Method for detecting leakage of cooing walls by using self-made pressurization leakage detector

A stave and leak detection technology, applied in the direction of cooling devices, etc., can solve the problems that affect the blast furnace condition, the long life of the blast furnace, the stave damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

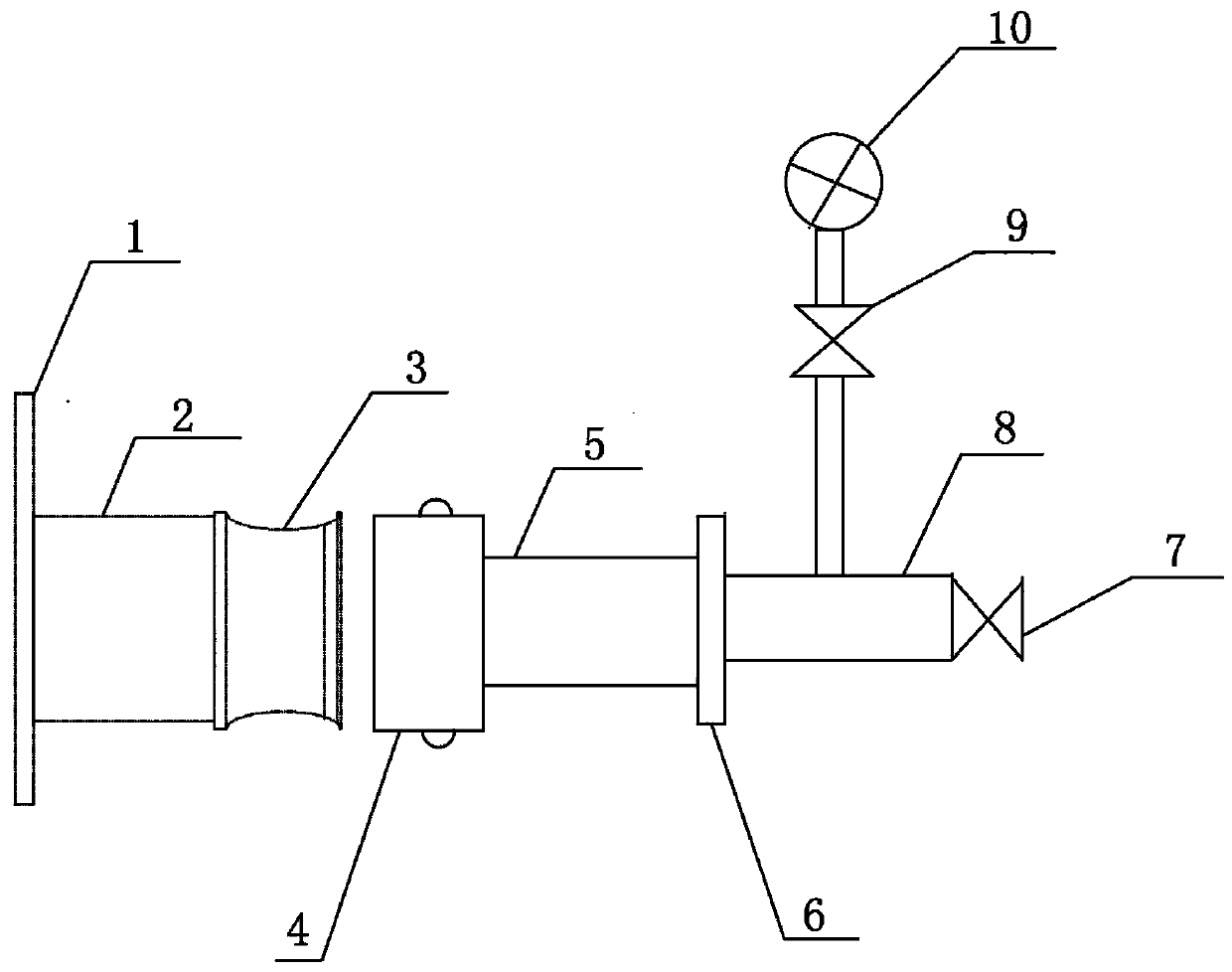

[0009] A method for leak detection of staves using a self-made pressure leak detection device. First, the hard connection of the "U" steel pipes for the inlet and outlet water pipes of the staves between the 10th and 16th staves of the blast furnace is replaced by quick connectors The flexible connection structure is used for connection: that is to install and weld the soft connection pin of the quick joint at the root of the water inlet and outlet respectively, and then use the self-made stave pressure leak detection device to connect with the added and welded quick joint pin, and carry out layer by layer Pressure leak detection, if the leak detection result is intact, use the metal hose quick connector to connect, and continue the normal circulation cooling, if the leak detection result is severely damaged, grouting is carried out to suffocate, and if the damage is small, the industrial water pipe maintenance is carried out; stave pressure leak detection device, such as figu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com