Patents

Literature

37results about How to "Uniform environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cell-Laden Hydrogels

InactiveUS20080193536A1Maximize cell viabilityEqually distributedBiocidePowder deliveryTissue engineeringChemistry

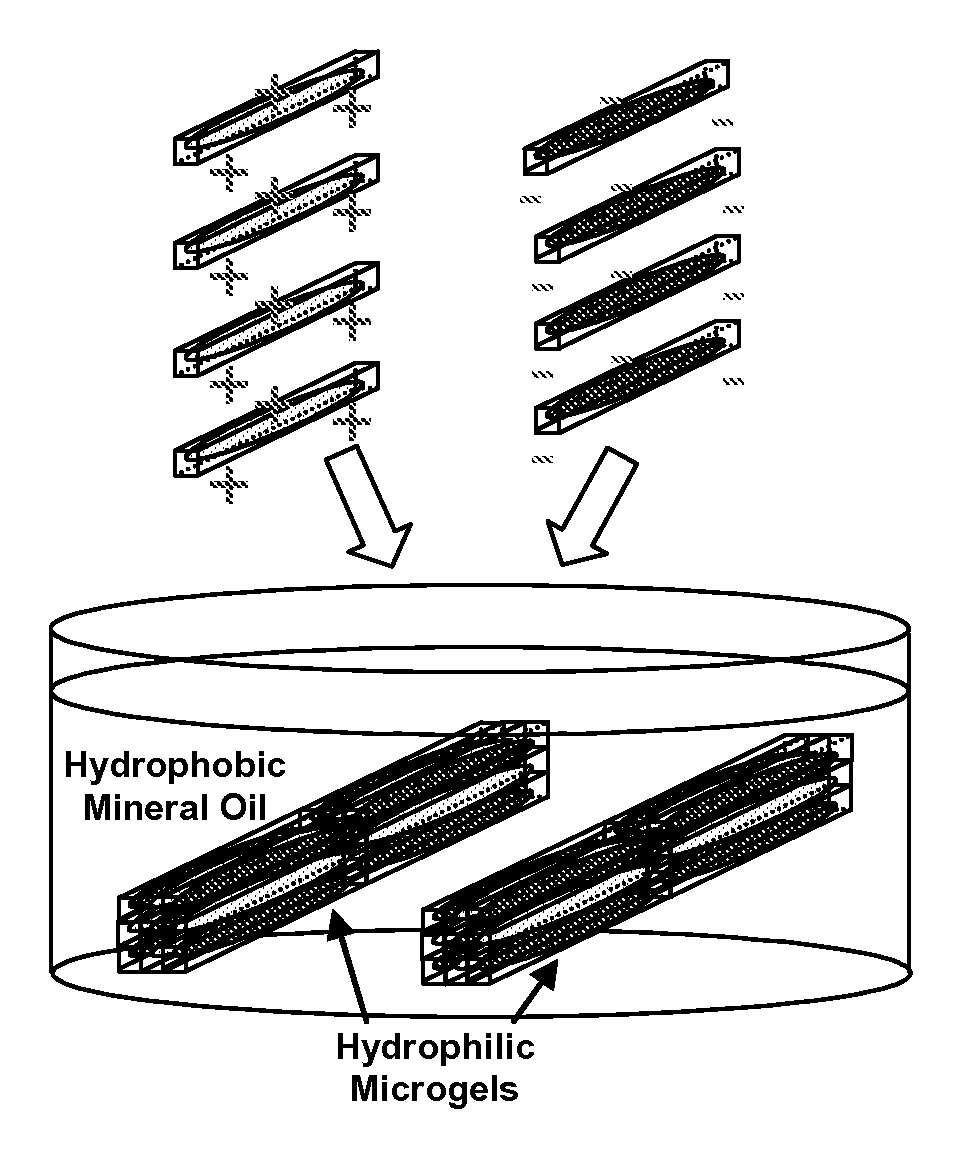

The present invention provides cell-laden hydrogels and hydrogel assemblies thereof for use in tissue engineering. The invention provides microscale hydrogels (i.e. microgels) having greatest dimensions ranging between about 1 μm and 1000 μm. The present invention provides methods of producing inventive hydrogels and hydrogel assemblies and pharmaceutical compositions thereof.

Owner:KHADEMHOSSEINI ALIREZA +3

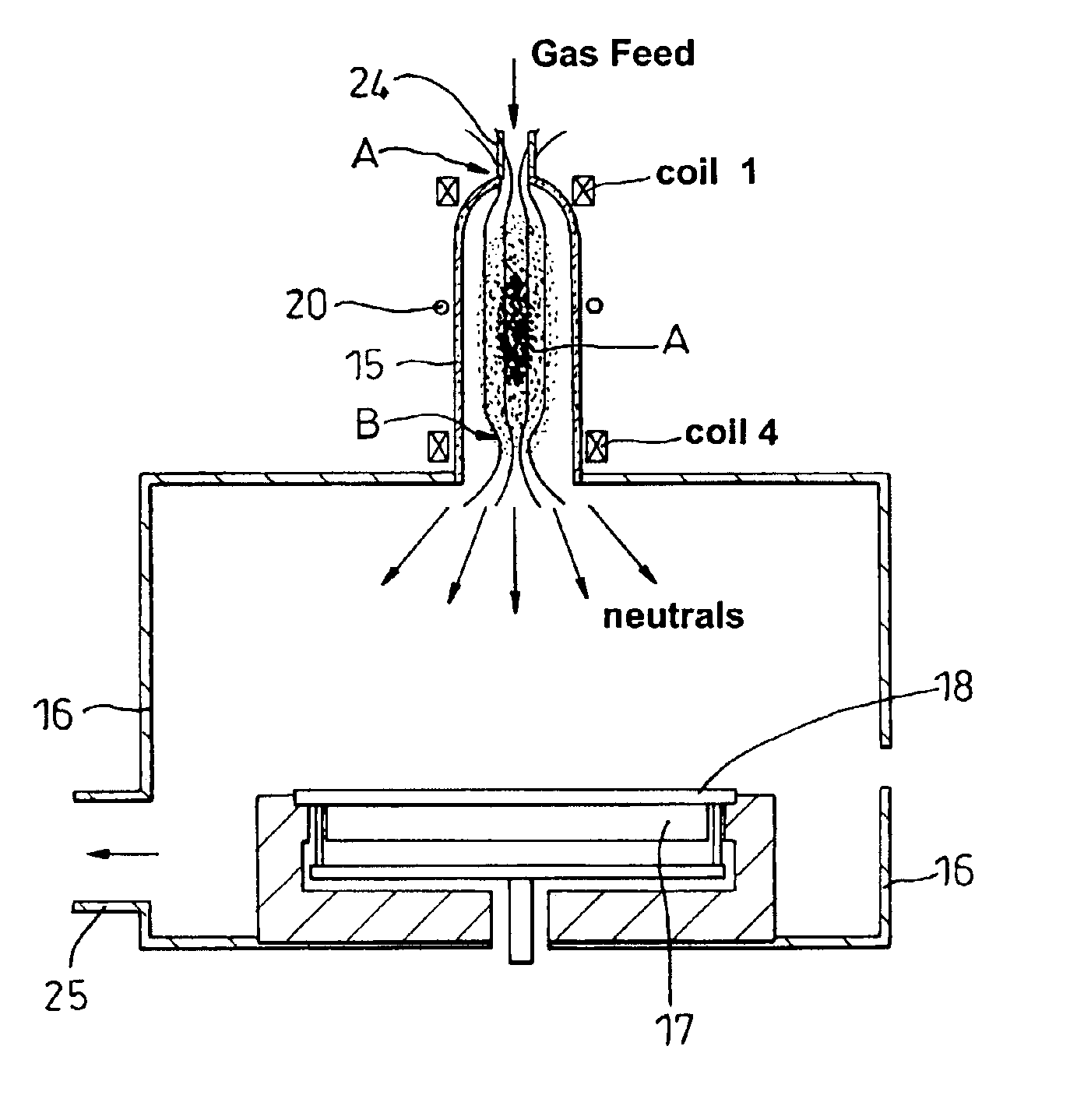

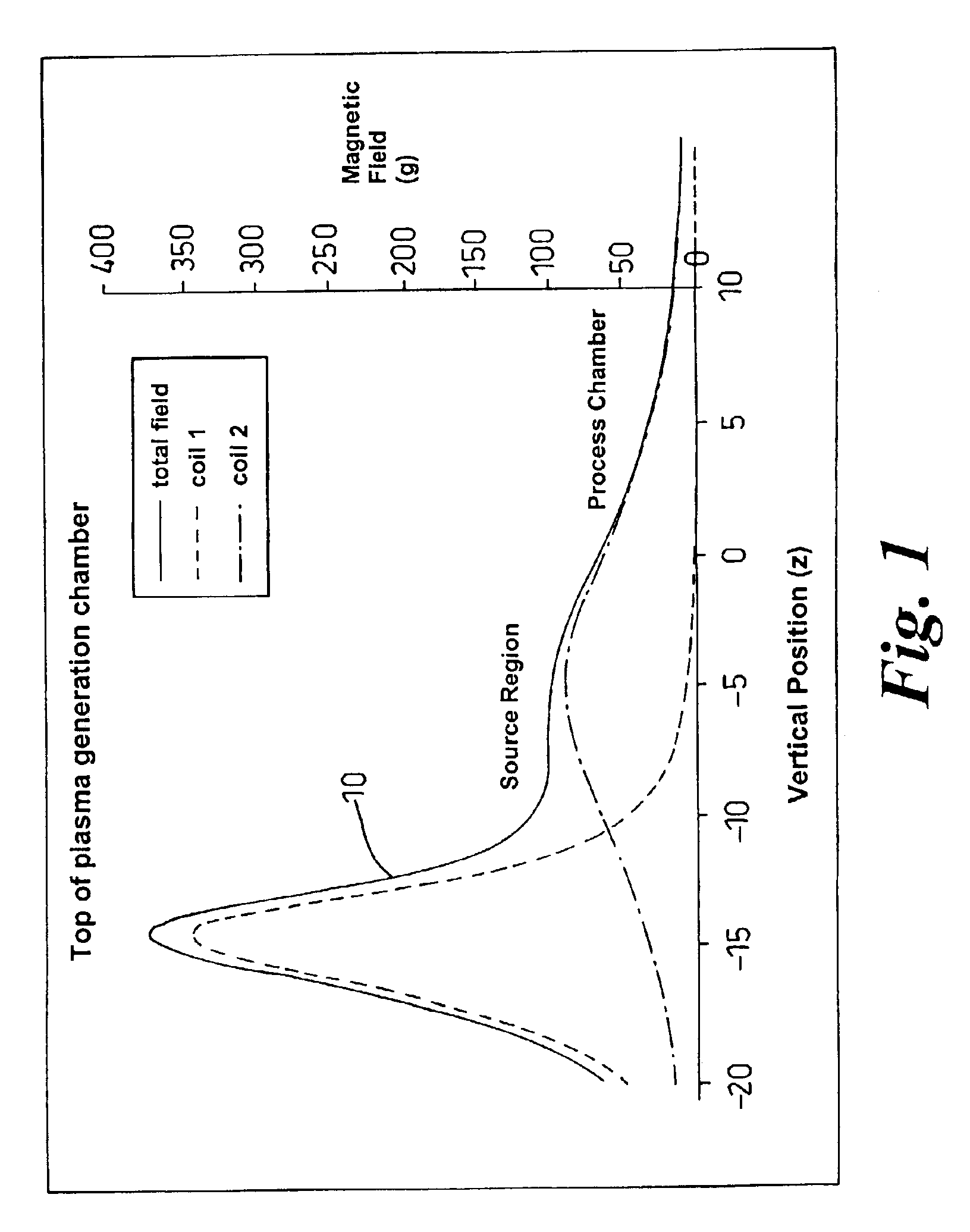

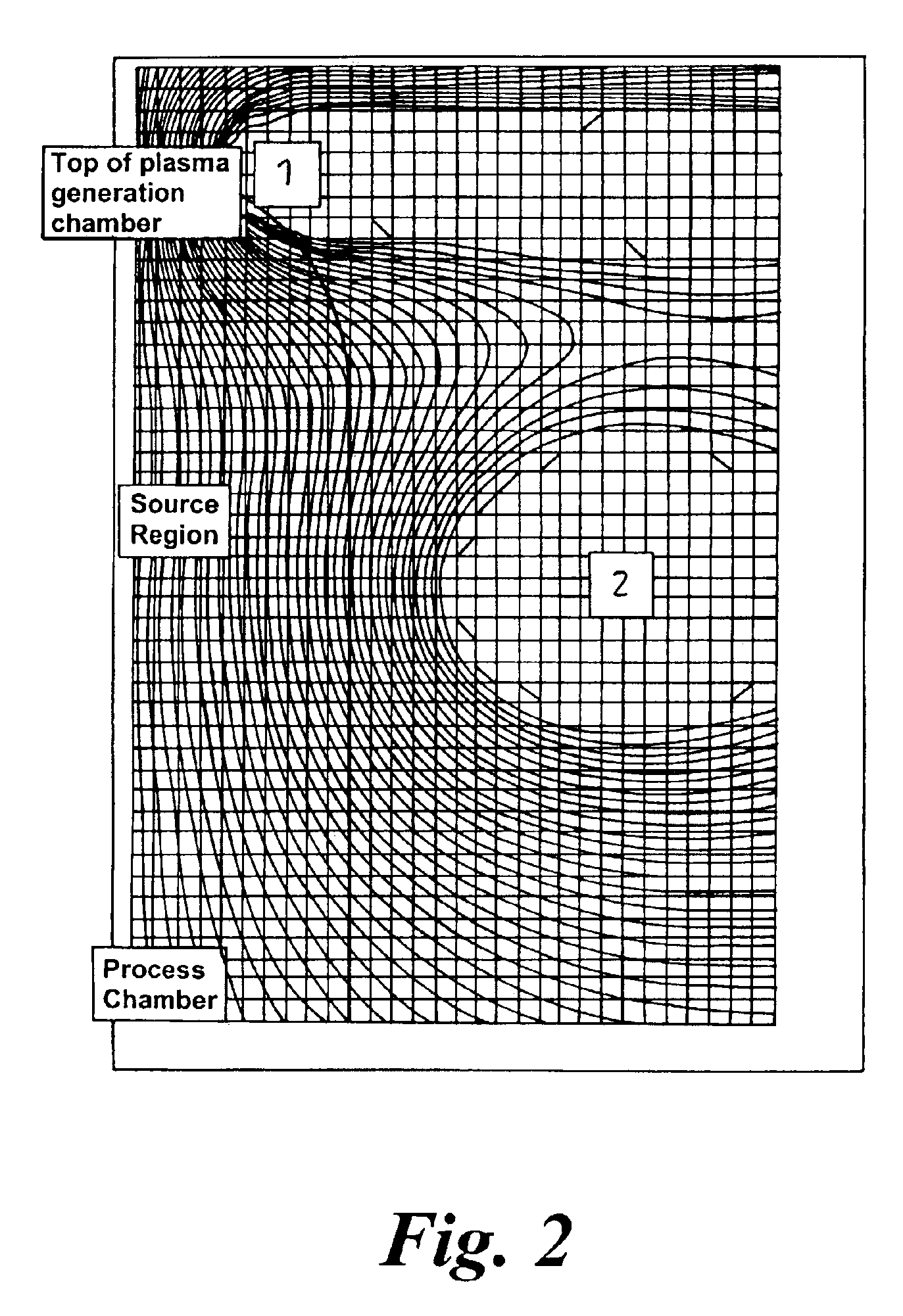

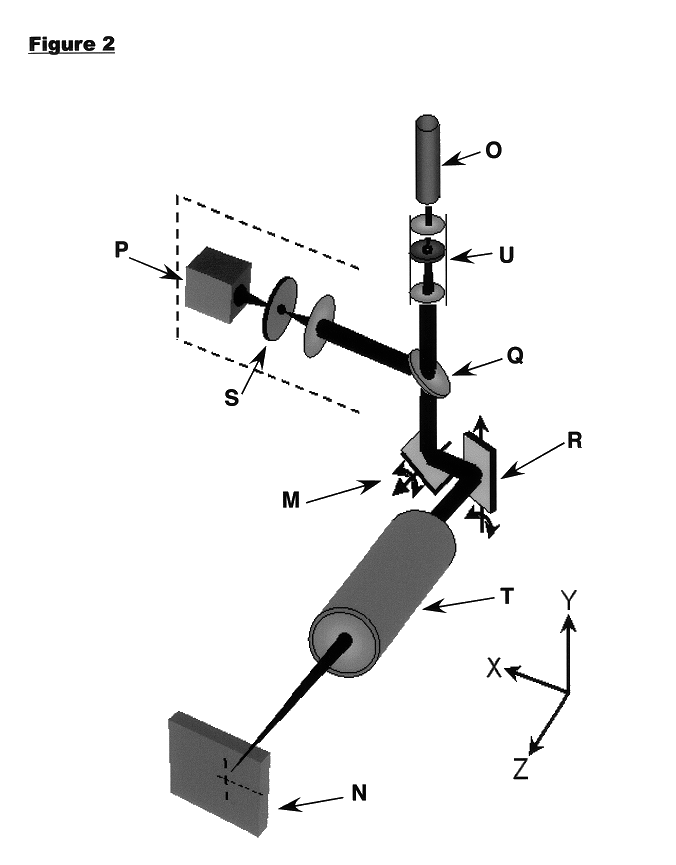

Plasma processing apparatus

ActiveUS6876154B2Zero net effectIncrease controlElectric arc lampsSolid cathode detailsPlasma processingMagnetic mirror

This invention relates to plasma processing apparatus and in particular, but not exclusively, to inductively coupled plasma helicon or electron cyclotron resonance apparatus. A plasma generation chamber is sat above a process chamber, in which is located a workpiece support. A plasma generation or source region exists and coils are provided to create magnetic mirrors above and below the plasma generation zone, whereby electrons will be reflected back towards the plasma zone and there is no electrical conductive path extending around or through at least the upper mirror.

Owner:SPTS TECH LTD

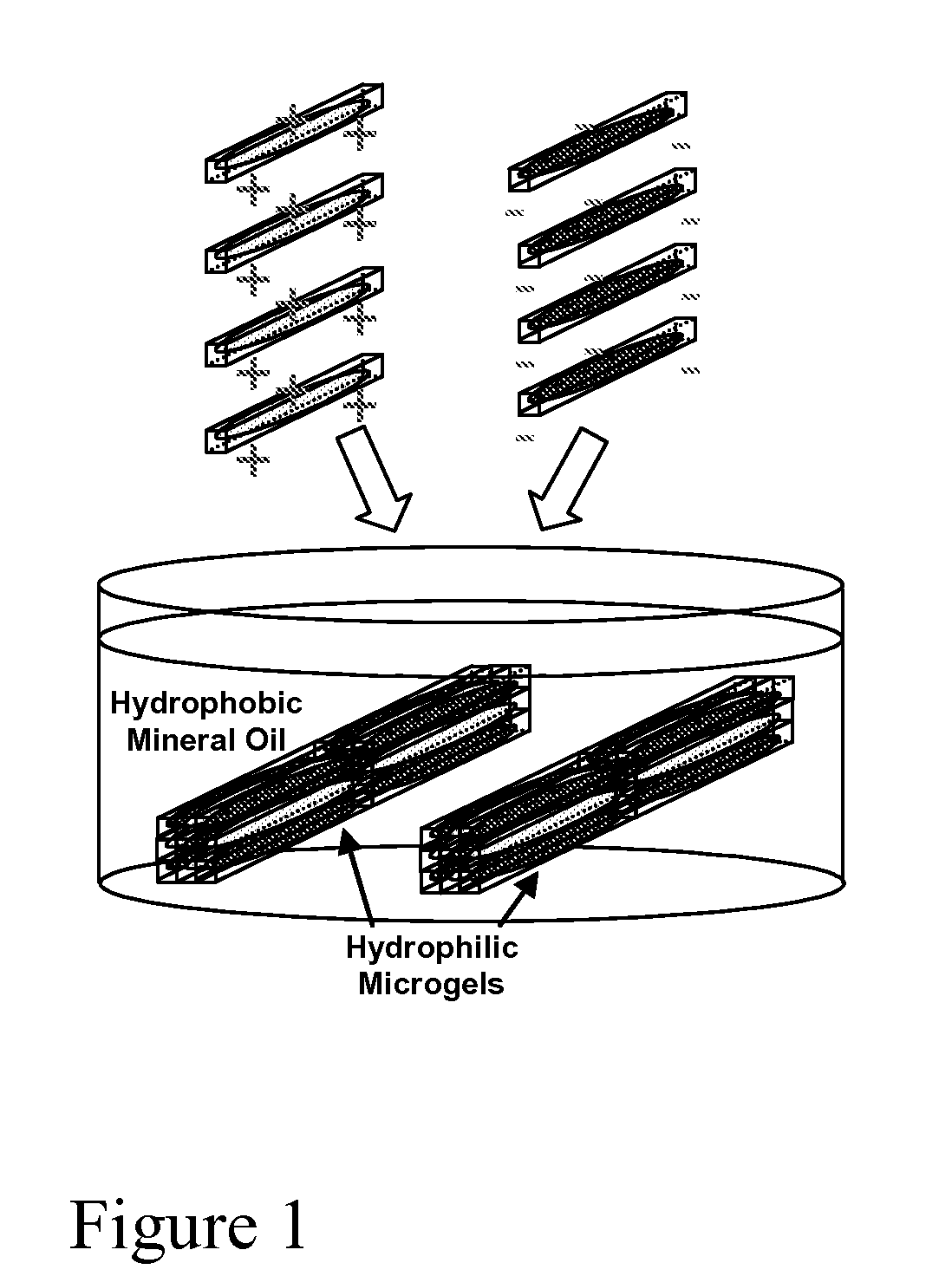

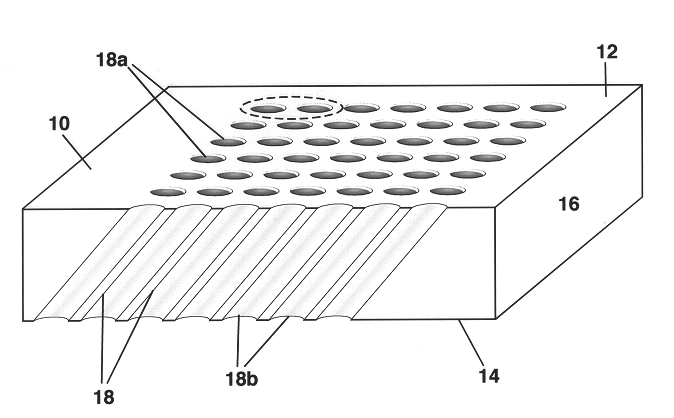

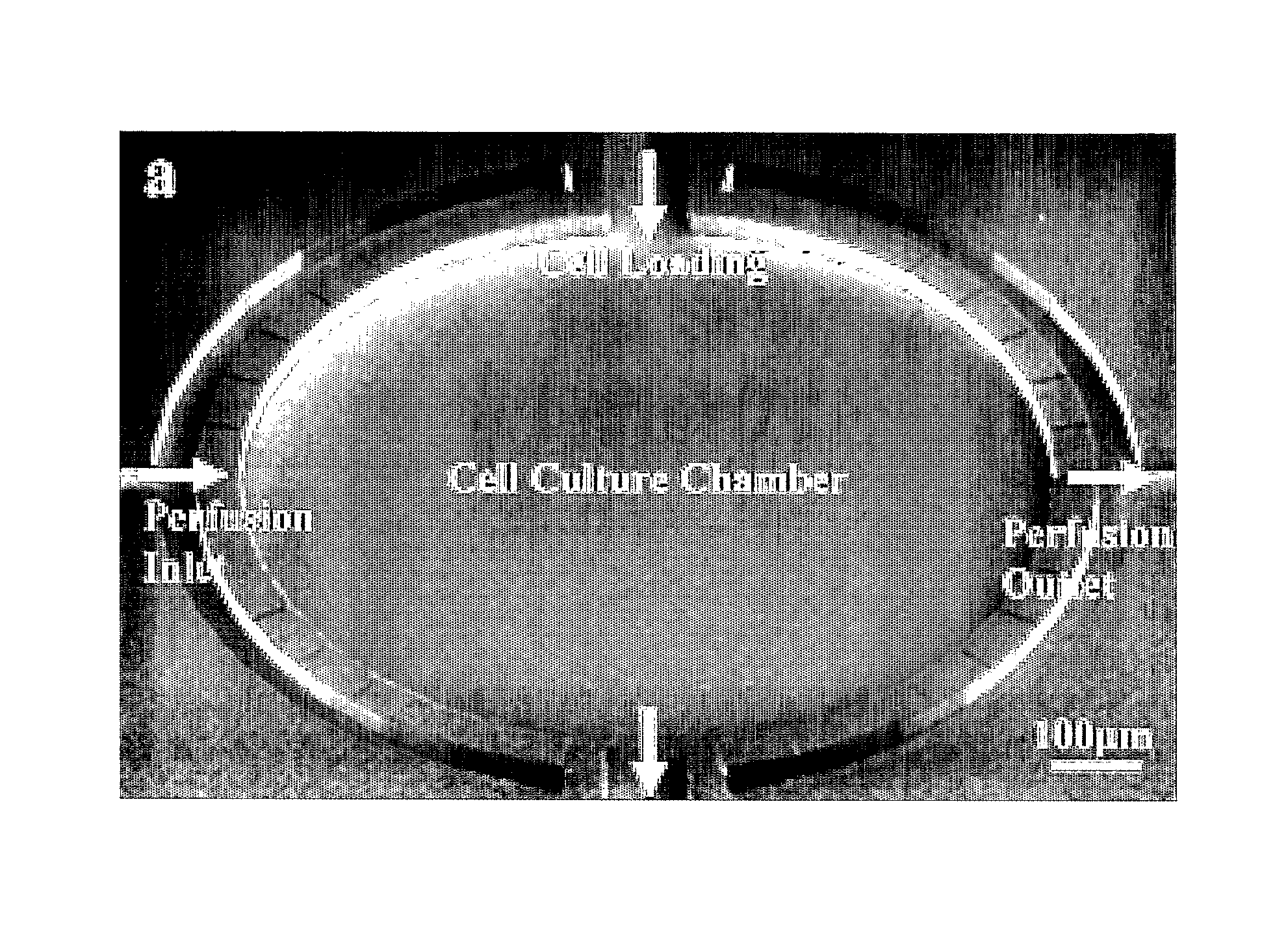

Multiple microchannels chip for biomolecule imaging, and method of use thereof

InactiveUS6587197B1Uniform test environmentExtensive testingOptical radiation measurementBioreactor/fermenter combinationsTotal internal reflectionAcute angle

A panel chip for supporting biological samples for observation with a microscope. The glass panel defines a top flat surface, a bottom bearing surface, and at least a few channels extending generally parallel to each other from top to bottom surfaces. Each of the channels defines a top access mouth for ingress of biological samples, wherein each channel is obliquely inclined so as to make a significant acute angle relative to an axis perpendicular to said top flat surface, in order to facilitate the guidance of maximum light into the channel due to zero loss of reflection and to produce the maximum number of total internal reflection and to guide the maximum light out of the microchannel in such a manner that produces no artifact halo for maximum detection and sensitivity. Each channel has such an inner diameter as to accommodate flow through viscosity of a biological sample containing fluid.

