A kind of fully shading polypropylene composite material for lamps and its preparation method

A composite material and polypropylene technology, which is applied in the field of full shading polypropylene composite material for lamps and its preparation, can solve the problem of reducing the reflectivity and gloss of the material, reducing the reflectivity of the material, difficult shading of the PP material, flame retardant and reflective properties and other problems, to achieve the effect of reducing adverse effects, reducing the amount of addition, and good scattering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

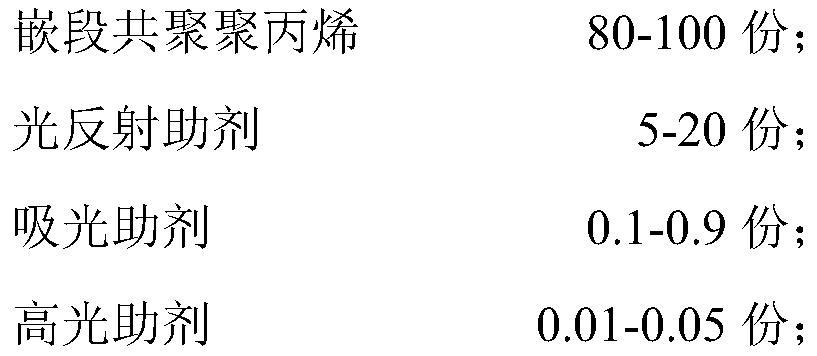

Method used

Image

Examples

Embodiment 1

[0037] A preparation method of a full-shade polypropylene composite material for lamps. Block copolymerized polypropylene, flame retardants, light reflection additives, light absorption additives, and high-gloss additives are mixed in a high-speed mixer for 5 minutes and then added to a twin-screw extruder. In the extruder, under the condition that the screw speed is 35HZ, it is melt-extruded and granulated to obtain a full-shade polypropylene composite material for lamps, wherein the mass content of the ethylene-containing block component in the block copolymerized polypropylene is 15%. The flame retardant is a compound of tris (tribromophenyl) cyanurate and zinc methyl ethyl hypophosphite with a mass ratio of 1:1. The melting temperature range of the flame retardant lies in the injection molding of block copolymer polypropylene Within the processing temperature range, the light reflection additive is rutile TiO with a particle size of 0.15-0.25 μm at a mass ratio of 1:1 2 an...

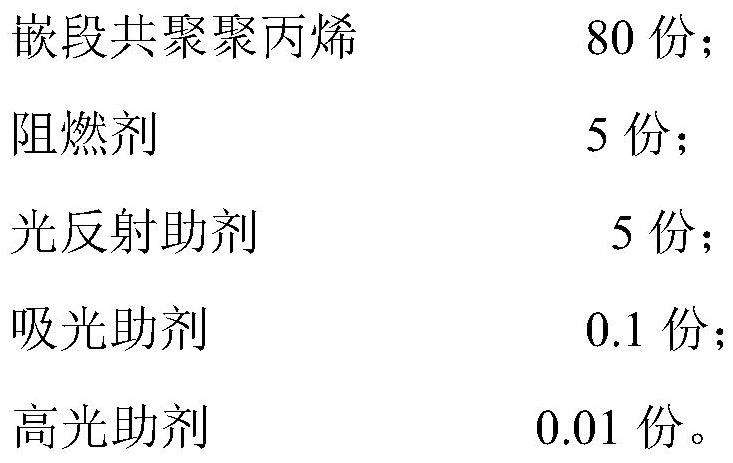

Embodiment 2

[0044] A method for preparing a full-shading polypropylene composite material for lamps, the steps of which are basically the same as in Example 1, the difference is that the mass content of the block component containing ethylene in the block copolymerized polypropylene, FeS 2 The particle size and the amount of each reactant added, the mass content of the ethylene-containing block component in the block copolymerized polypropylene is 20%, FeS 2 The particle diameter is 0.1-0.3 μ m, and by weight, the add-on of each reactant is as follows:

[0045]

[0046] The thickness of the finally prepared full-shading polypropylene composite material for lamps is 1.0 mm, the reflectance is 97%, the light transmittance is 0.05%, and the flame retardancy reaches the UL-94V2 level.

Embodiment 3

[0048] A method for preparing a full-shading polypropylene composite material for lamps, the steps of which are basically the same as in Example 1, the difference is that the mass content of the block component containing ethylene in the block copolymerized polypropylene, FeS 2 The particle size and the amount of each reactant added, the mass content of the ethylene-containing block component in the block copolymerized polypropylene is 18%, FeS 2 The particle diameter is 0.2-0.4 μm, and by weight, the add-on of each reactant is as follows:

[0049]

[0050] The finally prepared full-shading polypropylene composite material for lamps has a thickness of 1.0mm, a reflectivity of 93.7%, a light transmittance of 0%, and a flame retardancy of UL-94V0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com