Water permeable brick and its making method

A permeable brick and a part of the technology, applied in the field of permeable brick and its preparation, can solve the problems of high production energy consumption, poor water permeability, impermeability to contamination, etc., and achieve the effects of energy saving, simple manufacturing method, and elimination of process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] On the other hand, the present invention also provides a kind of preparation method of permeable brick, and this method comprises:

[0037] (1) curing the mixture of binder and silica sand to form at least one surface comprising a concave permeable brick body;

[0038] (2) The surface of the permeable brick body obtained in step (1) including the depression is coated with a stain-resistant paint, dried to form a stain-resistant paint layer, and at least a part of the depression is not covered by the stain-resistant coating. Paint coverage.

[0039] There is no special requirement for the method of forming the main body of the permeable brick with at least one surface including a depression, and various methods that can be thought of by those skilled in the art can be used. From the aspect of facilitating the preparation of the main body of the permeable brick, it is preferred to use a mixture of binder and silica sand Pour it into the cavity of the mold for making the ...

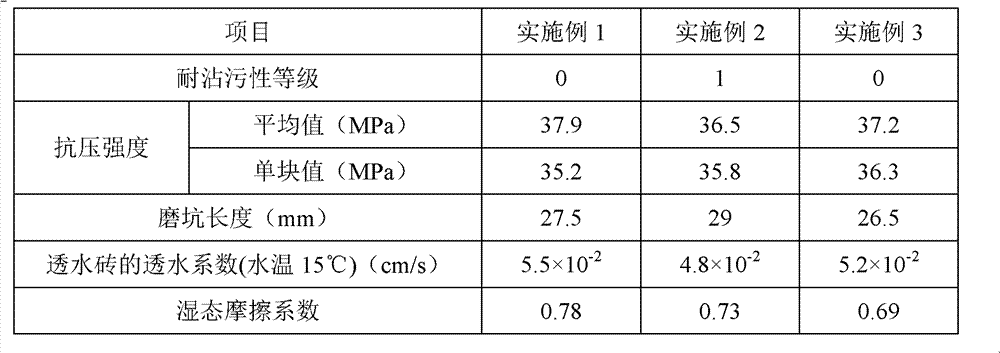

Embodiment 1

[0060] This embodiment is used to illustrate the preparation of the permeable brick provided by the present invention.

[0061] 100 grams of quartz sand with a particle diameter of 0.1-0.25 mm, 4.6 grams of hydrogenated bisphenol A epoxy resin (purchased from Wuhan Shizishan Paint Factory), 1.4 grams of aliphatic polyamine curing agent (purchased from Yuanhong Applied Materials Co., Ltd., model is H-3528), 0.12 g of γ-glycidyl etheroxypropoxypropyl trimethoxysilane (purchased from Beijing Shenda Fine Chemical Co., Ltd., model is A-187), After mixing 0.012g of light stabilizer UV-320, 0.006g of antioxidant 1010, 1g of perlite powder and 3g of alcohol, fill it into the cavity of the mold to form the main body of the permeable brick. The bottom surface of the cavity is inlaid with stones with a sphericity of 0.85 and a diameter of 5-7mm. The height of the stones on the bottom surface of the cavity is 4-8mm. The distance between the center points of two adjacent stones in the same...

Embodiment 2

[0064] This embodiment is used to illustrate the preparation of the permeable brick provided by the present invention.

[0065] 100 grams of quartz sand with a particle diameter of 0.2-0.45 mm, 4.6 grams of hydrogenated bisphenol A epoxy resin (purchased from Wuhan Shizishan Paint Factory), 1.4 grams of aliphatic polyamine curing agent (purchased from Yuanhong Applied Materials Co., Ltd., model is H-3528), 0.12 g of γ-glycidyl etheroxypropoxypropyl trimethoxysilane (purchased from Beijing Shenda Fine Chemical Co., Ltd., model is A-187), After mixing 0.012g of light stabilizer UV-320, 0.006g of antioxidant 1010, 1g of perlite powder and 3g of alcohol, fill it into the cavity of the mold to form the main body of the permeable brick. The bottom surface of the cavity is inlaid with stones with a sphericity of 0.85 and a diameter of 5-7mm. The height of the stones on the bottom surface of the cavity is 4-8mm. The distance between the center points of two adjacent stones in the same...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com