Rolling machine assistant maintenance device for large ring processing

A technology of a rolling machine and a ring piece, which is applied in the field of auxiliary maintenance device of a rolling machine for the processing of large-scale ring pieces, can solve the problems that the ring piece cannot meet the technological requirements, affect the surface quality of the rolling ring, and cannot record the position and size of the mold. The effect of convenient processing and convenient folding and shrinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

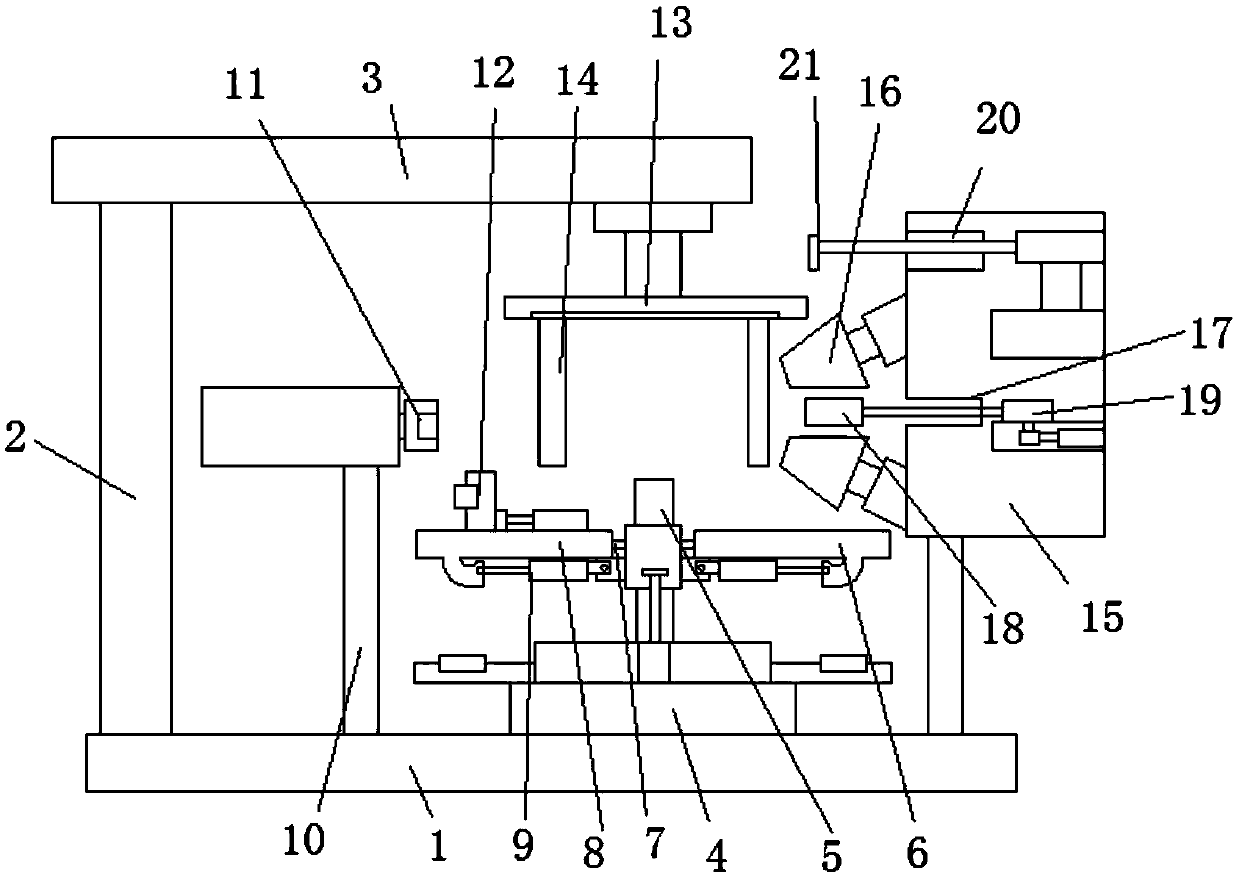

[0010] Referring to the drawings, an auxiliary maintenance device for a roller compactor for processing large-scale ring parts includes a base 1, on which a column 2 is provided, and a cross beam 3 is provided on the top of the column 2, and the base 1 is provided with Support seat 4, said support seat 4 is provided with a guide column 5, the side wall of the guide column 5 is sleeved with a workbench 6, the workbench 6 is provided with a guide rod 7, and the guide rod 7 slides on A telescopic plate 8 is installed, and the lower surface of the telescopic plate 8 can be moved left and right through the control of an air cylinder 9. A support frame 10 is provided on one side of the worktable 6, and the support frame 10 is provided with an extrusion die roller 11, A worktable on one side of the extrusion die 11 is provided with a squeeze roller 12, the squeeze roller 12 is controlled and connected by an air cylinder, and a heating frame 13 is connected to the lower surface of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com