Owner:ROYCE TECH

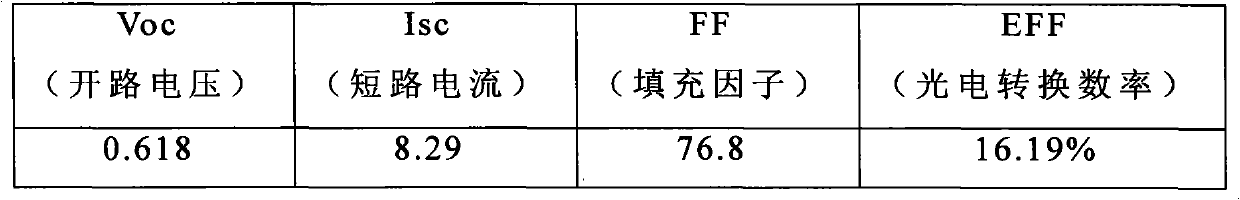

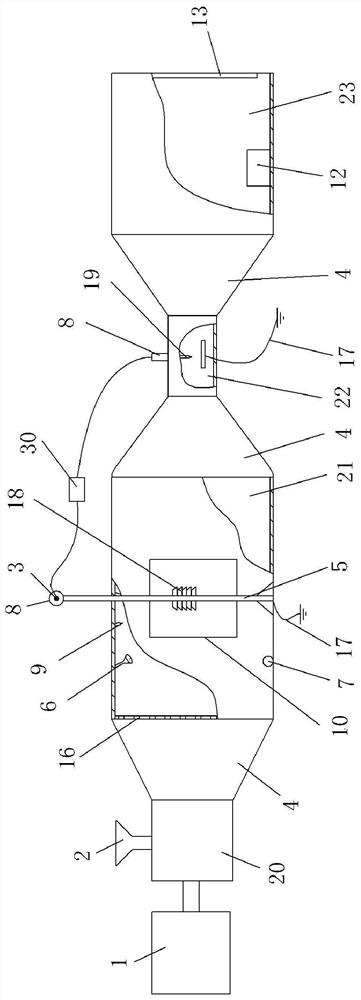

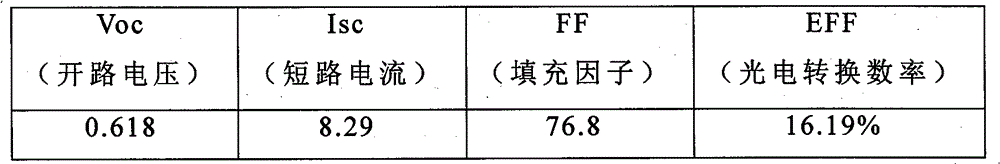

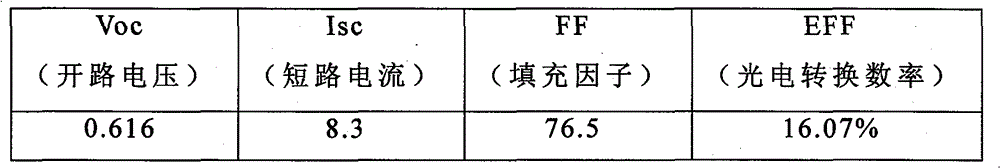

Method for improving phosphorus diffusion uniformity of solar cell

ActiveCN102005502AAvoid uneven diffusionReduce uneven diffusionFinal product manufactureSemiconductor devicesNitrogen atmosphereNitrogen gas

The invention discloses a method for improving phosphorus diffusion uniformity of a solar cell. The method comprises the following steps of: (1) placing a silicon slice in a diffusion furnace and raising the temperature of each region in the furnace to 700 to 780 DEG C, wherein the environment in the furnace is uniform nitrogen atmosphere, and the flow rate of the nitrogen gas is 8 to 30L / minute; (2) simultaneously introducing phosphorus-carrying source gas at the speed of 0.8 to 2L / minute and dry oxygen at the speed of 0.4 to 2.5L / minute after the temperature is stable, ensuring that the gas environment in the furnace is uniform, and diffusing for 10 to 40 minutes; (3) stopping introduction of the phosphorus-carrying source gas source and the dry oxygen, synchronously and uniformly raising the temperature of each region in the furnace at the rate of below 5 DEG C / minute, raising temperature to 810 to 900 DEG C and diffusing for 10 to 40 minutes; and (4) reducing temperature and discharging out of a boat. Through uniform gas and consistent temperature in the furnace, the phosphorus diffusion uniformity during preparation of the battery plate is improved, and the conversion efficiency of the solar cell is improved to a certain extent.

Owner:YANCHENG CANADIAN SOLAR INC

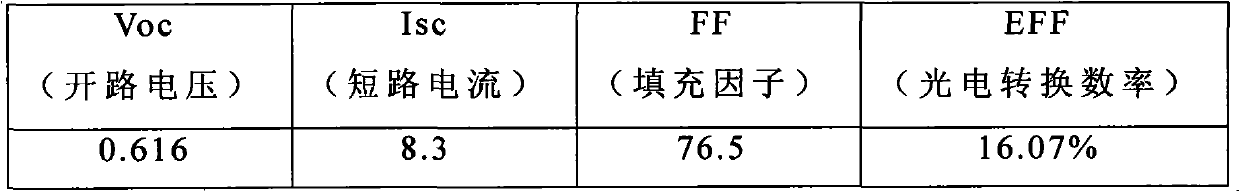

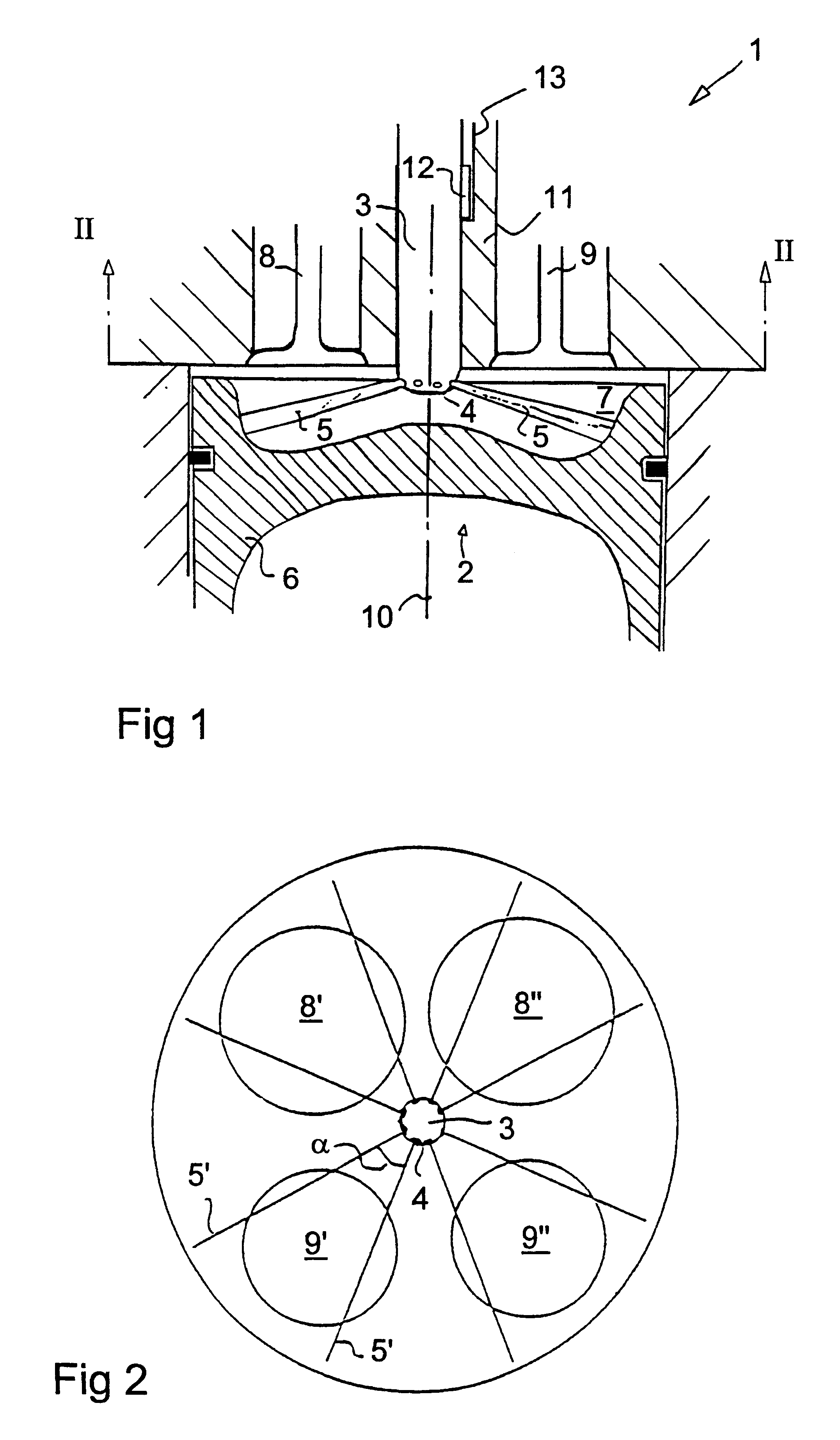

Internal combustion engine with fuel injection

InactiveUS6382179B1Efficient combustionMore combustionInternal combustion piston enginesCylinder headsCombustionEngineering

A combustion engine with direct injection has in each cylinder a fuel injector (3) whose fuel orifices (4) are so oriented that the projection (5') of the direction of each fuel spray, viewed in a plane perpendicular to the cylinder centerline, crosses a projection (8', 8'', 9', 9'') in the same plane of the valve disc of one of the valves.

