A kind of streptomyces thermoviolet chitinase and its preparation method and application

A technology for chitinase and Streptomyces violaceum, which is applied in the field of chitinase, can solve the problems of increased production cost of chitosan oligosaccharide, large amount of enzyme used, etc., and achieves the effects of improved efficiency and efficient secretion and expression

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

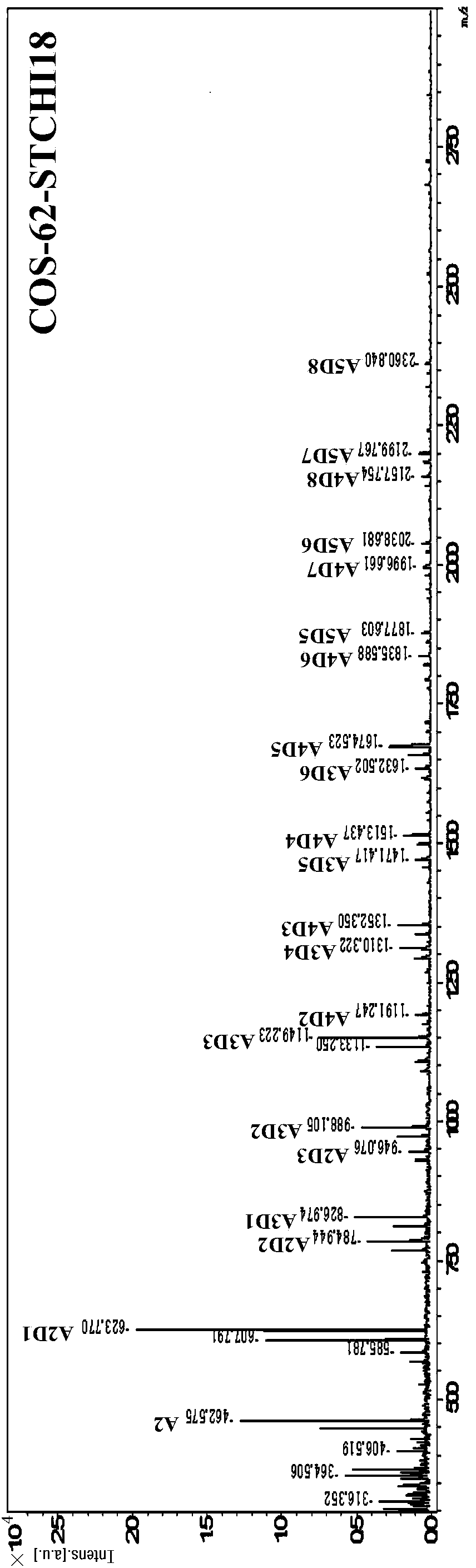

[0030] Example 1 Codon optimization and total gene synthesis of chitinase gene

[0031] On the premise of not changing the amino acid sequence, the chitinase (GH18 family) of Streptomyces thermopurpurindae (GH18 family) was artificially designed using the preferred codon of Pichia pastoris (as shown in the sequence SEQ ID NO.1, GenBank accession number: BAA88835 ) coding gene, see SEQ ID NO.2 for the specific nucleotide sequence. The optimized nucleotide sequence has the highest homology of 77% with the original coding gene sequence (as shown in sequence SEQ ID NO.3, GenBank accession number: AB016844.1). The optimized gene sequence was entrusted to Sangon for full synthesis, and the synthesized gene sequence was named chitinase gene stchi18.

Embodiment 2

[0032] The expression vector construction of embodiment 2 chitinase gene stchi18

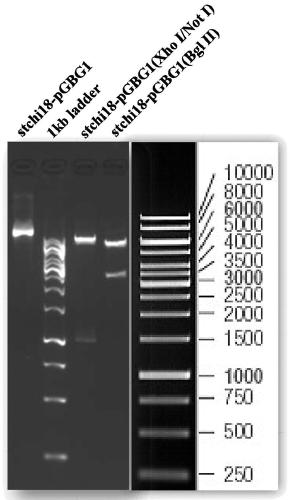

[0033] First, use restriction endonucleases Xho I and Not I to double-enzyme digest the cloning vector containing the chitinase gene stchi18 to obtain the target gene fragment, and use the same endonuclease to double-enzyme digest the expression vector pGBG1, recover large fragments. The two recovered products were connected to obtain a recombinant vector named stchi19-pGBG1. In order to confirm that the target chitinase gene has been constructed into the vector, we used Xho I / Not I and Bgl II to carry out double and single digestion of the recombinant vector respectively, and performed agarose gel electrophoresis on the product. The results are as follows: figure 1 Shown: After double enzyme digestion, the target gene fragment appeared near 1000bp, consistent with the 975bp fragment of stchi18; after Bgl II digestion, two expected fragments appeared, which were the large fragment containing th...

Embodiment 3

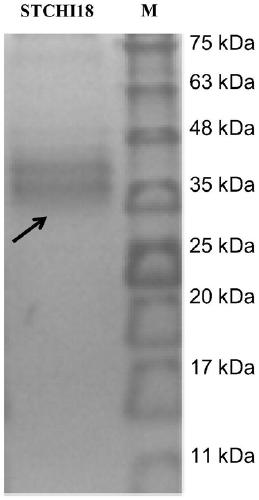

[0034] Example 3 Screening of Chitinase Pichia Pichia Engineering Bacteria and Preparation of Chitinase

[0035] After the obtained recombinant plasmid stchi18-pGBG1 was linearized by the restriction endonuclease BglII, gel electrophoresis was used to separate and excise the nucleotide fragment containing the gene of interest (such as figure 2 shown in the larger fragment), electroporation introduced into Pichia pastoris GS115, and the recombinant obtained by screening on the histidine auxotrophic MD plate was spread on the BMMY agar plate containing colloidal chitosan (0.5%) for cultivation , from which the monoclonal strain with the largest hydrolytic circle was screened out. A single colony of the screened monoclonal strain was inoculated in 200 mL of BMGY medium, cultured at 30° C. and 250 rpm for 48 hours, the supernatant was discarded by centrifugation, and an equal amount of BMMY was added to induce expression. After 24 hours, add methanol to a final concentration of ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap