Patents

Literature

42results about How to "Ensure longevity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

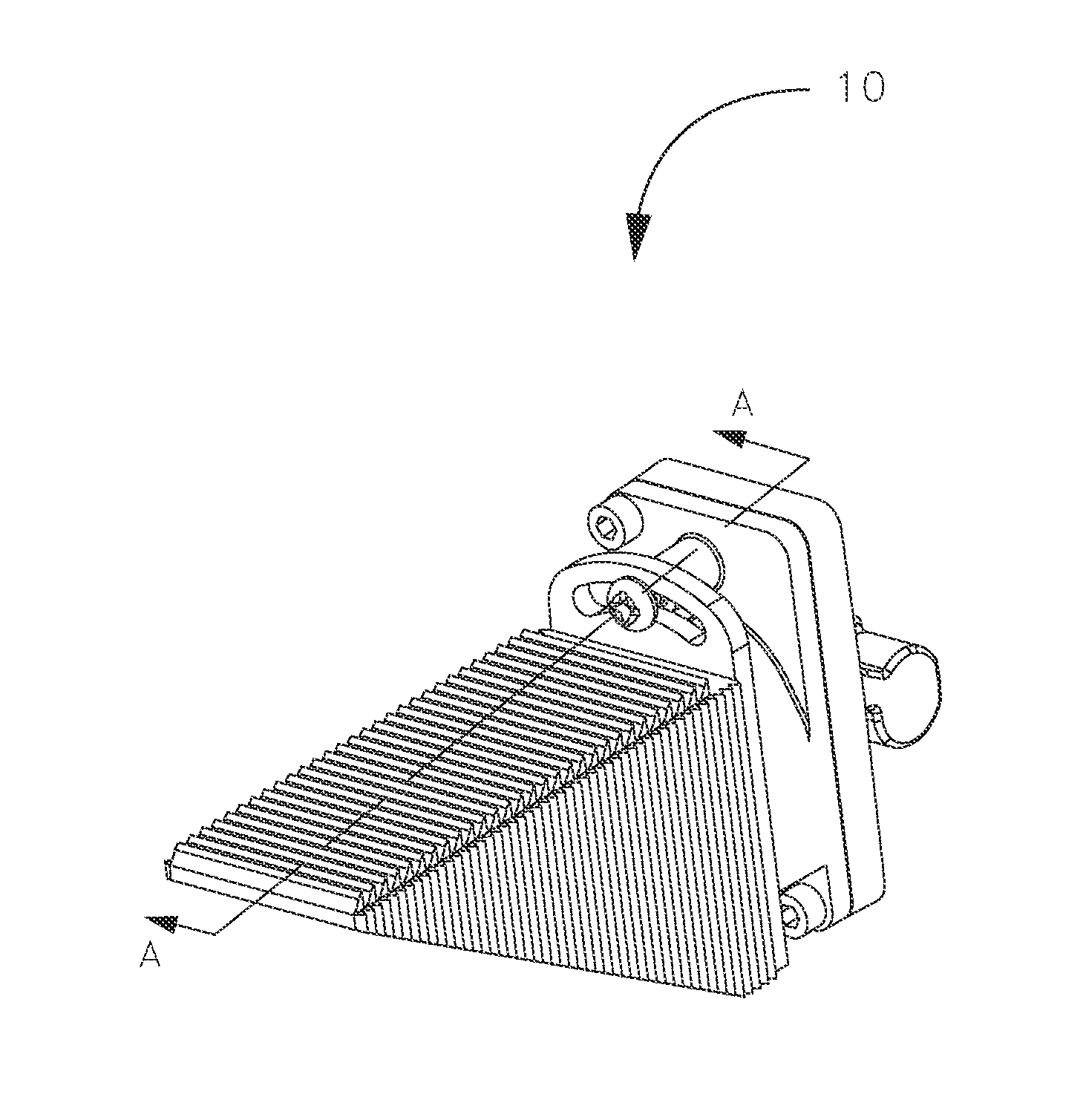

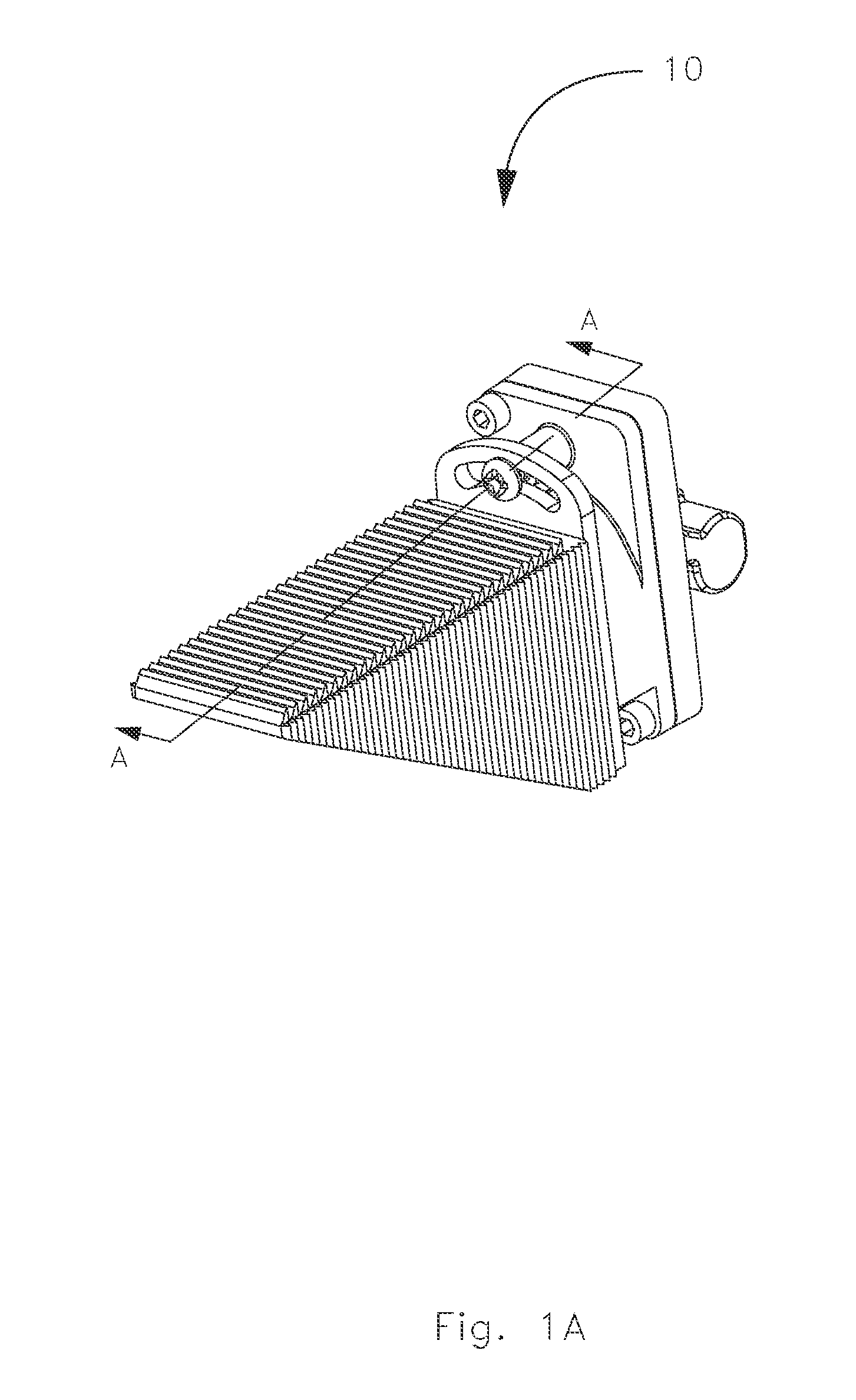

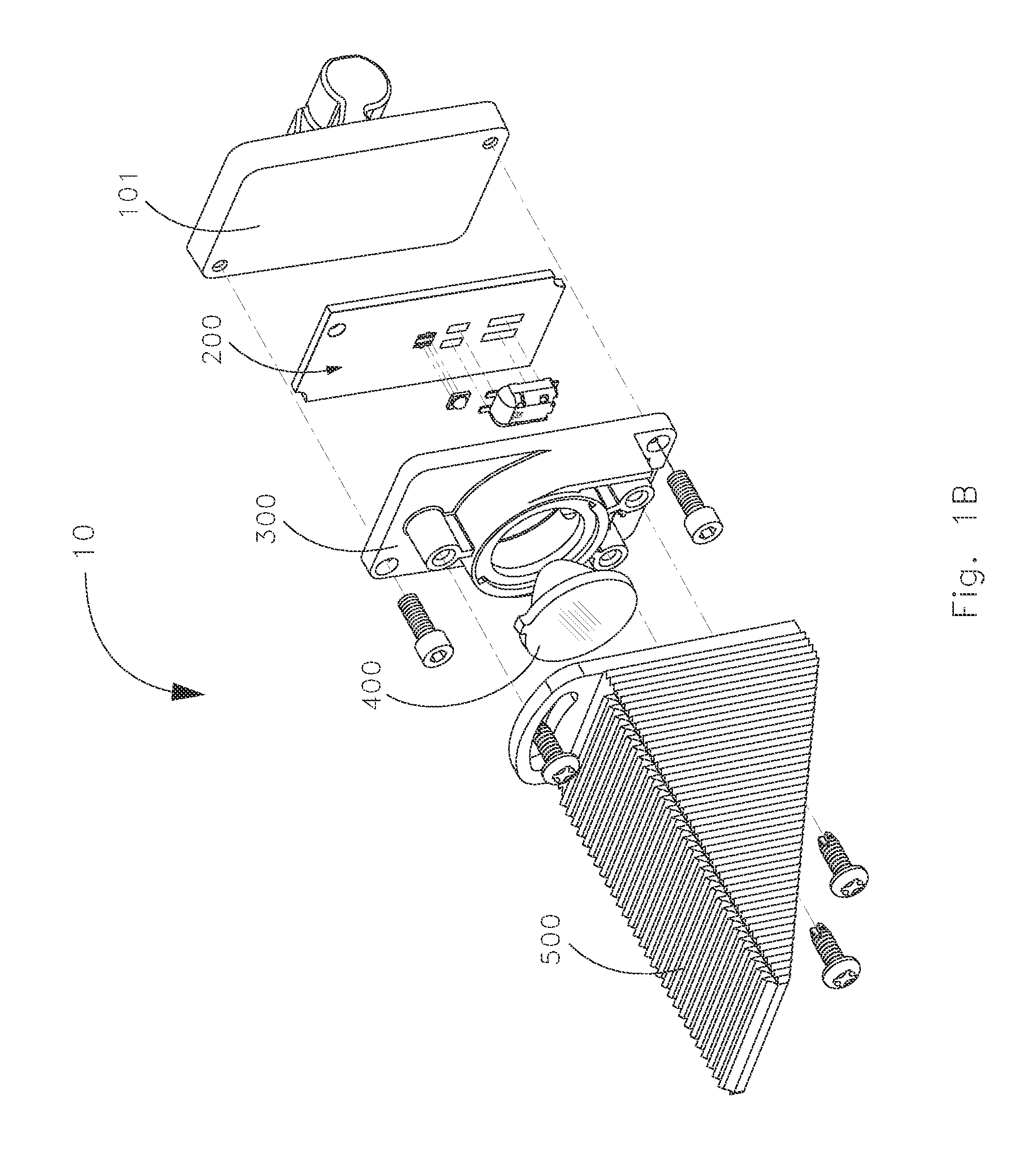

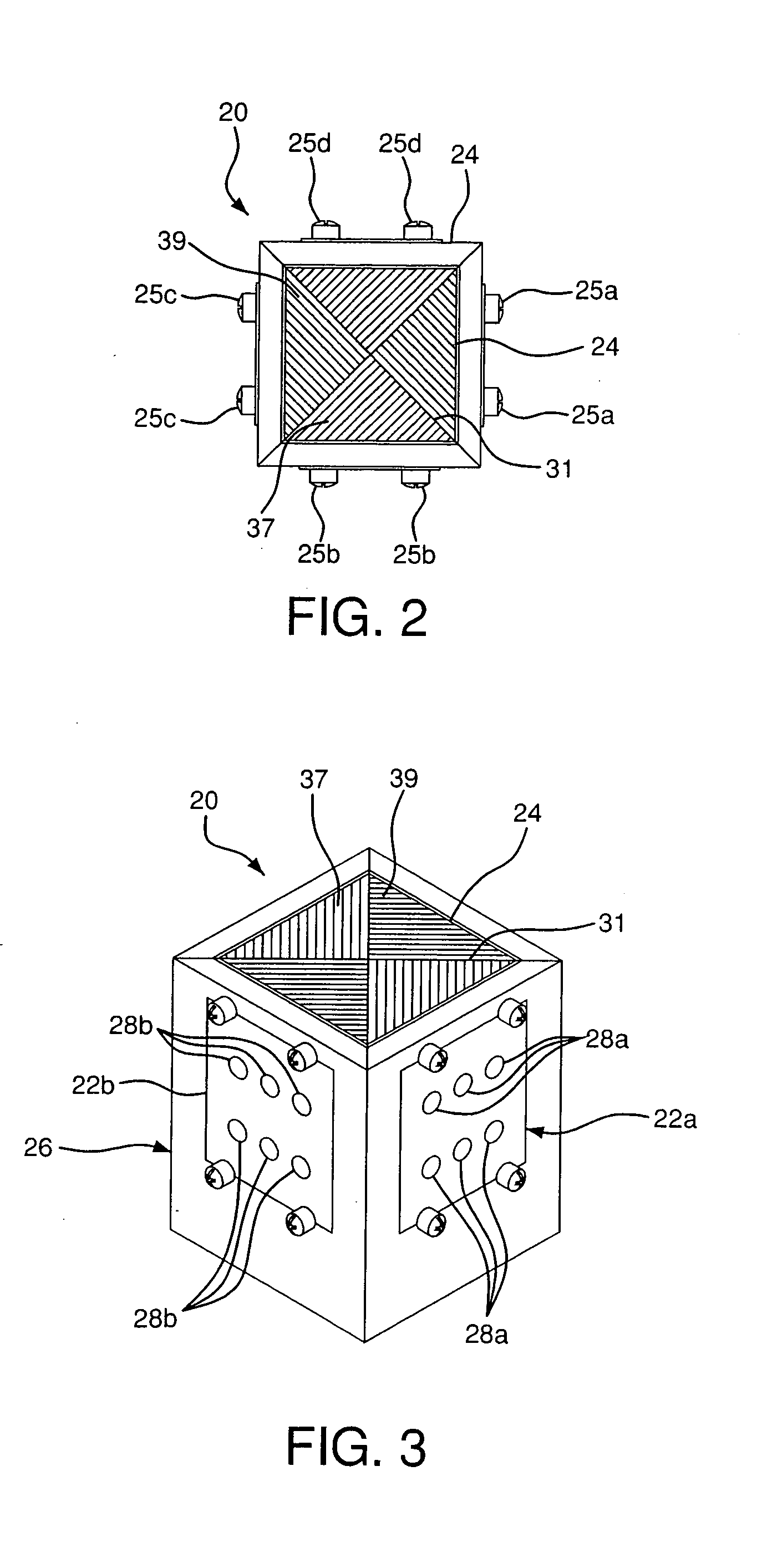

Compact and adjustable LED lighting apparatus, and method and system for operating such long-term

ActiveUS20120217897A1Ensure longevityEfficient designMechanical apparatusPoint-like light sourceConstant lightEngineering

A lighting system is provided whereby long operating life can be reasonably ensured by taking into account requirements of the application, characteristics of the LEDs, characteristics of the fixture containing said LEDs, the desired number of operating hours, and—via developed relationships—taking an iterative approach to supplying power to the LEDs. Through the envisioned compensation methodology and effective luminaire design, a relatively constant light level can be assured for a predetermined number of operating hours (possibly longer); this is true even if operating conditions change, known behavior of LEDs proves untrue over untested period of time, or some other condition occurs which would otherwise cause end-of-life prematurely and prevent the system from meeting the desired number of operating hours.