Owner:SCANIA CV AB

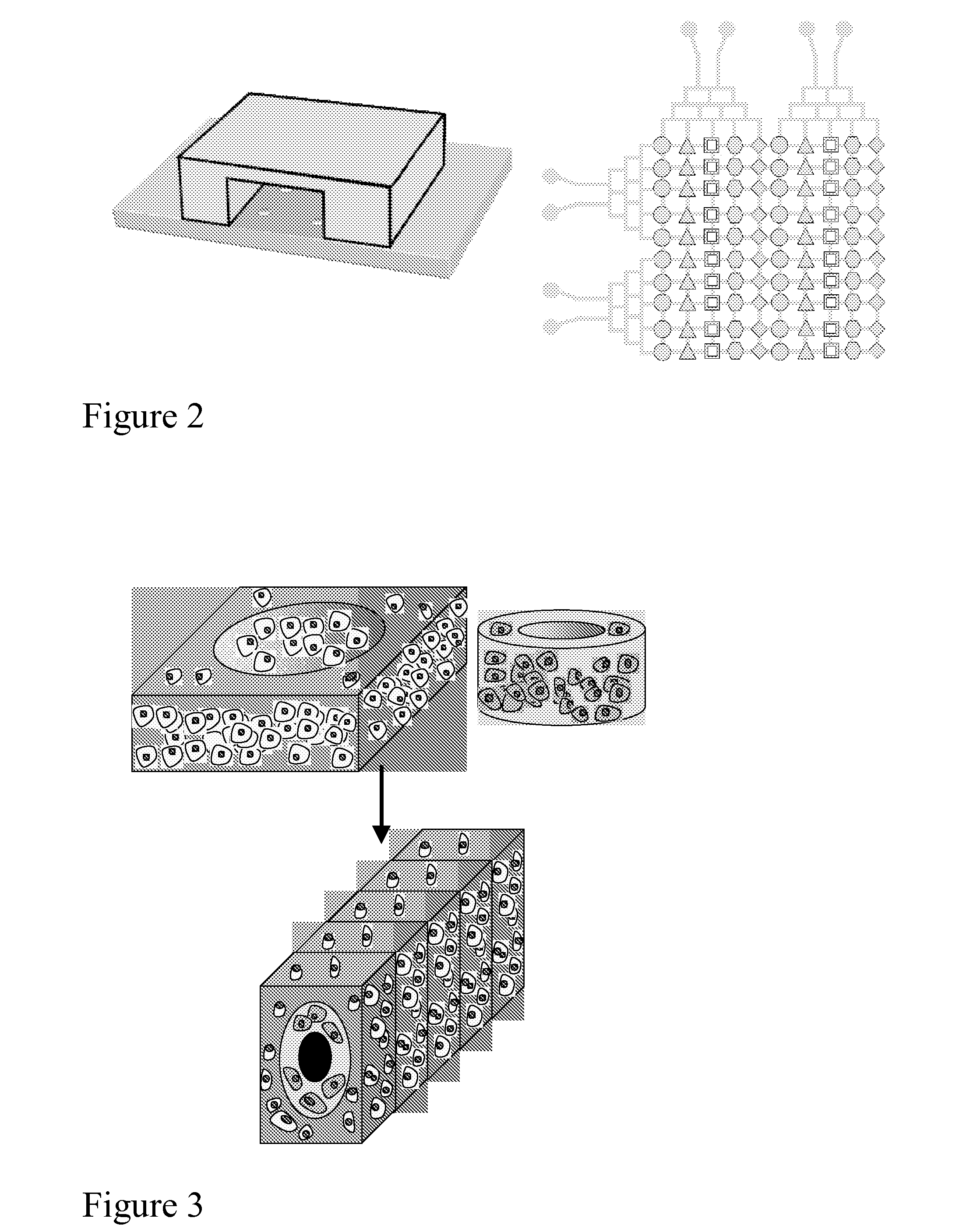

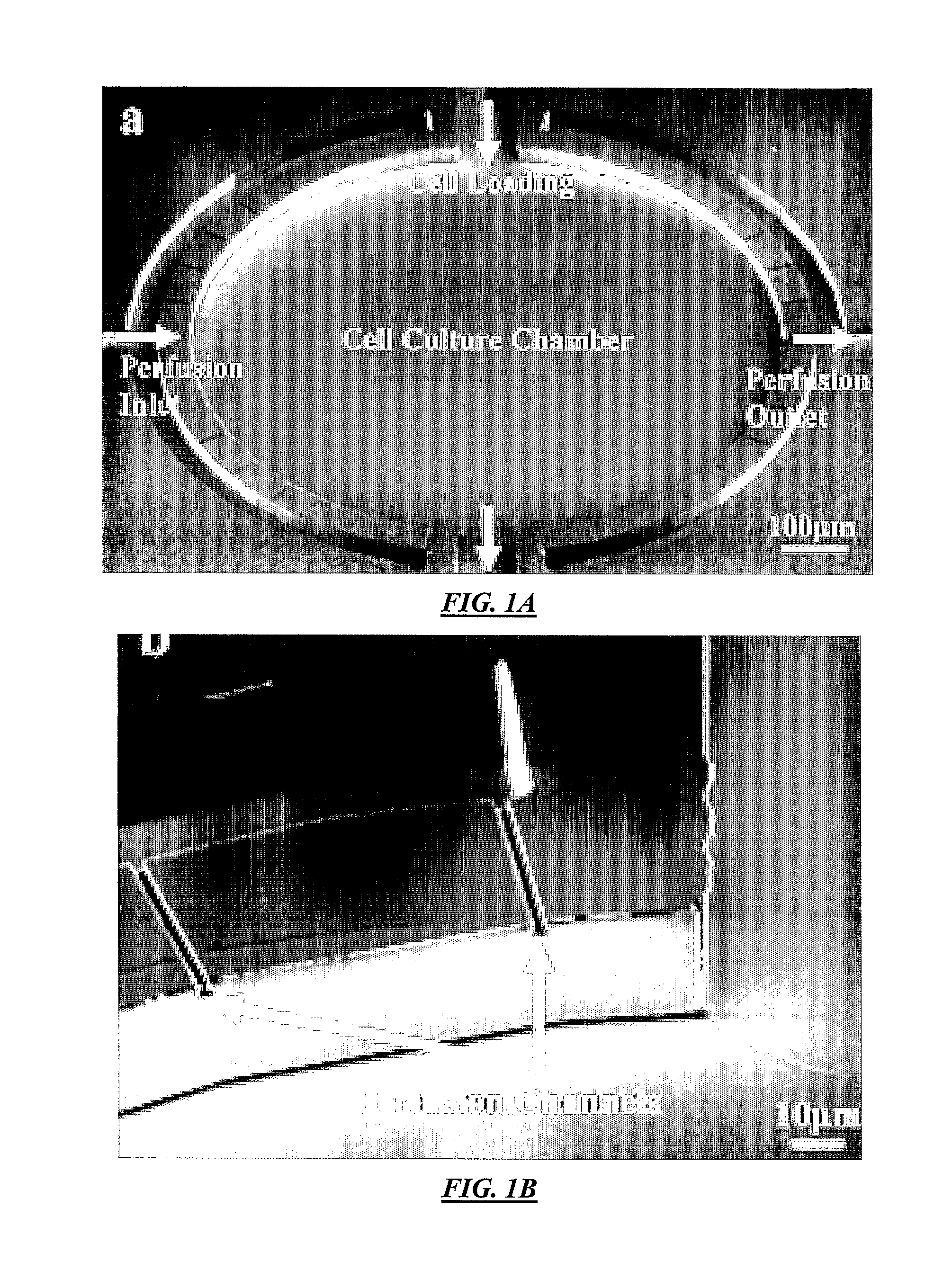

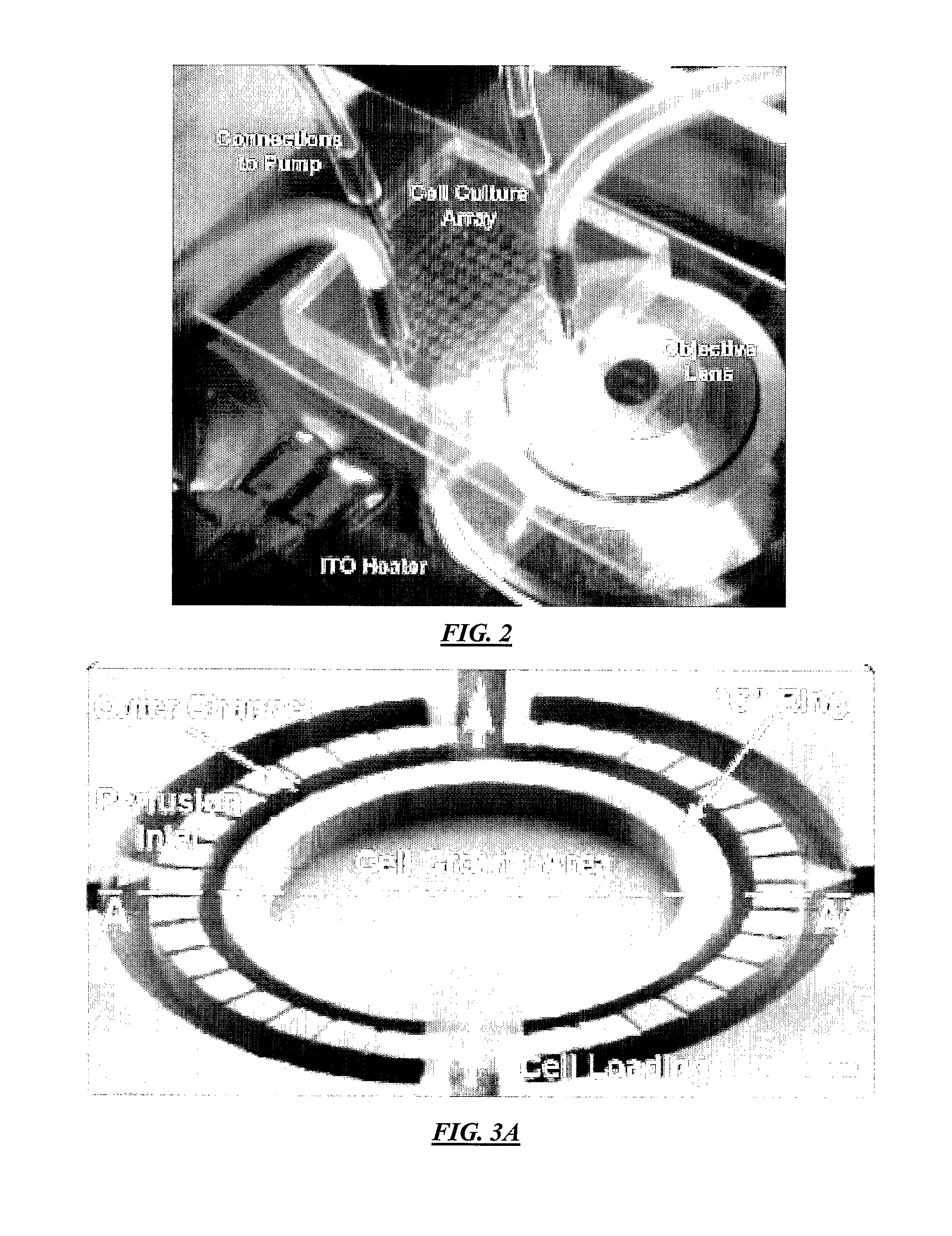

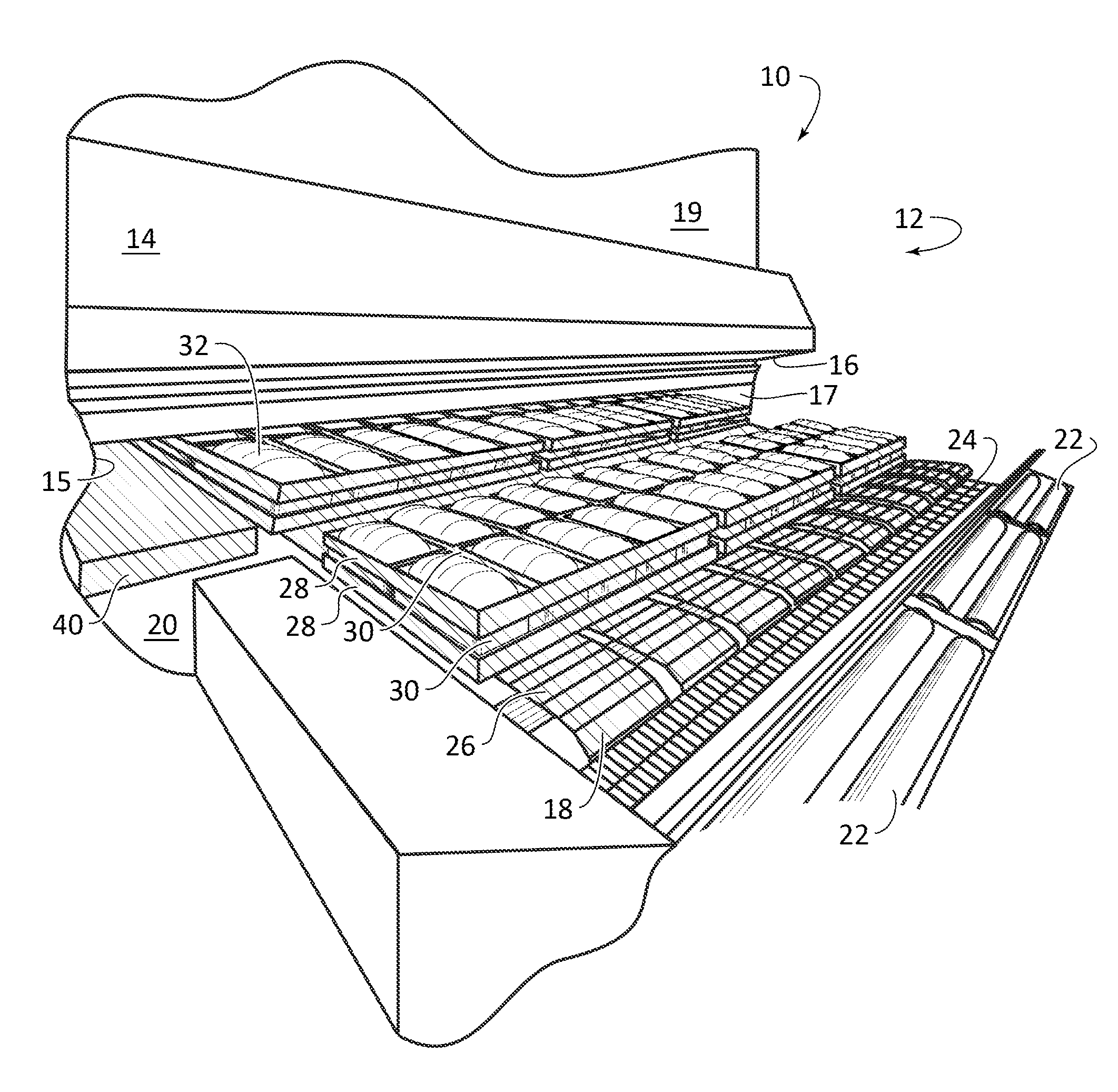

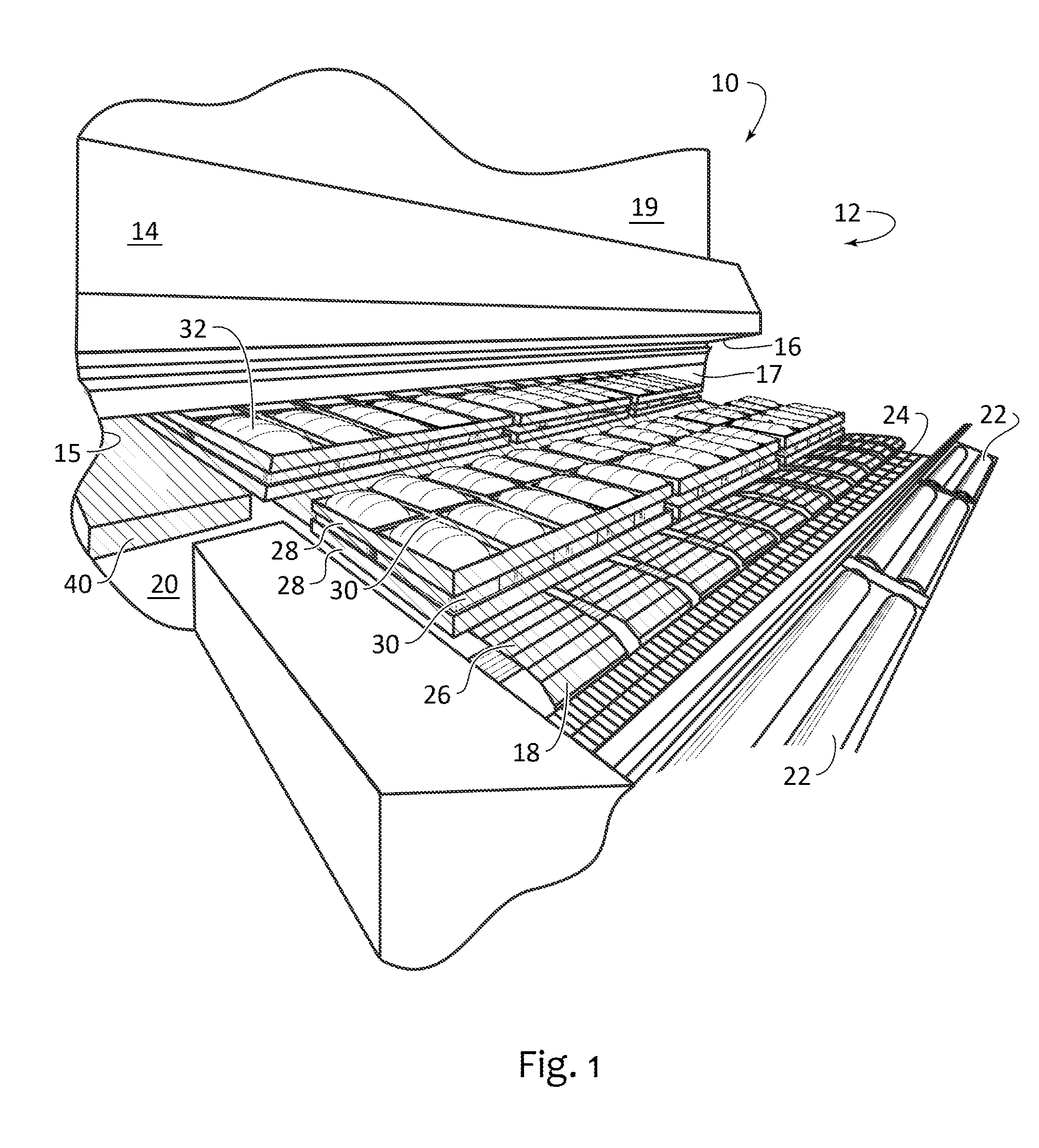

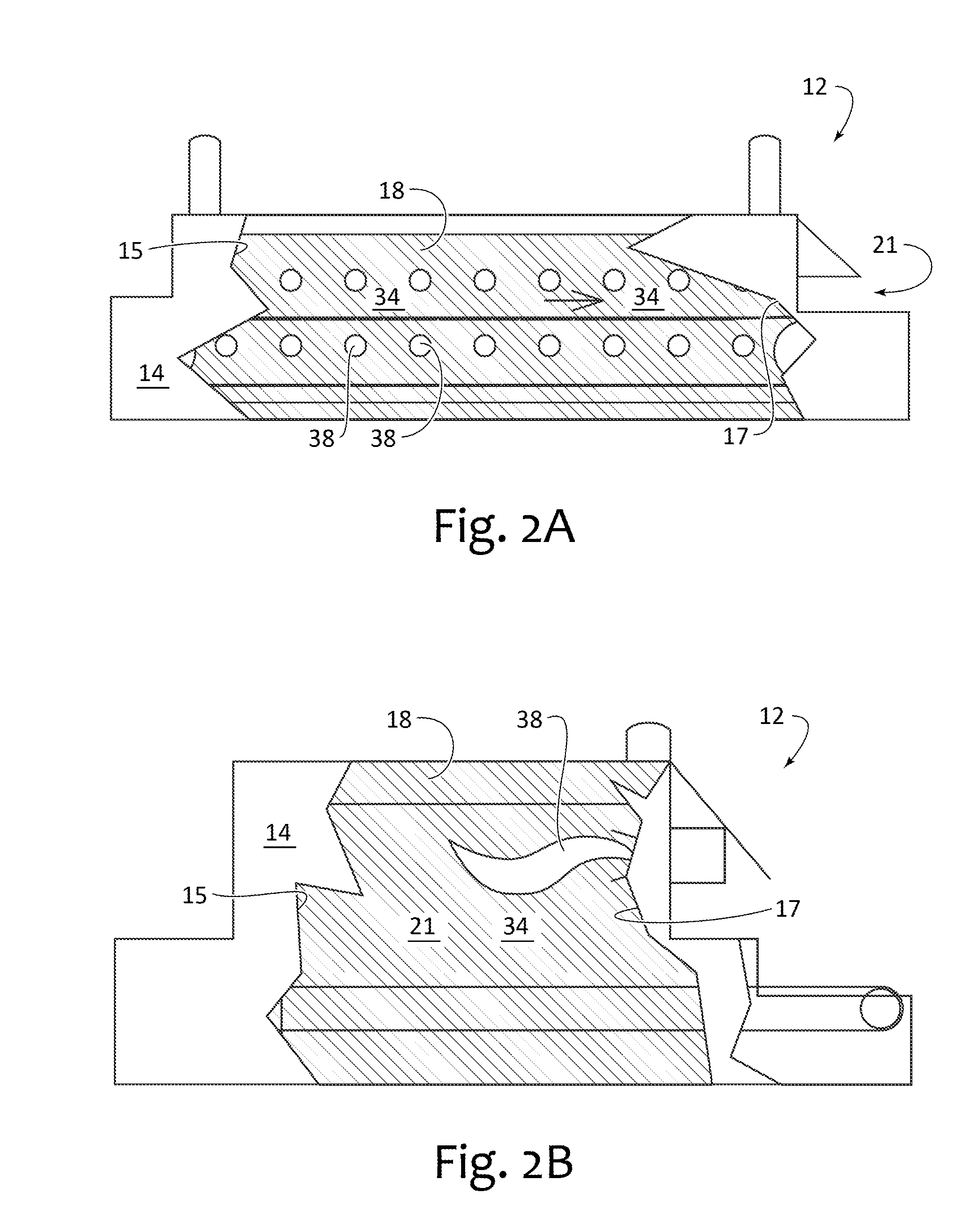

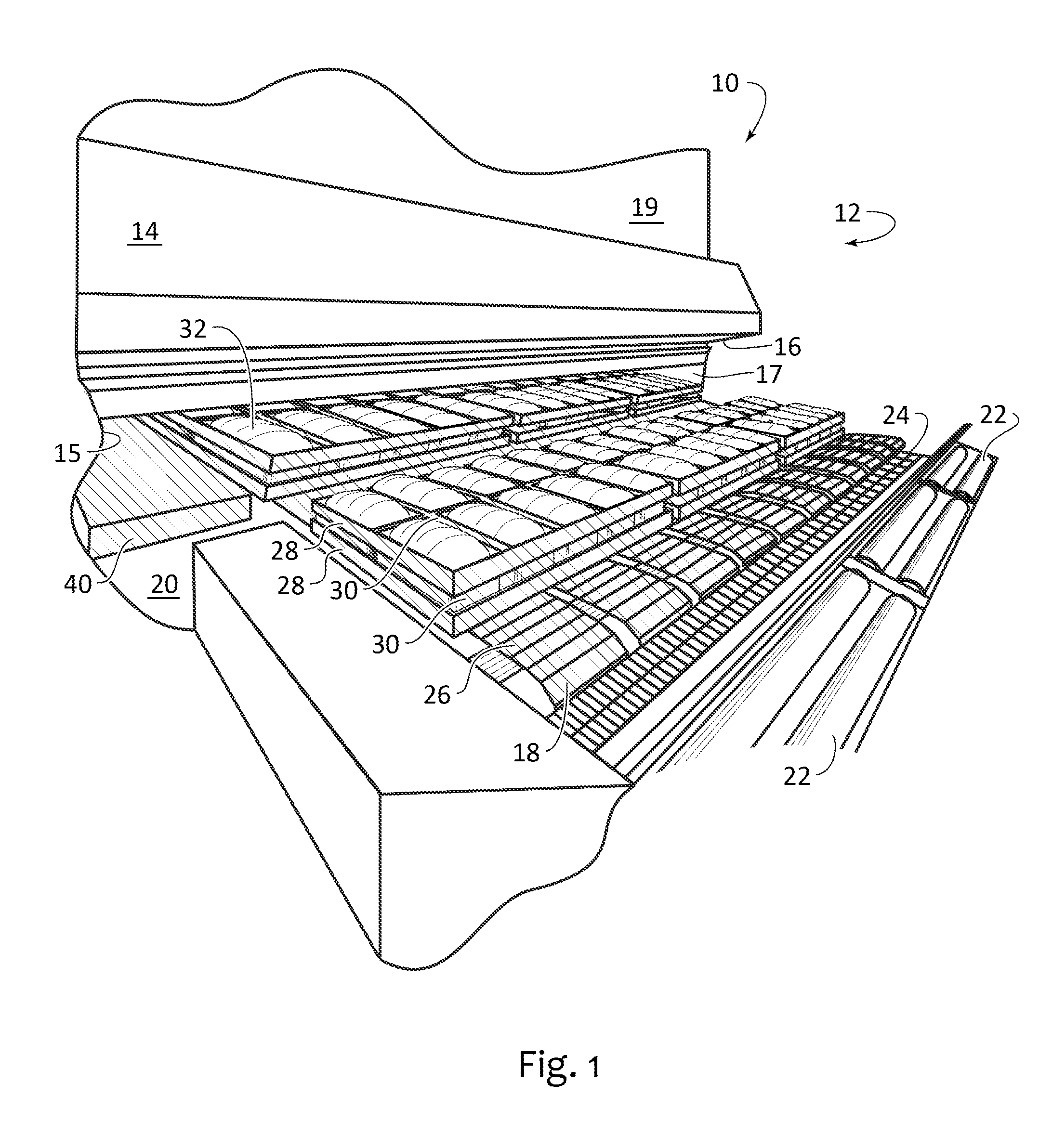

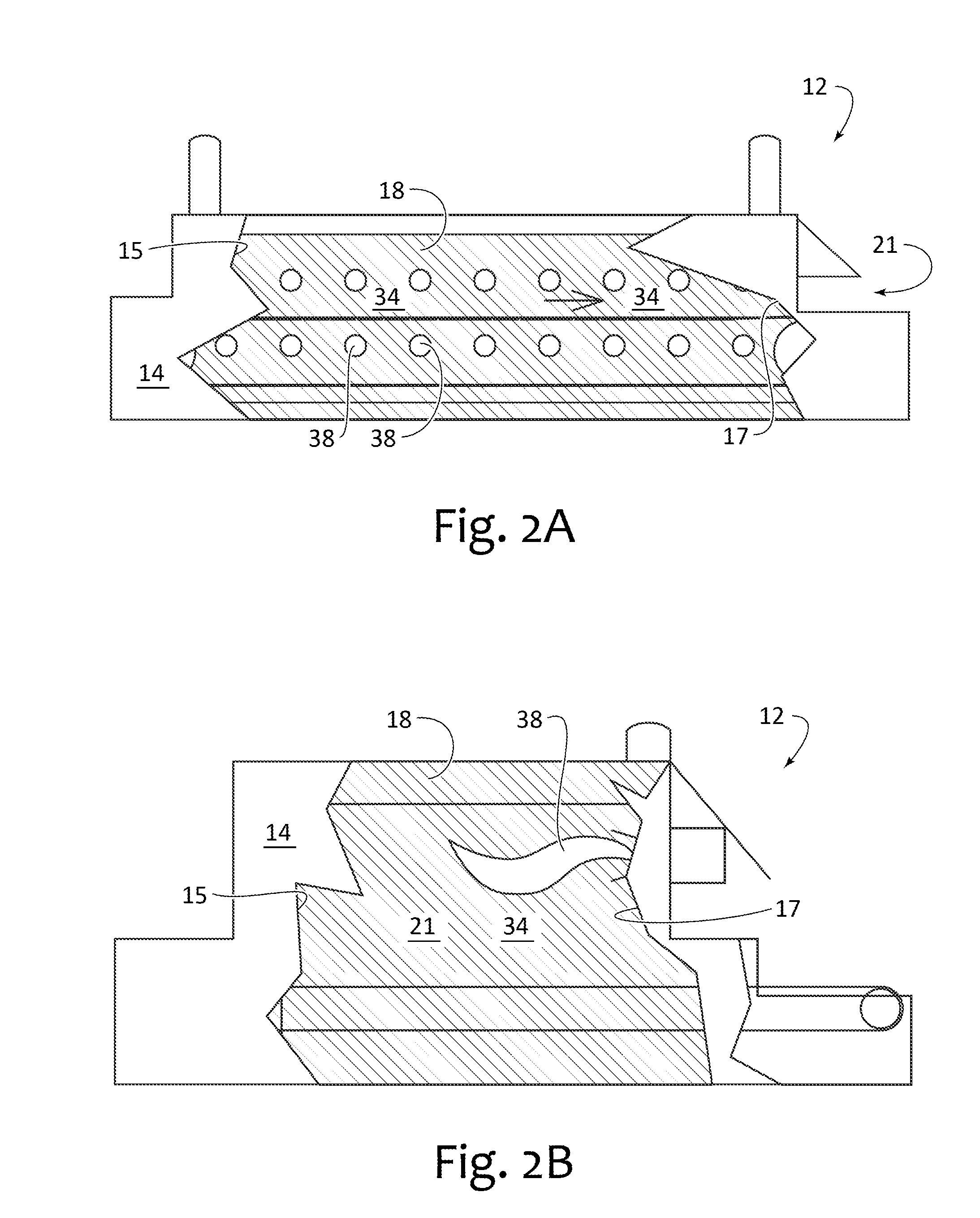

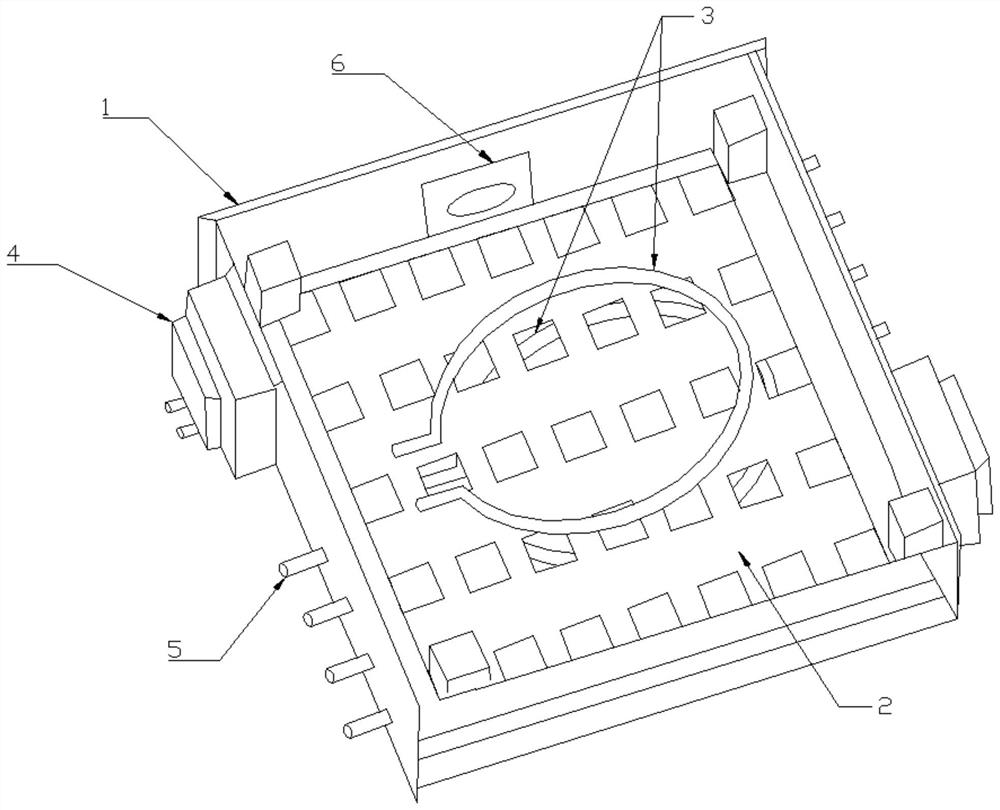

Methods and apparatus for cell culture array

ActiveUS9260688B2Easy to manufactureSpread evenlyBioreactor/fermenter combinationsBiological substance pretreatmentsBiochemistryCultured Cell Line

Owner:RGT UNIV OF CALIFORNIA

Fertilizer capable of enhancing grape quality

InactiveCN106397062AIncrease productionImprove qualitySuperphosphatesExcrement fertilisersVitis viniferaPotassium nitrate

The invention discloses a fertilizer capable of enhancing grape quality. The fertilizer is prepared from the following raw materials in parts by weight: 20-35 parts of potassium nitrate, 5-15 parts of double superphosphate, 16-24 parts of kiln ash potassium fertilizer, 8-15 parts of rotten chicken manure, 40-60 parts of fermented bean dregs, 12-18 parts of cotton seed pulp, 8-16 parts of straw powder, 10-16 parts of wormcast, 2-6 parts of modified illite-montmorillonite clay, 2-4 parts of carbonized corn cob powder, 15-35 parts of plant ash, 1-4 parts of meerschaum powder, 1-4 parts of vermiculite powder, 1-2 parts of diatomite, 0.5-1 part of manganese humate, 0.5-1 part of ferrous sulfate, 0.04-0.09 part of composite bacterium and 1-3 parts of Chinese herbal medicine additive. The fertilizer has balanced nutrients, and pays attention to the nitrogen / phosphorus / potassium mixing ratio, so that the grapes can quickly and sufficiently acquire the nutrients in various growth periods, thereby ensuring the normal growth of roots, leaves, flowers, fruits and the like of the grapes, enhancing the yield and quality of the grapes and being beneficial to yield increase and income increase.

Owner:安徽爱能洁生物科技有限公司

Food product and method and apparatus for baking

ActiveUS20120074122A1Less timeLess energyEnvelopes/bags making machineryCharge supportsColloidal silicaCooking & baking

Provide an oven and optional cooking accessories having a high emissivity thermal protective layer on a substrate surface which comprises a metal or ceramic. The layer comprises from about 5% to 30% of an inorganic adhesive, from about 45% to 92% of at least one filler, and from about 1% to 25% of one or more emissivity agents; or from about 5% to 35% of colloidal silica, colloidal alumina, or combinations thereof, from about 23% to 79% of at least one filler, and from about 1% to 25% of one or more emissivity agents.

Owner:EMISSHIELD +1

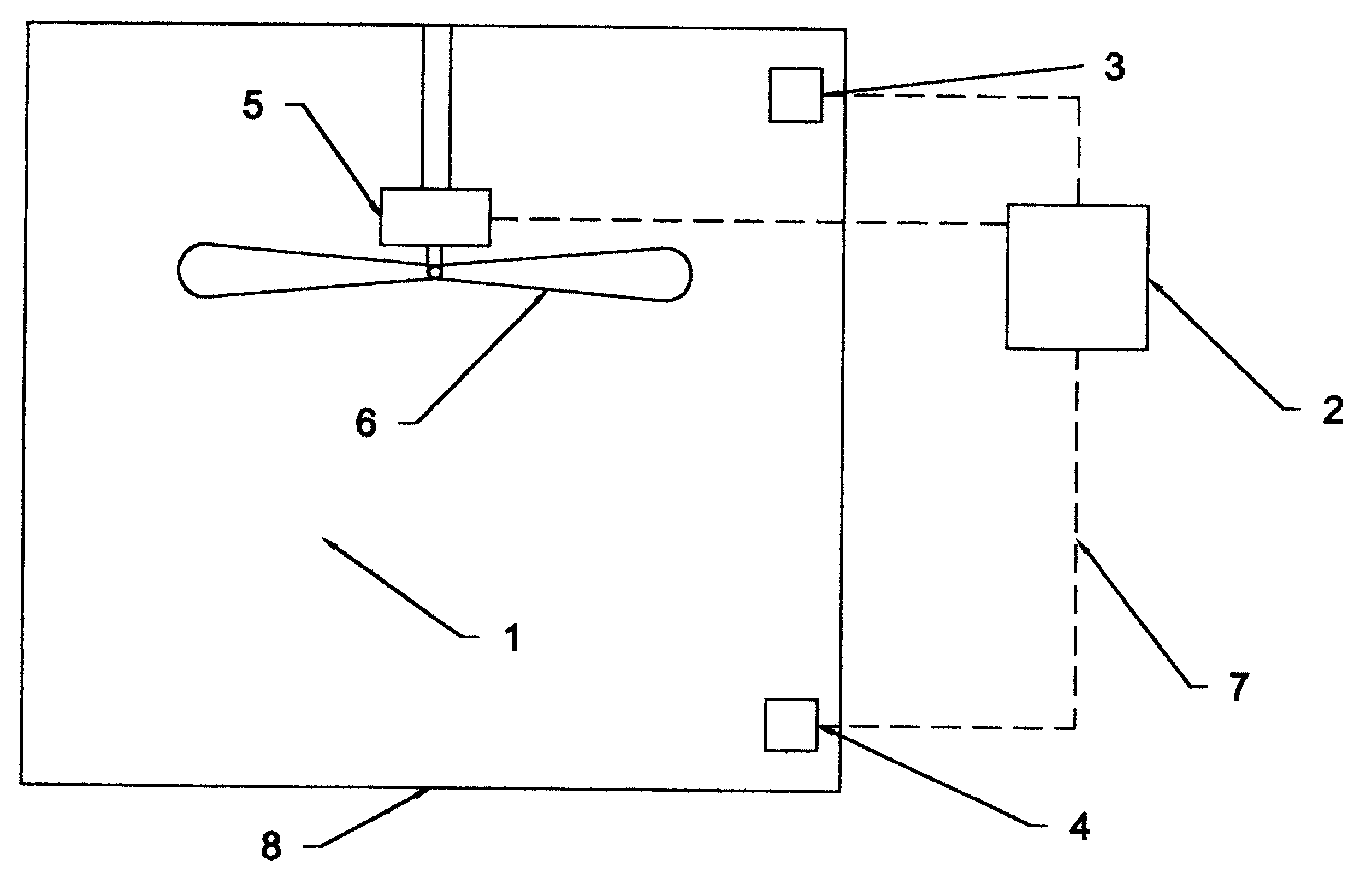

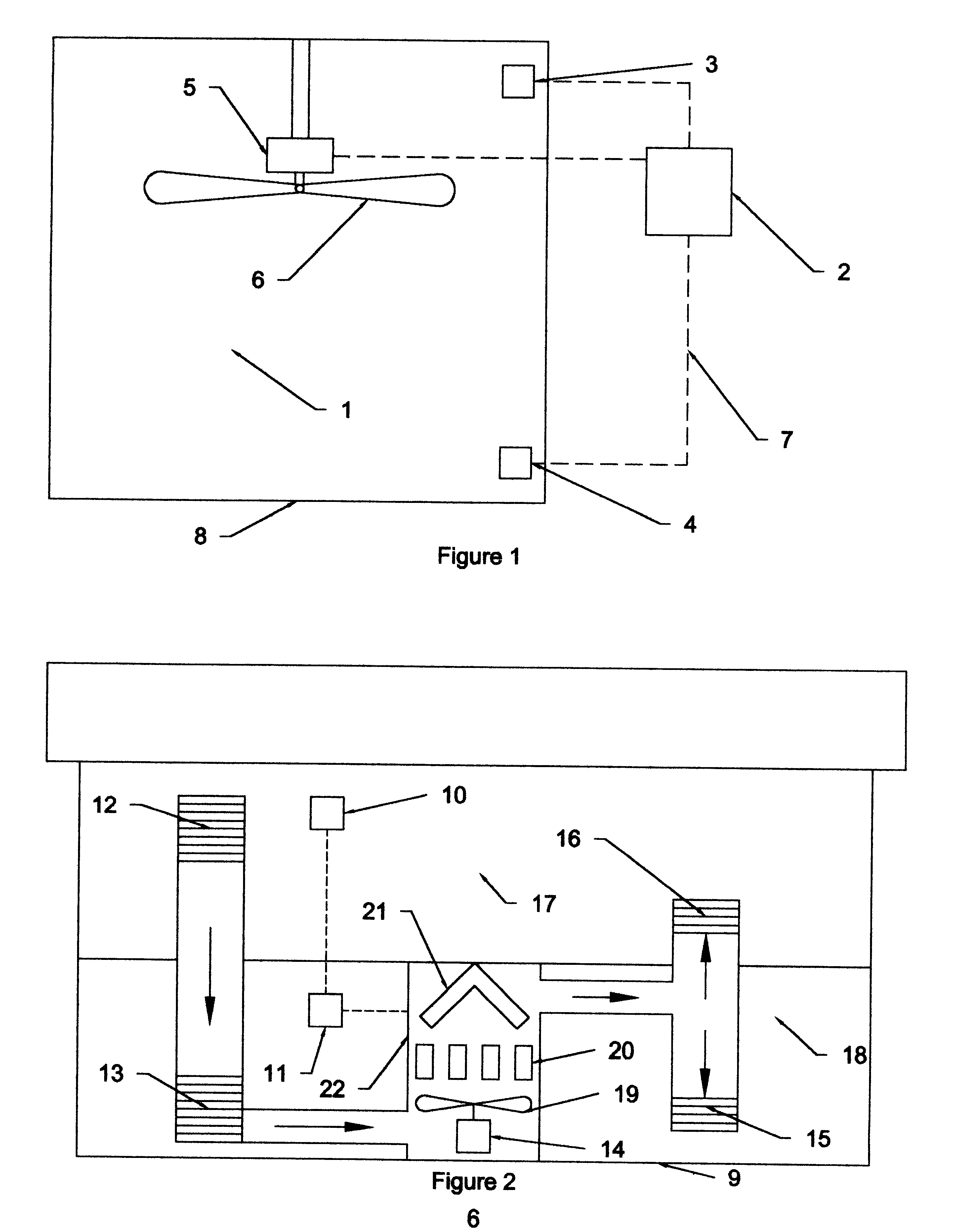

Environmental distribution control module

InactiveUS6209335B1Save energyUniform environmentMechanical apparatusSpace heating and ventilation safety systemsDistribution controlAir conditioning

Enhanced controls added to conventional heating and air conditioning equipment provides a uniform comfort environment though out the structure. Enhanced control module monitors variously placed sensors within the structure and activates a conventional fan. The fan mixes air throughout the structure maintaining a uniform comfort though out economically.

