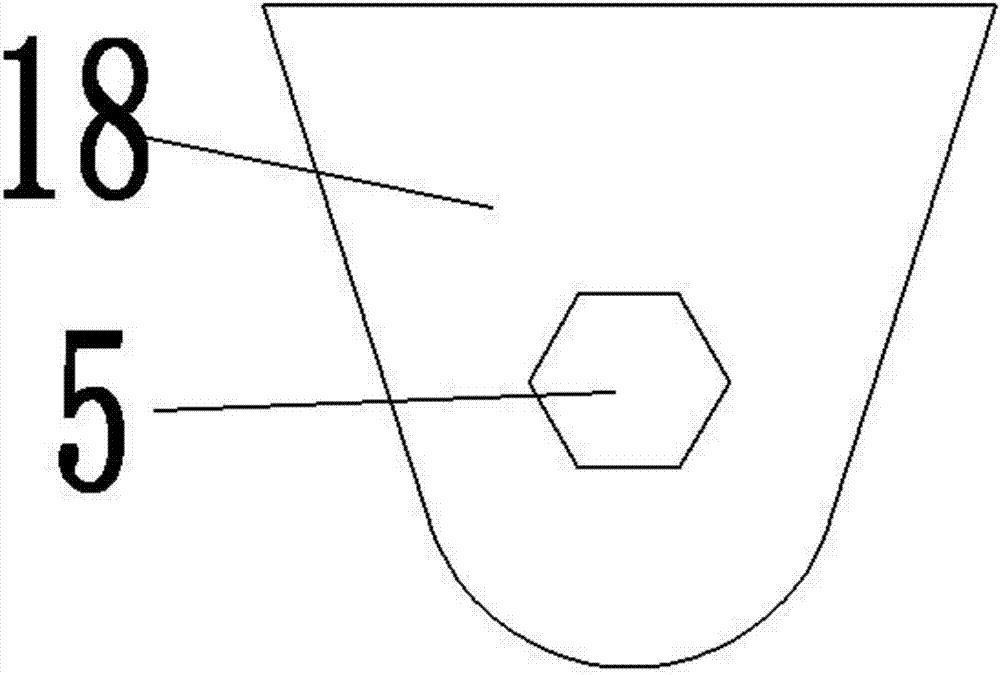

[0018] see Figure 1-3 , a mechanical lubricating device for a toner cartridge scraper, comprising a base 1 and a horizontal plate 2; a groove 7 is provided in the center of the upper surface of the base 1 to facilitate fixing the toner cartridge scraper; sliders are provided on the left and right sides of the groove 7 4; the slider 4 is slidably connected inside the slide rail 19; the slide rail 19 is set on the upper surface of the left and right ends of the base 1; the upper end of the slider 4 is fixed on the lower end of the electric telescopic rod 3; the upper end of the electric telescopic rod 3 A horizontal plate 2 is provided; the left and right ends of the horizontal plate 2 are welded to the top of the electric telescopic rod 3; the upper surface of the horizontal plate 2 is provided with a lubricating powder storage box 12 at the center...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com