Owner:MUSCO

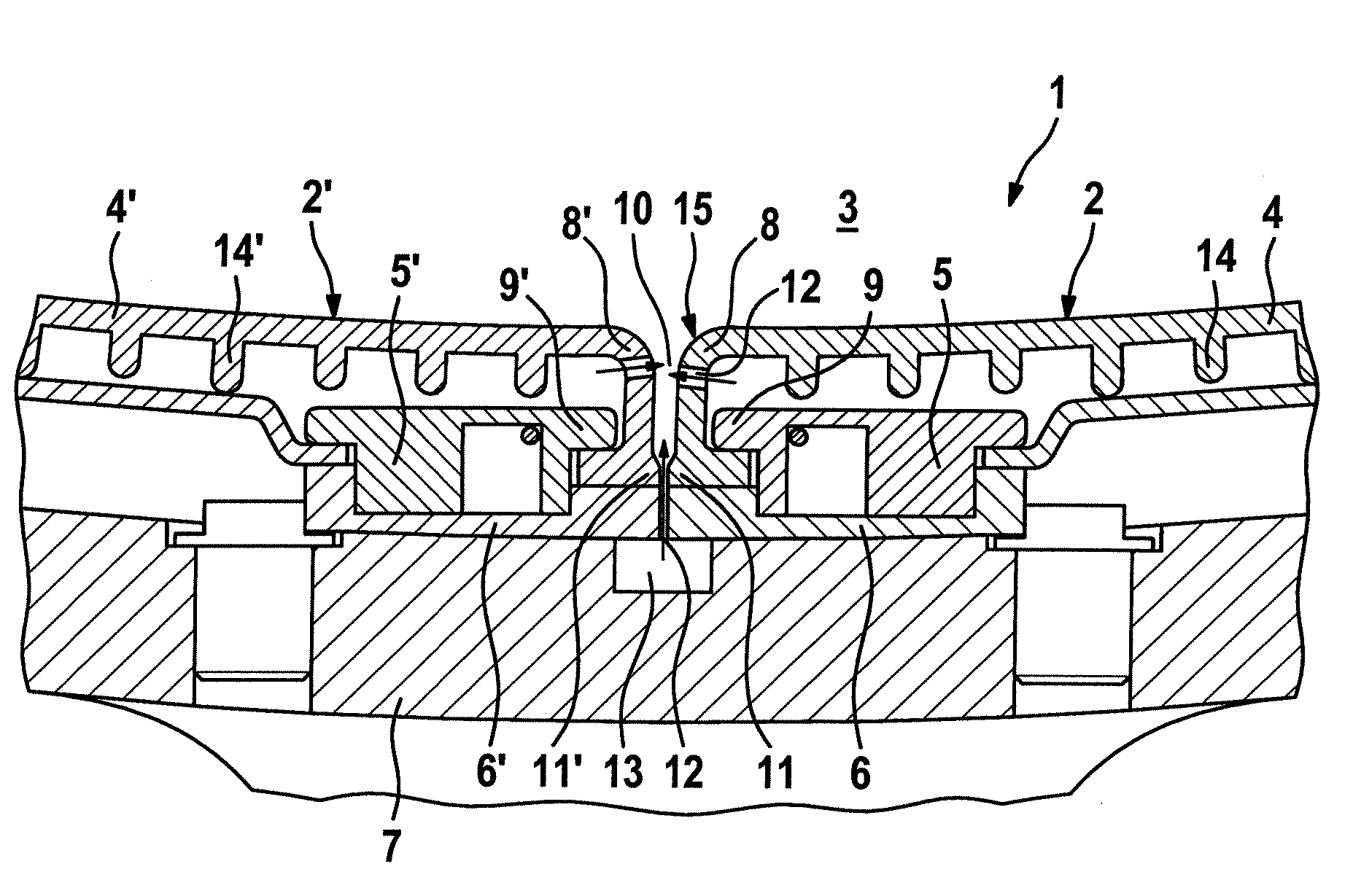

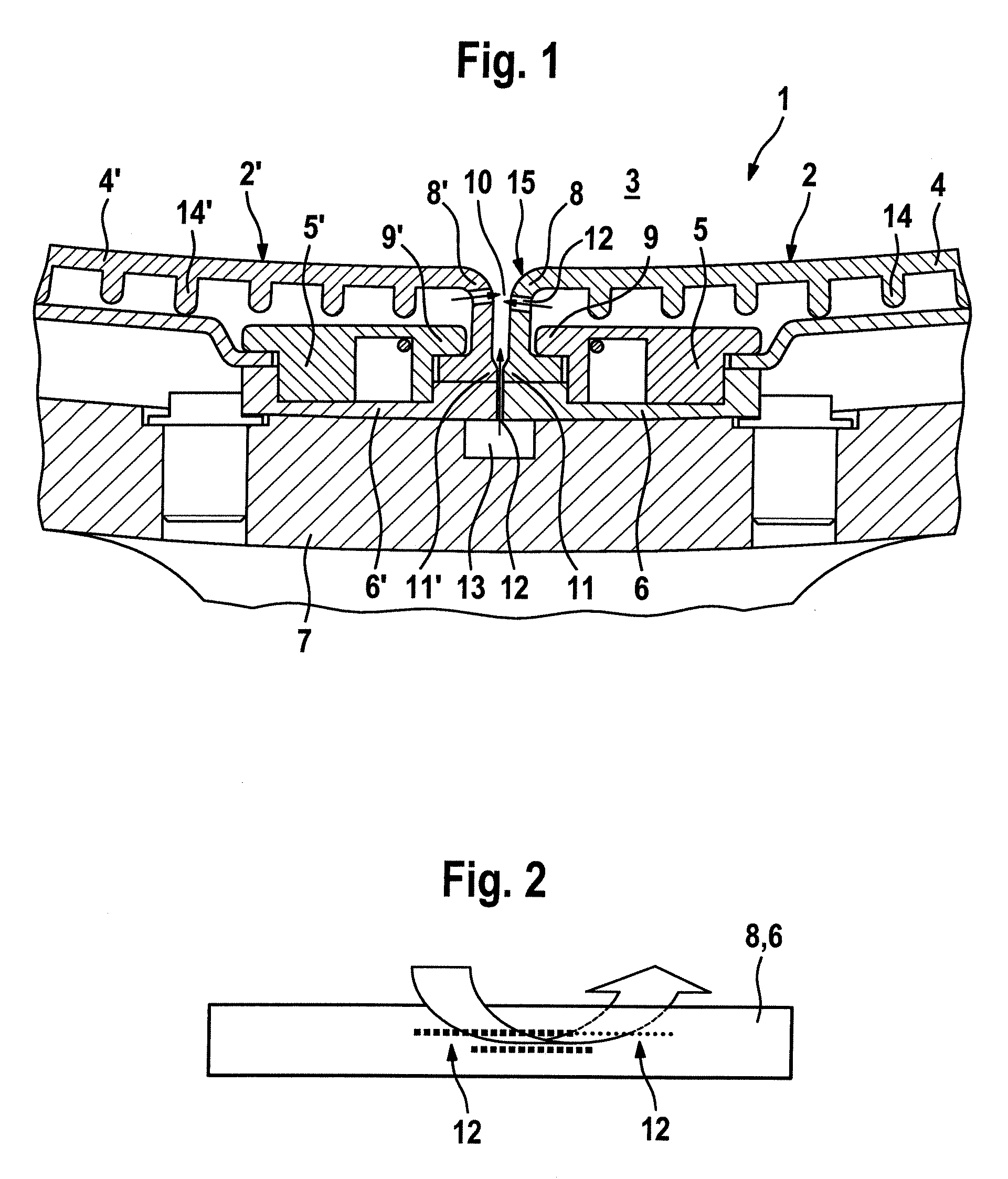

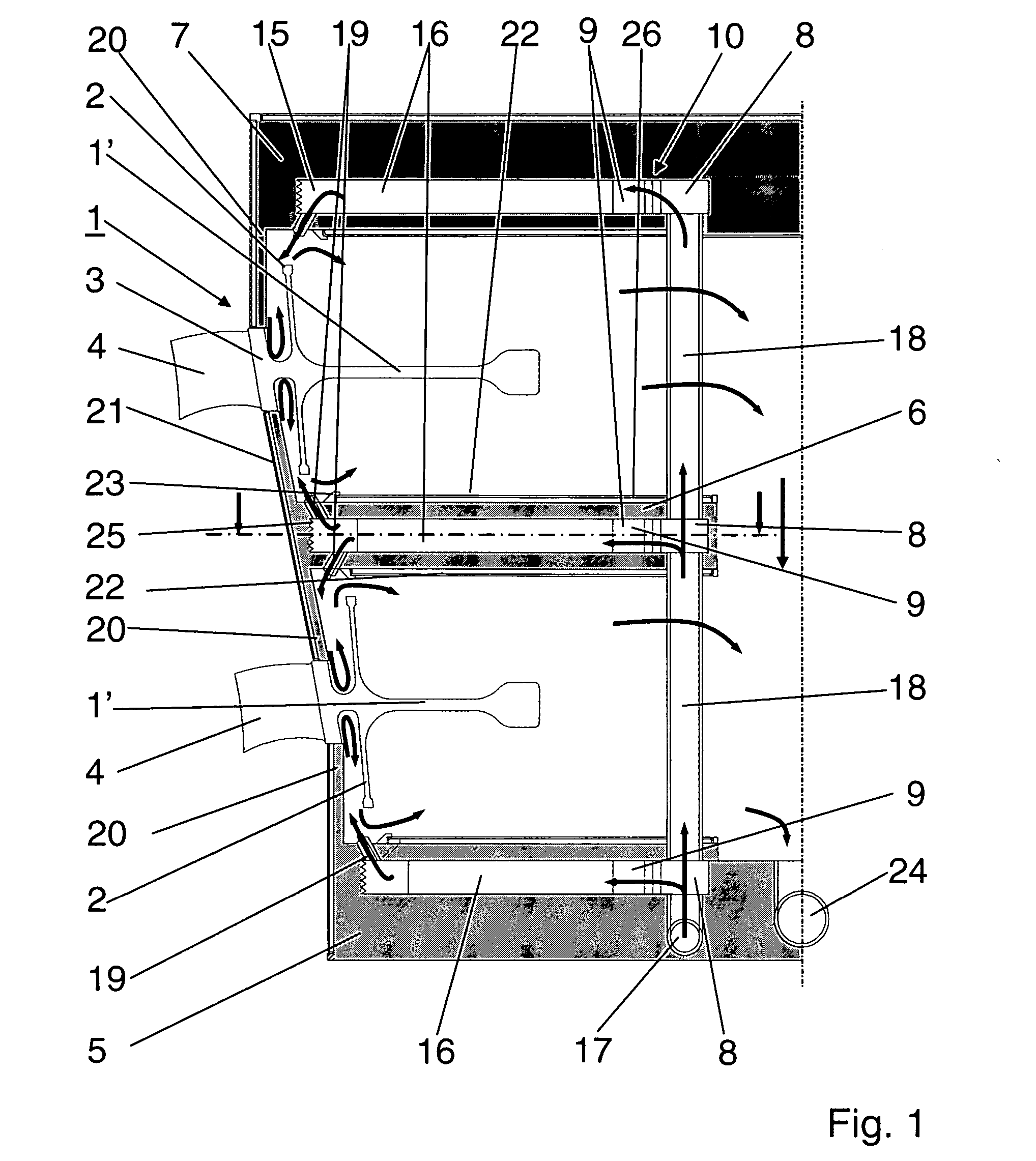

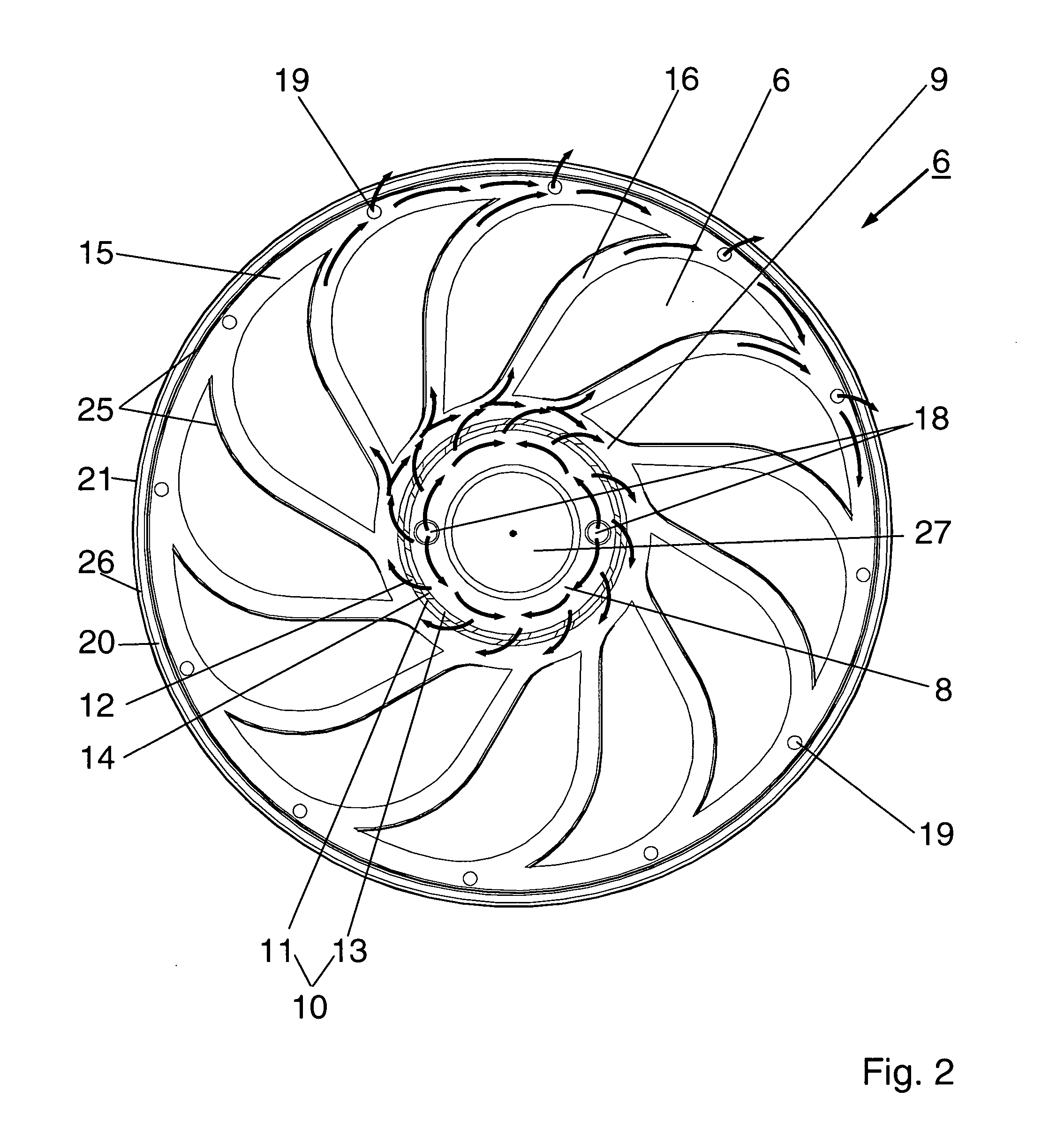

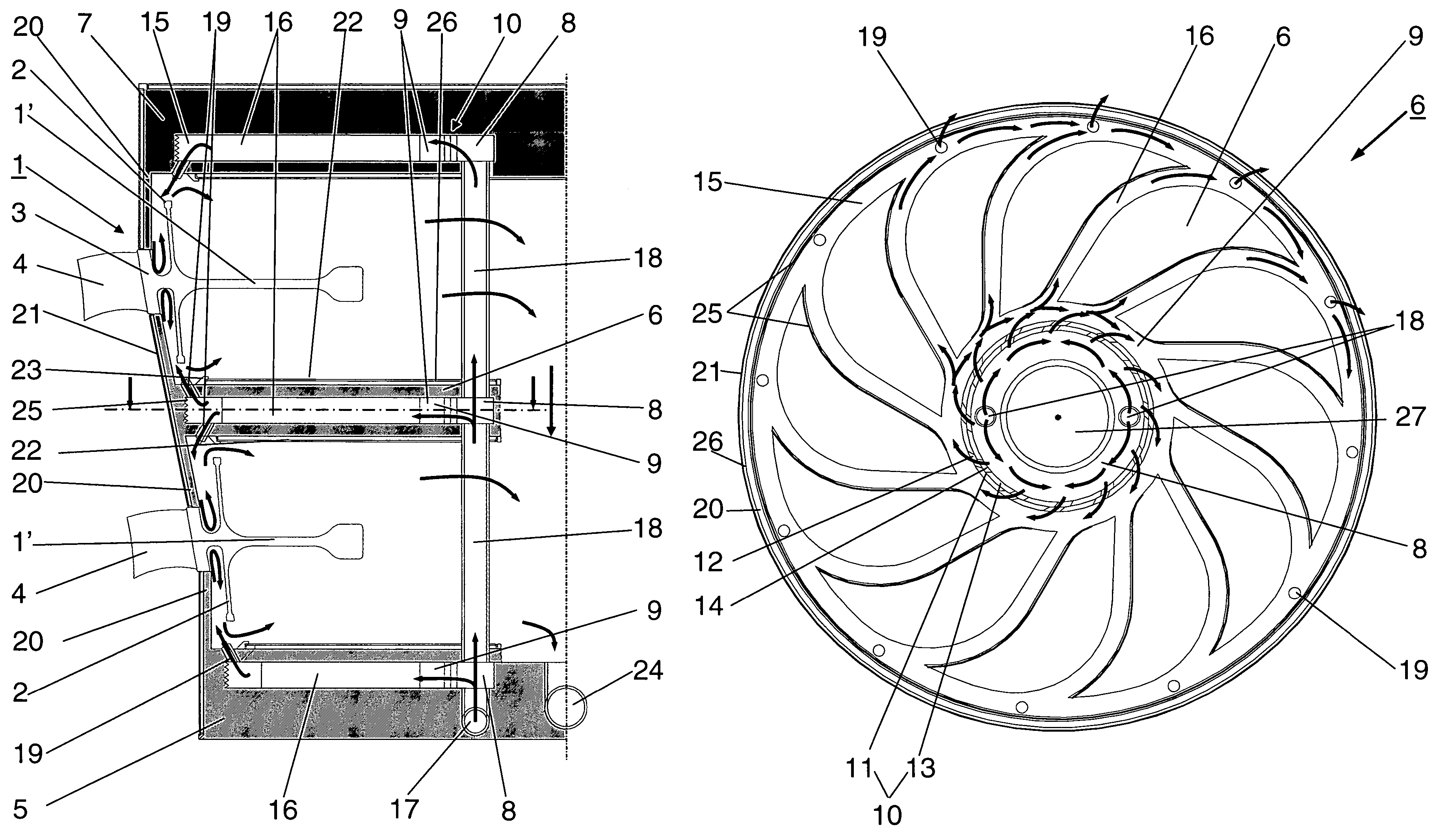

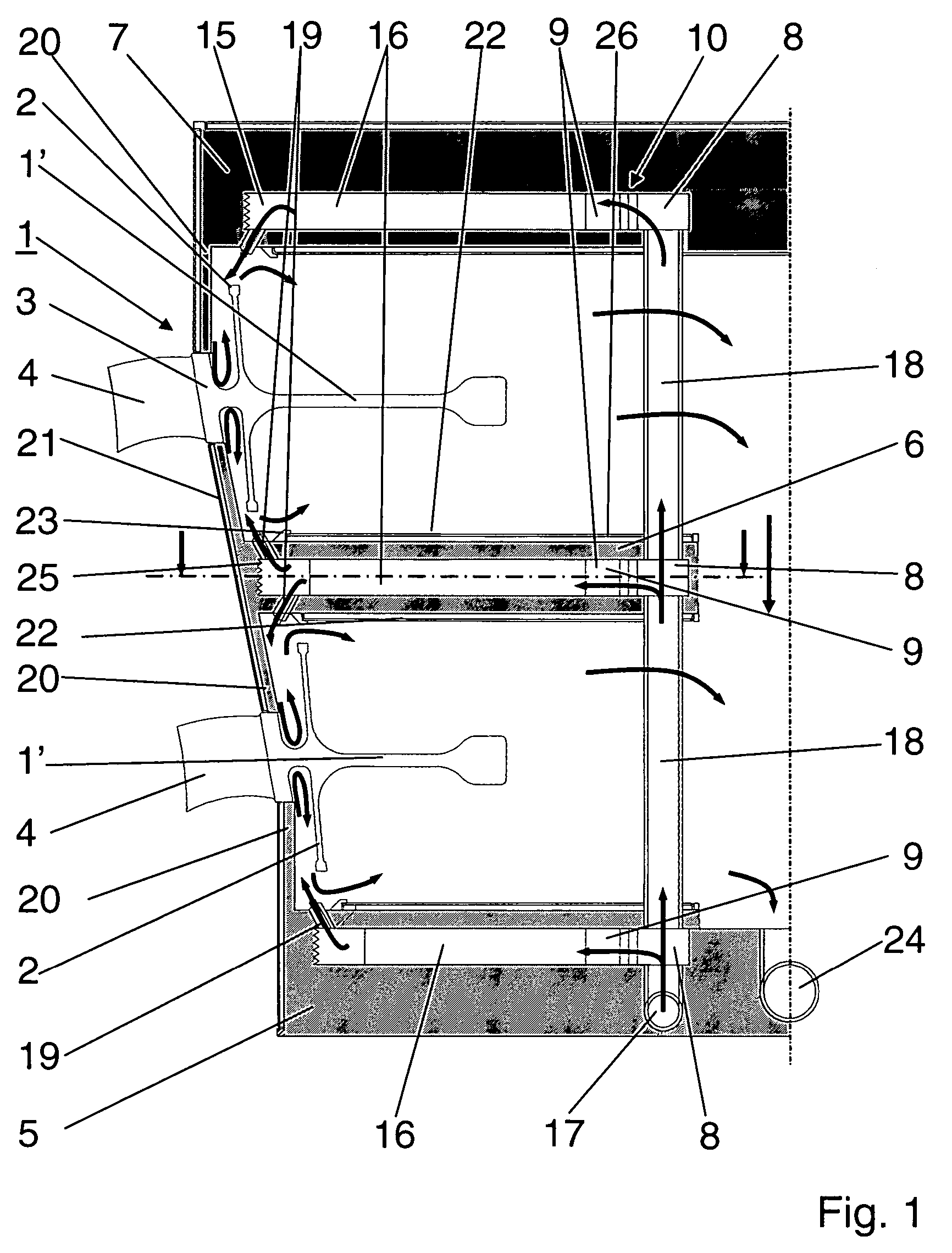

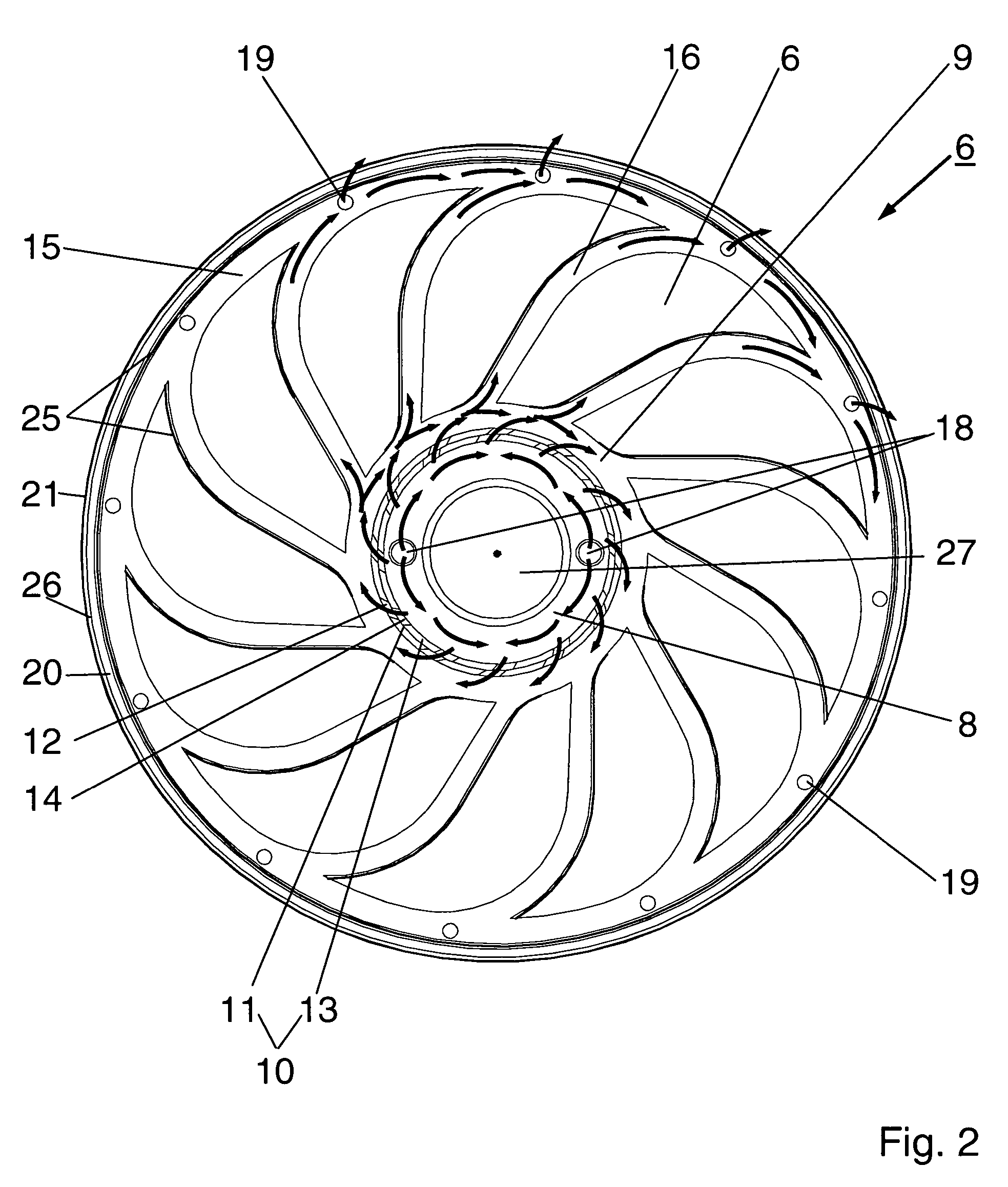

Combustion chamber of a combustion system

InactiveUS20090199837A1Ensure longevityLongevityContinuous combustion chamberDomestic stoves or rangesCombustion systemCombustion chamber

A combustion chamber of a combustion system comprises a combustion space, a support structure, a heat shield, and at least one through-opening. The heat shield has at least two segments, and each segment has an edge region, a gap communicating with the combustion space being formed between edge regions of adjacent segments, and a retaining device. The adjacent segments include a support element disposed in a bottom region of the gap. The retaining device fixes the respective liner element on the support structure via the respective support element. The at least one through-opening communicates with the gap so as to enable a cooling gas to flow through the through-opening. The at least one through-opening is disposed in at least one of the respective edge region and the support element at the bottom region of the gap.

