Ultrasonic shotblast strengthening equipment

An ultrasonic shot peening and shot peening technology is applied in the field of fan blade surface treatment equipment, which can solve the problems of affecting the service life of parts and large impact energy of projectiles, and achieve the effects of reducing dust and noise pollution, improving efficiency and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

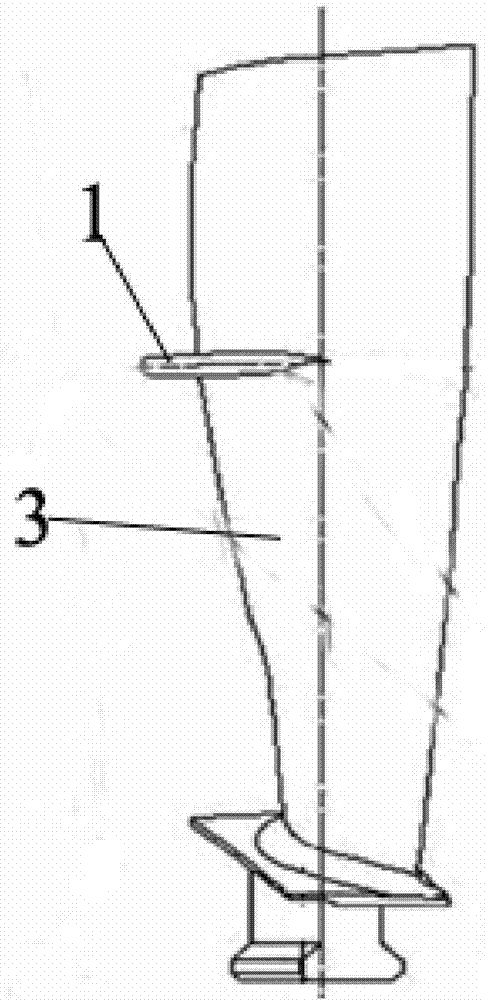

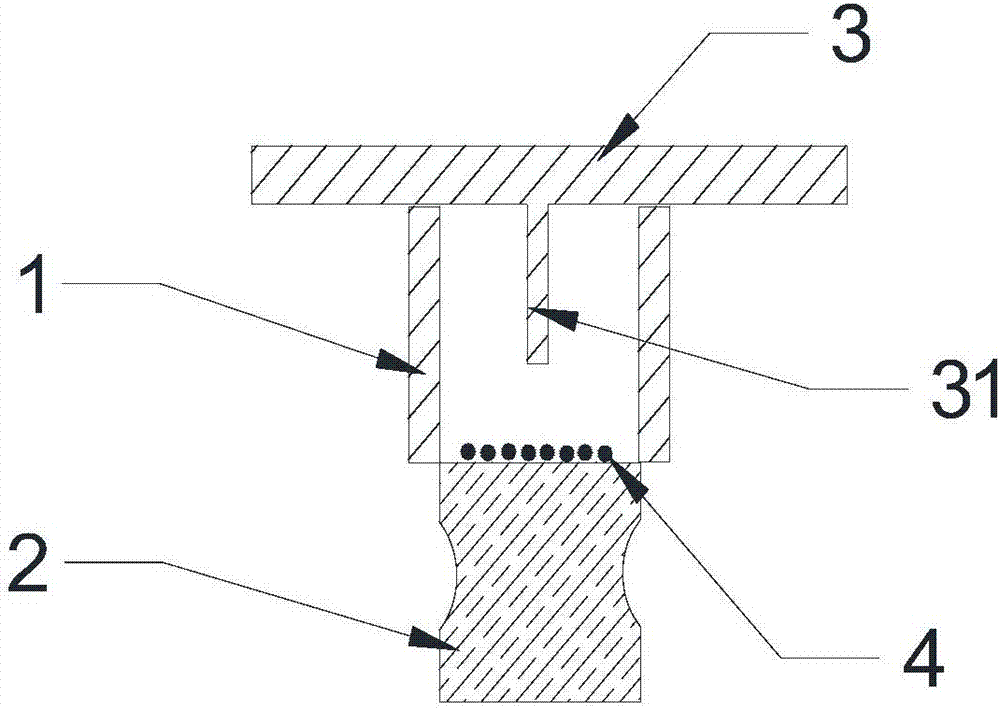

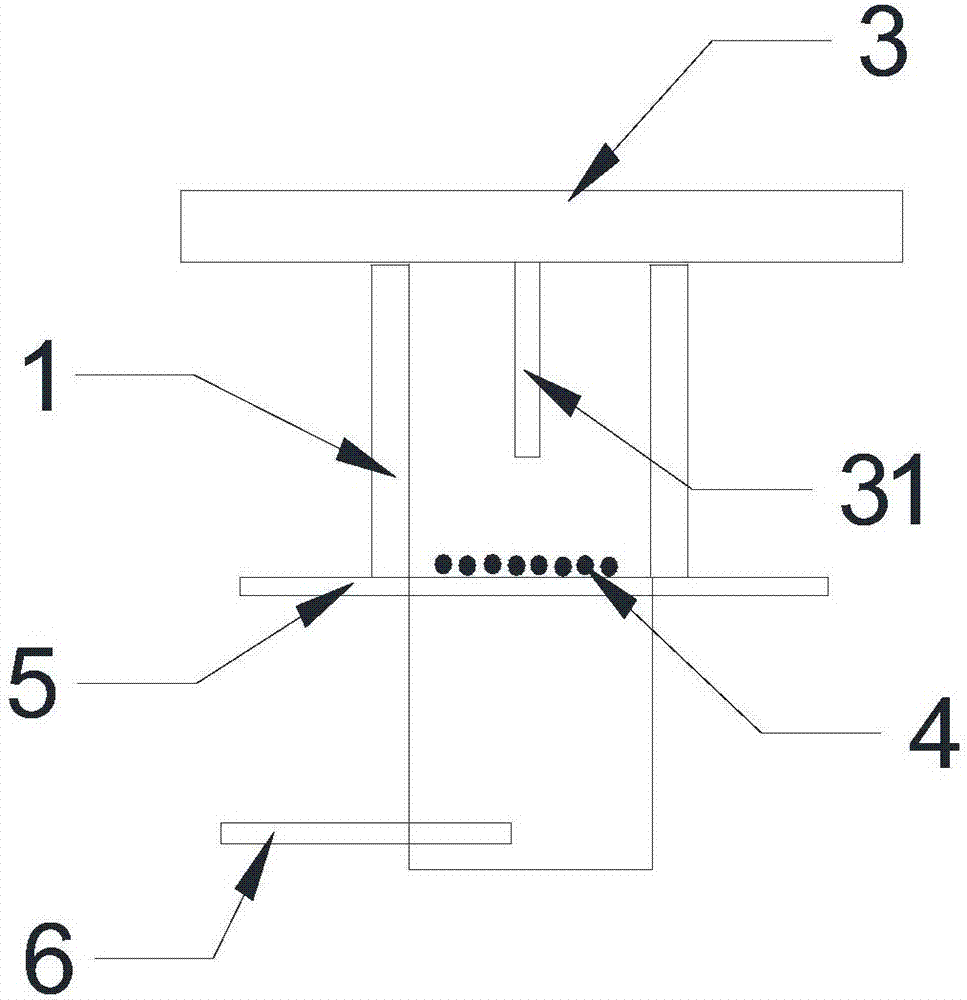

[0021] Such as Figure 1 to Figure 3 As shown, the present invention provides a kind of ultrasonic shot peening strengthening equipment, which includes: ultrasonic vibration device, projectile and shot blasting chamber 1 that can accommodate projectile, projectile 4 is selected high-quality tungsten steel projectile, and the diameter of projectile 4 is 1mm-4mm . Wherein, the shot blasting chamber 1 is a cylindrical structure with a diameter of 200mm-300mm, a height of 150mm-200mm, and a wall thickness of 8-12mm. The surface of the upper port of the shot peening chamber 1 is a curved surface conforming to the surface of the fan blade 3 , and the lower end of the shot peening chamber 1 is connected with the ultrasonic vibration device 2 . The upper surface of the shot-peening chamber 1 can cooperate with the lower surface of the fan bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com