Owner:NOWACZYLE DAVID

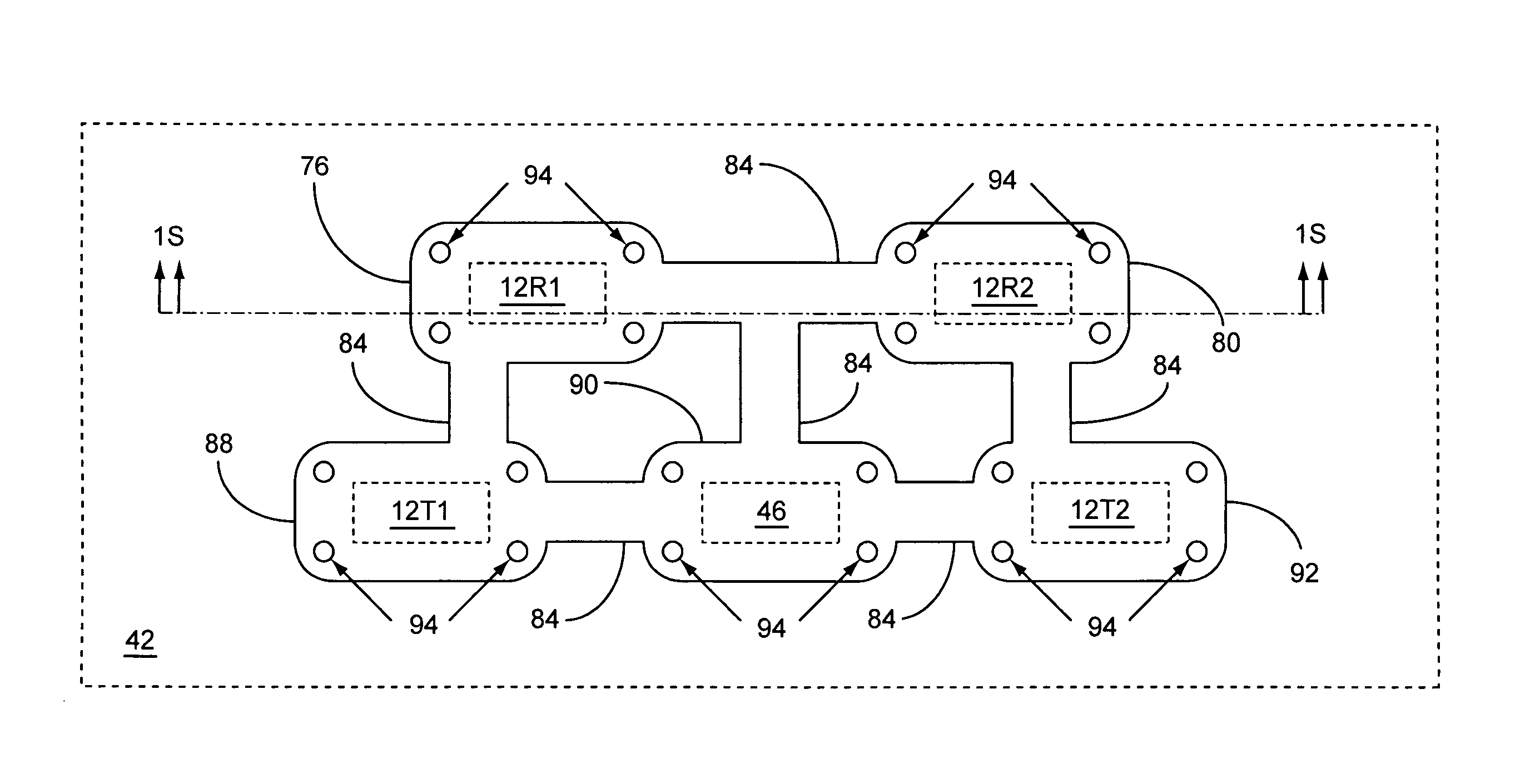

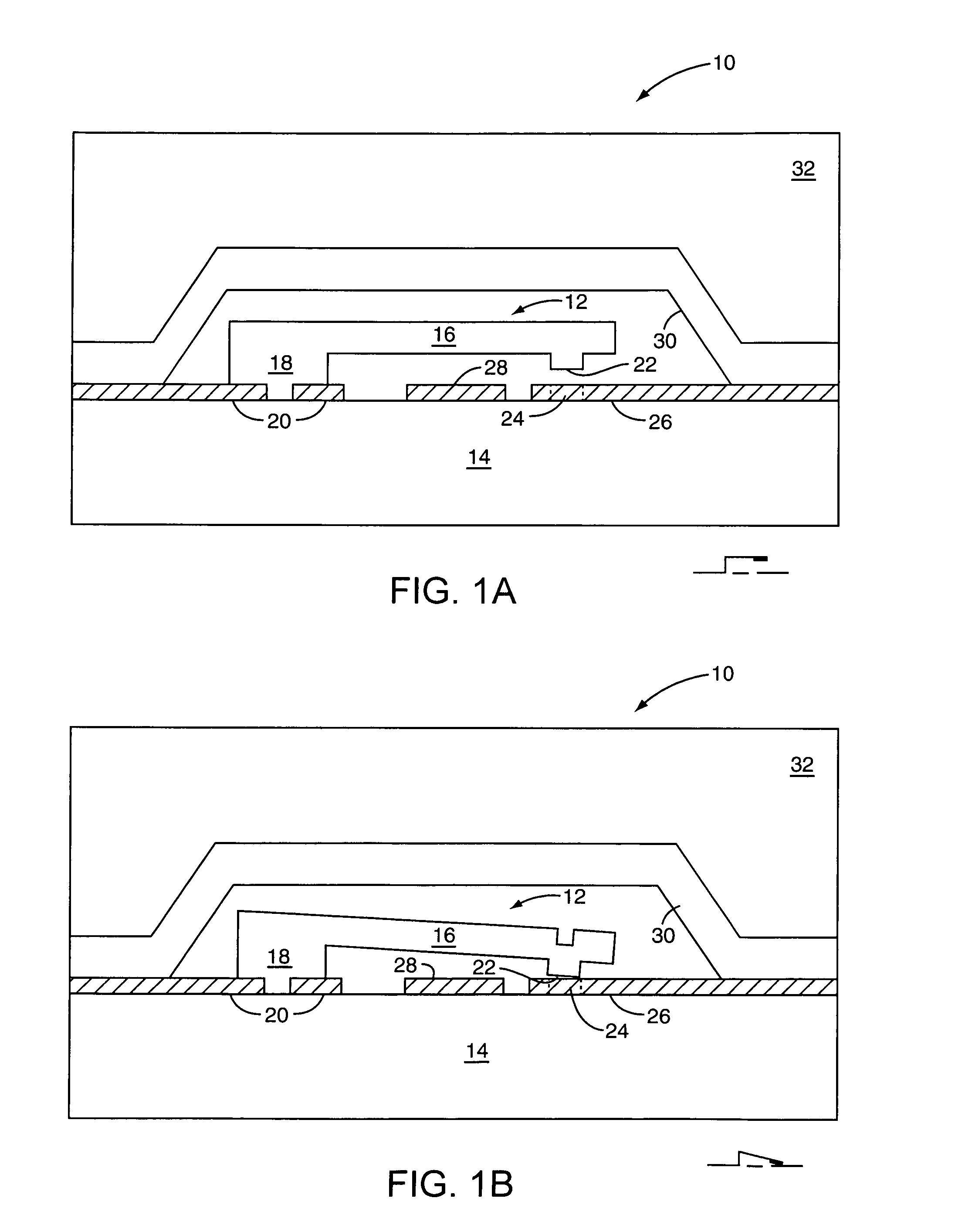

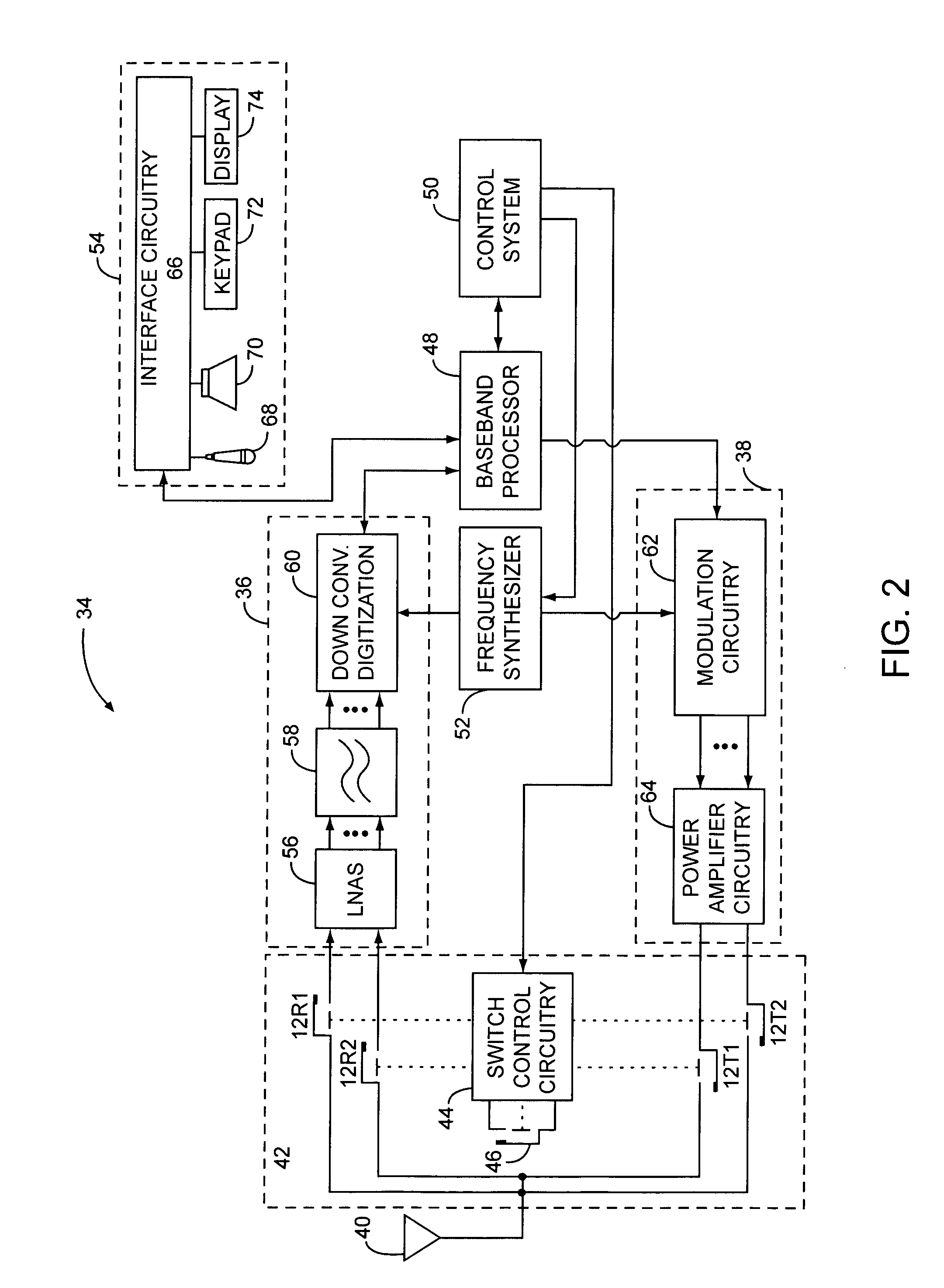

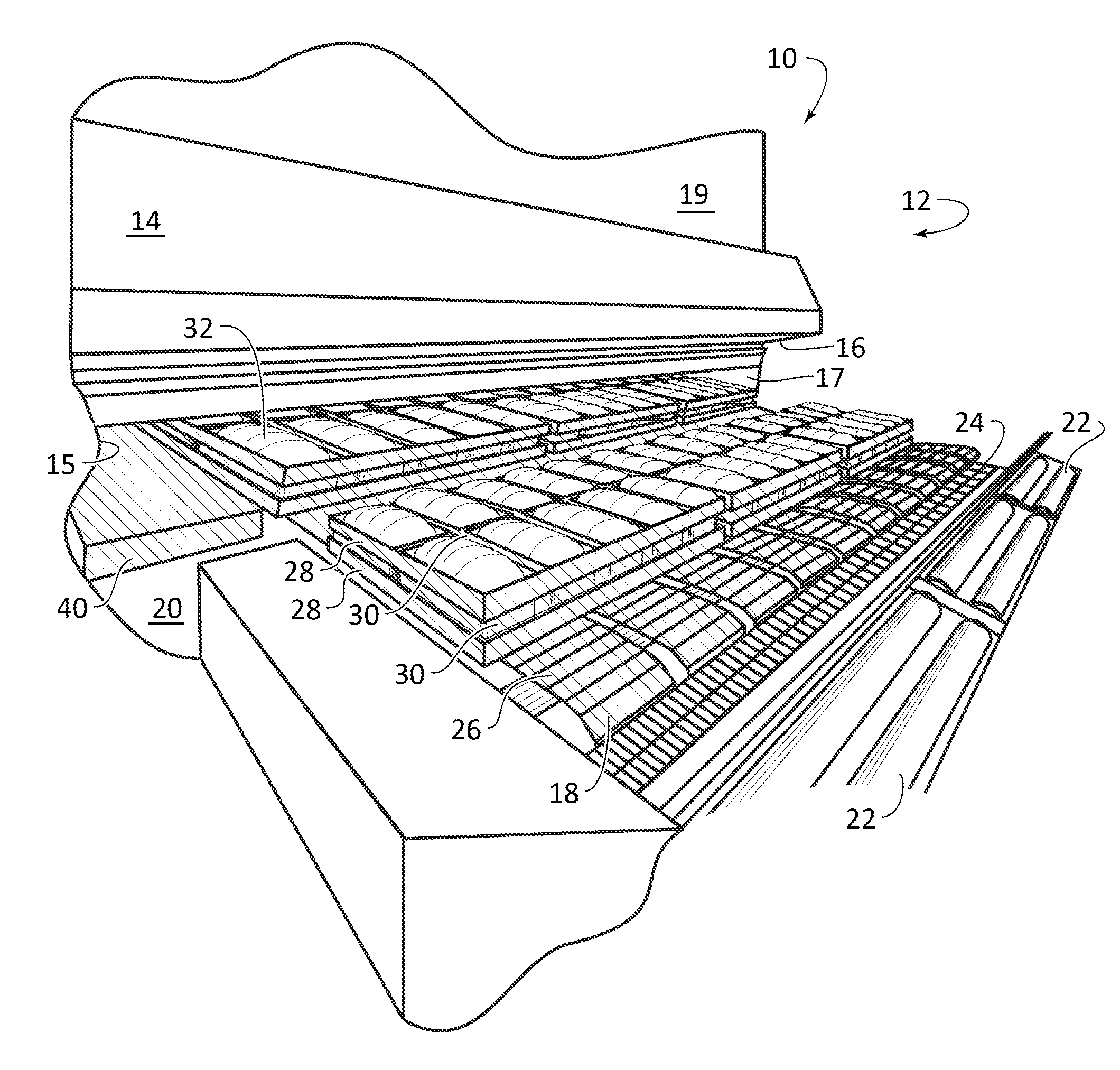

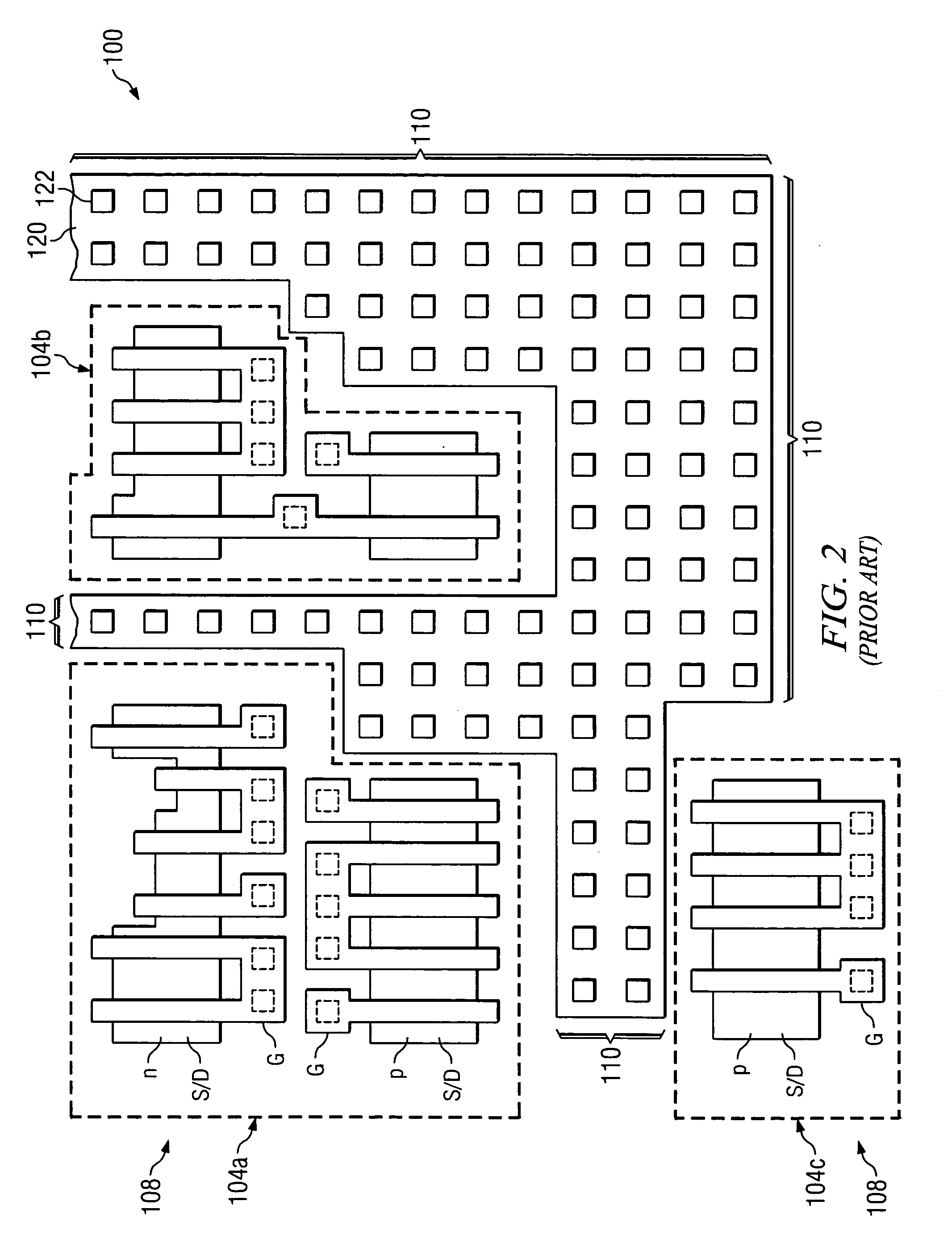

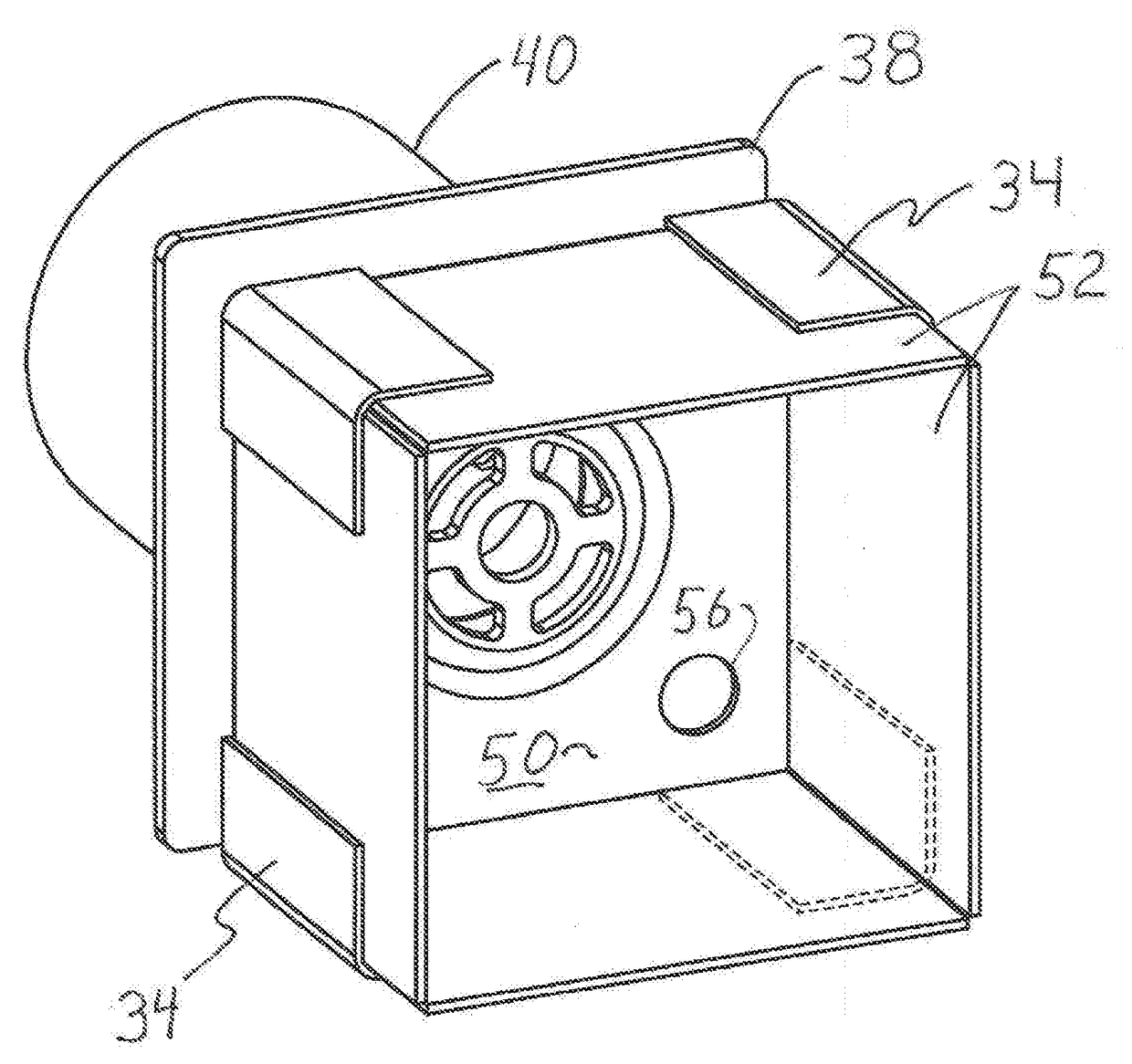

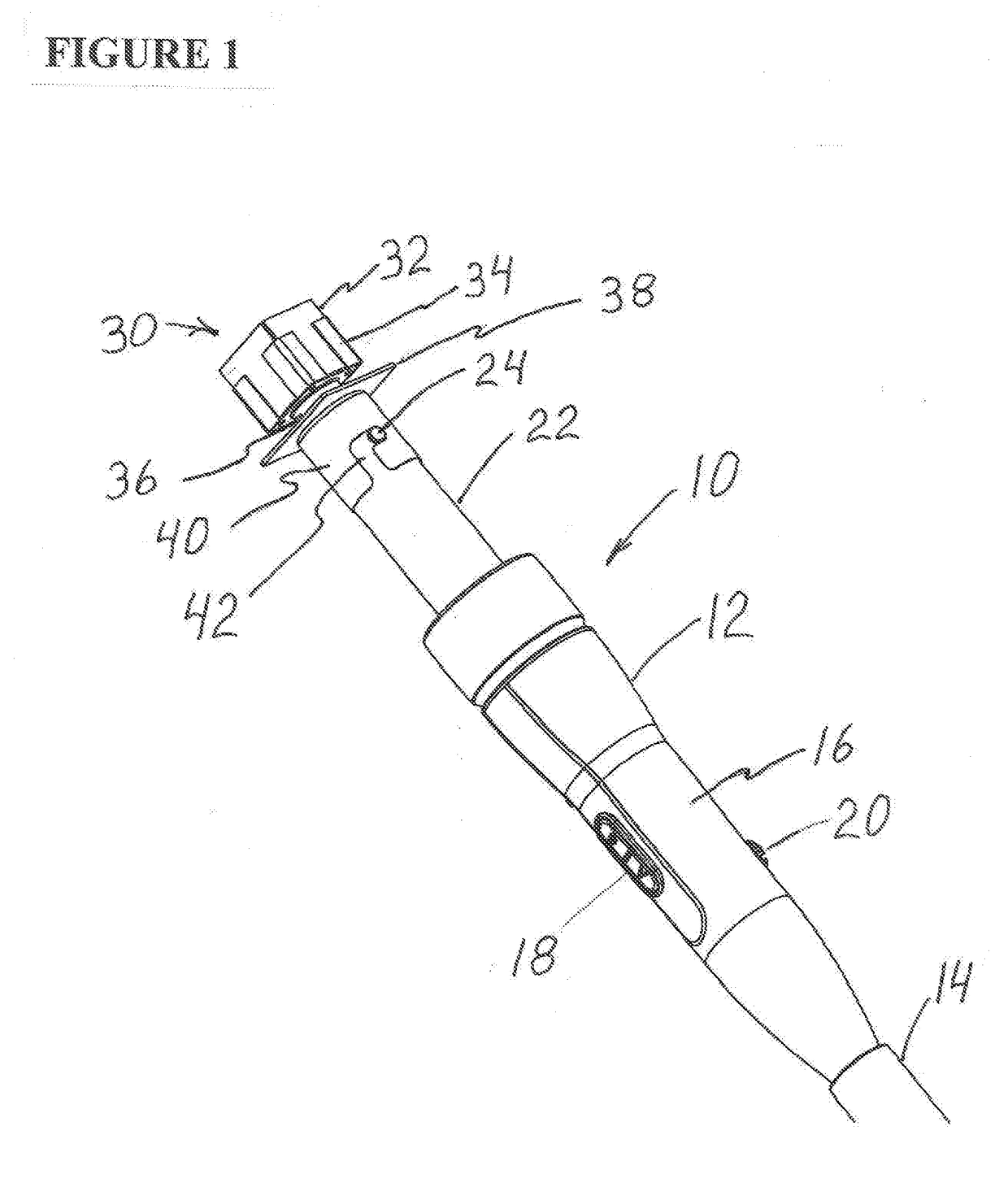

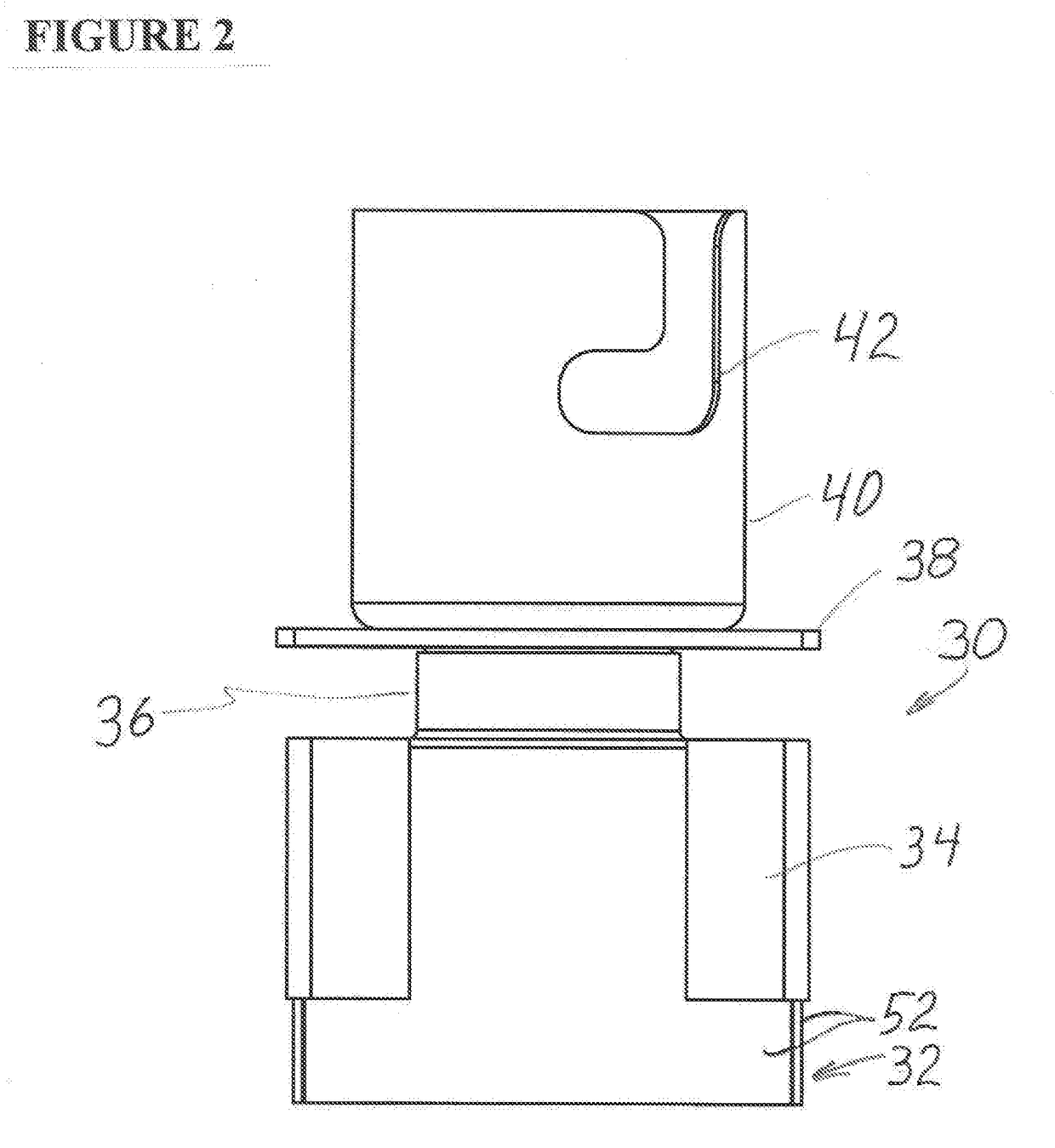

Providing a common environment for multiple MEMS devices

InactiveUS7999643B1Uniform operating environmentReduce and minimize ringingElectrostatic/electro-adhesion relaysContacts enclosures/screensMultiple deviceOperating environment

The present invention relates to providing a uniform operating environment for each of multiple devices by providing a common environment to the devices. The common environment is provided by multiple cavities, which are interconnected by at least one environmental pathway, which may be provided by at least one tunnel. The common environment may help provide uniform operating pressure, which may be a partial or near vacuum, a surrounding gas of uniform contents, such as an inert gas or mixture of inert gases, or both. The devices may include micro-electro-mechanical system (MEMS) devices, such as MEMS switches.

