A construction method of prefabricated steel-frp composite corrugated plate tunnel bottom support structure

A technology of support structure and construction method, applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve problems such as low elastic modulus, high price, and limited application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and examples.

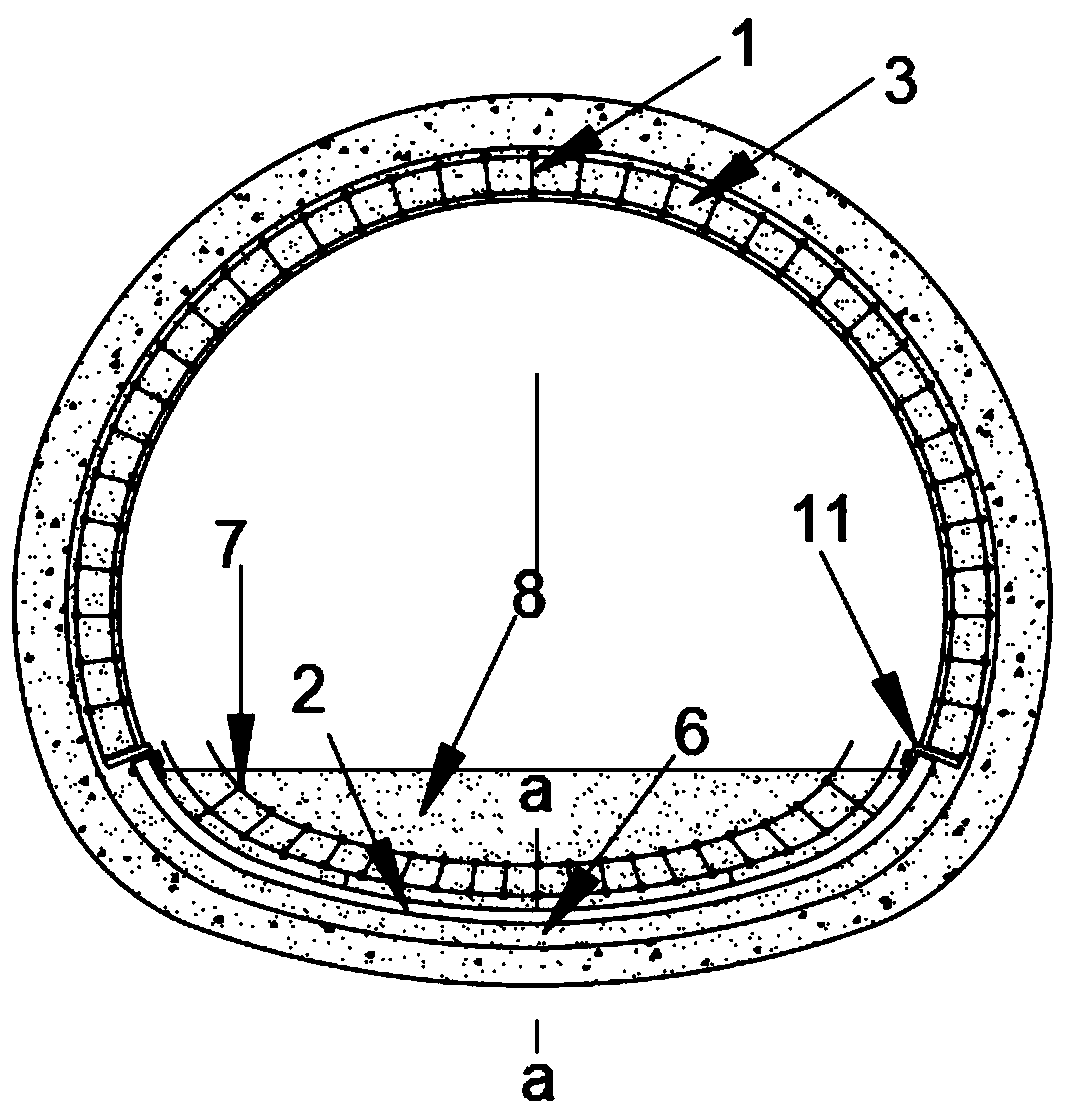

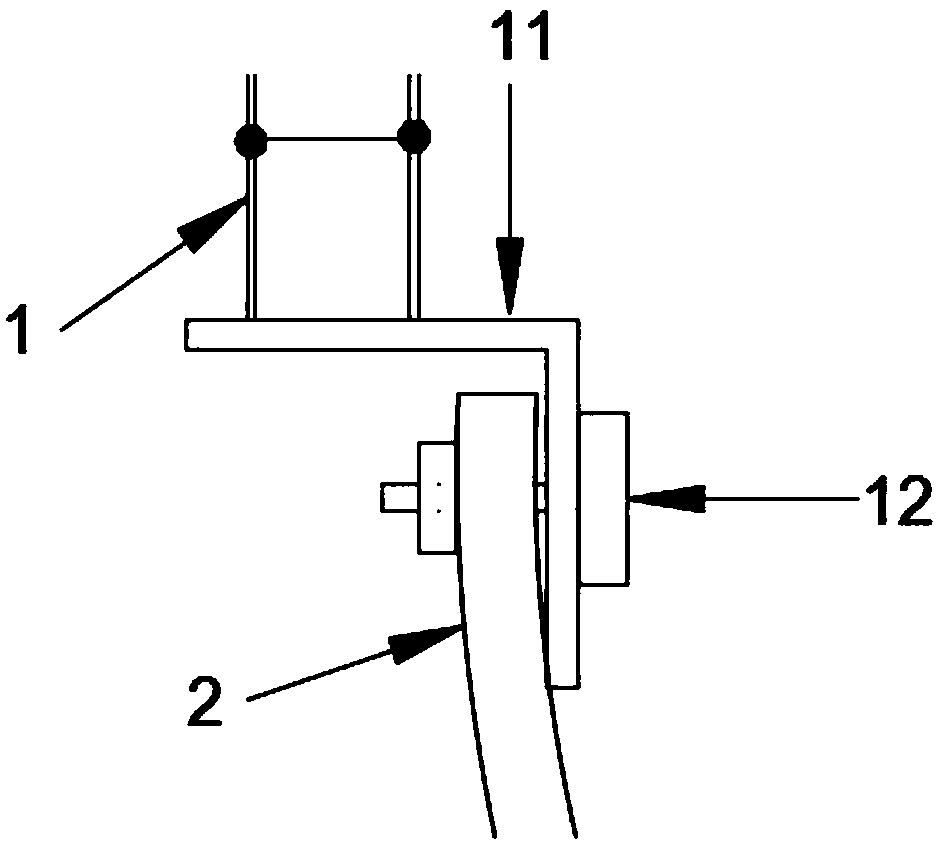

[0031] like figure 1 As shown in Figure 1, this example provides a construction method for the integral support structure at the bottom of a prefabricated tunnel. In the entire primary lining structure, the top and both sides of the primary