Owner:ANSALDO ENERGIA IP UK LTD

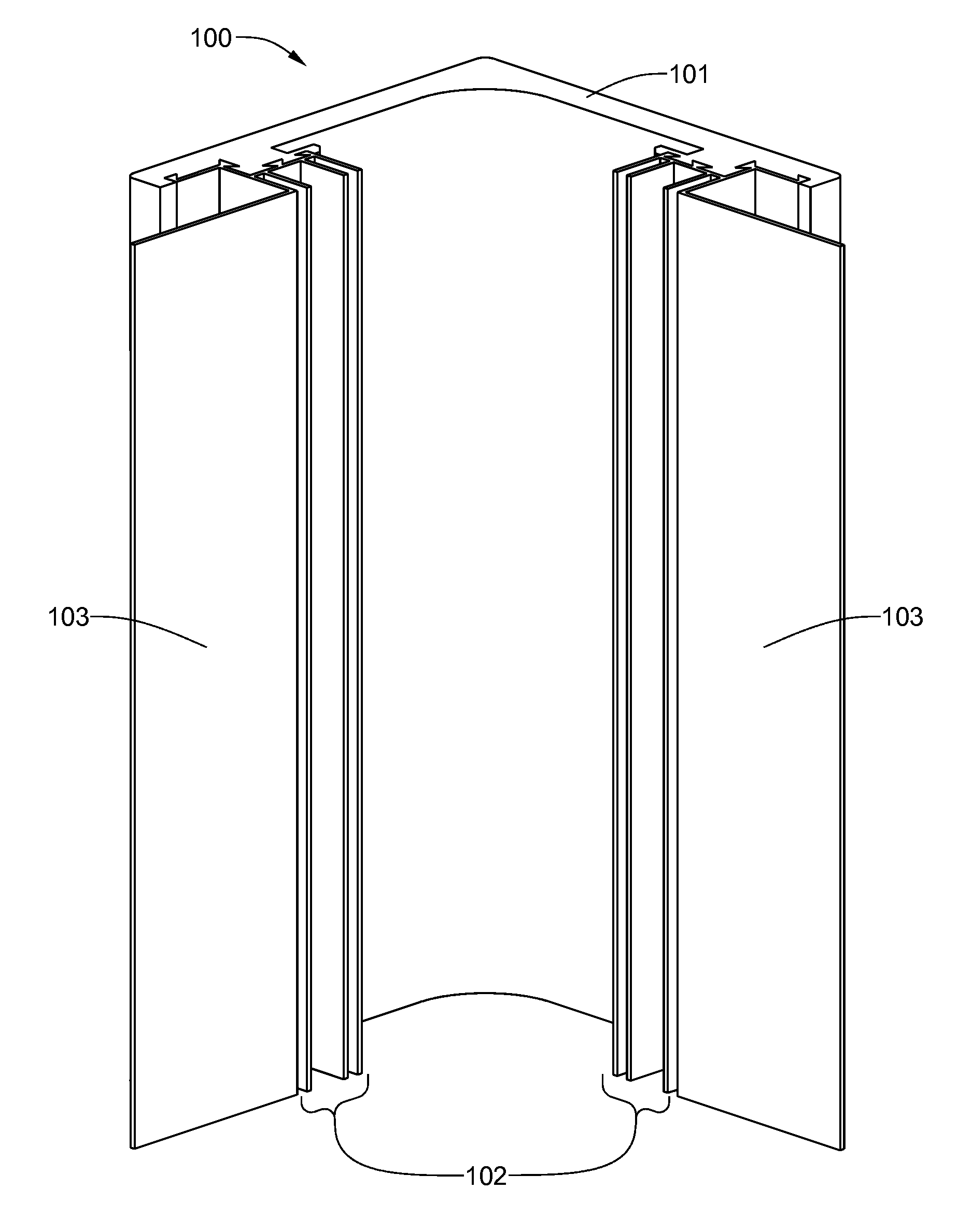

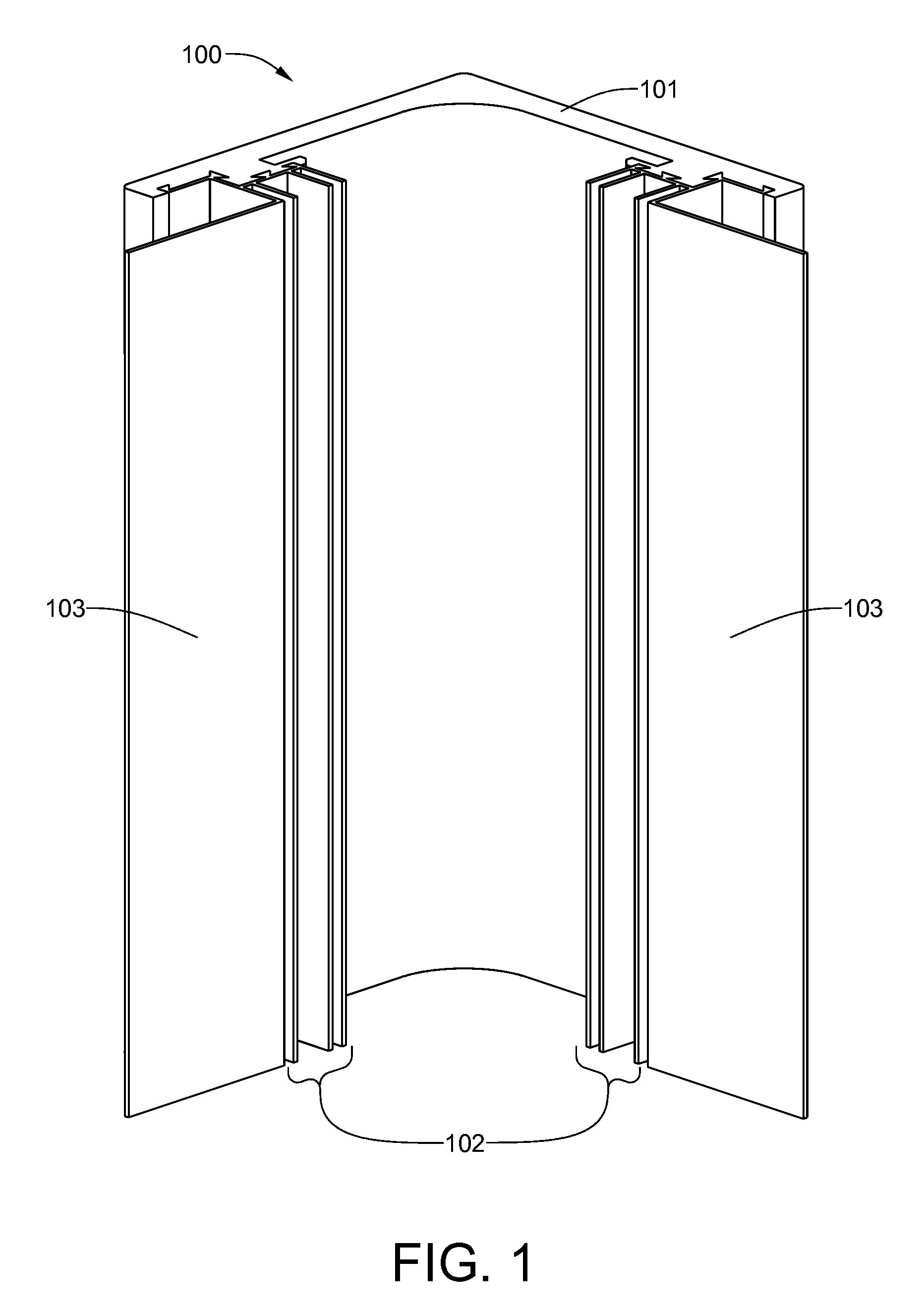

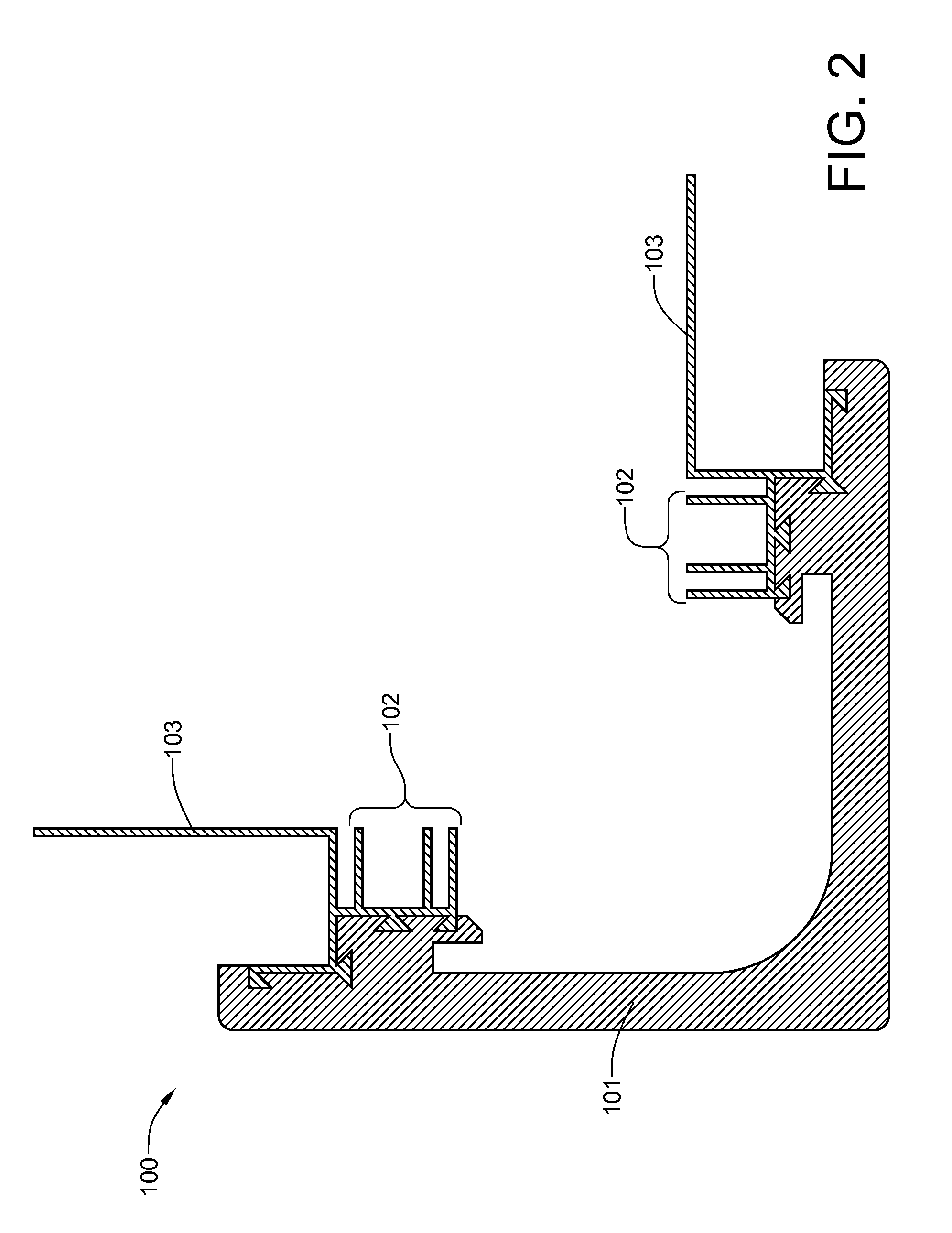

Trim components for lapboard siding that are co-extruded from wood-plastic composites and polyvinyl chloride

ActiveUS20120328823A1Reduce installation costsUse amountCovering/liningsSynthetic resin layered productsPolyvinyl chlorideEngineering

A lapboard siding and trim system is provided in which trim siding components for board-and-batten siding and associated trim components are manufactured using a co-extrusion process, whereby wood / thermoplastic resin composite material and polyvinyl chloride thermoplastic resins are co-extruded through a single die assembly, thereby producing a trim piece having a plastic composite component, that will be visible following installation, fused under heat and pressure to the polyvinyl chloride standoff and attachment fins, that will be hidden following installation. Also provided is a lapboard siding and trim system in which siding components for clapboard siding are manufactured by extruding wood / thermoplastic resin composite material through a die. Associated trim components are manufactured using the co-extrusion process described above. The siding and trim components are completely waterproof, and installation proceeds with almost no face nailing and almost no caulk.