Owner:QORVO US INC

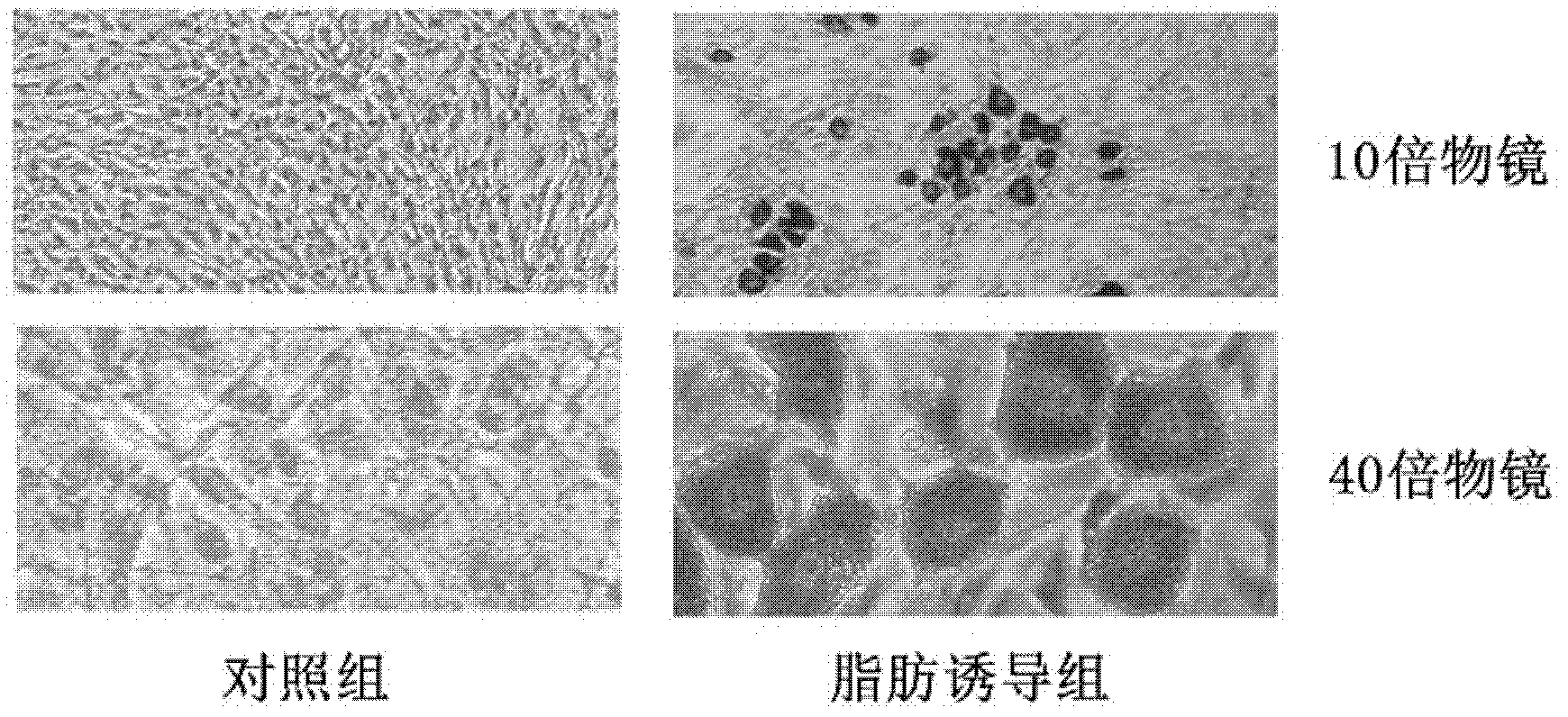

Method for extensive amplification of cell line and mesenchymal stem cell in vitro

ActiveCN102321566ALow costEasy to operateSkeletal/connective tissue cellsMesenchymal stem cellMicrocarrier

The invention discloses a method for extensive amplification of cell line and mesenchymal stem cells in vitro. Microcarrier and Hyperflask cell culture container are combined for extensive amplification of cell line and mesenchymal stem cells in vitro. The invention combines commercialized microcarrier and Hyperflask for extensive amplification of cells in vitro in a small culture space, so as to obtain a large amount of target cells on the premise of saving costs.

Owner:UNION STEMCELL & GENE ENG

Composite base fertilizer for grapes

InactiveCN106747730AIncrease productionImprove qualityBiocideBio-organic fraction processingPotassiumNormal growth

The invention discloses a composite base fertilizer for grapes. The composite base fertilizer comprises the following raw materials in parts by weight: 50-70 parts of fermented chicken manure, 14-22 parts of edible mushroom dregs, 20-26 parts of biogas digester dregs, 14-22 parts of fishbone dust, 16-24 parts of sunflower seed meal, 10-20 parts of monopotassium phosphate, 25-40 parts of ammonium nitrate, 20-28 parts of potassium fulvic acid, 20-40 parts of a kiln dust potassium fertilizer, 4-8 parts of carbonized coconut shell powder, 3-7 parts of sepiolite powder, 4-8 parts of kieselguhr, 1.5-2.5 parts of seashell powder, 4-8 parts of modified illite-montmorillonoid clay, 1-2 parts of fulvic acid diamine iron, 2-3 parts of fulvic acid manganese, 4-6 parts of traditional Chinese herbal medicine additives and 0.1-0.2 part of compound bacteria. The composite base fertilizer is balanced in nutrition and focuses on the mixing ratio of nitrogen, phosphorus and potassium, grapes can take nutrient components rapidly and sufficiently in different growth periods, normal growth of roots, leaves, flowers, fruits and the like of the grapes can be ensured, the yield of the grapes can be increased, the quality of the grapes can be improved, and the yield and the income can be increased.

Owner:安徽爱能洁生物科技有限公司

Food product and method and apparatus for baking

ActiveUS8840942B2Less timeLess energyEnvelopes/bags making machineryDough treatmentColloidal silicaCooking & baking

Provide an oven and optional cooking accessories having a high emissivity thermal protective layer on a substrate surface which comprises a metal or ceramic. The layer comprises from about 5% to 30% of an inorganic adhesive, from about 45% to 92% of at least one filler, and from about 1% to 25% of one or more emissivity agents; or from about 5% to 35% of colloidal silica, colloidal alumina, or combinations thereof, from about 23% to 79% of at least one filler, and from about 1% to 25% of one or more emissivity agents.

Owner:EMISSHIELD +1

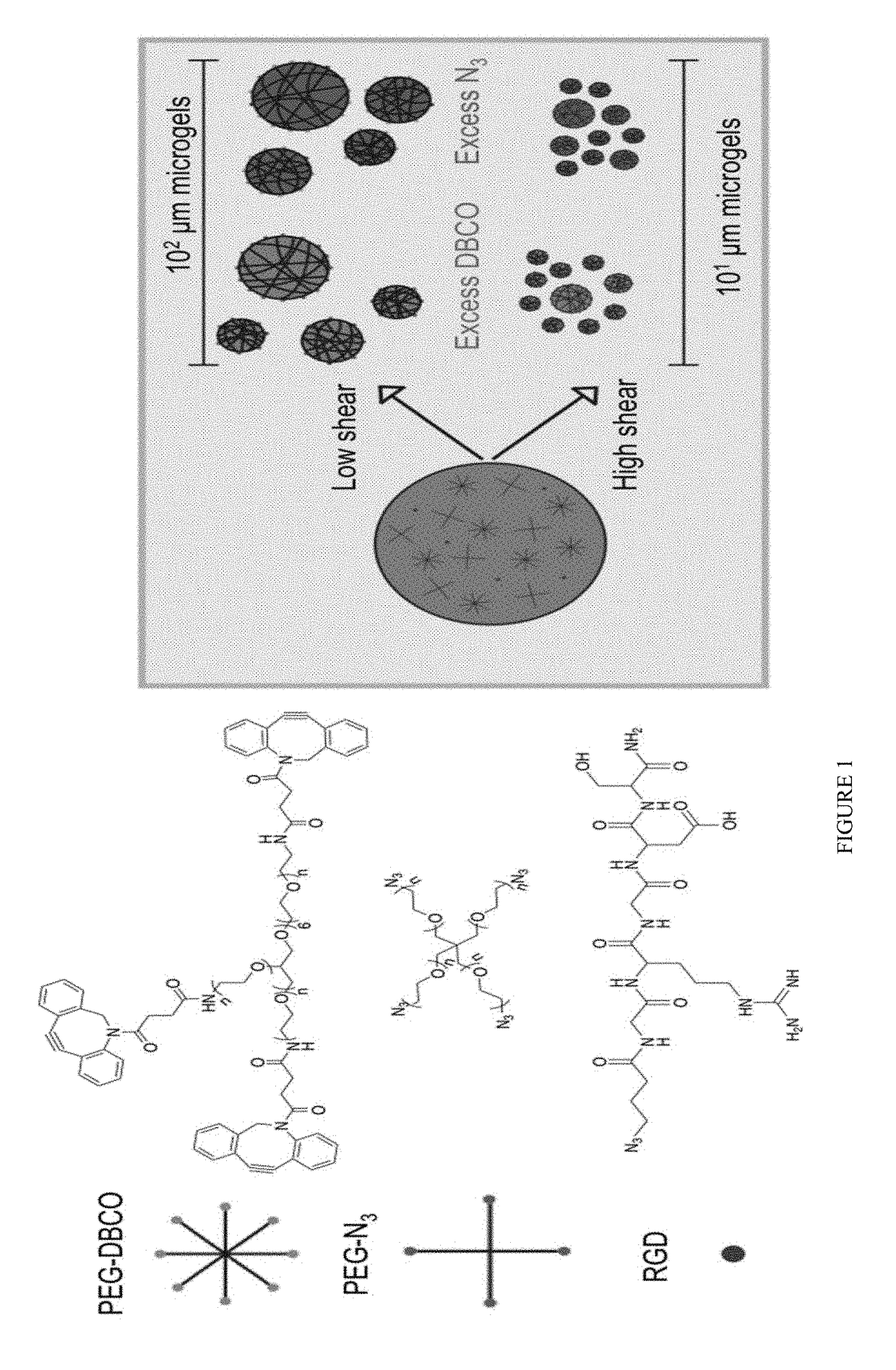

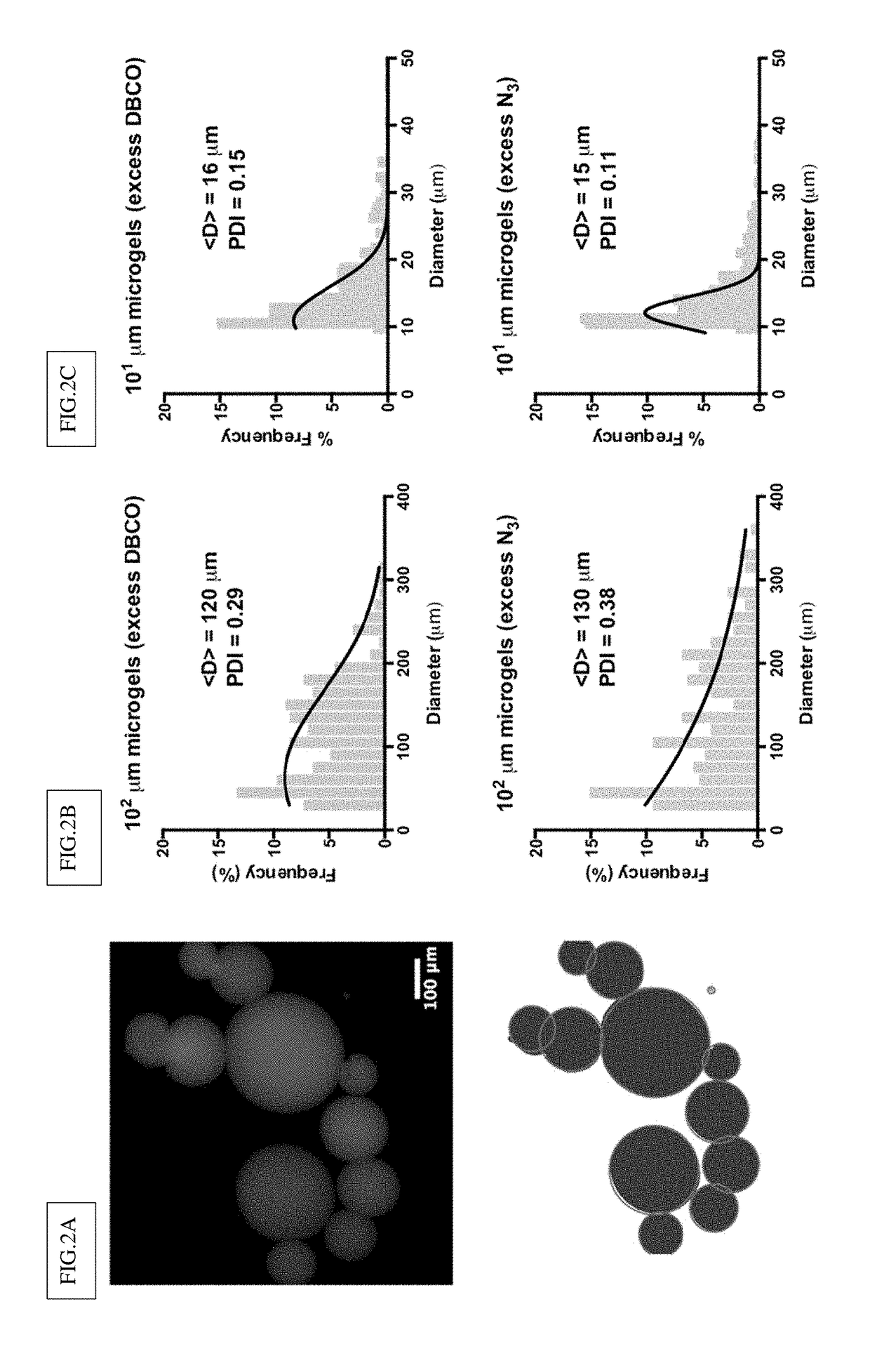

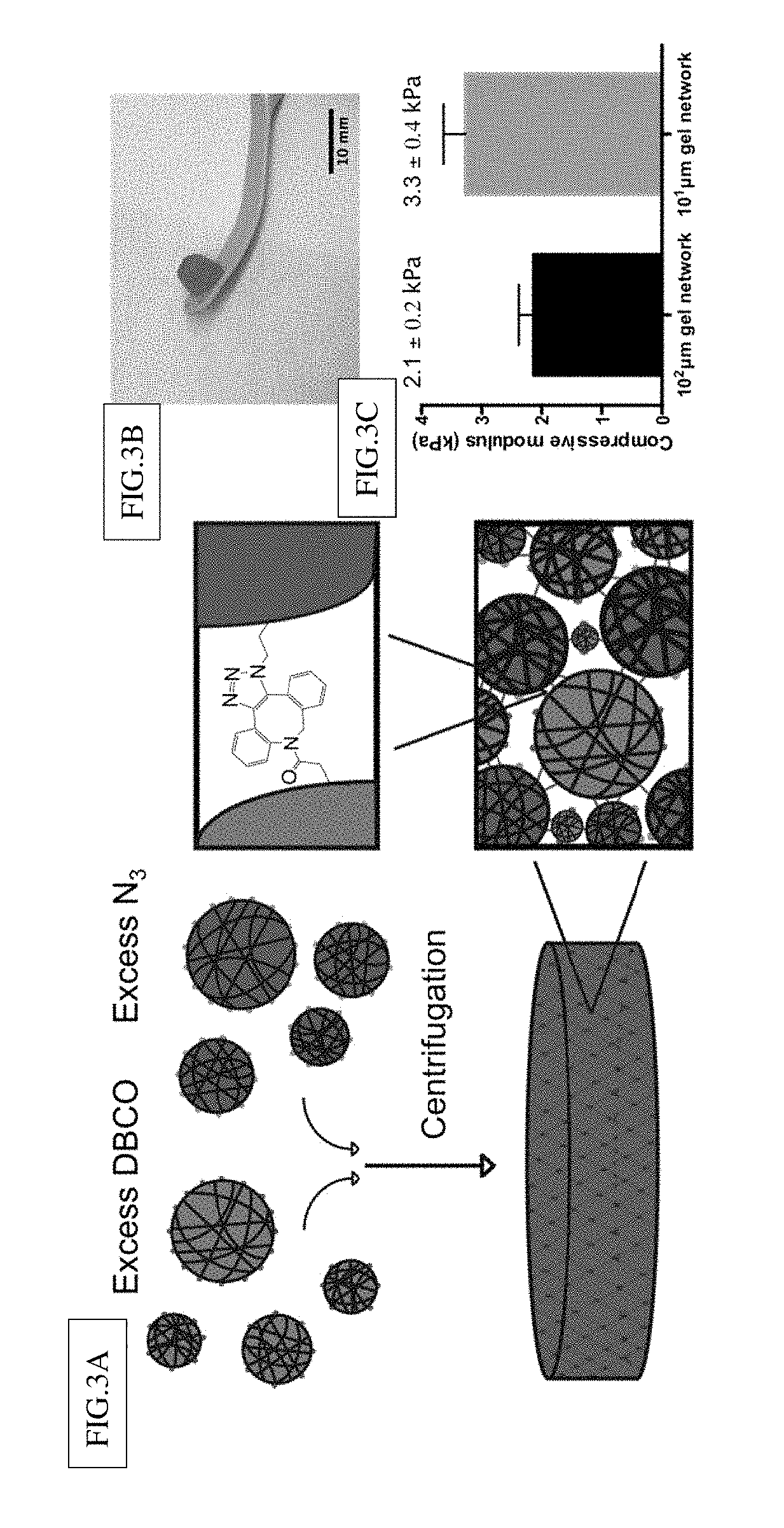

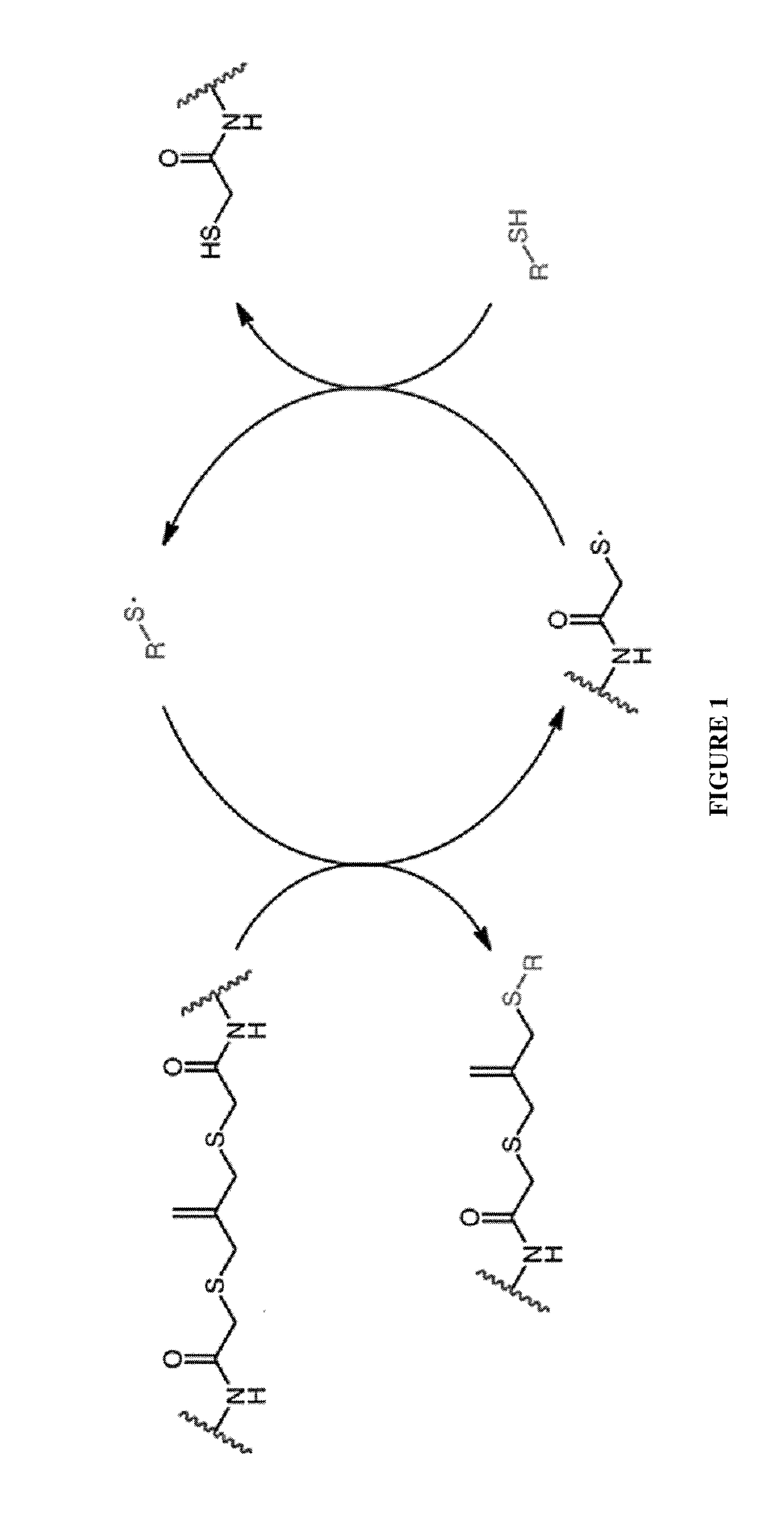

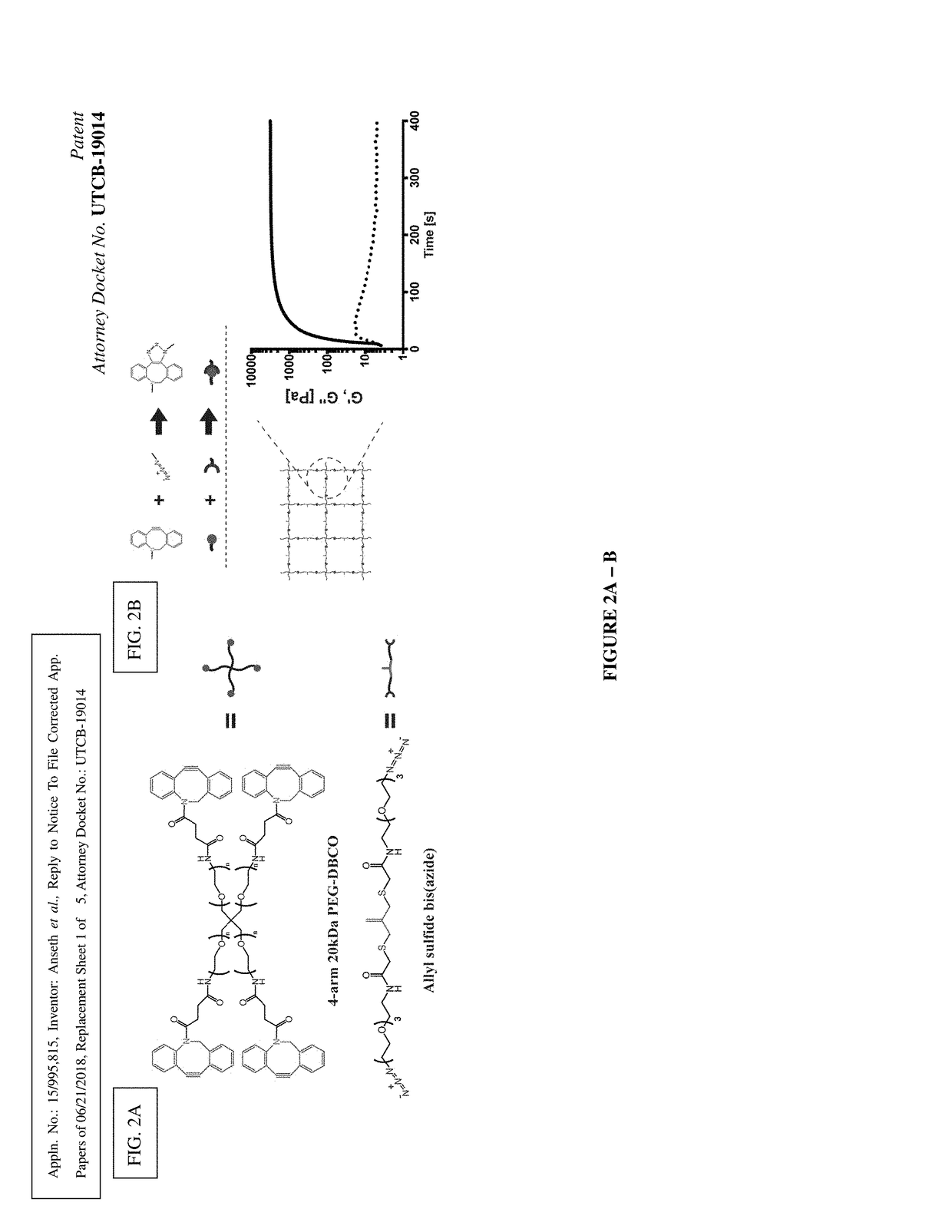

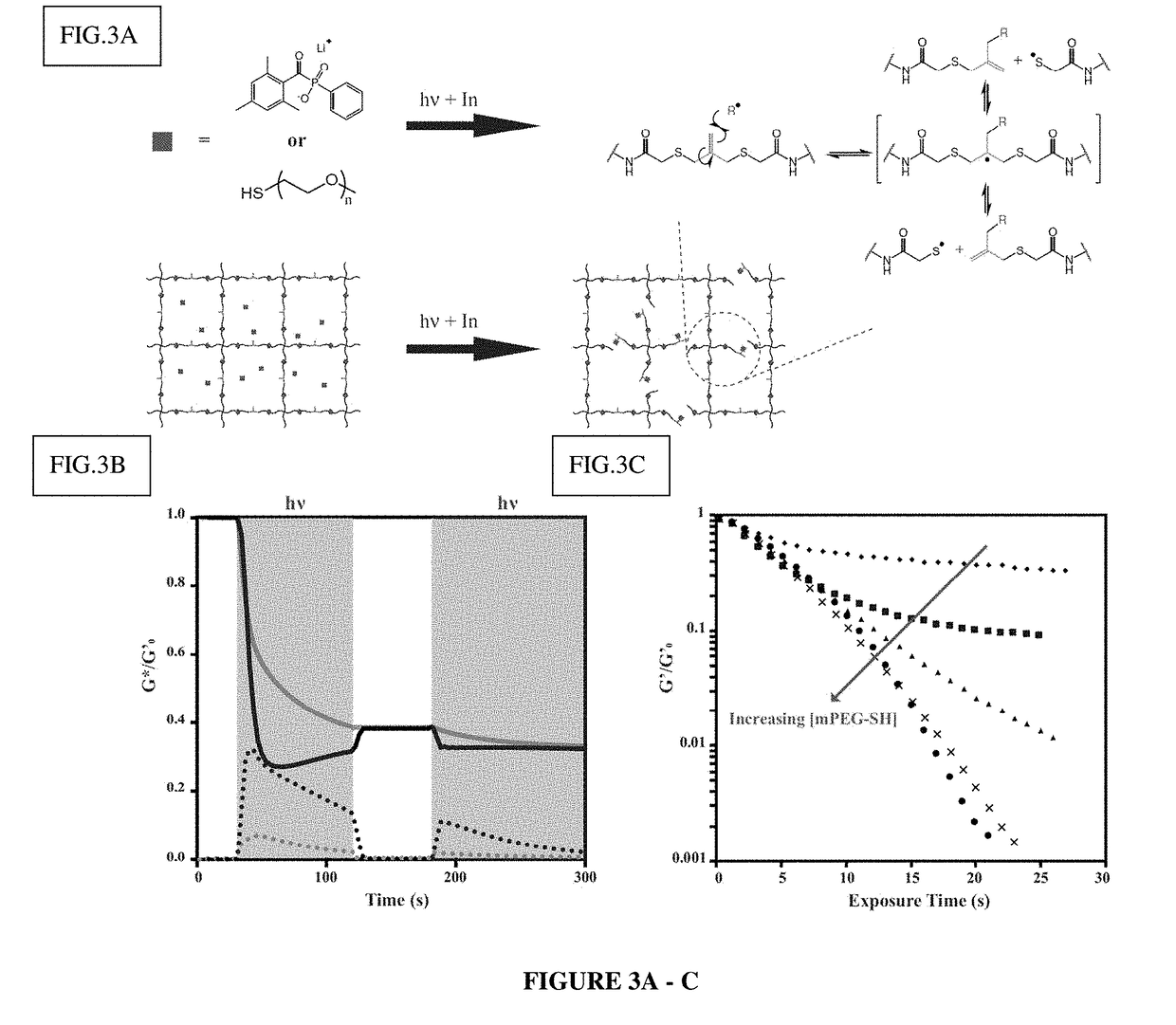

Synthesis and assembly of clickable microgels into cell-laden porous scaffolds

InactiveUS20180371117A1Maximize cell viabilityEqually distributedGroup 4/14 element organic compoundsCell culture supports/coatingHuman cellPolymer

This invention is in the field of medicinal chemistry. The present invention provides cell-laden hydrogels and hydrogel assemblies thereof for use in tissue engineering. The present invention provides methods of producing various hydrogels and hydrogel assemblies and pharmaceutical compositions thereof. The present invention provides for a microgel comprising an encapsulated population of live primary human cells in a hydrogel comprising a polymeric network.