lining are in the form of a steel grid 1 . After the excavation of the surrounding rock on the upper part of the tunnel, the steel bar grid 1 is applied and the concrete 3 is sprayed for curing.

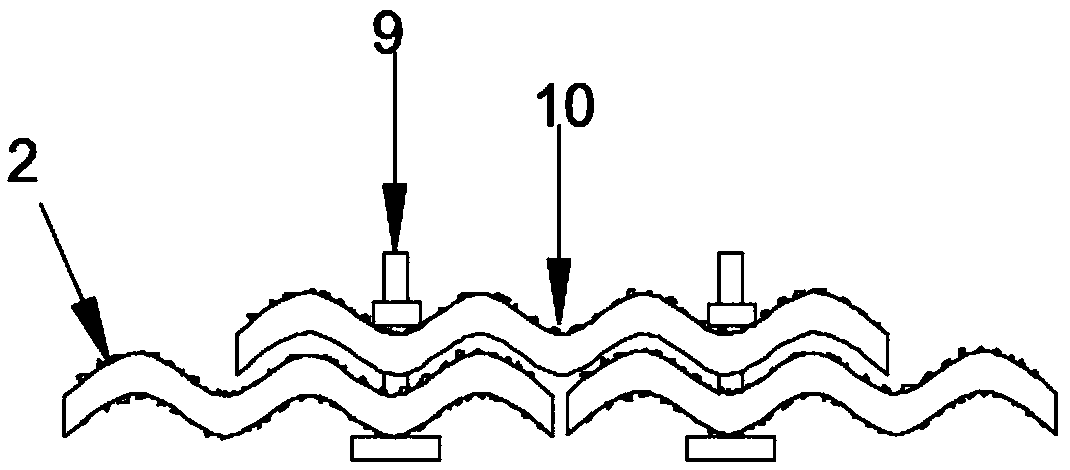

[0032] Step-up method construction, after the excavation of the bottom tunnel is completed, the steel-FRP composite corrugated plate 2 is arranged at the predetermined position, the connection of the bottom steel-FRP composite corrugated plate 2 is completed, and the steel-FRP composite corrugated plate is poured between the steel-FRP composite corrugated plate and the surrounding rock Concrete 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com