Owner:MONTEER SHAUN ROBERT

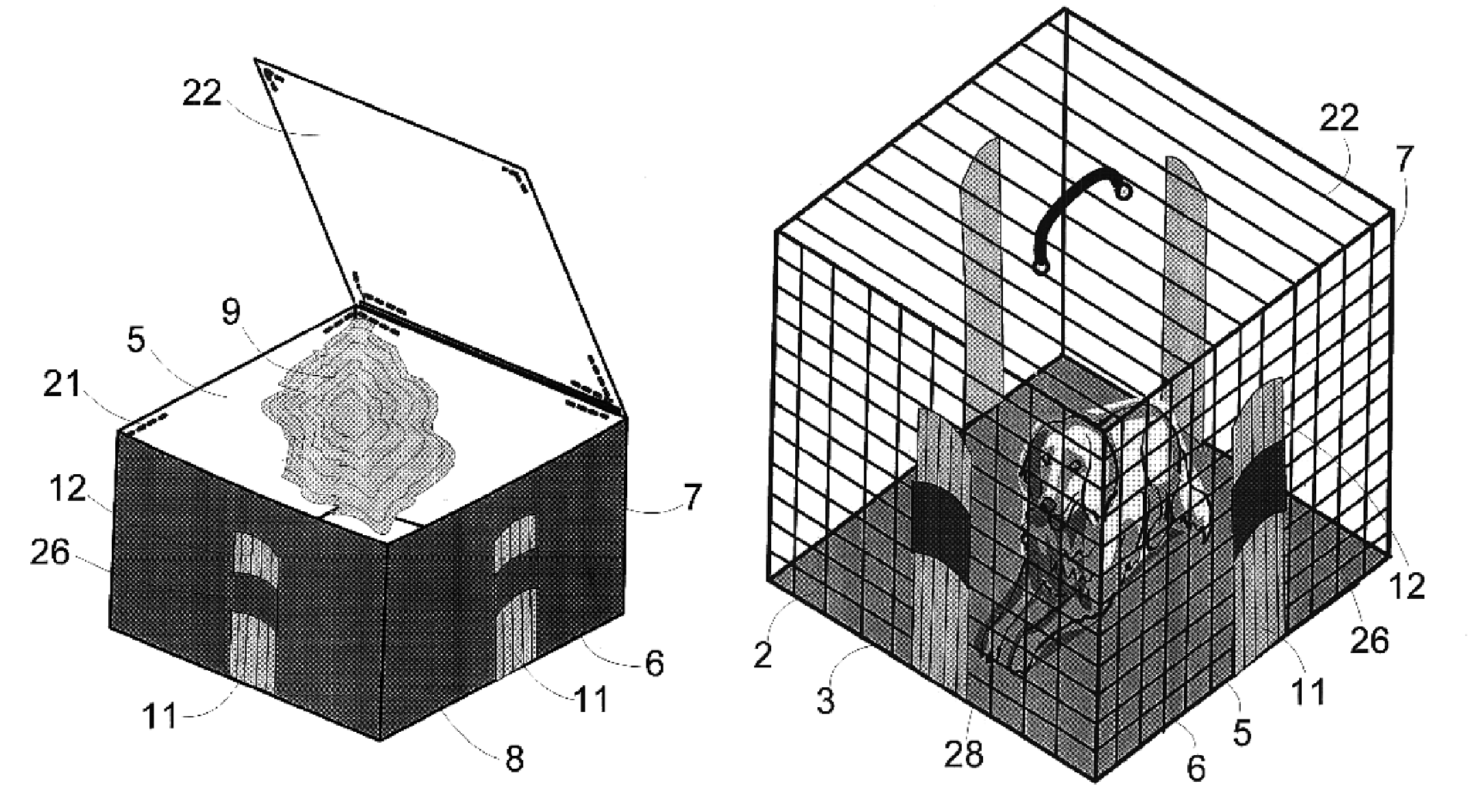

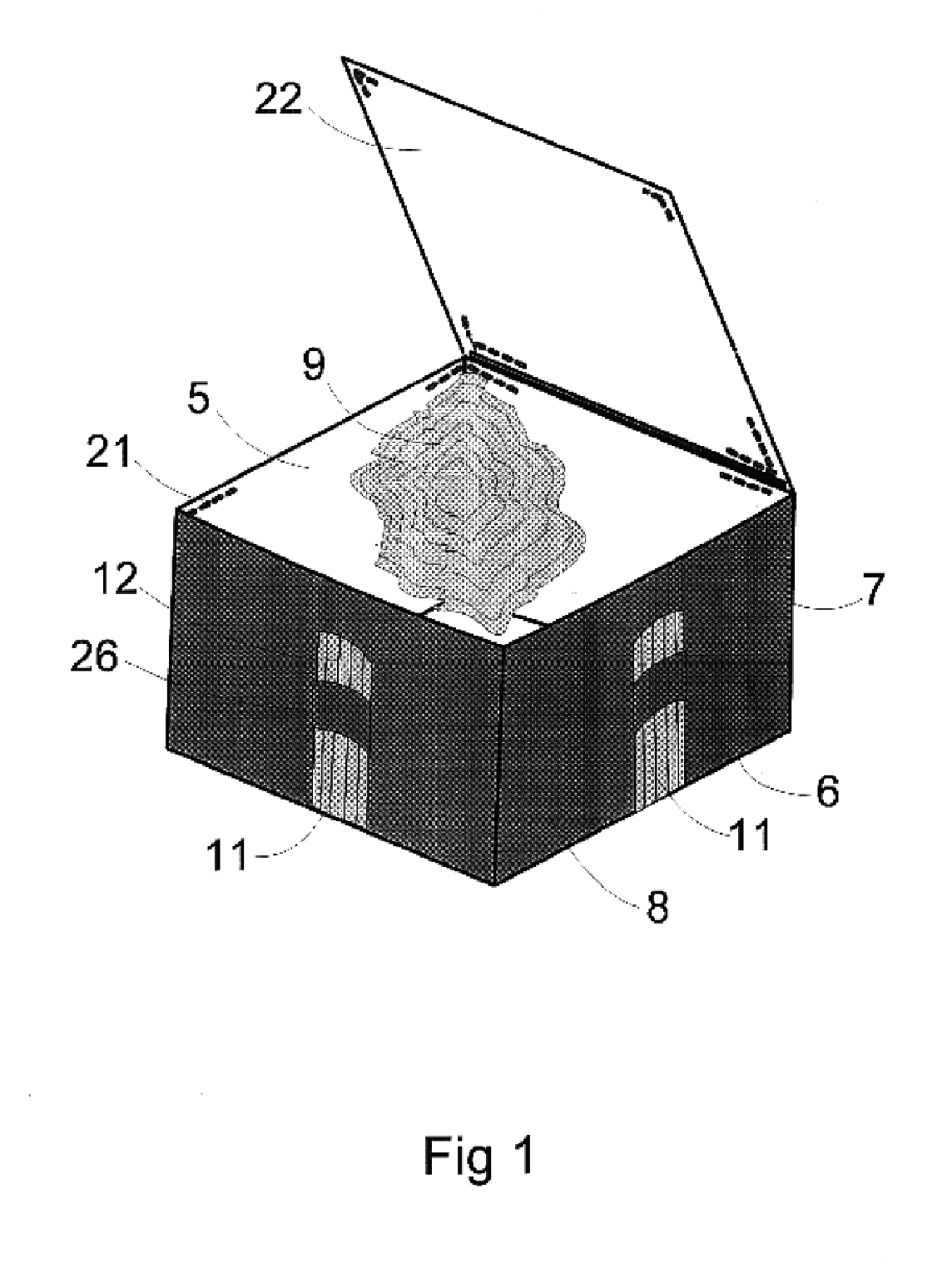

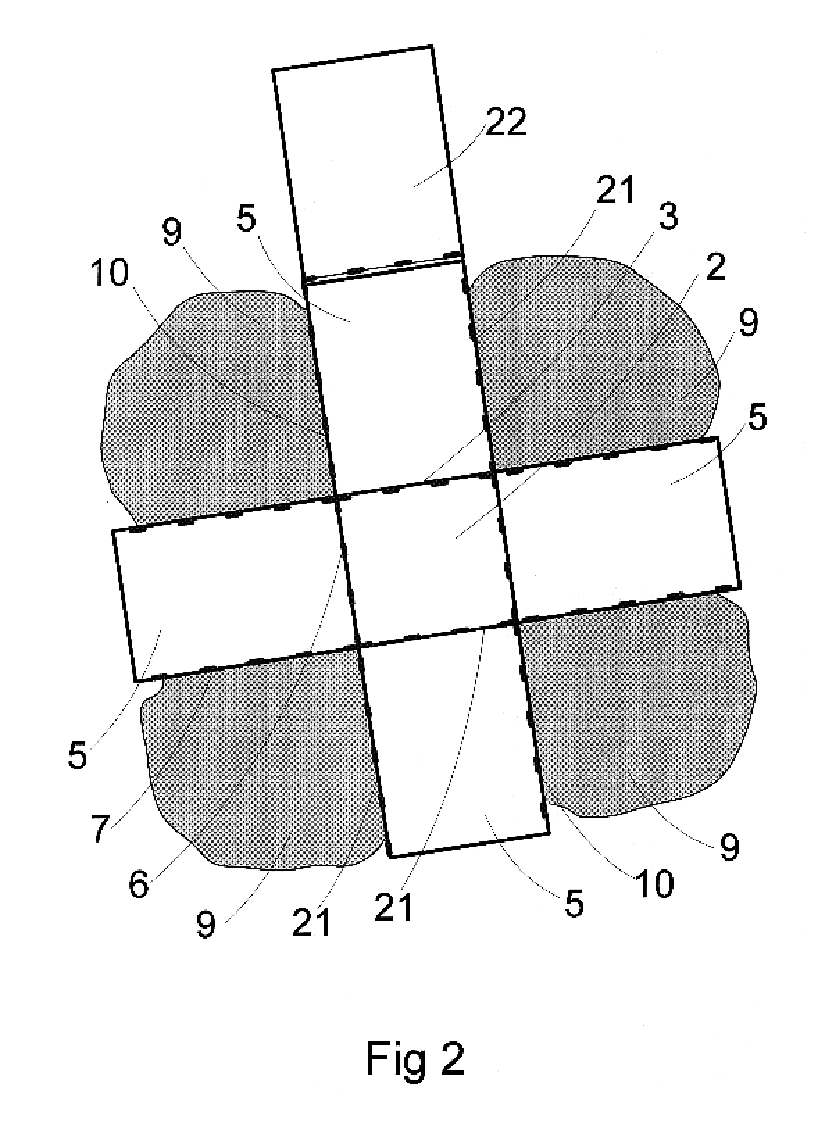

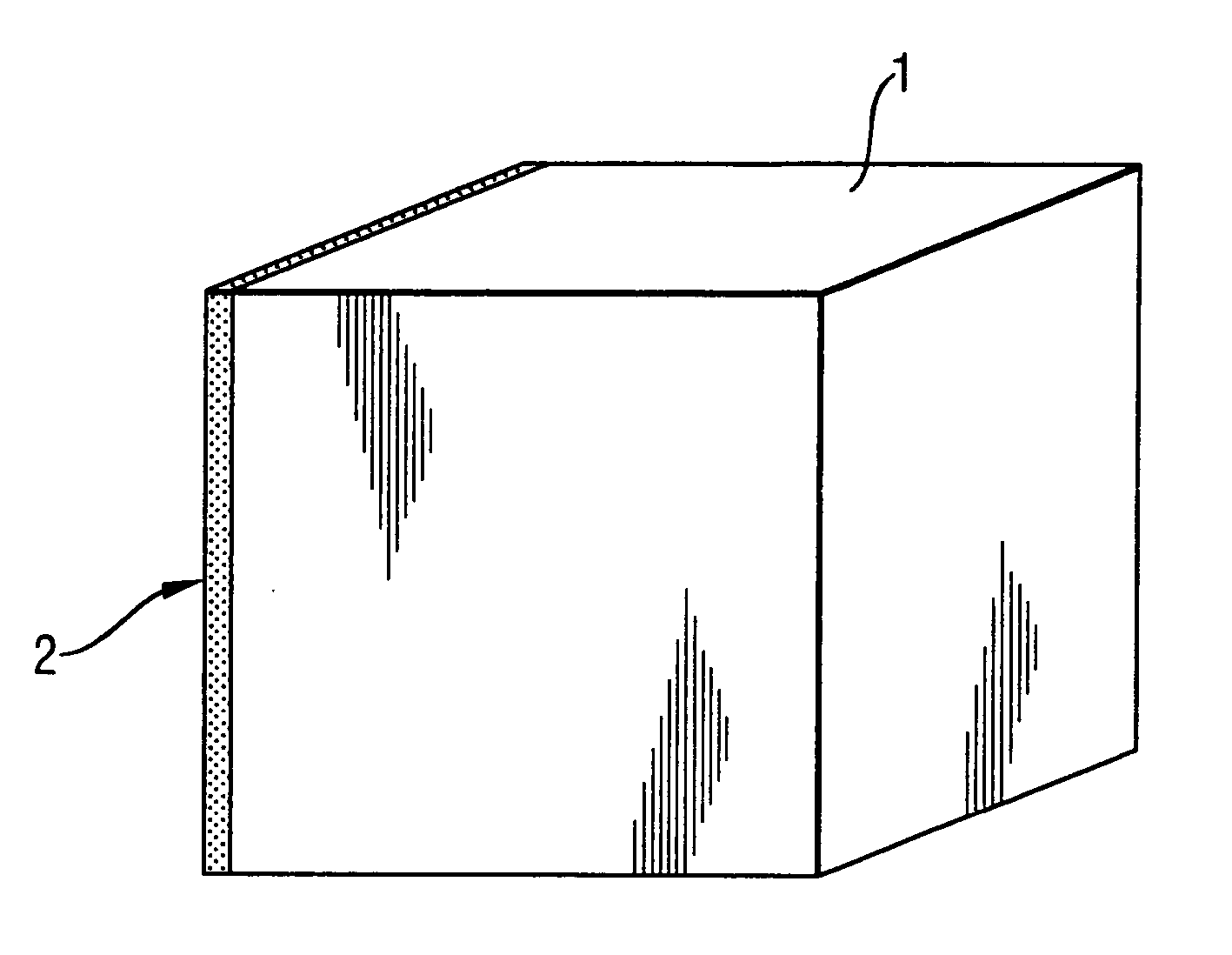

Universal semi-automatic foldable box

InactiveUS6688516B1Easy to transportEasily and quicklyAnimal housingMetal working apparatusSemi automaticEngineering

Owner:USSEN BAKHYTBEK Z

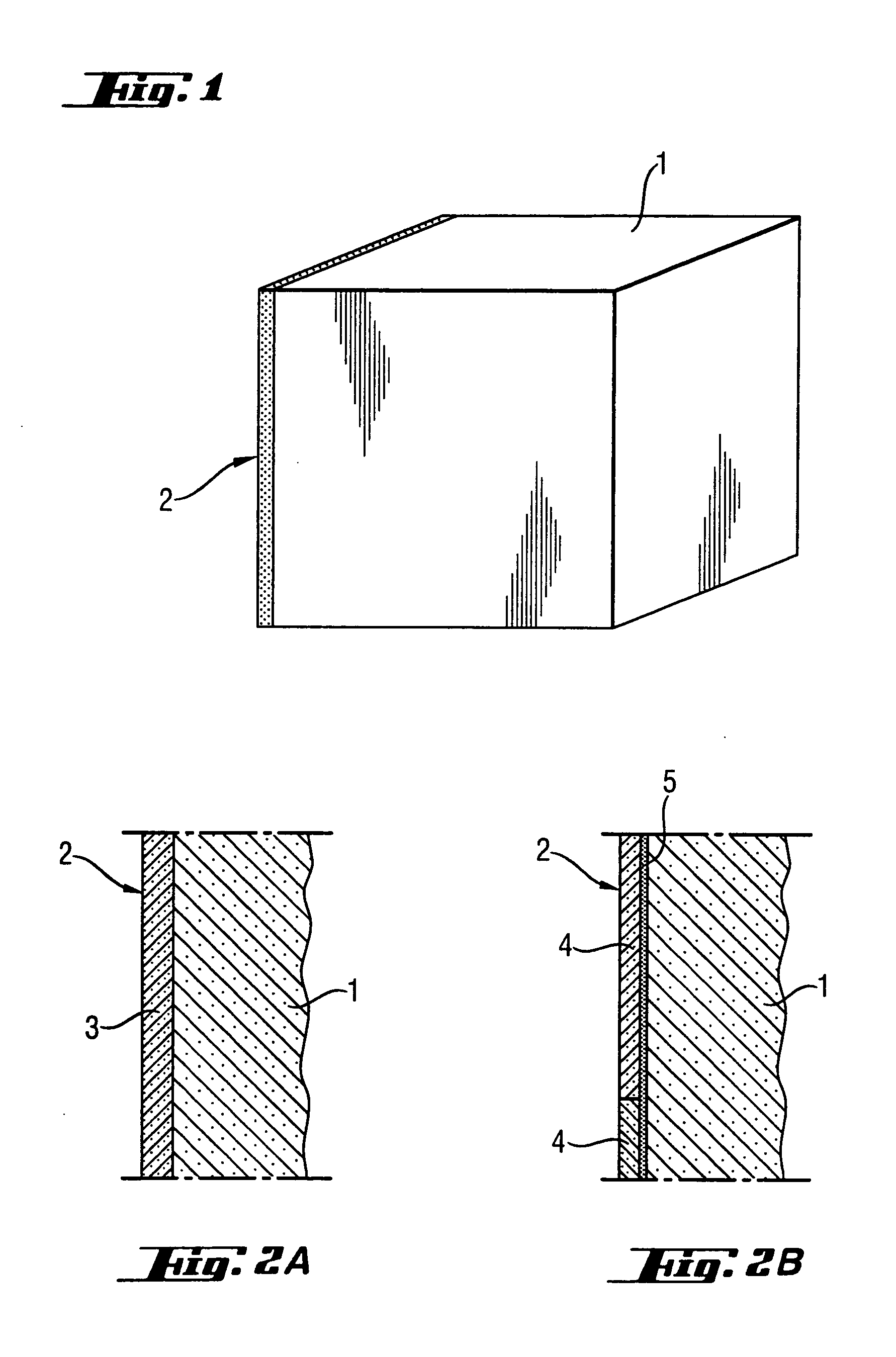

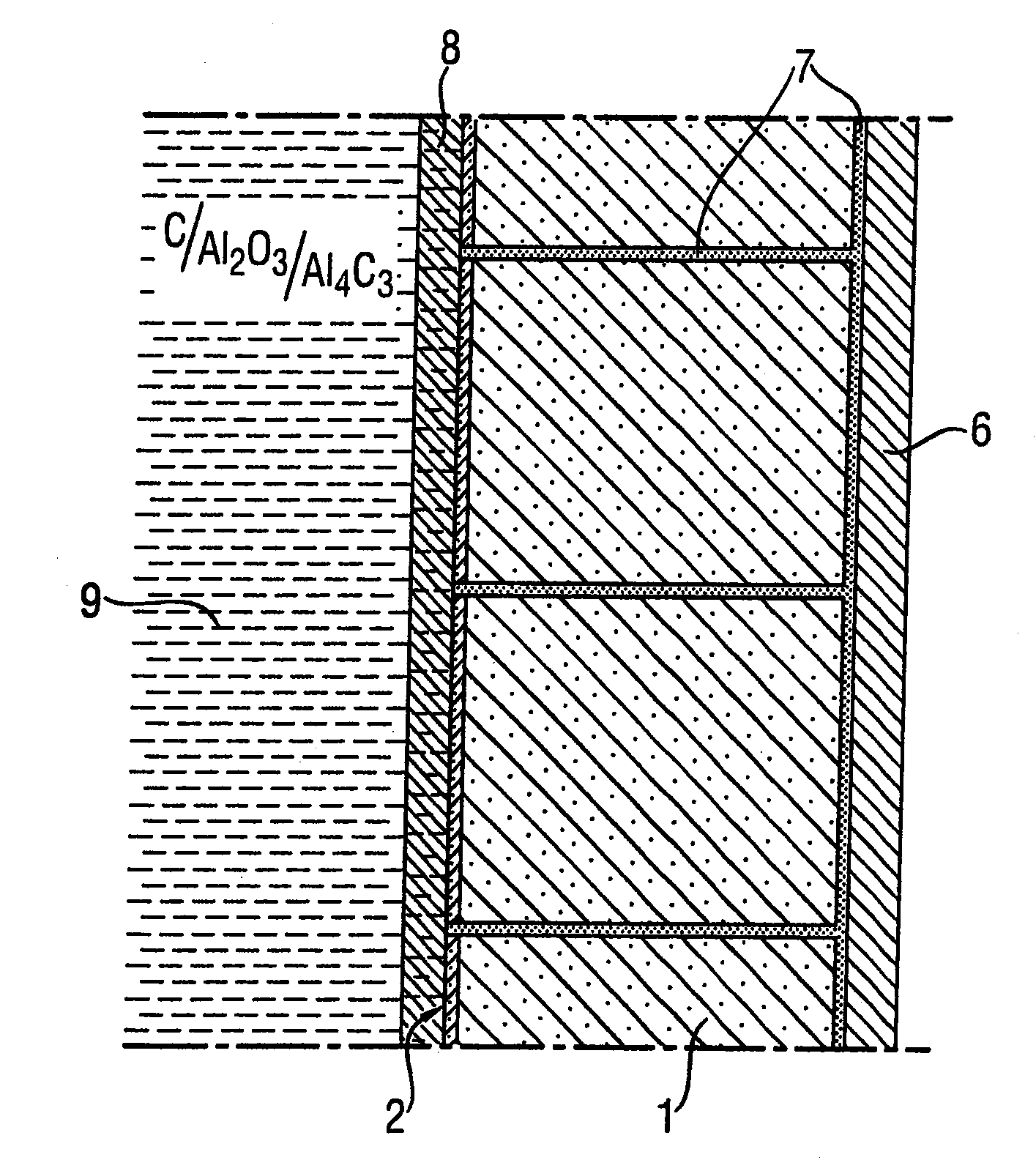

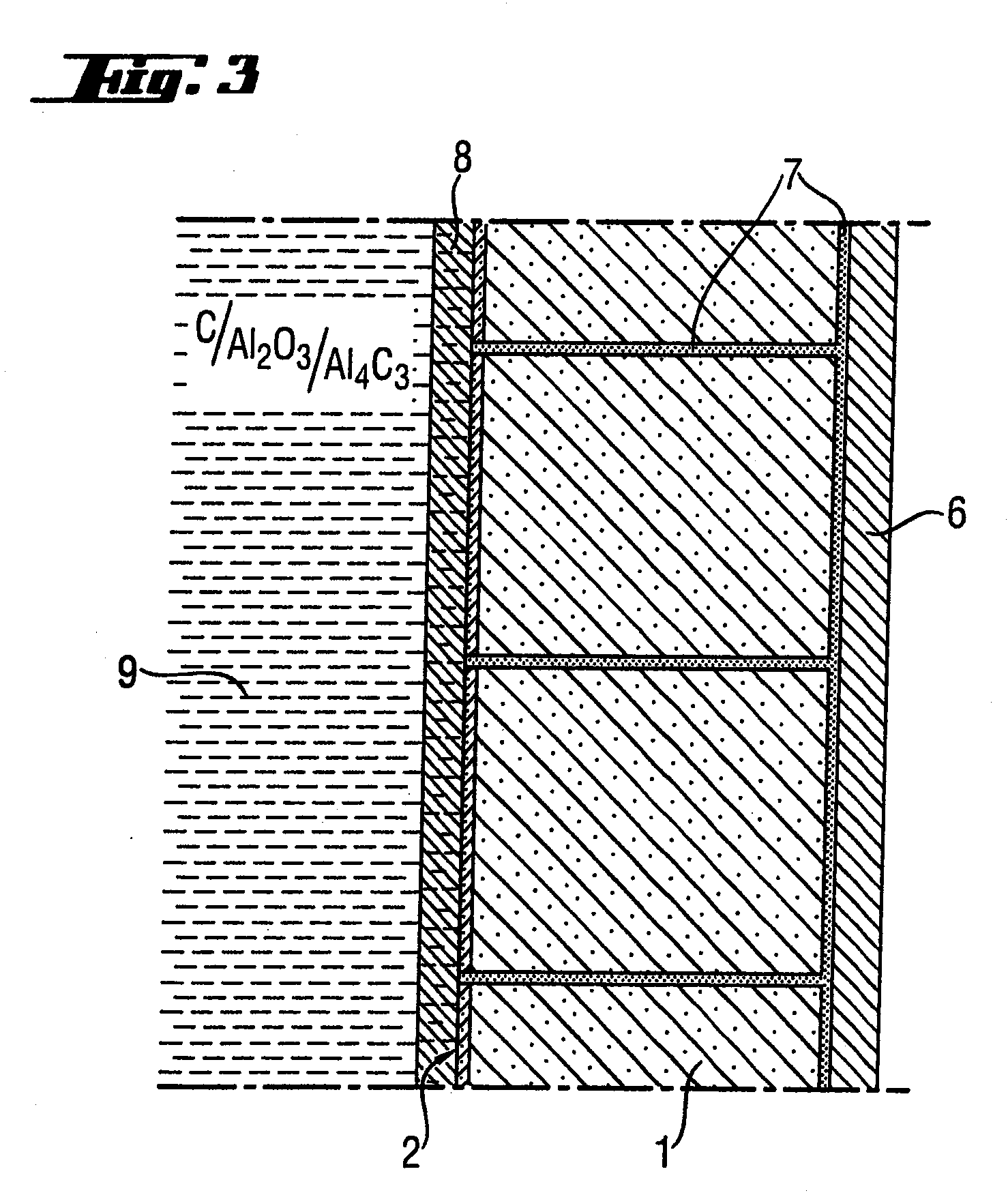

Lining for carbothermic reduction furnace

InactiveUS20050254543A1Effective heat dissipation systemOvercome disadvantagesElectric discharge heatingLinings repairRefractoryGraphite

An inner lining for the steel shell of a carbothermic reduction furnace for the production of alumina has a base layer of graphite and a coating layer of refractory material. The refractory material is corundum (Al2O3) bound by Sialon (Si.Al.O.N). The lining structure provides protection against the molten slag and it is not attacked by the CO-rich melt furnace atmosphere. Further, the lining does not contaminate the melt and it provides an effective heat dissipation system in case of a power shut-off.

