Vacuum cavity of multi-cavity structure

A vacuum cavity and cavity structure technology, which is applied in the direction of transportation, packaging, conveyors, etc., to achieve the effect of reasonable structure design, high strength and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0021] Example.

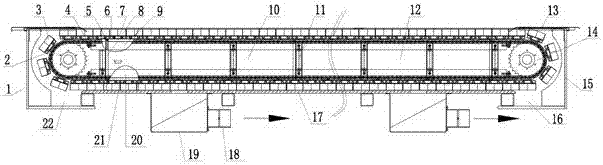

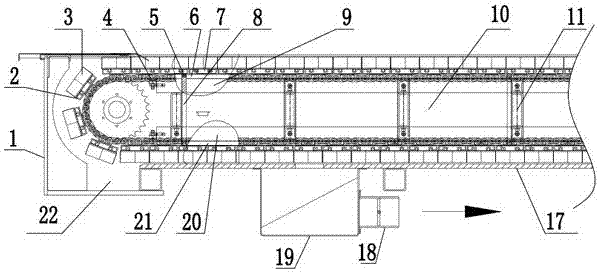

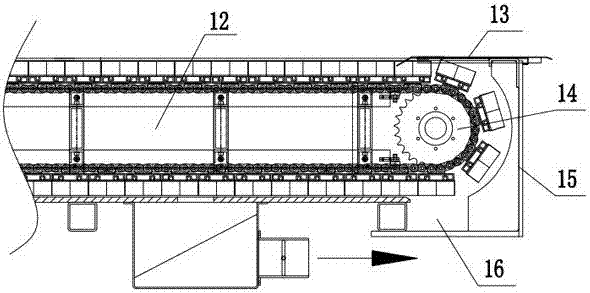

[0022] see Figure 1 to Figure 4 The multi-cavity structure vacuum cavity of this embodiment includes a rear baffle 1, a front baffle 15, a right baffle 27, a left baffle 28, a bottom plate 17, an upper structural beam 9, a transverse structural beam 11, a lower structural beam 20, a horizontal Dividing plate 8, straight dividing plate 26, upper slide rail 6, lower slide rail 21, support bar 2, cut raw brick 3, transmission chain disc 14 and transmission chain 23.

[0023] The rear baffle 1, the front baffle 15, the right baffle 27, the left baffle 28 and the bottom plate 17 of the present embodiment are connected to each other to form a sealed vacuum chamber structure; the upper part area is cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com