Owner:UNIV OF COLORADO THE REGENTS OF

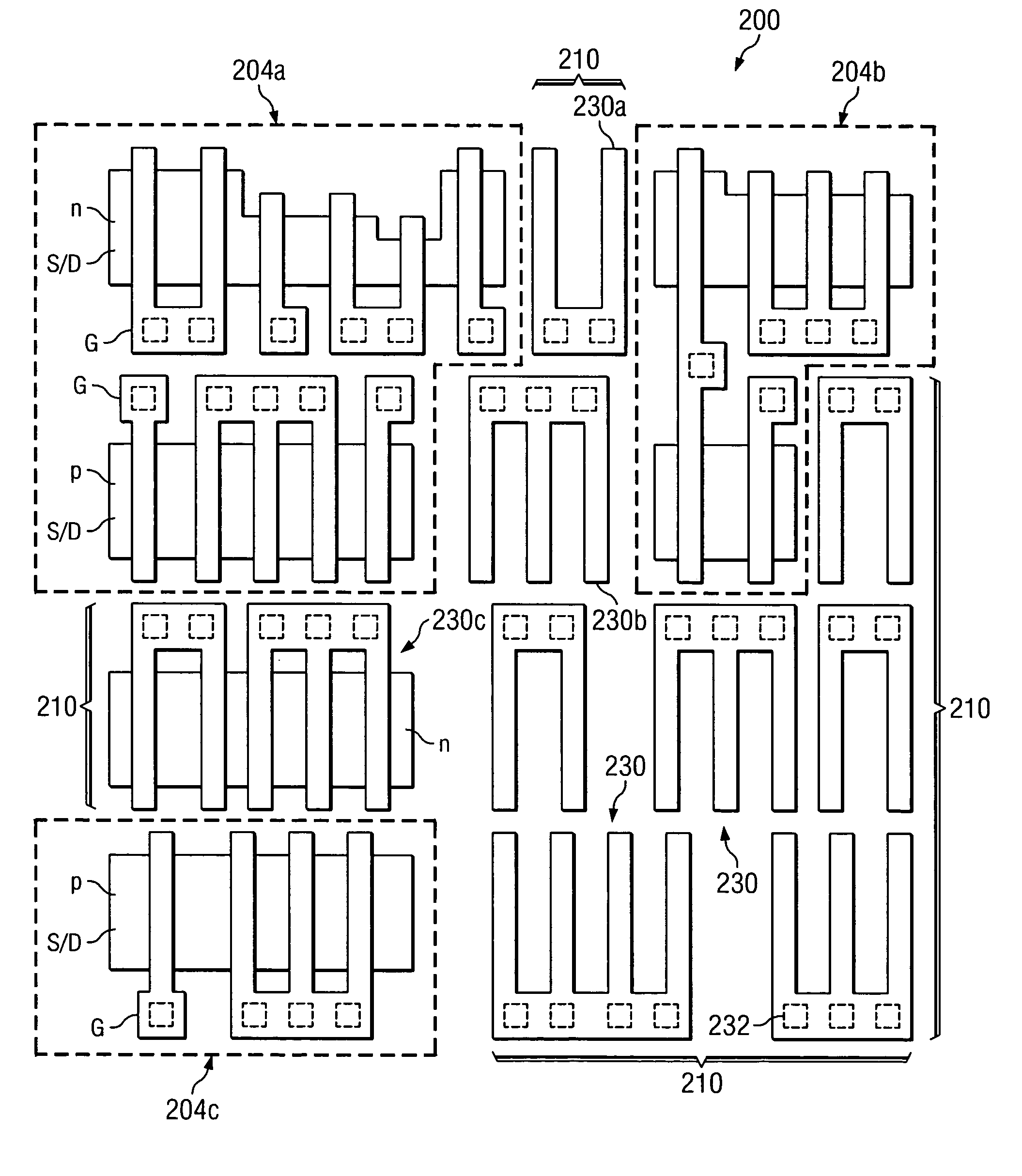

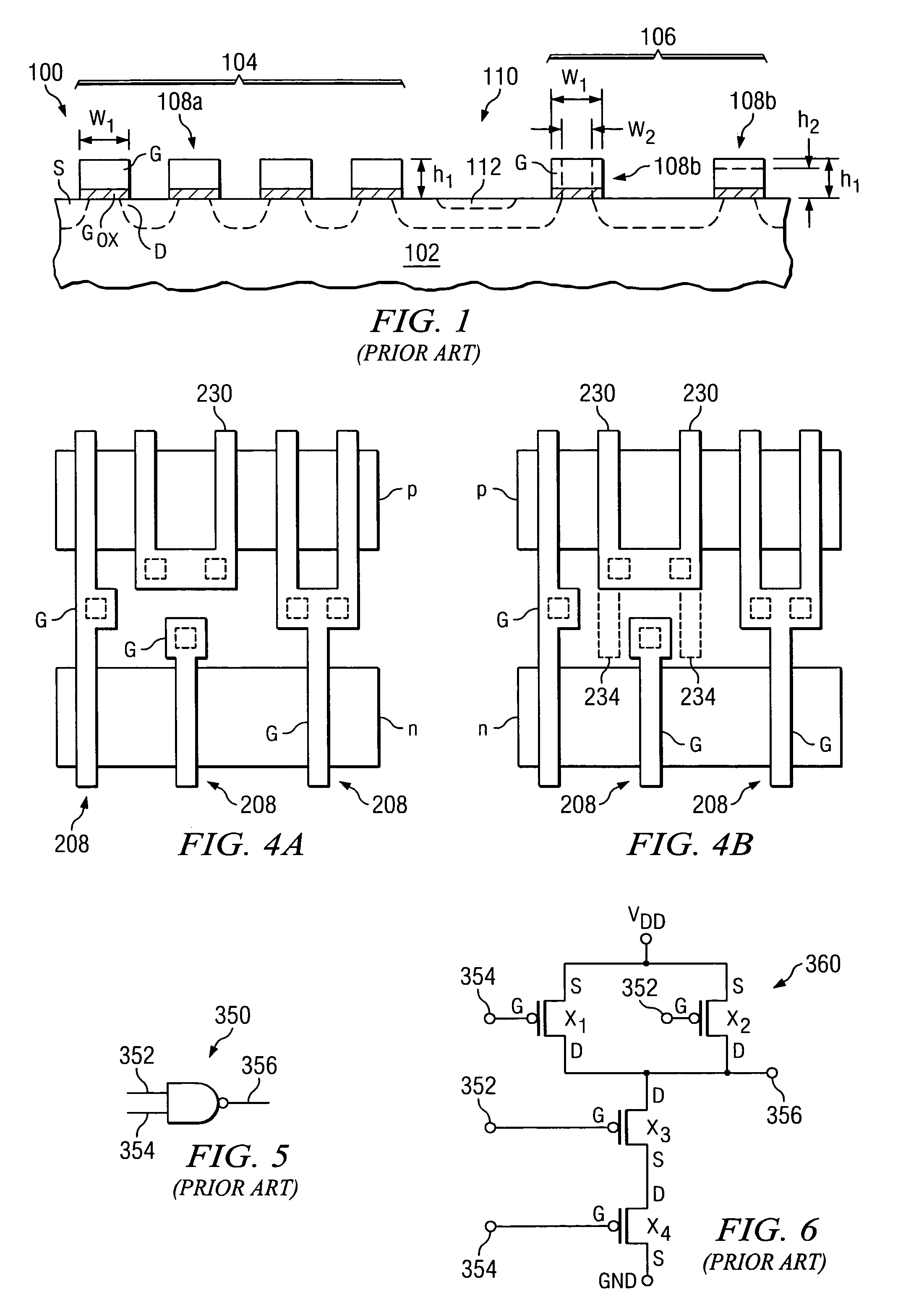

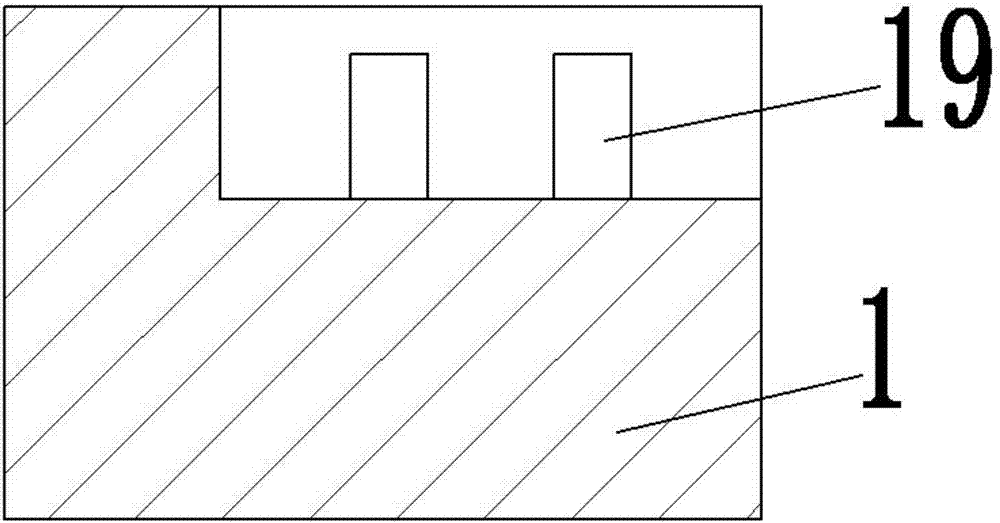

Layer fill for homogenous technology processing

InactiveUS20060091423A1Uniform environmentImprove flatnessSemiconductor/solid-state device detailsSolid-state devicesLithographic artistLithography process

Spare transistors are formed in regions of a semiconductor device where functional transistors are not formed, providing uniformity in etch and polishing processes, and resulting in transistors with more uniform parameters on the semiconductor device. The spare transistors may not be electrically connected to other components on the device, or alternatively, the spare transistors may be connected to other components for use as spare transistors, for example. The gates of the spare transistors provide a homogeneous gate material layer, resulting in improved etch, polishing, and lithography processes for the semiconductor device.

Owner:INFINEON TECH AG

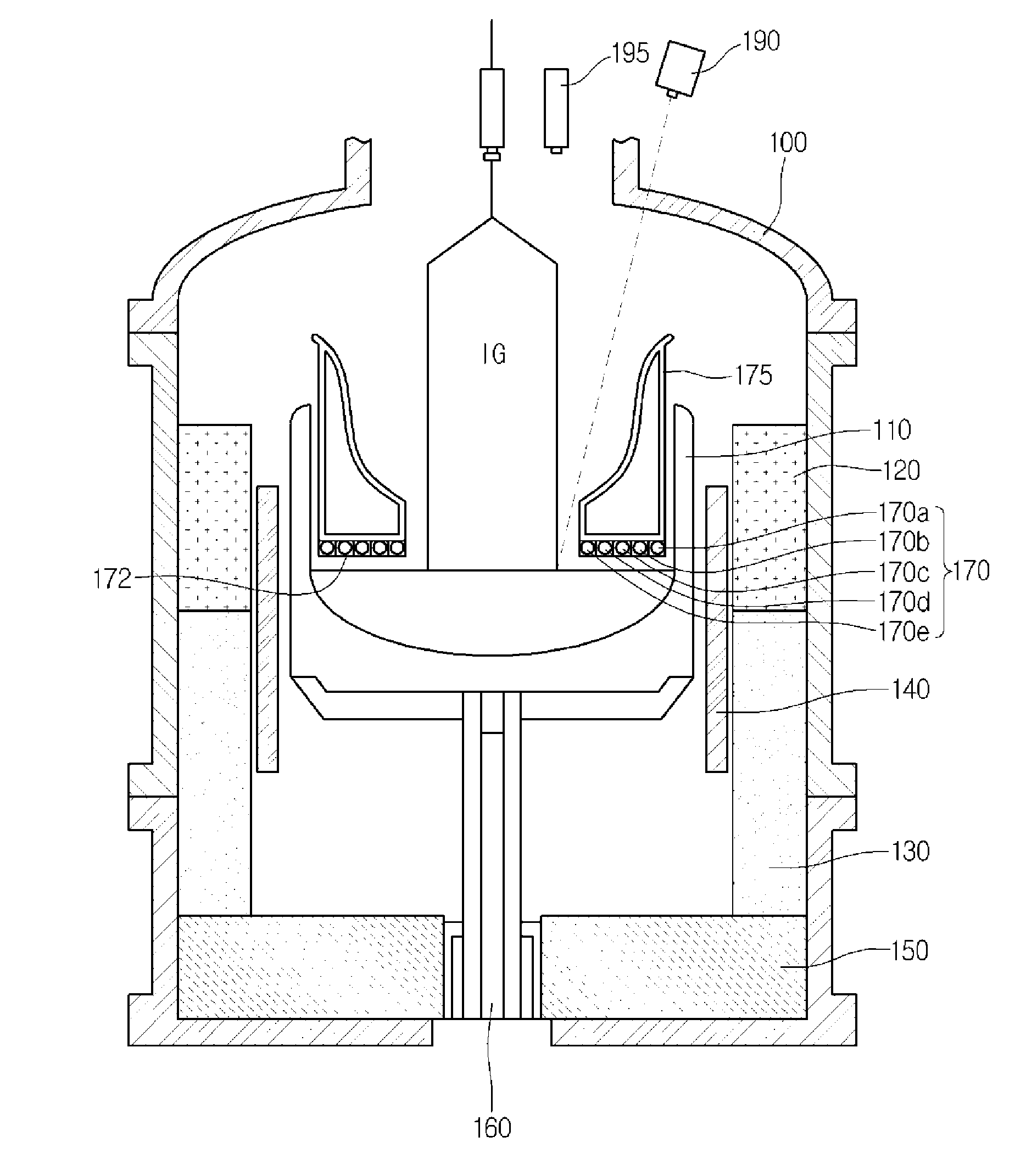

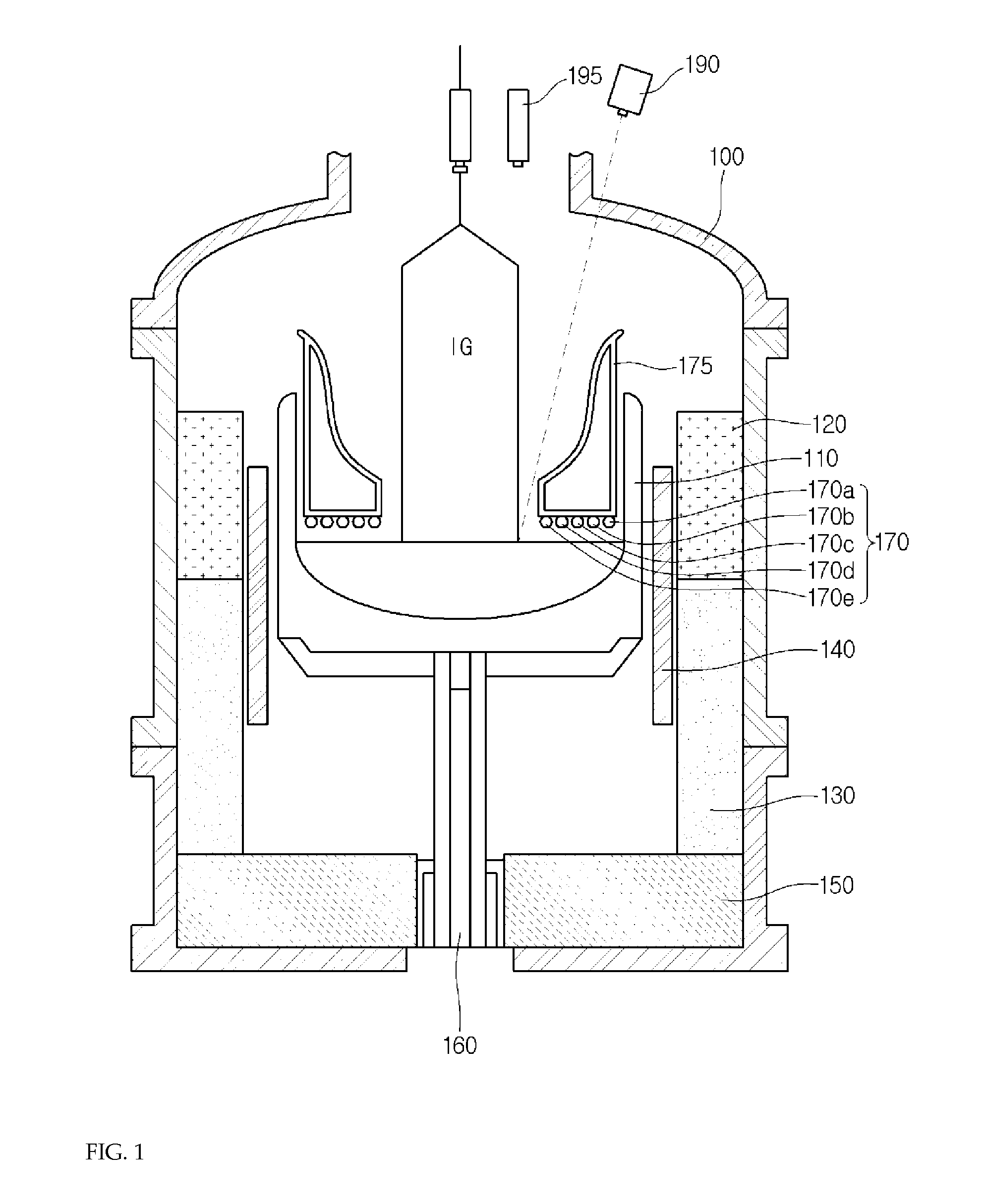

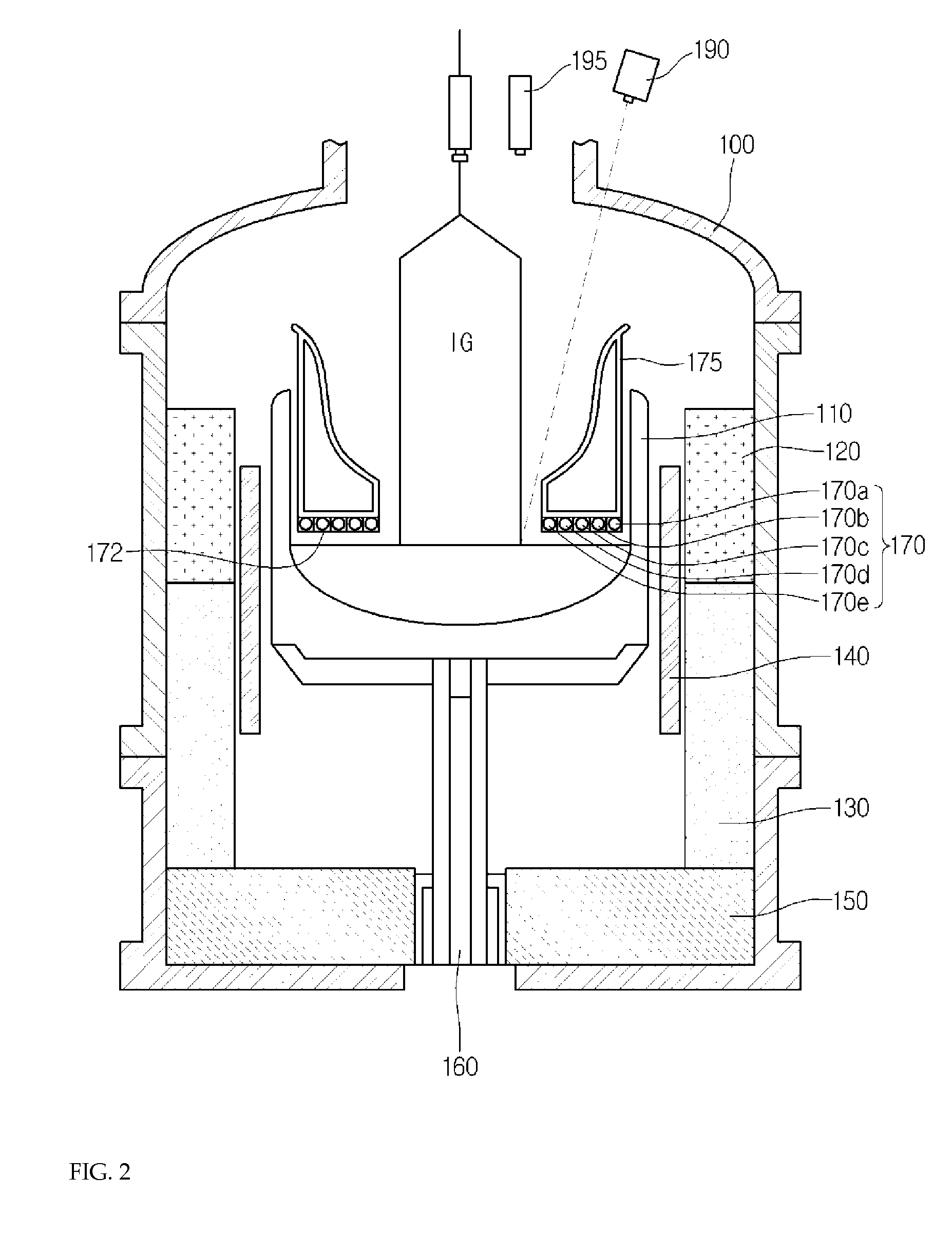

Silicon single crystal growing device and method of growing the same

ActiveUS20160102419A1Prevent solidificationPulling speed can be controlledPolycrystalline material growthBy zone-melting liquidsCrucibleSingle crystal

An apparatus for growing a silicon single crystal according to embodiments includes a chamber including a crucible accommodating silicon melt; a support shaft rotating and lifting the crucible while supporting the crucible; a main heater part for applying heat to the crucible side, the heater disposed beside the crucible; an upper heat insulation member located over the crucible; and upper heater parts located at a lower end portion of the upper heat insulation member, wherein the upper heater parts have diameters different from each other with respect to a center of the crucible, and include a plurality of ring-shaped heaters which are spaced apart from each other. Due to the individually controllable upper heater parts, a uniform thermal environment can be provided for silicon melt accommodated in a crucible, and localized solidification of the silicon melt can be prevented so that the quality of a silicon single crystal and the ingot pulling speed can be readily controlled.

Owner:LG SILTRON

Photocatalytically degraded slow-release coated fertilizer and preparation method thereof

InactiveCN107602238AStable in natureUniform environmentFertilizer mixturesPig farmsPesticide residue

The invention discloses photocatalytically degraded slow-release coated fertilizer and a preparation method thereof. The photocatalytically degraded slow-release coated fertilizer is prepared from thefollowing raw materials: corn starch, acrylic ester, tofu residue, pig farm excrement and urine, plant ash, graphite, potassium permanganate, hollow fly ash microspheres, zinc acetate, and the like.The fertilizer provided by the invention is completely prepared from organic components, ultrafine corn starch and the acrylic ester are used as a coating material at the outer layer, the coating material is stable in properties in the soil and has an ideal slow-release effect, and compound nutrient particles and a zinc sulfide composite material are used at the inner layer; due to the diversity of nutrients, the photocatalytically degraded slow-release coated fertilizer can meet the multiple demands of plants for the nutrition; furthermore, the photocatalytically degraded slow-release coatedfertilizer can purify the soil environment, has an excellent catalytic degradation effect on pathogenic microorganisms, organic pesticide residues and the like in the soil, and is good in economic andenvironmental benefits, thus being suitable for being applied to large-scale cultivation.