Owner:SGL CARBON SE

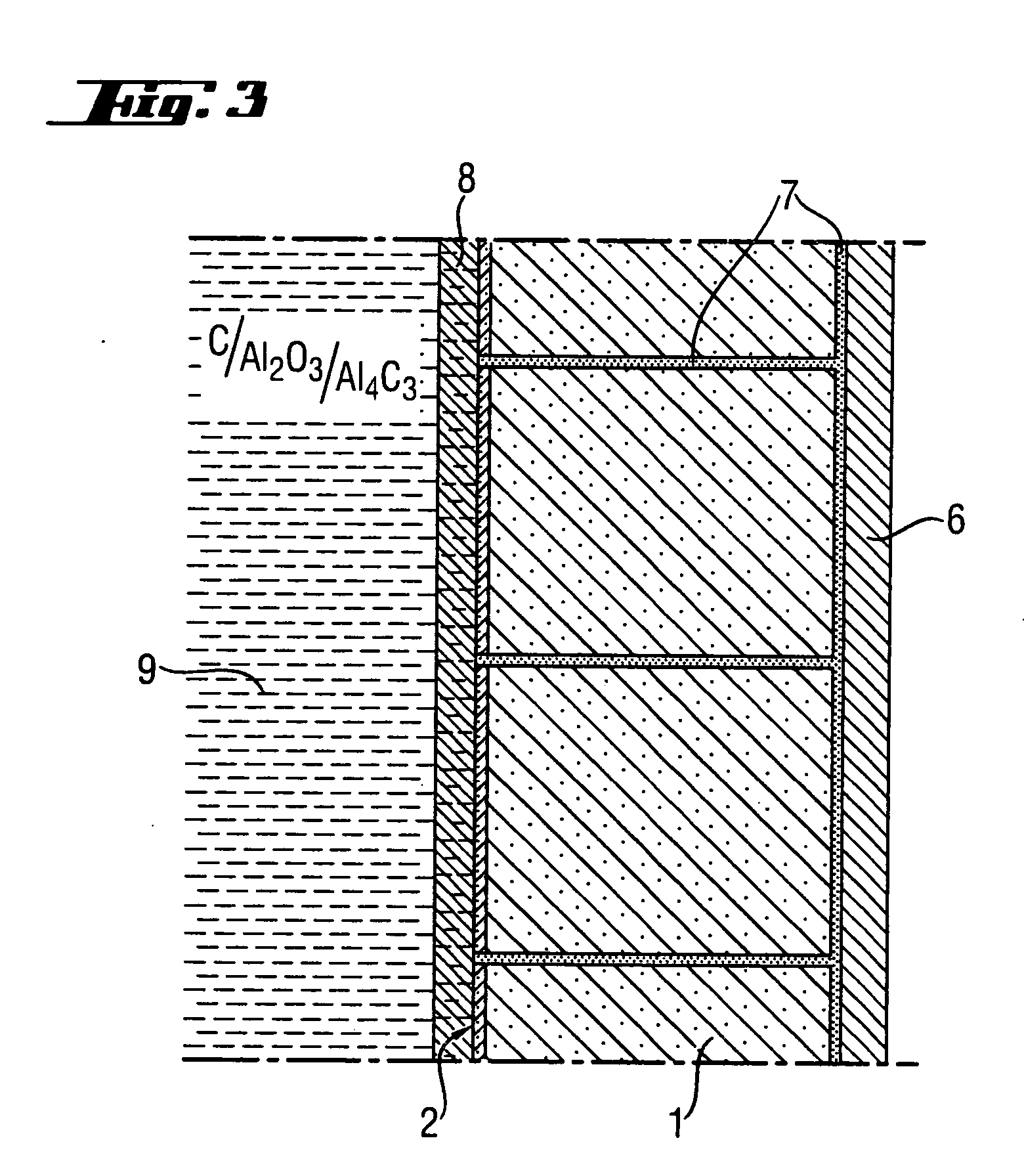

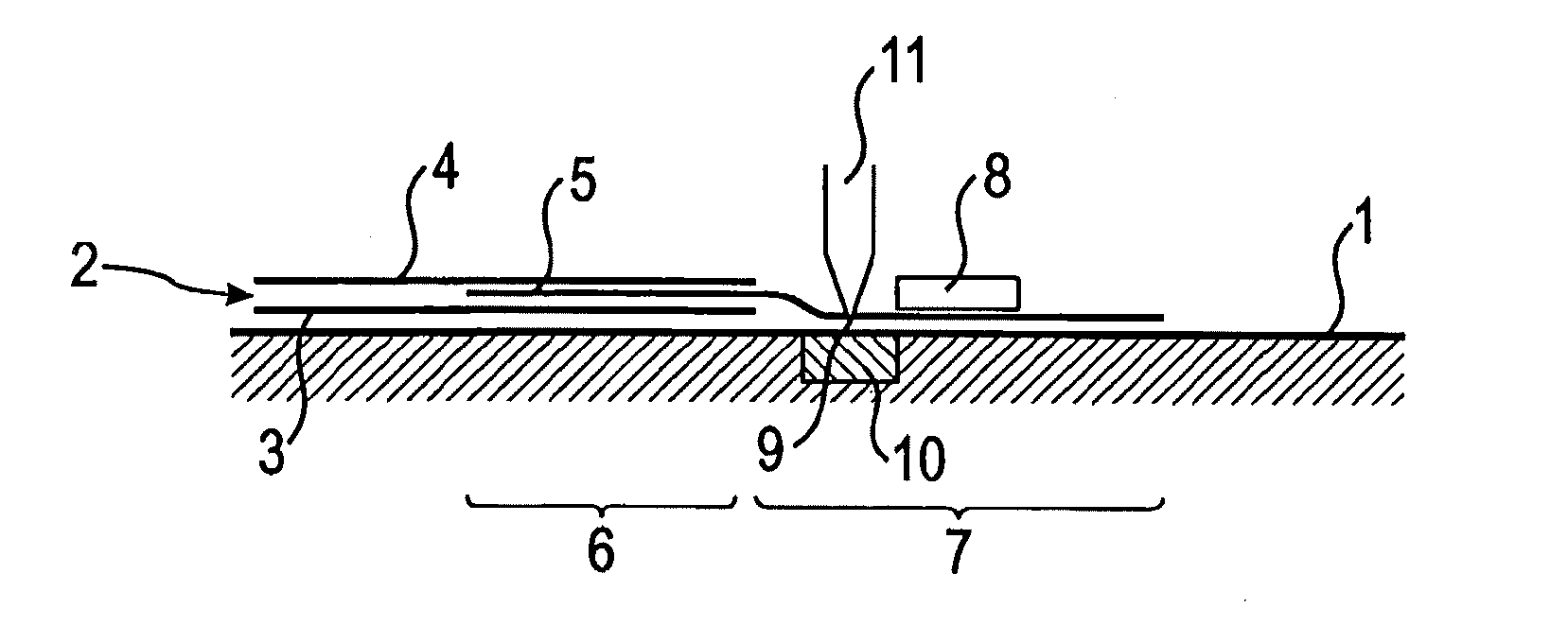

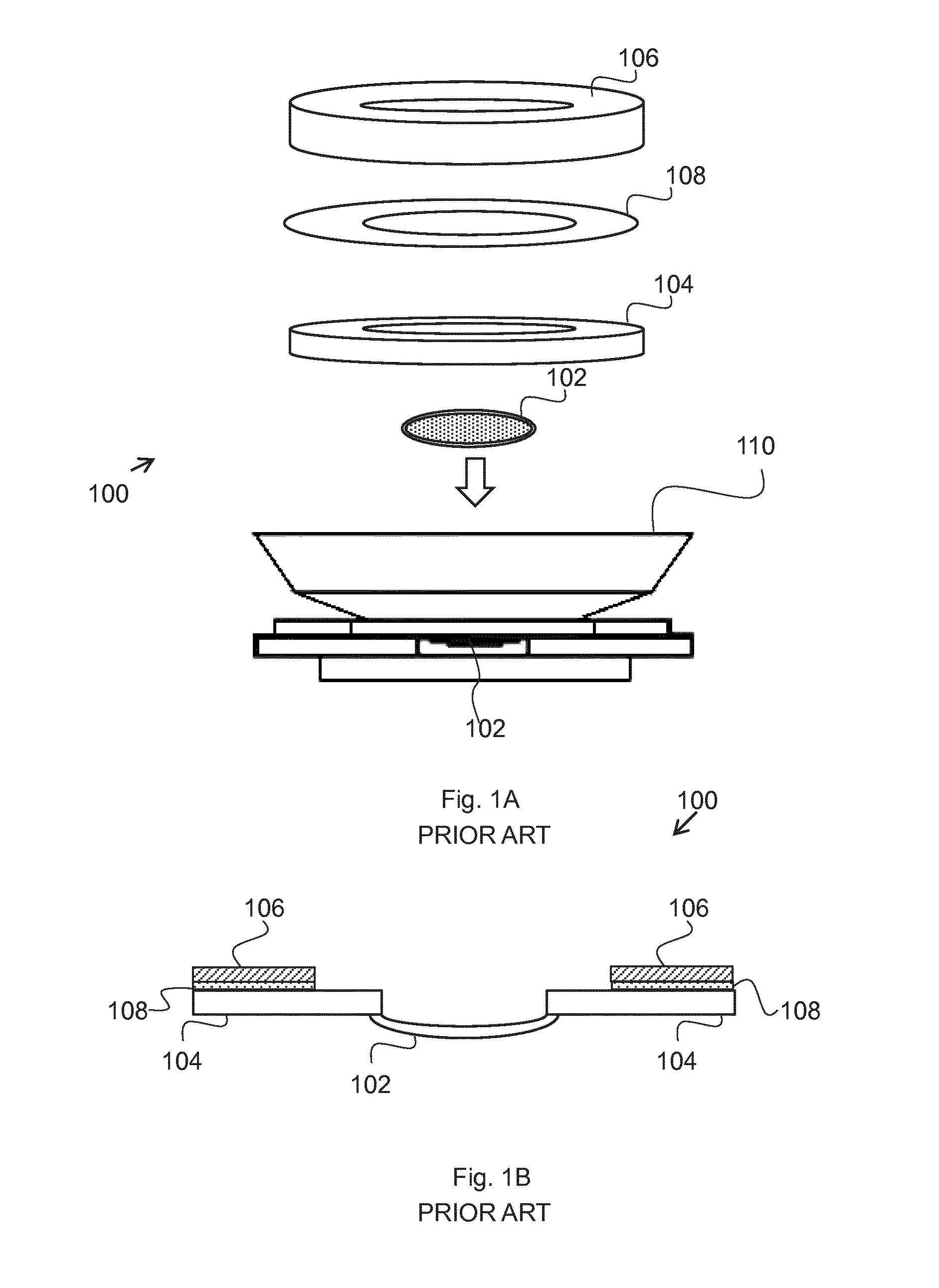

inertial type acoustic transducer

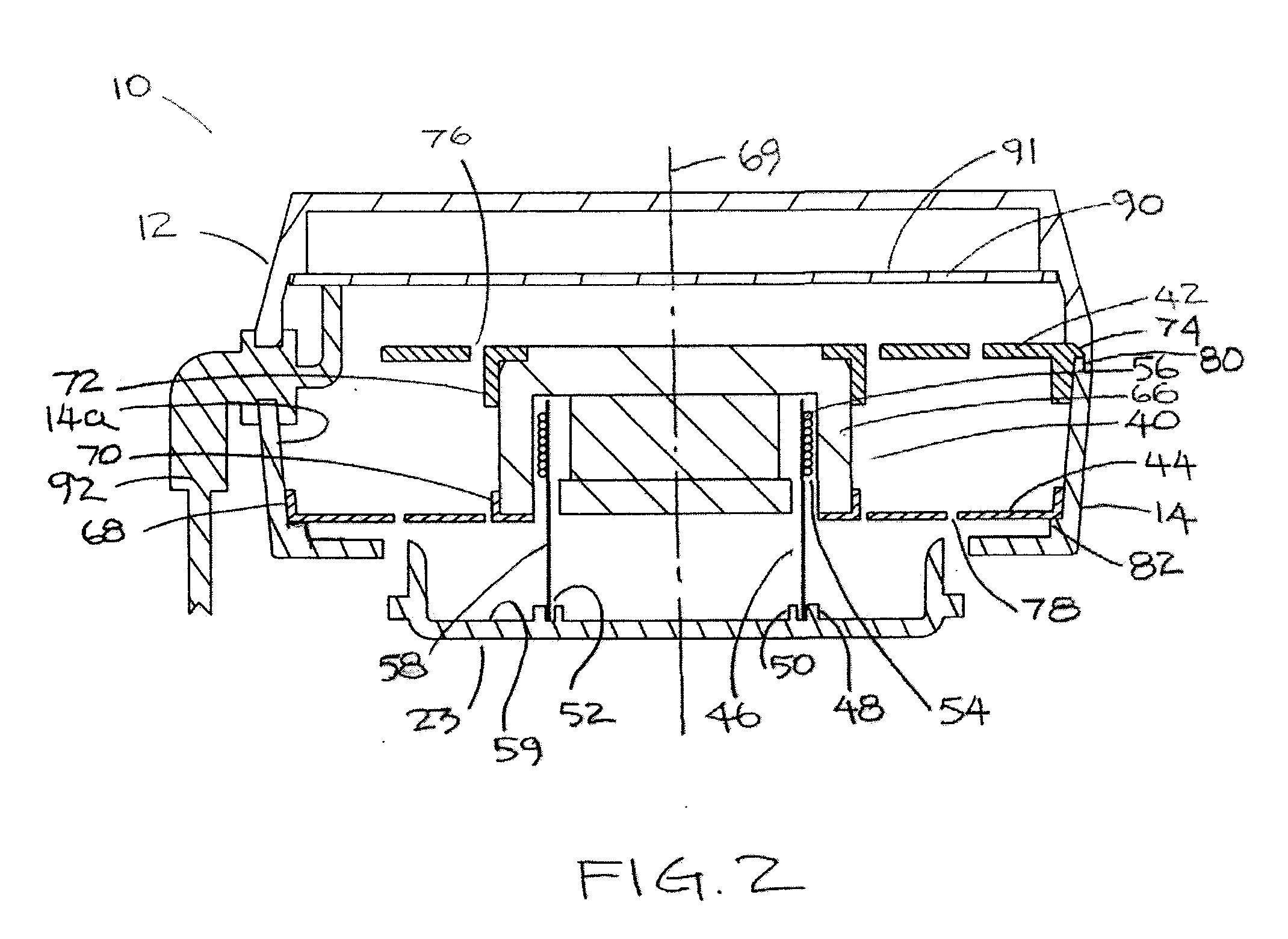

InactiveUS20120039491A1Create soundImprove efficiencyAmplifiersTransducer casings/cabinets/supportsAudio power amplifierControl signal

The present invention is drawn to inertial type transducers and a system for reducing the complexity and difficulty of installing the transducers internal to a structure. The transducer is equipped with a wireless receiver for receiving both sound content signals and control signals, and an amplifier, along with a power supply. Because the amplifier is activated by the wireless receiver, there are no wires necessary to connect the transducer to the source of the sound content or control signals thereby vastly simplifying installation. Heat dissipation and height minimization are also addressed.

