Ferrite water-based pigment paste for cosmetics, preparation method thereof and preparation method of make-up products

A technology of water-based pigment paste and cosmetics, applied in the direction of cosmetic preparations, cosmetics, cosmetics, etc., can solve the problems of poor storage stability, high production cost, and inconvenient color matching, and achieve good compatibility and coordination, and stable storage The effect of good performance and overall environmental balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-12

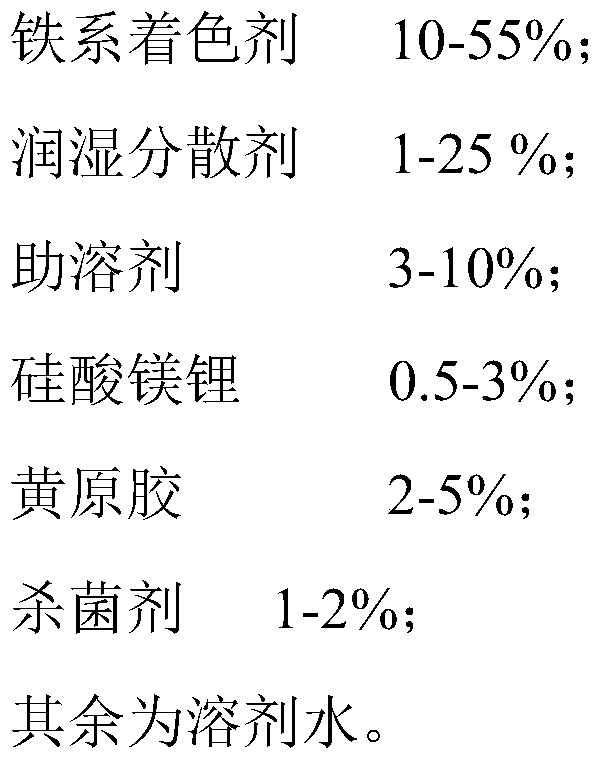

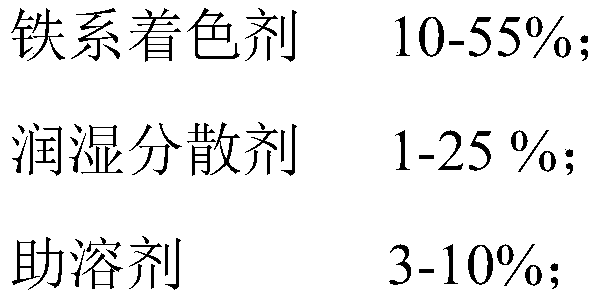

[0025] An iron-based water-based pigment paste for cosmetics, the formula of each embodiment is shown in Table 1. The iron coloring agent in table 1, specifically, embodiment 1,2,3 is iron oxide yellow, embodiment 4,5,6 is iron oxide red, embodiment 7,8,9 is iron oxide blue, embodiment 10, 11, and 12 are ferrous iron oxide, and examples 13, 14, and 15 are iron oxide black. The wetting and dispersing agent in Table 1 is an anionic acrylic acid-acrylic ester copolymer with a molecular weight of 5000-30000, and the proportion of acrylic acid groups is 20%-40%. The wetting bactericide in Table 1 is a compound system of phenoxyethanol-sodium dehydroacetate.

[0026] Its preparation process is as follows:

[0027] Step 1: shearing and dispersing lithium magnesium silicate and xanthan gum in the ingredients to obtain an anti-sedimentation agent;

[0028] Step 2: Put the other raw materials in the ingredients and the anti-sedimentation agent obtained in step 1 into a nano sand mill...

Embodiment 9

[0035] A water-based nail polish, comprising the following components: 98.0g of water-based polyurethane dispersion, 0.7g of YCK1110 (leveling agent, Shanghai YCK company), 0.4g of LCN407 (wetting agent, Klein), 0.5g of 2 -1352 emulsion ((brightening agent, Dow Corning), 0.02g of nano-alumina dispersion (hardening agent, Nanjing Haitai Nano Material Co., Ltd., wt%=30%), 0.02g of aldehyde and ketone resin (hardening agent, Zibo Gaohuan Fine Chemical Co., Ltd.), 1.0g of Lakewax 20 (thickener, Tongyi Chemical Industry), 1.0g of bentonite (thickener, Xinjiang Jinlong Building Materials Co., Ltd.), 0.02g zinc octanoate (drying agent), 0.4g of KH-560 (epoxy silane coupling agent, Yuxin plastics), 4.5g of color paste, 1.0g of DMDMH (preservative, Dow Chemical)

[0036] Wherein the color paste is obtained by compounding Example 7 and Example 13 at a mass ratio of 60%:40%.

Embodiment 10

[0038] A liquid material for an eyeliner pen, comprising the following components: water, 33.0g; butylene glycol, 1.0g; sodium polyacrylate, 1.0g; color paste, 24.0g; silicon dioxide, 0.5g; silicone oil, 2.0g; Caprylic / Capric Triglyceride, 2.0g; Diisostearyl Malate, 2.0g; Cetearyl Olivate, 2.0g; Laureth, 2.0g; Oxyethanol, 0.5 g; Acrylate Copolymer, 30.0 g.

[0039] Wherein color paste is embodiment 13.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com