Device for cleaning construction reserved hole

A technology of cleaning device and reserved hole, applied in the field of cleaning device and building reserved hole cleaning device, can solve problems such as poor cleaning effect, low cleaning efficiency, blocked holes, etc., and achieve the effect of improving cleaning efficiency and improving cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

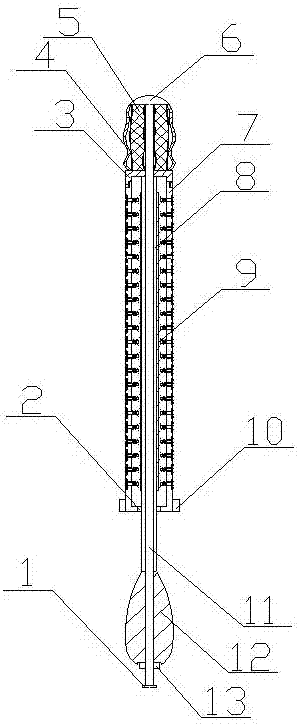

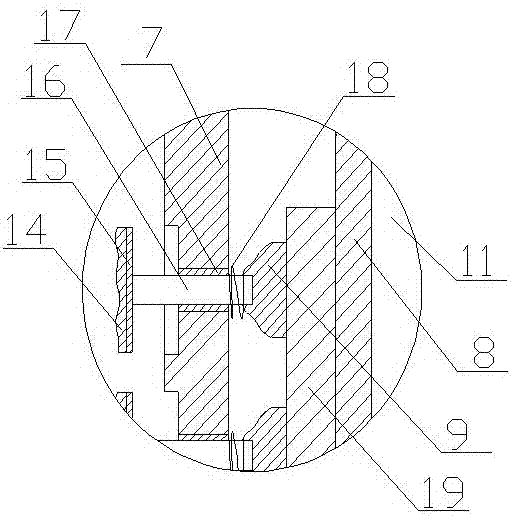

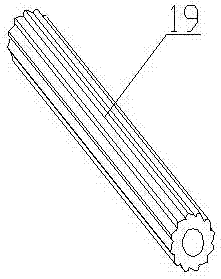

[0022] A cleaning device for building reserved holes of the present invention is realized in this way. When in use, in the initial state, all the fixing plates (15) are put into the corresponding strip grooves, firstly, the drive wheel (10) and the external The power device is connected, hold the grip block (12), and extend the rotating cylinder (7) into the reserved hole until the fixed block (6) touches the bottom of the reserved hole, and the external power device drives the transmission wheel (10) to rotate , the transmission wheel (10) drives the rotating cylinder (7) to rotate, and then the rotating cylinder (7) drives all the fixed plates (15) to rotate in the reserved holes, and at the same time, slightly rotate the grip block (12), and the grip block (12) Drive the spline shaft (11) to rotate, and the spline shaft (11) drives the gear rod (19) to rotate in the rotating cylinder (7). Since the outer surface of the gear rod (19) fits with the slider (9), when the gear W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com