Owner:KATZ ROBERT

Trim components for lapboard siding that are co-extruded from wood-plastic composites and polyvinyl chloride

ActiveUS9079380B2Reduce installation costsUse amountCovering/liningsSynthetic resin layered productsPolyvinyl chlorideEngineering

A lapboard siding and trim system is provided in which trim siding components for board-and-batten siding and associated trim components are manufactured using a co-extrusion process, whereby wood / thermoplastic resin composite material and polyvinyl chloride thermoplastic resins are co-extruded through a single die assembly, thereby producing a trim piece having a plastic composite component, that will be visible following installation, fused under heat and pressure to the polyvinyl chloride standoff and attachment fins, that will be hidden following installation. Also provided is a lapboard siding and trim system in which siding components for clapboard siding are manufactured by extruding wood / thermoplastic resin composite material through a die. Associated trim components are manufactured using the co-extrusion process described above. The siding and trim components are completely waterproof, and installation proceeds with almost no face nailing and almost no caulk.

Owner:MONTEER SHAUN ROBERT

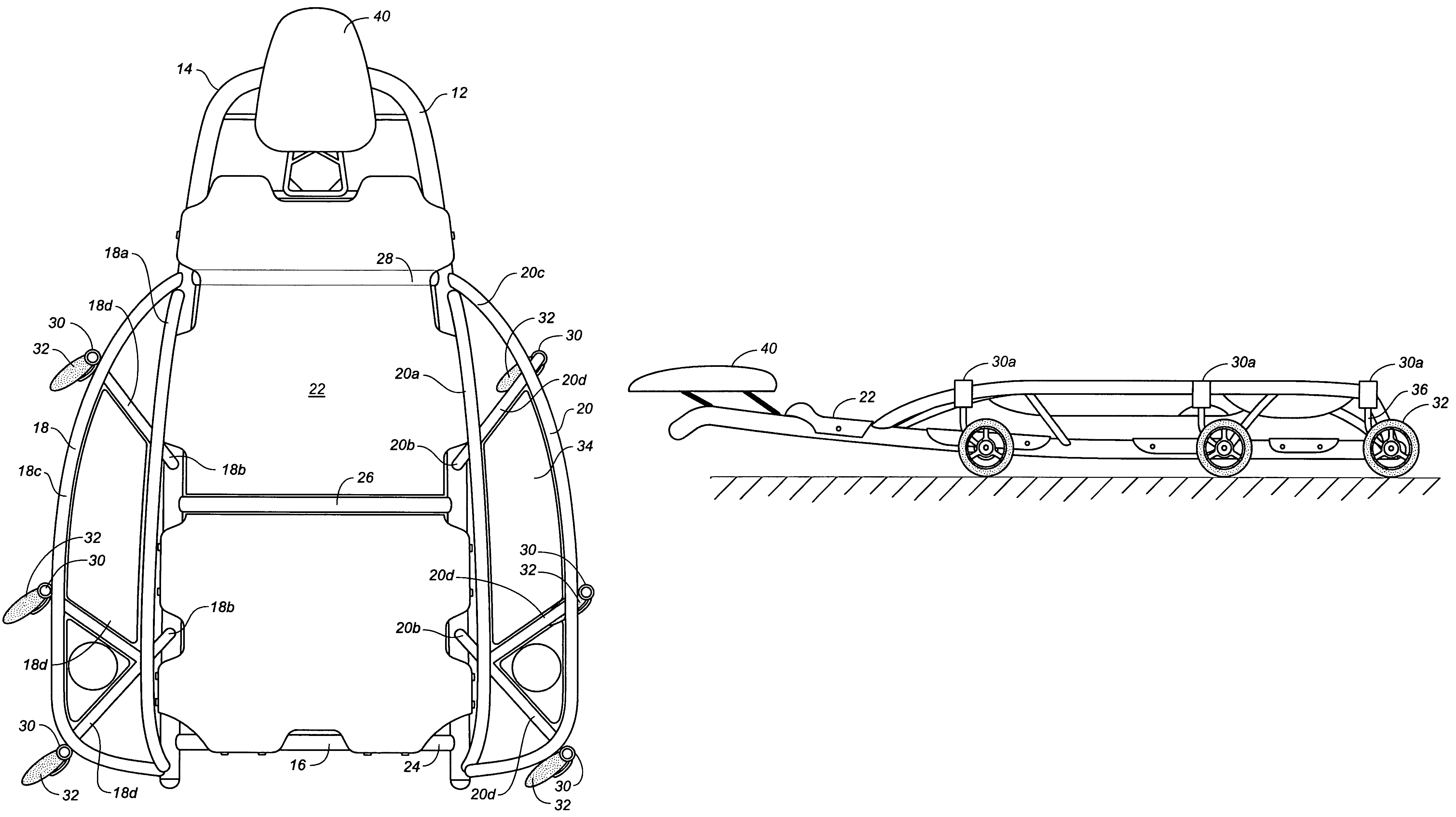

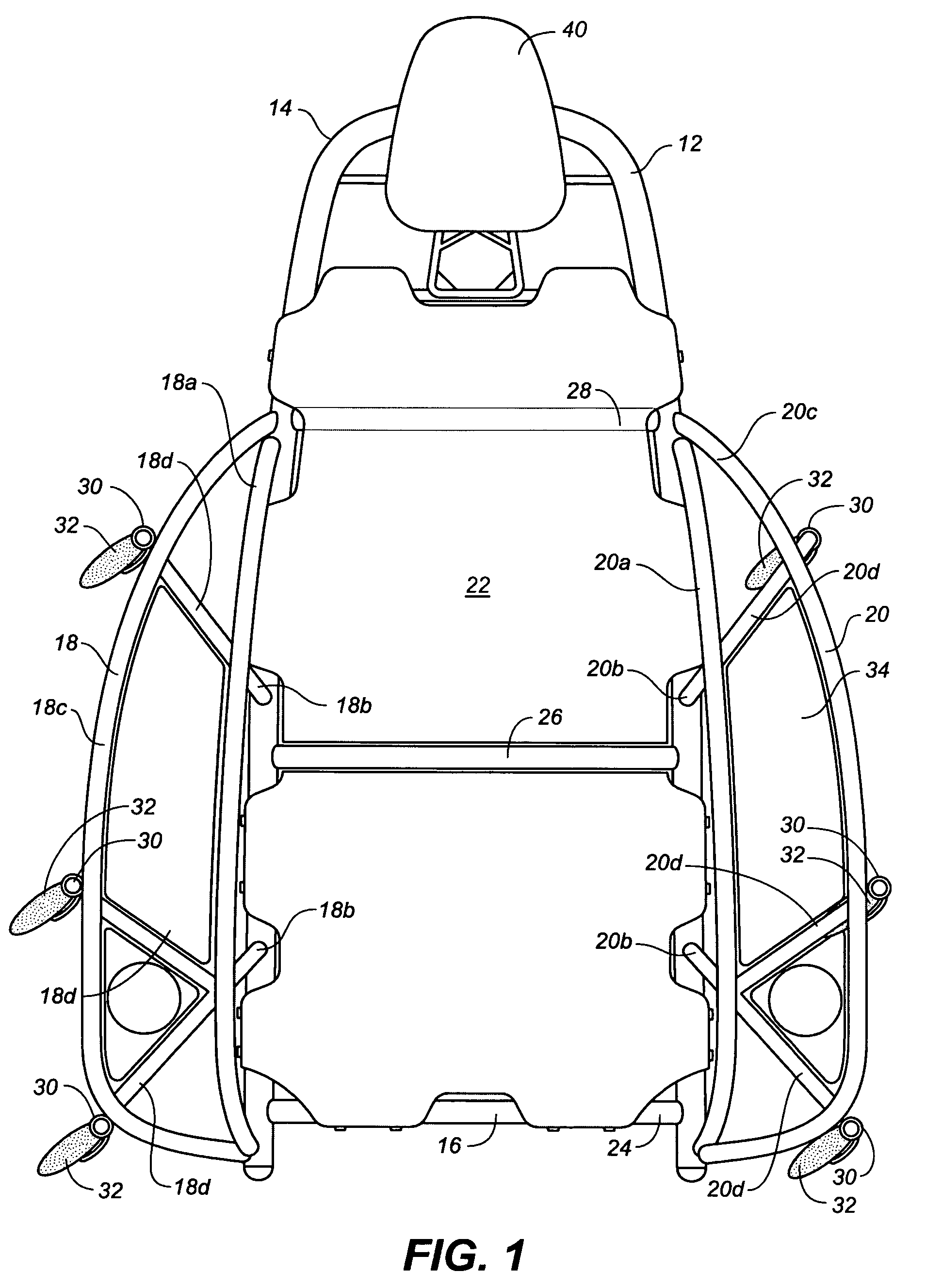

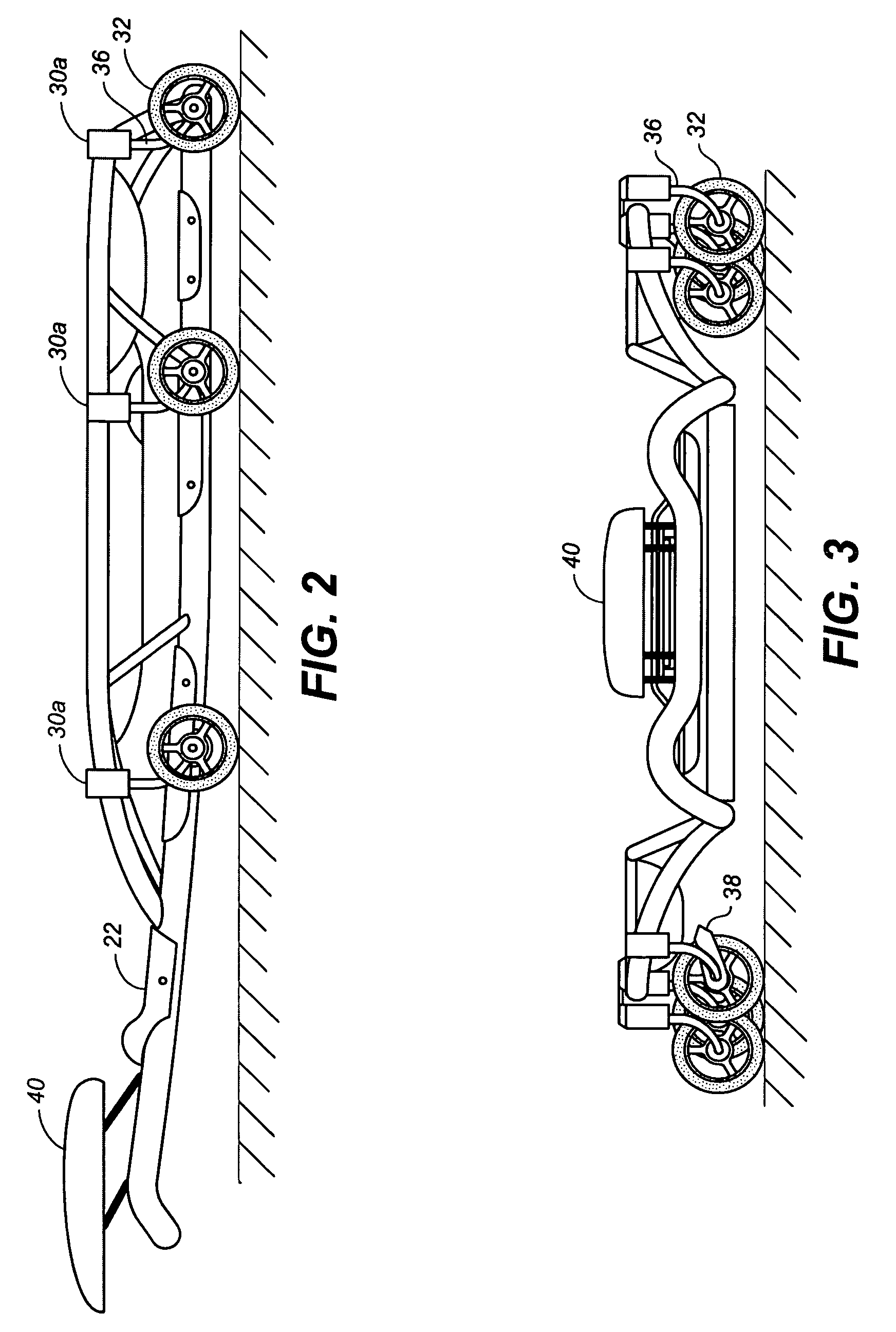

Mechanic's creeper

InactiveUS7434817B2Avoid captureLight weightHarvestersAgricultural undercarriagesEngineeringExpansion joint