Owner:王玉红

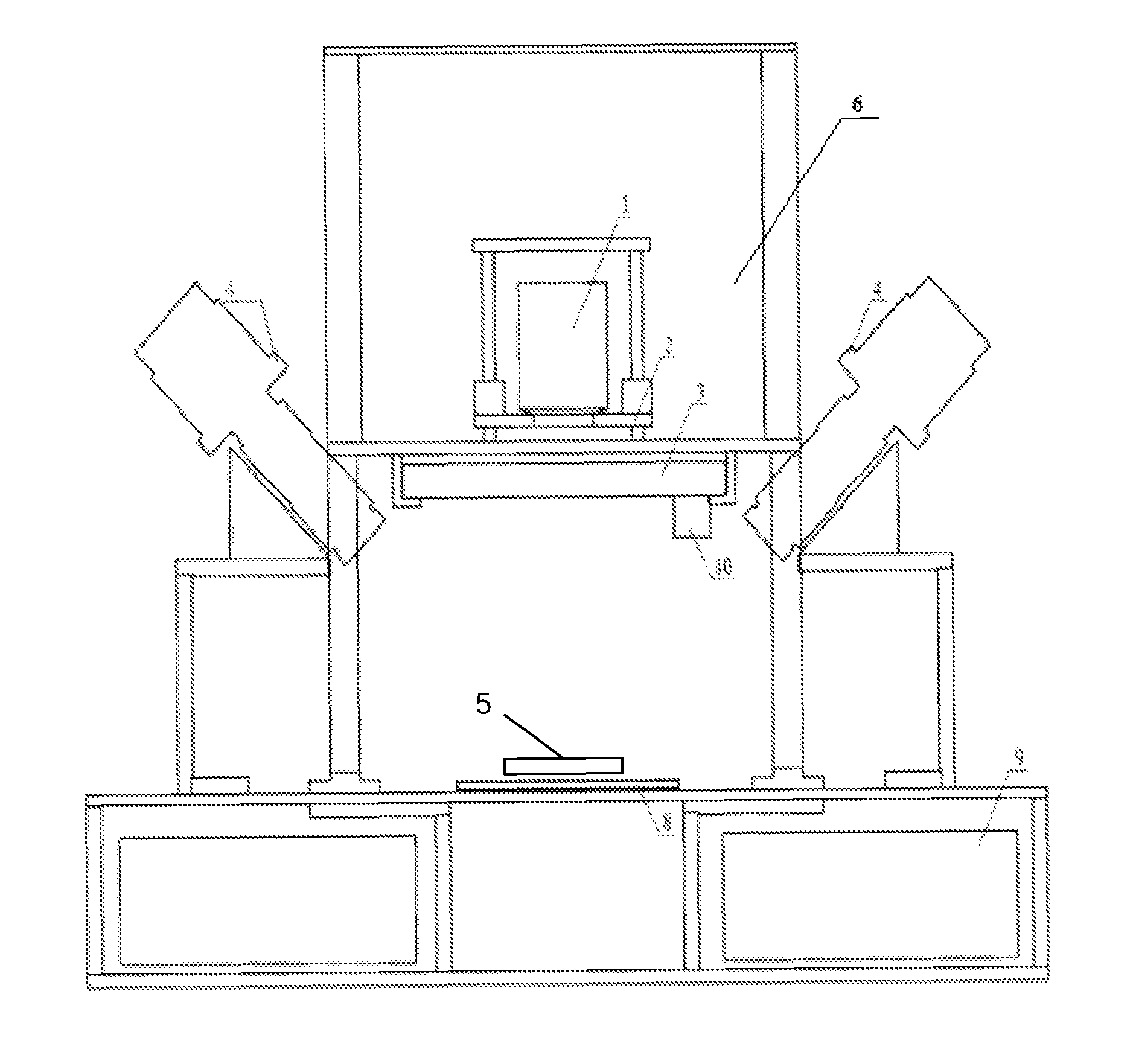

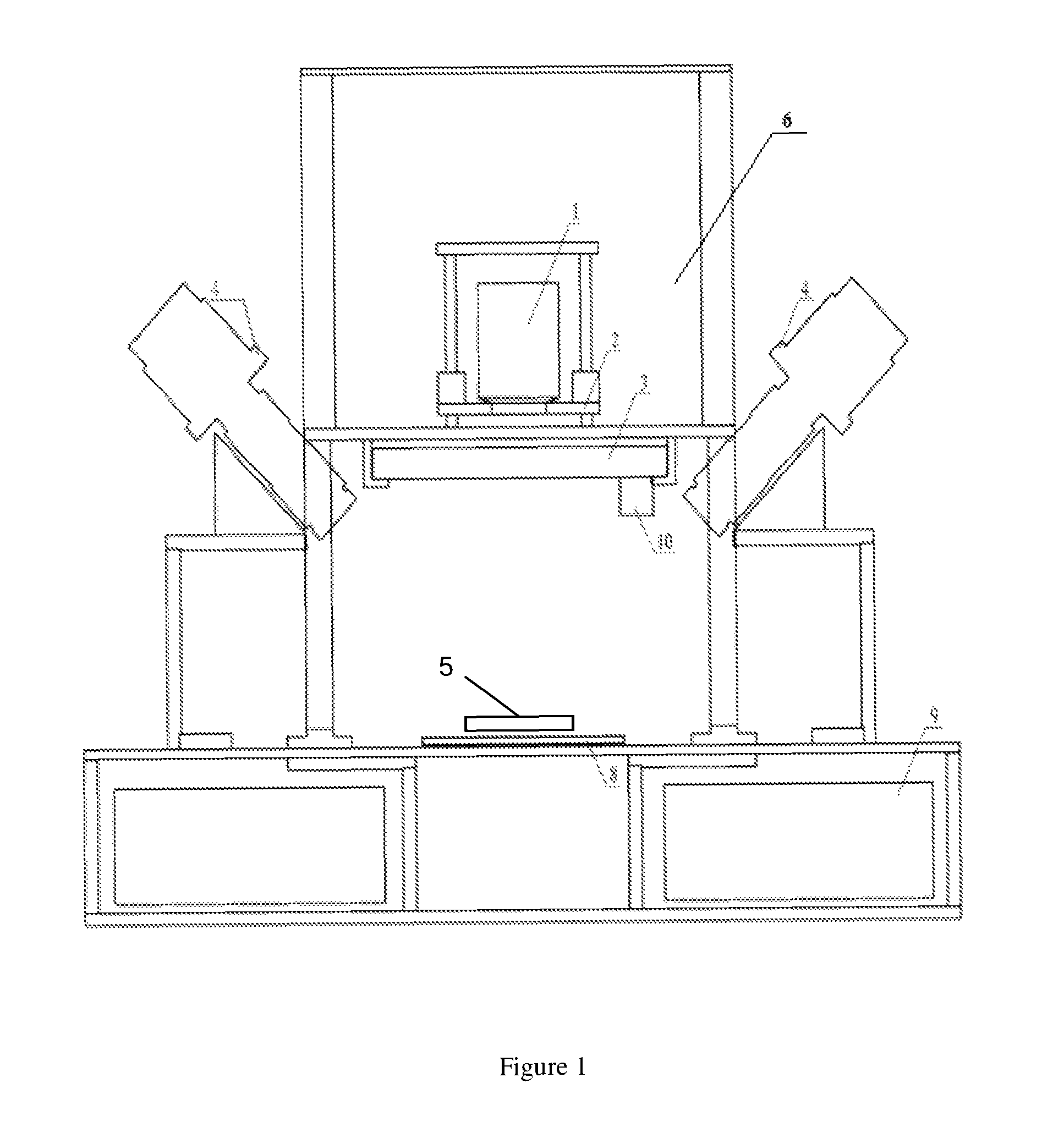

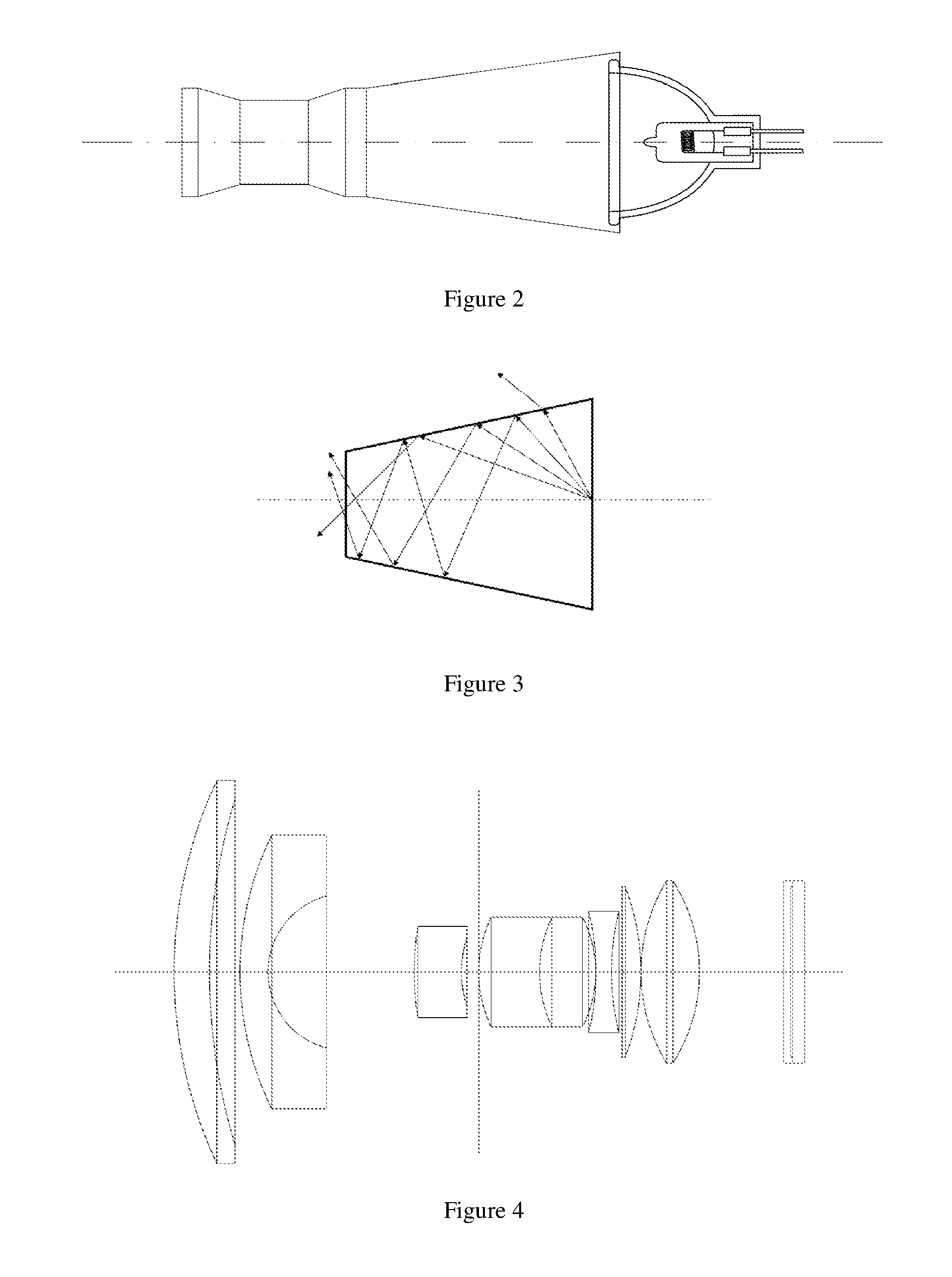

Multispectral imaging color measurement system and method for processing imaging signals thereof

ActiveUS9417132B2Improve accuracyLow accuracyRadiation pyrometrySpectrum investigationDigital imagingMedicine

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

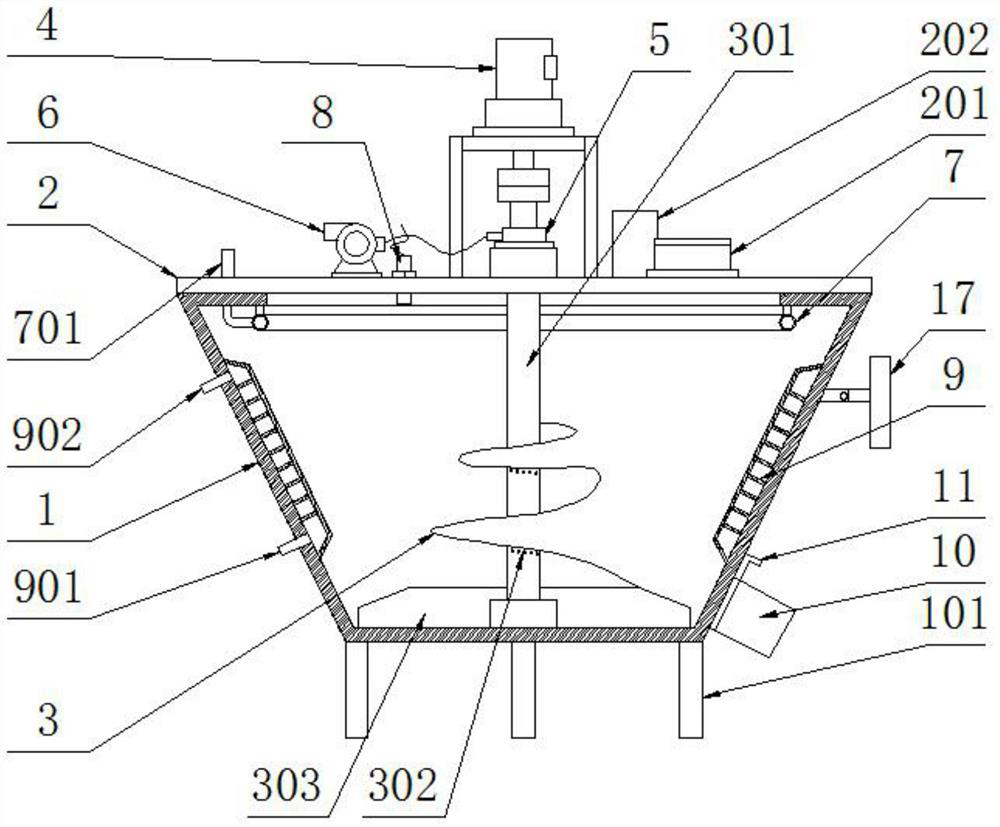

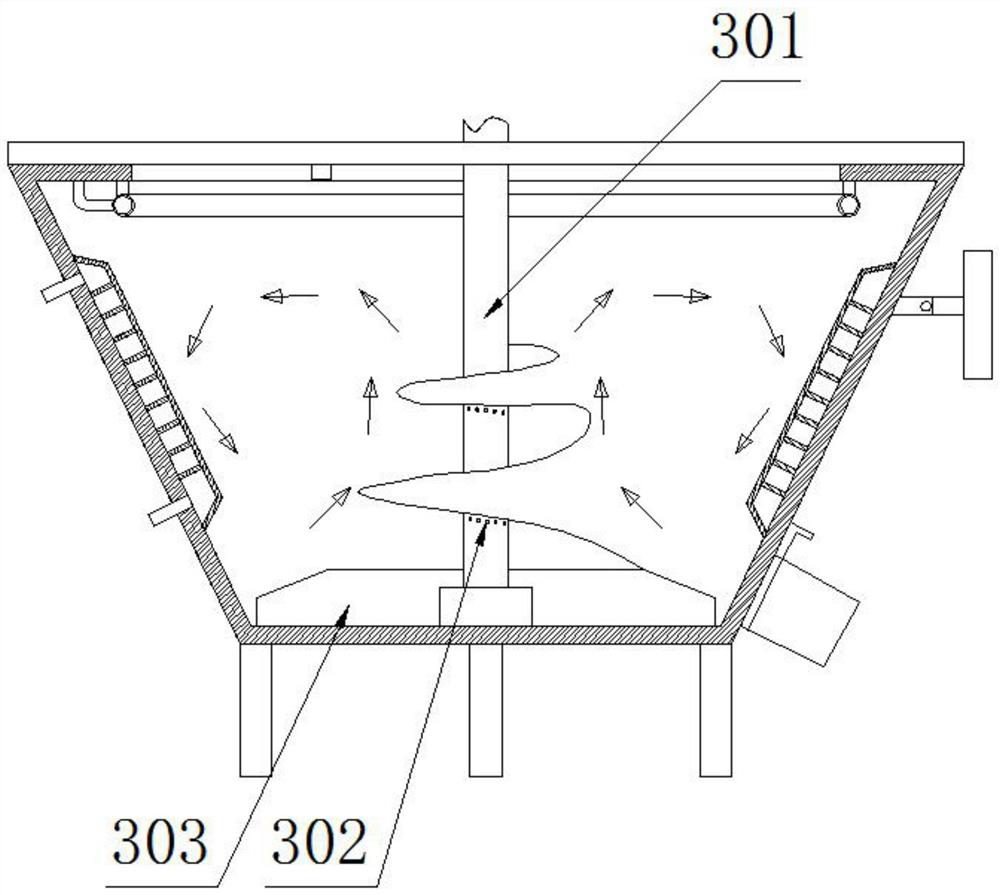

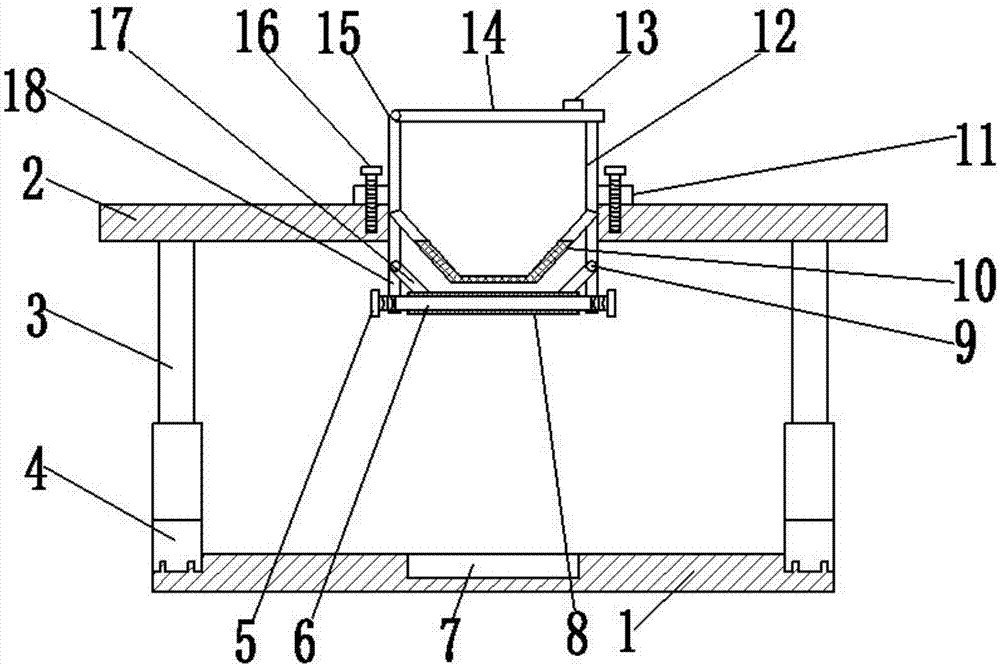

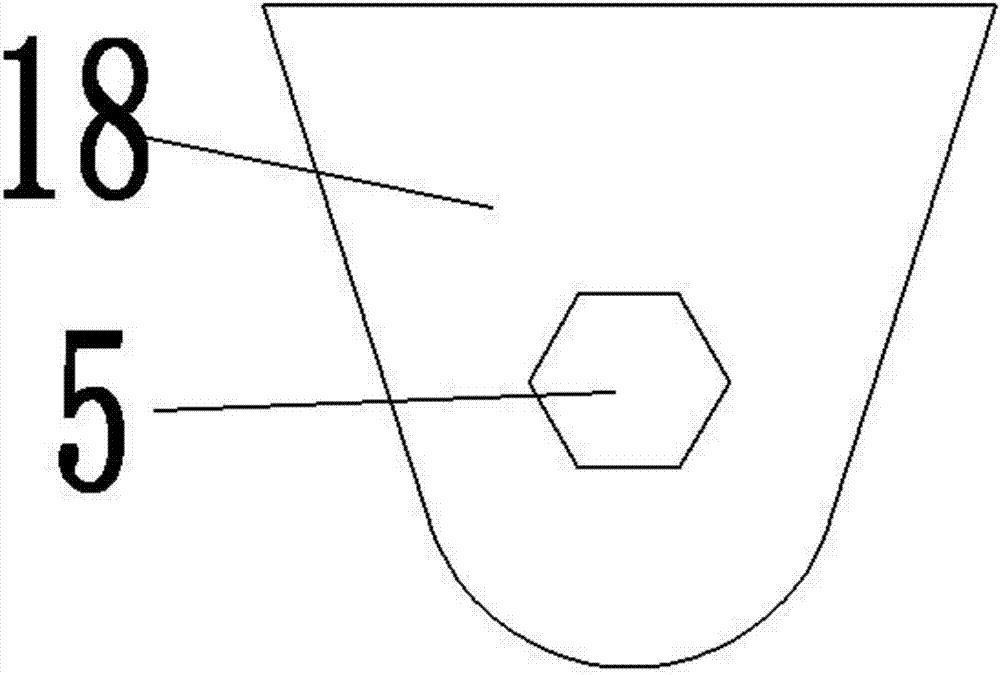

Traditional Chinese medicine decoction piece constant-temperature fermentation device and working method thereof

InactiveCN112812955AReduce risk of leakageAvoid uneven distributionBioreactor/fermenter combinationsBiological substance pretreatmentsFresh airProcess engineering

The invention discloses a traditional Chinese medicine decoction piece constant-temperature fermentation device. The traditional Chinese medicine decoction piece constant-temperature fermentation device comprises a machine shell, a bin cover, a stirring auger, an air supply mechanism, a water supply mechanism, a heating jacket and a discharging port, wherein an inner cavity of the machine shell is a fermentation bin, the fermentation bin is in an inverted circular truncated cone shape, a feeding port and an air outlet are formed in the bin cover, the discharging port is formed in the bottom of the side wall of the fermentation bin, and the heating jacket is arranged on the inner side of the side wall of the fermentation bin; the stirring auger is arranged at the bottom of the fermentation bin and is driven by a driving unit to rotate, the stirring auger is a stirring shaft which is vertically arranged in the middle of a spiral blade in a surrounding mode, and the stirring auger is arranged in a narrow-end-up mode; the air supply mechanism is arranged on the bin cover, the stirring shaft is of a hollow cylindrical structure, and a plurality of air outlet holes are formed in the stirring shaft below the spiral blade; and the water supply mechanism can input humidifying water. According to the traditional Chinese medicine decoction piece constant-temperature fermentation device and a working method thereof, a material flow which rolls up and down can be formed in the stirring bin when materials are stirred, fresh air can be directly blown into the side wall of the stirring shaft, so that loose materials can be directly fed, and the fermentation efficiency is improved.

Owner:安国润德药业有限公司

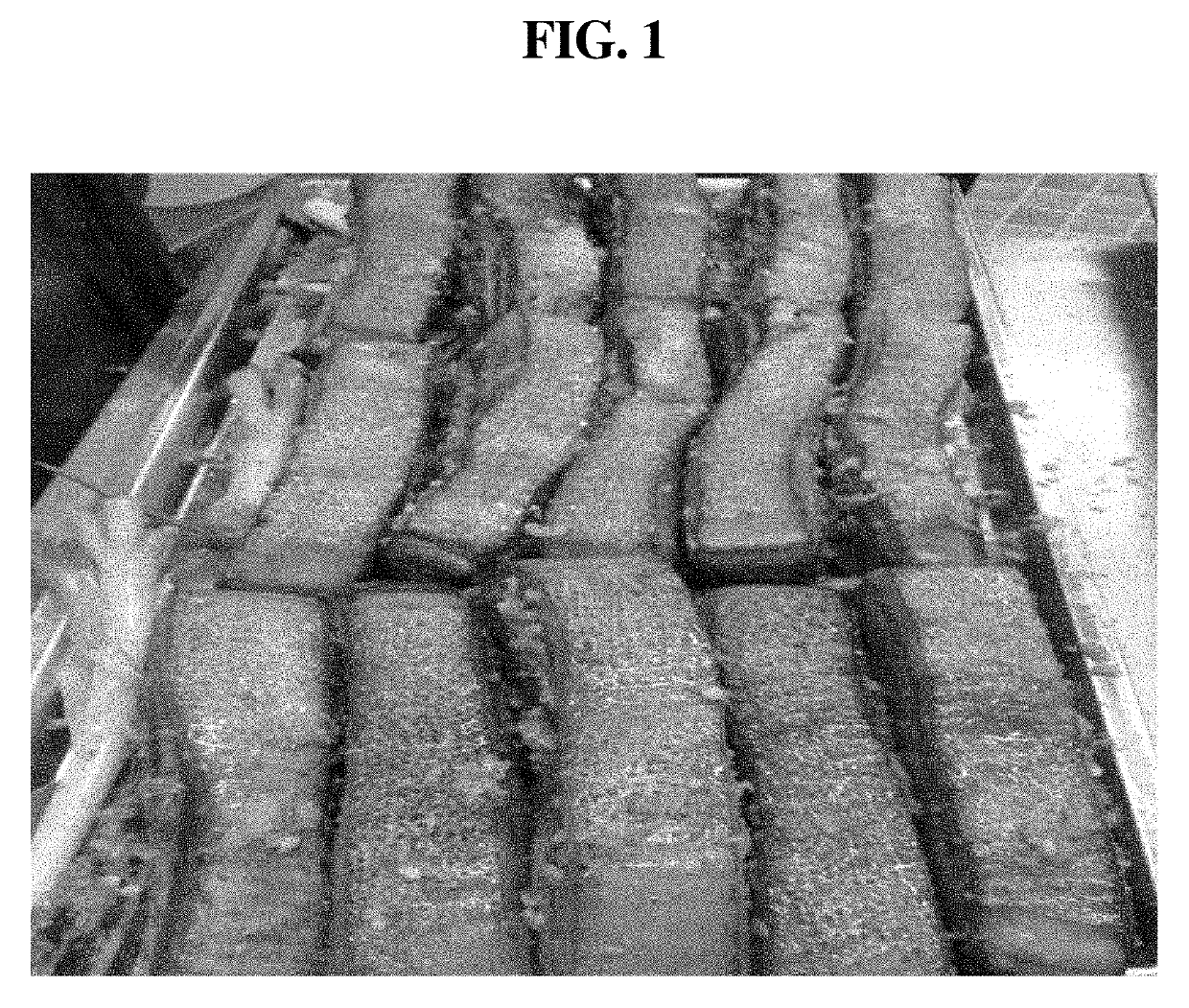

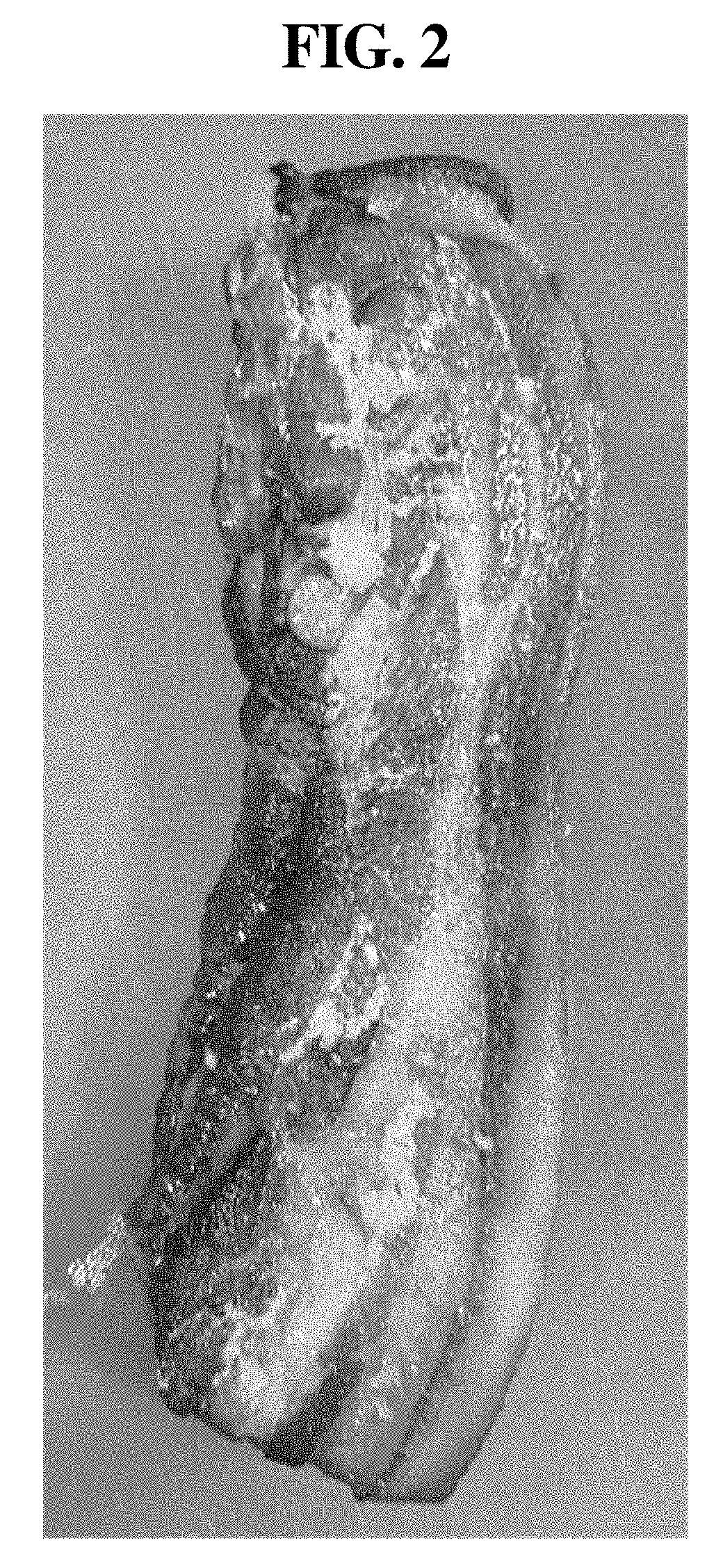

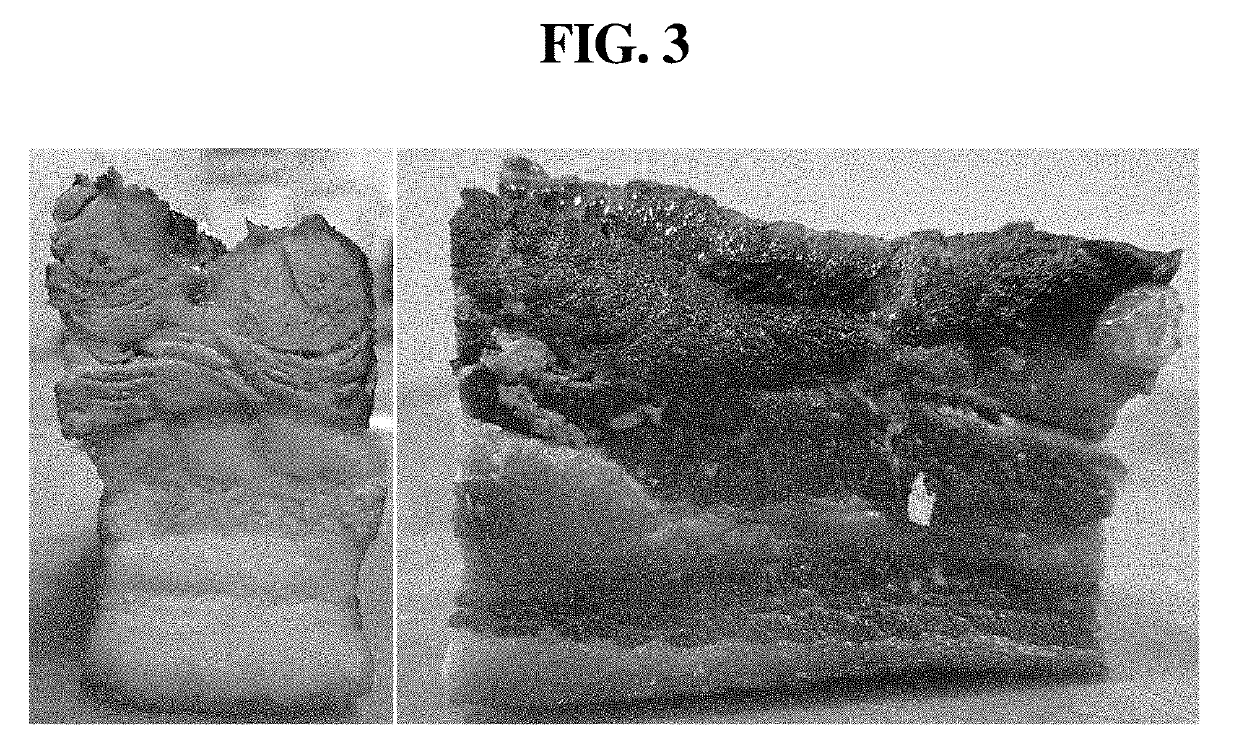

Boiled pork bossam and preparation method therefor

InactiveUS20190313676A1Improve sensory propertiesUniform cooking environmentNatural extract food ingredientsFlavorUniform - quality

The present invention relates to boiled pork which has improved flavor and taste as a result of keeping the unique savory taste of fat and preventing the loss of meat juice while effectively removing animal fat during preparation thereof, and to a standardized preparation method capable of preparing the boiled pork with uniform quality, and more particularly to boiled pork having on its surface a film formed by frying in oil and a method for preparing the same.

Owner:LHS FOOD CO LTD

Amplified Photodegradation of Hydrogels and Methods of Producing the Same

ActiveUS20180361016A1Readily adjustMaximize cell viabilityCapsule deliveryProsthesisChemistryPhotodegradation

This invention is in the field of synthesis and amplified photodegradation of hydrogel network and methods of producing and using the same.

Owner:UNIV OF COLORADO THE REGENTS OF

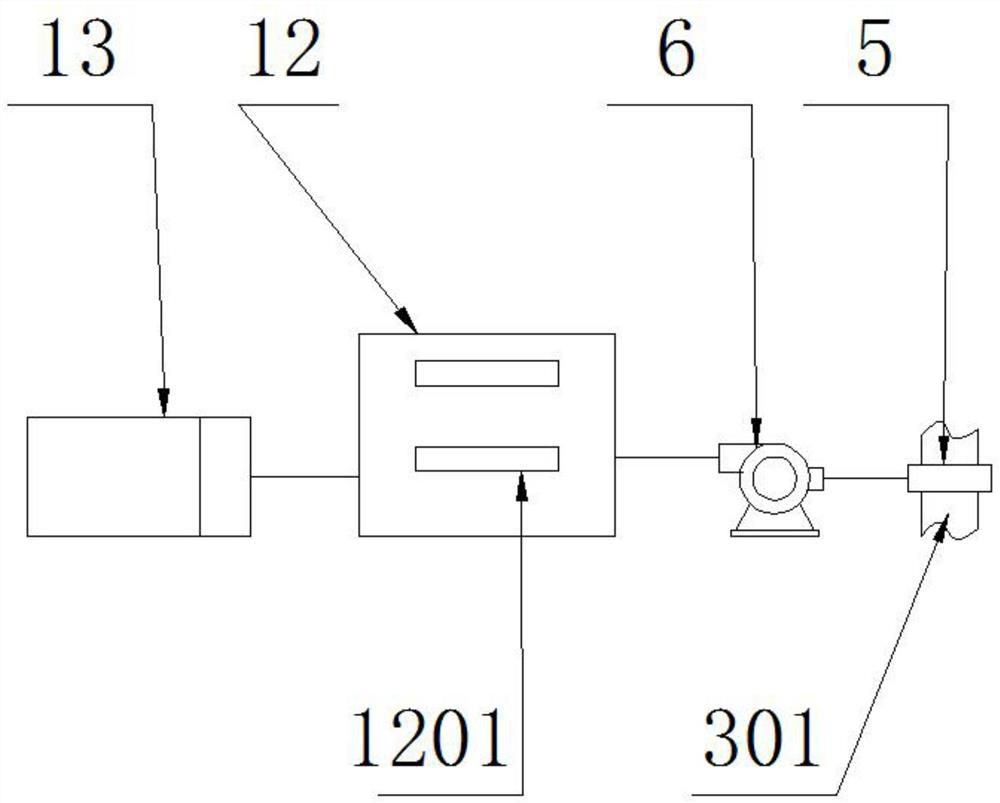

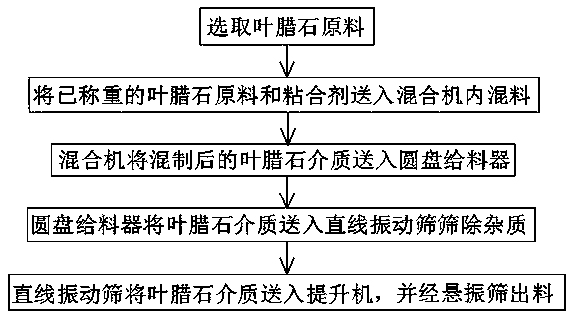

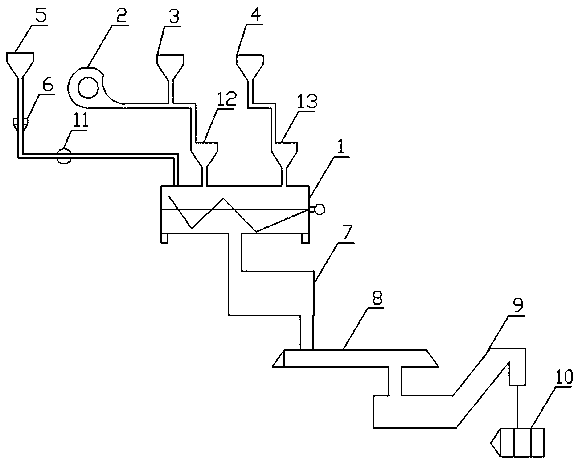

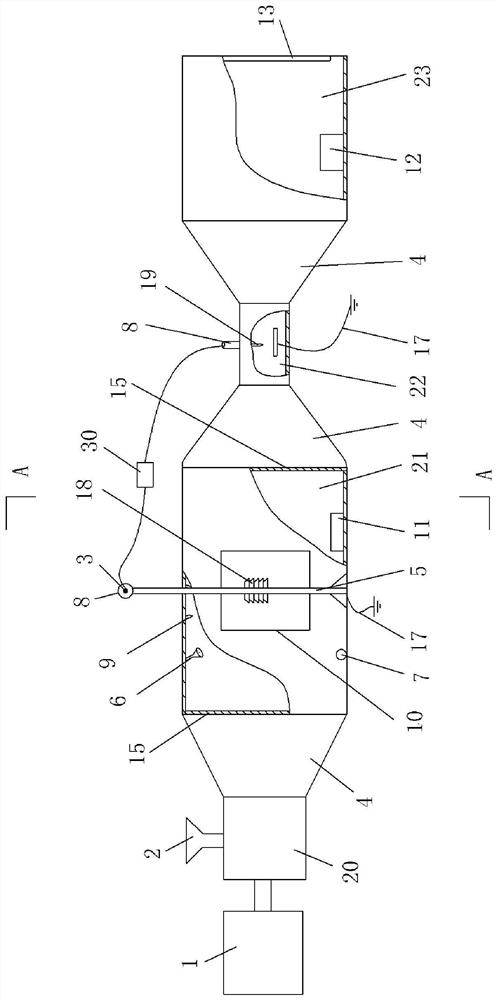

Raw material mixing method and system of superhard material industry

InactiveCN108854805ANo pollutionImprove the environmentTransportation and packagingMixersCircular discSuperhard material

The invention provides a raw material mixing method and system of a superhard material industry. The method comprises the following steps: step 1: selecting a pyrophyllite raw material; step 2: sending the weighed pyrophyllite raw material and a binding agent to a mixing machine for mixing; step 3: sending a mixed pyrophyllite medium to a disk feeder by the mixing machine; step 4: sending the pyrophyllite medium to a linear vibrating sieve for sieving impurities by the disk feeder; and step 5: sending the pyrophyllite medium to a lifting machine by the linear vibrating sieve, and discharging by a suspended vibrating sieve. A whole mixing process pipeline is sealed without overflowing dust, and a workshop environment is effectively improved. The ribbon-type mixing machine is capable of mutually diffusing materials in a process of mixing the pyrophyllite material, and performing convection and radial movement, and a mixing amount is 3 times greater than the mixing amount of a kneading machine, the mixed pyrophyllite medium is more uniform, and higher in quality. A whole mixing process is automatically controlled without a surplus working procedure, a worker does not need to operate manually, labor intensity of the worker is reduced, and the method is helpful to improve production automation of a workshop.

Owner:河南中南工业有限责任公司

Ferrite water-based pigment paste for cosmetics, preparation method thereof and preparation method of make-up products

ActiveCN111449988AGood storage stabilityHigh viscosityCosmetic preparationsMake-upSolventXanthan gum

The invention relates to ferrite water-based pigment paste for cosmetics, a preparation method thereof and a preparation method of make-up products. The pigment paste is prepared from the following components in percentage: 10-55 percent of ferrite colorant, 1-25 percent of a wetting dispersant, 3-10 percent of cosolvent, 0.5-3 percent of magnesium lithium silicate, 2-5 percent of xanthan gum, 1-2percent of bactericide and the balance being solvent water. An excellent effect can be achieved by using an antisettling technology of combining 0.5-3 percent of magnesium lithium silicate and 2-5 percent of xanthan gum, and the paste is excellent in storing stability, can be placed at normal temperature for 3 years or placed at high temperature of 55 DEG C for 6 months, and has the disperse system viscosity variation being less than 5 percent. The invention provides a set of paste meeting the requirement of related regulations of cosmetics (including eyes and mucous contact cosmetics) from different countries in the world and can be used for making different colors by mixing different colors of pastes. The stability and compatibility of paste are highly required to meet the demand of combination.

Owner:宁波爱诗化妆品有限公司

Mechanical lubrication device for toner cartridge scraping knife

InactiveCN107570390AFix fixResolve forward and backward movementLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention provides a mechanical lubrication device for a toner cartridge scraping knife. The mechanical lubrication device comprises a base and a transversal plate, wherein a groove is formed in the center of the upper surface of the base; slide blocks are arranged at the left side and the right side of the groove; the upper ends of the slide blocks are fixed to the lower end of an electric telescopic rod; a lubricant powder storage box is formed in the central position of the upper surface of the transversal plate; a box cover is arranged at the upper end of the lubricant powder storage box; a filter screen is arranged at the bottom of the lubricant powder storage box; sealed scraping sheets are arranged below the filter screen; two groups of the sealed scraping sheets are arranged, and symmetrically distributed at the two sides below the center line of the filter screen; the surfaces of the sealed scraping sheets are in contact connection with a powder coating rolling wheel; thesealed scraping sheets are hinged to a hinge shaft; the hinge shaft is fixed to the middle position of the inner wall of a fixing plate; the fixing plate is welded to the lower end of the lubricant powder storage box; and the powder coating rolling wheel is fixed to the outer side of a rolling shaft. The mechanical lubrication device provided by the invention is simple in structure and convenientto use; the sealed scraping sheets are arranged on the fixing plate, and capable of sealing the lubrication device, so that lubricant powder can be saved.

Owner:周蒙

Method for extensive amplification of cell line and mesenchymal stem cell in vitro

ActiveCN102321566BLow costEasy to operateSkeletal/connective tissue cellsMesenchymal stem cellMicrocarrier

The invention discloses a method for extensive amplification of cell line and mesenchymal stem cells in vitro. Microcarrier and Hyperflask cell culture container are combined for extensive amplification of cell line and mesenchymal stem cells in vitro. The invention combines commercialized microcarrier and Hyperflask for extensive amplification of cells in vitro in a small culture space, so as to obtain a large amount of target cells on the premise of saving costs.

Owner:UNION STEMCELL & GENE ENG

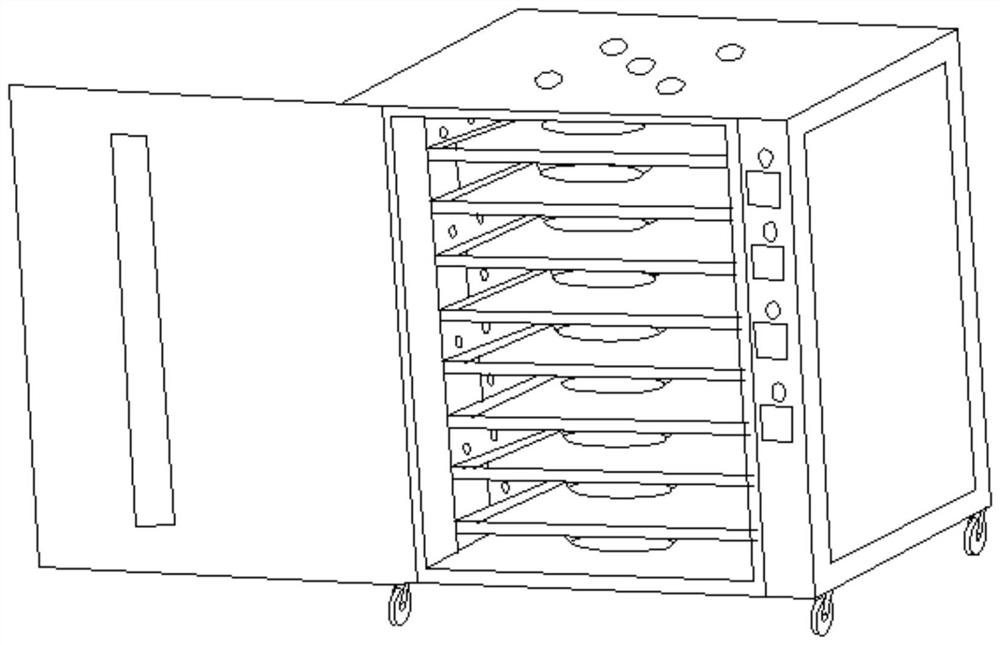

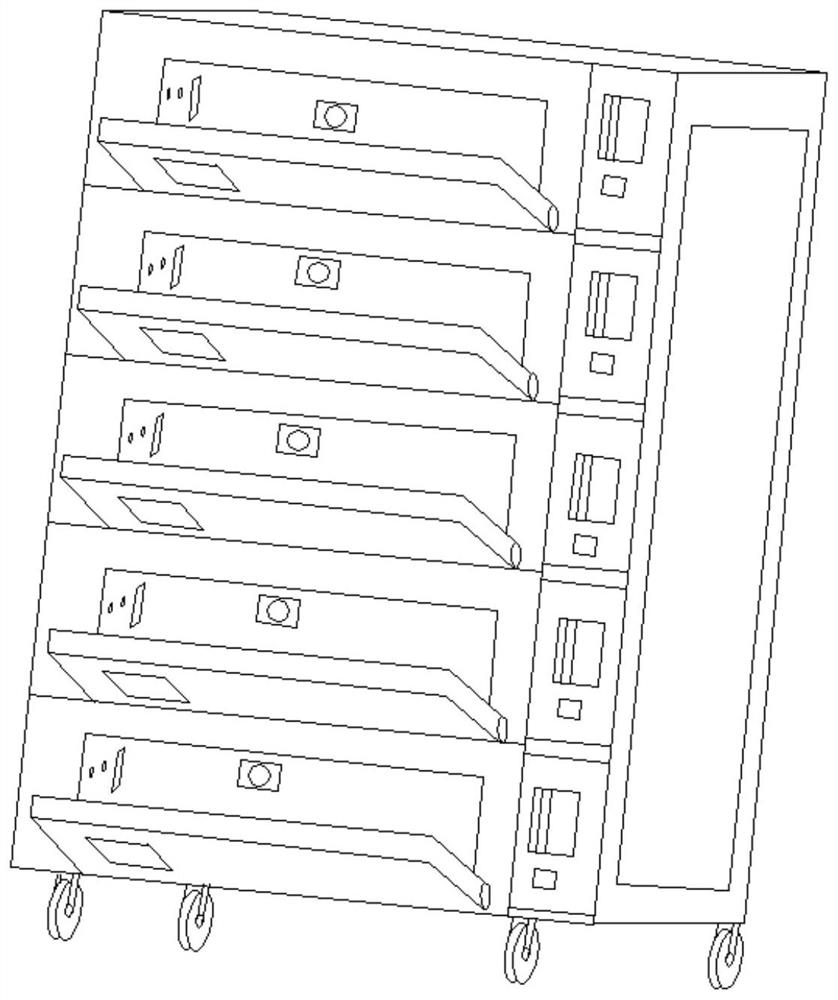

Novel machine integrated with degerming, peculiar smell removing, aroma enhancing and baking functions

PendingCN113632916AReach titianEliminate odorBaking ovenHigh-frequency/infra-red heating bakingFiberCarbon fibers

The invention discloses a machine integrated with degerming, peculiar smell removing, aroma enhancing and baking functions. The machine comprises a machine box, wherein a baking tray is arranged in the machine box; symmetrical short wave carbon fiber far infrared heating structures are arranged at the upper end and the lower end of the center of the baking tray, and asymmetrical hot air delivery mechanisms are arranged on a left inner plate and a right inner plate in the machine box; asymmetrical anionic transmission electrodes are arranged on two sides of the baking tray; and an exhaust port is formed in the inner plate of the machine box. Compared with the prior art, the machine integrated with degerming, peculiar smell removing, aroma enhancing and baking functions has the advantages that symmetrical short-wave carbon fiber far infrared heating is additionally arranged on the baking table, and radiation heating is utilized, so that products in the center of the baking table are heated more uniformly (air heating loss is made up, and the temperature of the middle baking table is insufficient); and asymmetric hot air heating systems are designed on the left side and the right side of the baking table, so that hot air forms a non-convectional state in a baking oven, and the heating environment of baked objects is more uniform.

Owner:谢隆兴

Mesenchymal stem cell and application thereof in resisting HIV-1 (human immunodeficiency virus)

ActiveCN102719397BIncrease productionLarge culture surface area/volume ratioOrganic active ingredientsPeptide/protein ingredientsT lymphocyteT cell

The invention discloses a mesenchymal stem cell and the application thereof in resisting HIV-1 (human immunodeficiency virus), and particularly relates to a mesenchymal stem cell of a secreted-expression high-concentration keratinocyte growth factor (KGF), and the mesenchymal stem cell is produced through a micro-carrier culturing system. According to the invention, the mesenchymal stem cell can be used for promoting the development of the thymus gland, maintaining the functions of the thymus gland, and enhancing the immunologic function of specific T cells through increasing the output of T lymphocytes to peripheral blood, thereby achieving an effect of treating HIV-1 infection, and providing an effective new strategy for the clinical treatment of the acquired immunodeficiency syndrome.

Owner:UNION STEMCELL & GENE ENG

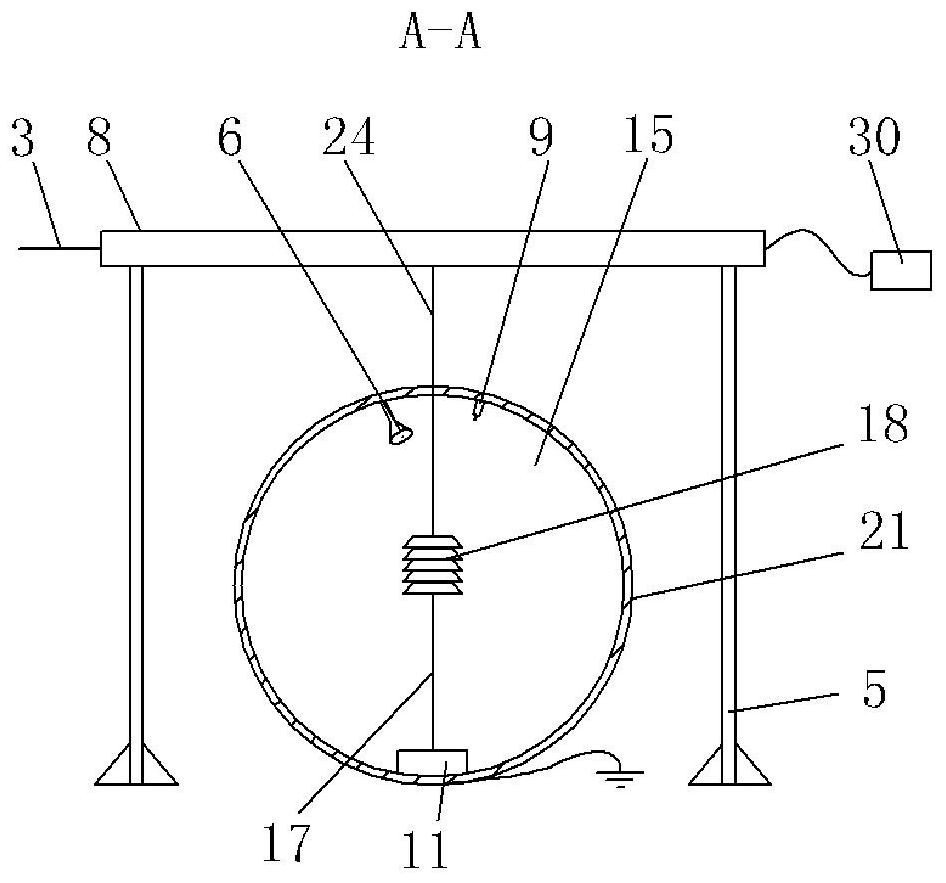

An insulation performance test device for EMU roof insulators in complex environments

ActiveCN109307828BGuaranteed safe operationSmall variation in insulation propertiesTesting dielectric strengthSpeed testUltraviolet

An insulation performance test device for EMU roof insulators in a complex environment. There are four chambers from left to right: the stable chamber, the low-speed test chamber, the high-speed test chamber and the expansion chamber, and the left side of the stable chamber and the aerosol generator The nozzles of the low-speed test chamber are connected to each other, and the upper part is provided with a funnel; there are roof insulators in the low-speed test chamber, and the upper end of the roof insulator is connected to a high-voltage power supply; the upper surface of the inner wall of the low-speed test chamber is equipped with an ultraviolet There is a glass observation window at the top; a negative pressure fan and an anemometer are installed at the right end of the expansion chamber. The test environment is close to the actual operating environment of the roof insulator, and the test results are more accurate and reliable. At the same time, it can also test and analyze the relationship between various environmental factors and the insulation performance of the roof insulator. So as to provide a more reliable and accurate test basis for the design, manufacture and maintenance of the roof insulator, and better ensure the safe operation of the train.

Owner:SOUTHWEST JIAOTONG UNIV

Method for improving phosphorus diffusion uniformity of solar cell

ActiveCN102005502BUniform environmentConsistent temperatureFinal product manufactureSemiconductor devicesDiffusionNitrogen atmosphere

The invention discloses a method for improving phosphorus diffusion uniformity of a solar cell. The method comprises the following steps of: (1) placing a silicon slice in a diffusion furnace and raising the temperature of each region in the furnace to 700 to 780 DEG C, wherein the environment in the furnace is uniform nitrogen atmosphere, and the flow rate of the nitrogen gas is 8 to 30L / minute;(2) simultaneously introducing phosphorus-carrying source gas at the speed of 0.8 to 2L / minute and dry oxygen at the speed of 0.4 to 2.5L / minute after the temperature is stable, ensuring that the gas environment in the furnace is uniform, and diffusing for 10 to 40 minutes; (3) stopping introduction of the phosphorus-carrying source gas source and the dry oxygen, synchronously and uniformly raising the temperature of each region in the furnace at the rate of below 5 DEG C / minute, raising temperature to 810 to 900 DEG C and diffusing for 10 to 40 minutes; and (4) reducing temperature and taking out the silicon slice. Through uniform gas and consistent temperature in the furnace, the phosphorus diffusion uniformity during preparation of the battery plate is improved, and the conversion efficiency of the solar cell is improved to a certain extent.

Owner:YANCHENG CANADIAN SOLAR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com