Owner:RUSH GARLAND

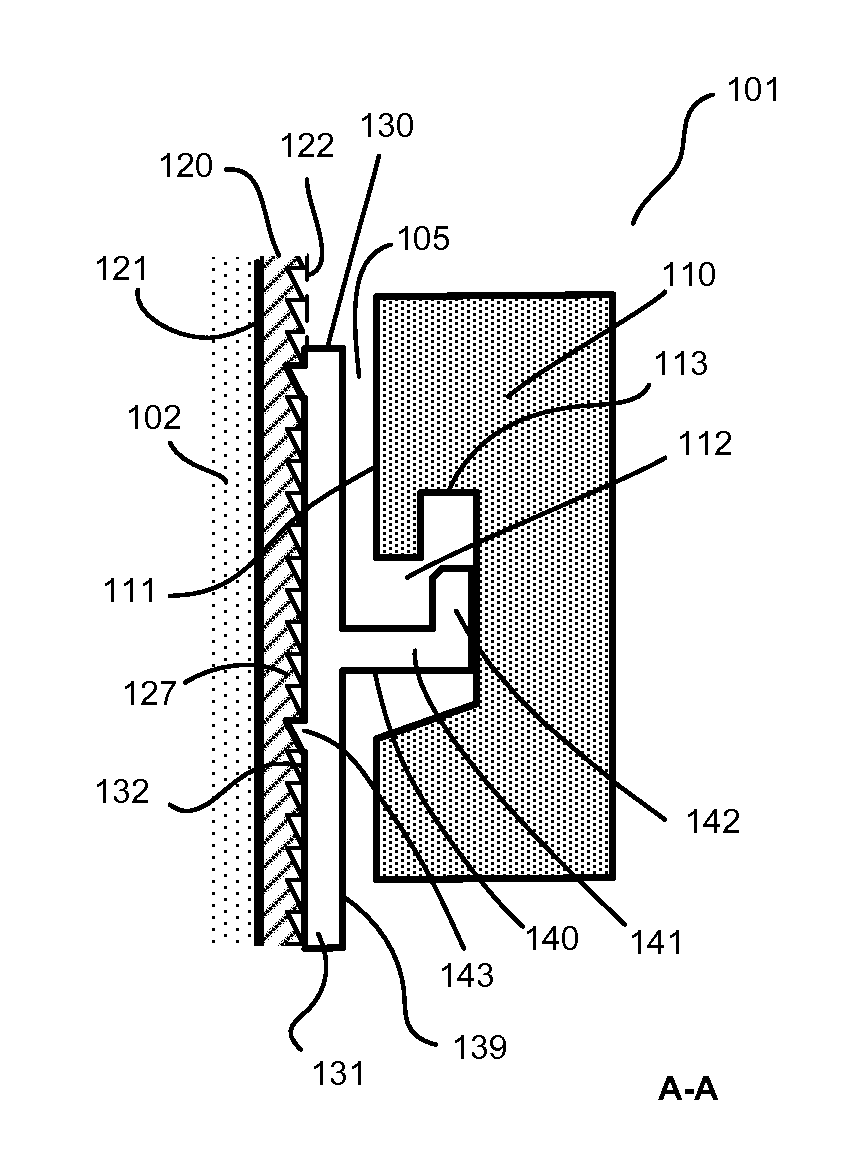

Fastening system

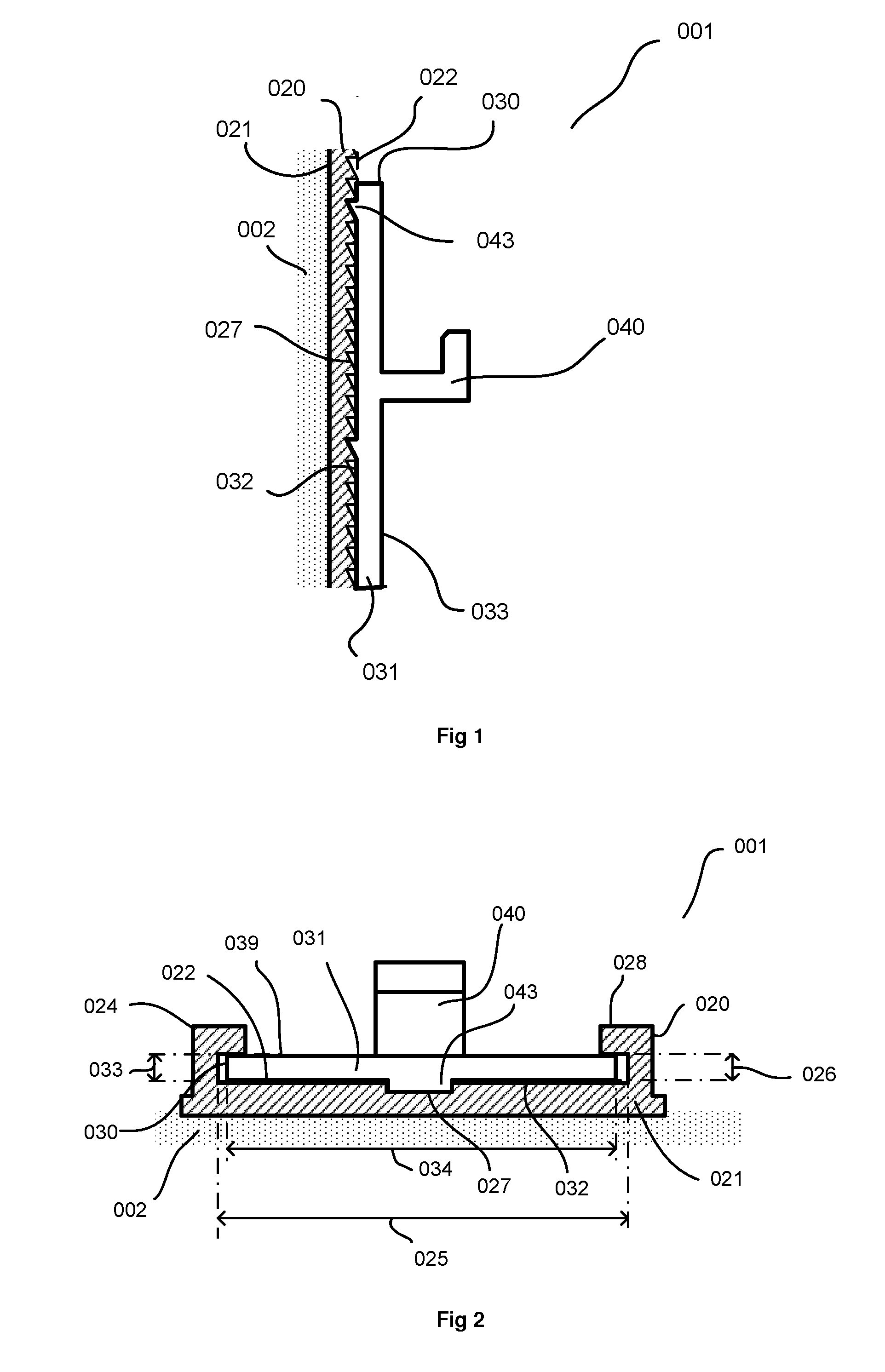

ActiveUS20140161516A1Ensure longevityAvoid displacementCovering/liningsCouplings for rigid shaftsFastenerElectrical and Electronics engineering

Owner:VETEDY S A R L

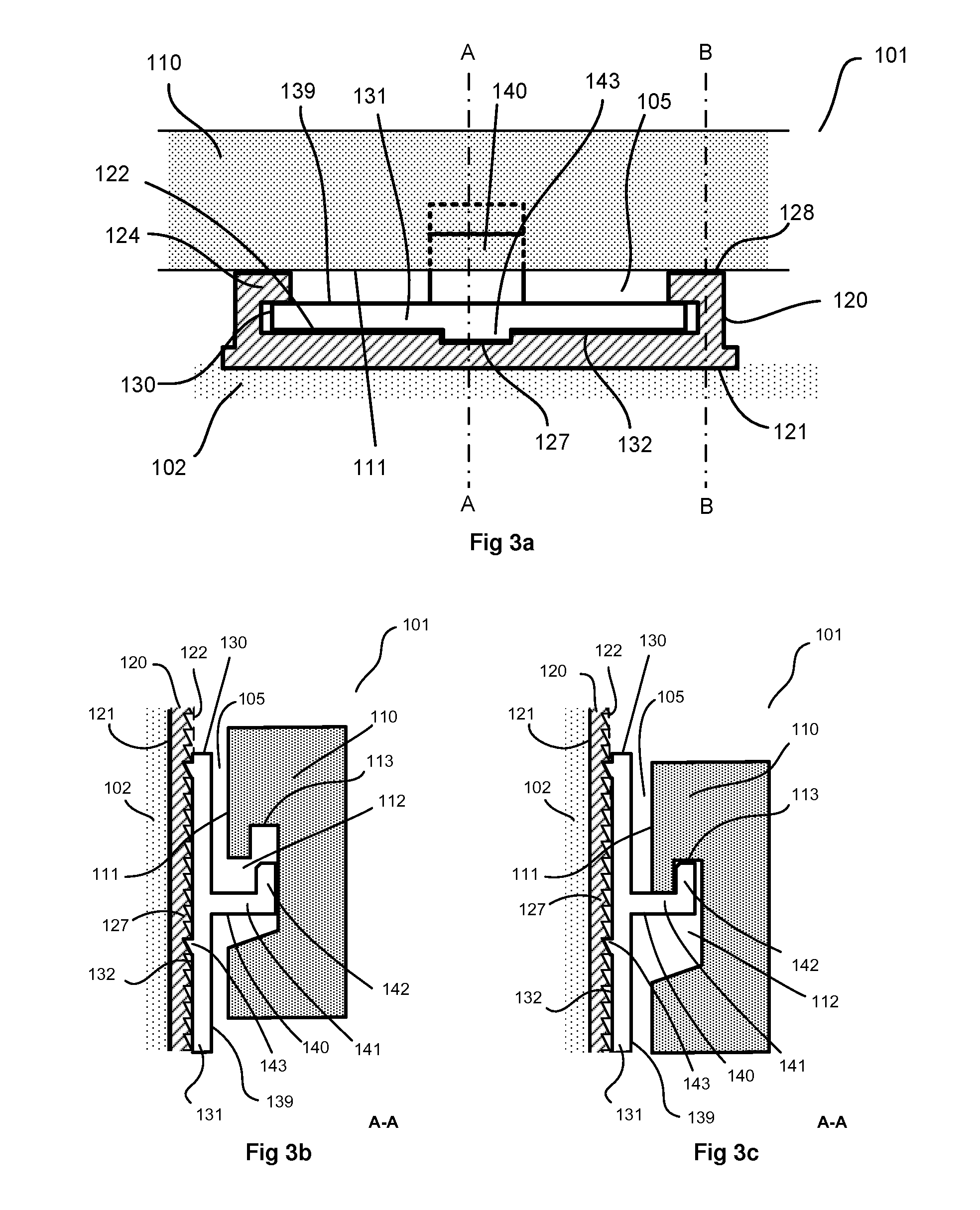

Hot spraying metal ceramic powder for stove roller surface coatings

The invention relates to a furnace roller surface coating, in particular to a hot-spraying metal ceramic powder used for the furnace roller surface coating and mainly aiming at solving the technical problem that the anti-burl and wear-resistant capability of the existing coating can be reduced when a large quantity of high-strength steel plates are manufactured. The invention has the technical proposal that the hot-spraying metal ceramic powder used for the furnace roller surface coating consists of alloy powders and ceramic powders; the alloy powder is an alloy powder containing M, Cr, Al, Y and Ta; the ceramic powder consists of powders of ZrB2 and Cr3C2; a weight percentage of the alloy powder and the ceramic powder is that the alloy powder accounts to 89 to 75 percentage and the ceramic powder accounts to 11 to 25 percentage. The M, Cr, Al, Y and Ta alloy powder, against a gross weight of the metal ceramic powder, contains 13 to 25 percentage of Cr, 3 to 10 percentage of Al, 0.1 to 1 percentage of Y and less than 12 percentage of Ta, and the rest is M which is one of Co and Ni. In the ceramic powder, against a gross weight of the metal ceramic powder, the contents of ZrB2 and Cr3C2 are respectively 10 to 20 percentage and 1 to 5 percentage. The invention can be used for the furnace roller surface coating for a steel-strip continuous annealing production line.

Owner:SHANGHAI BAOSTEEL EQUIP MAINTENANCE CO LTD

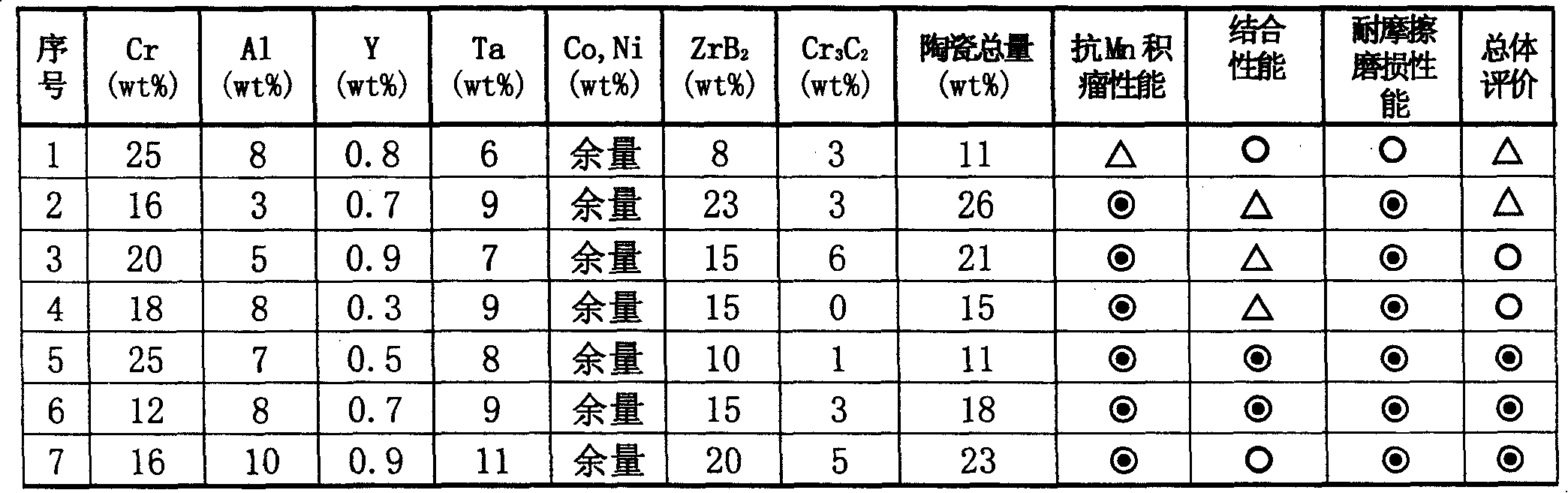

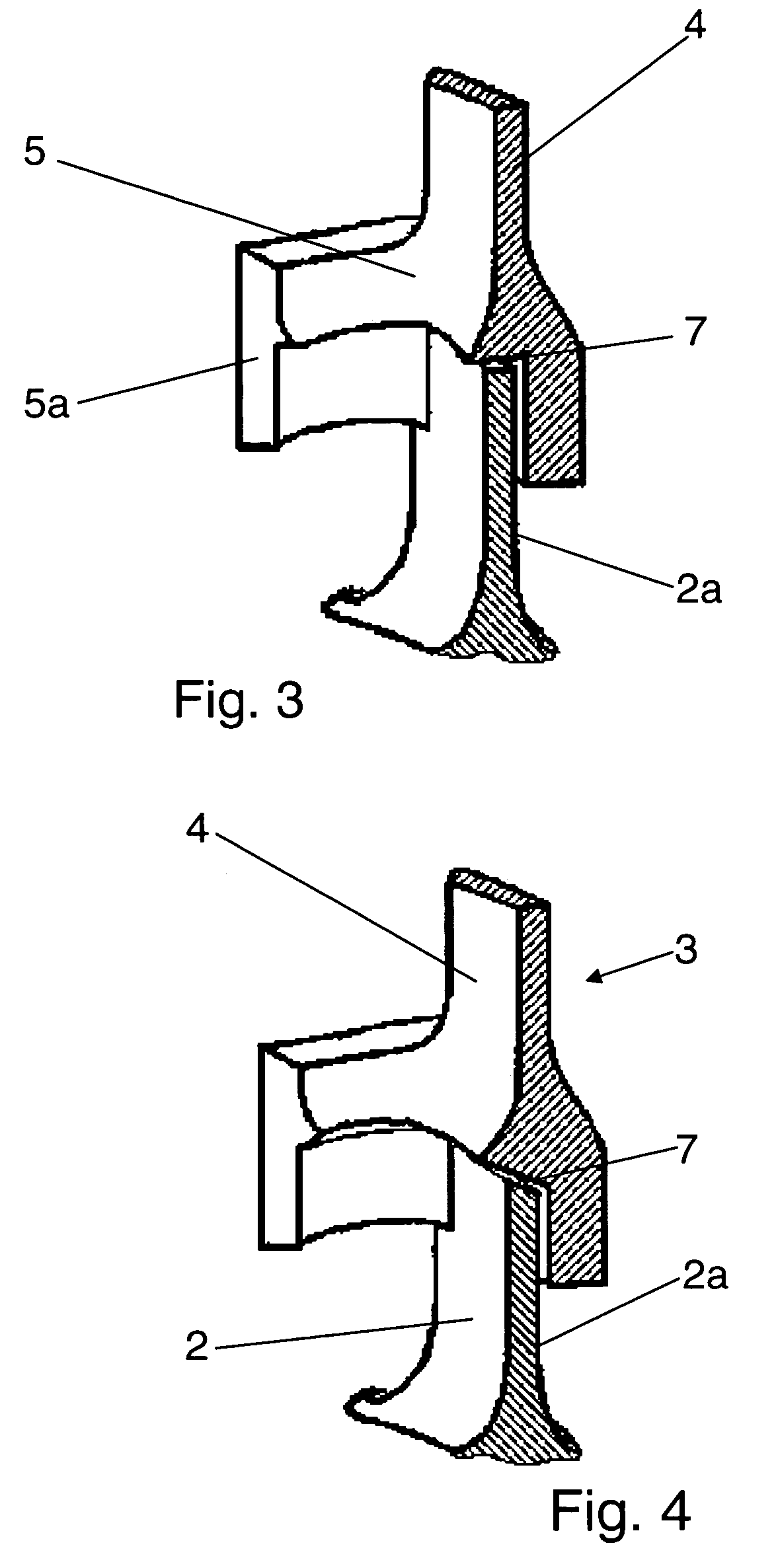

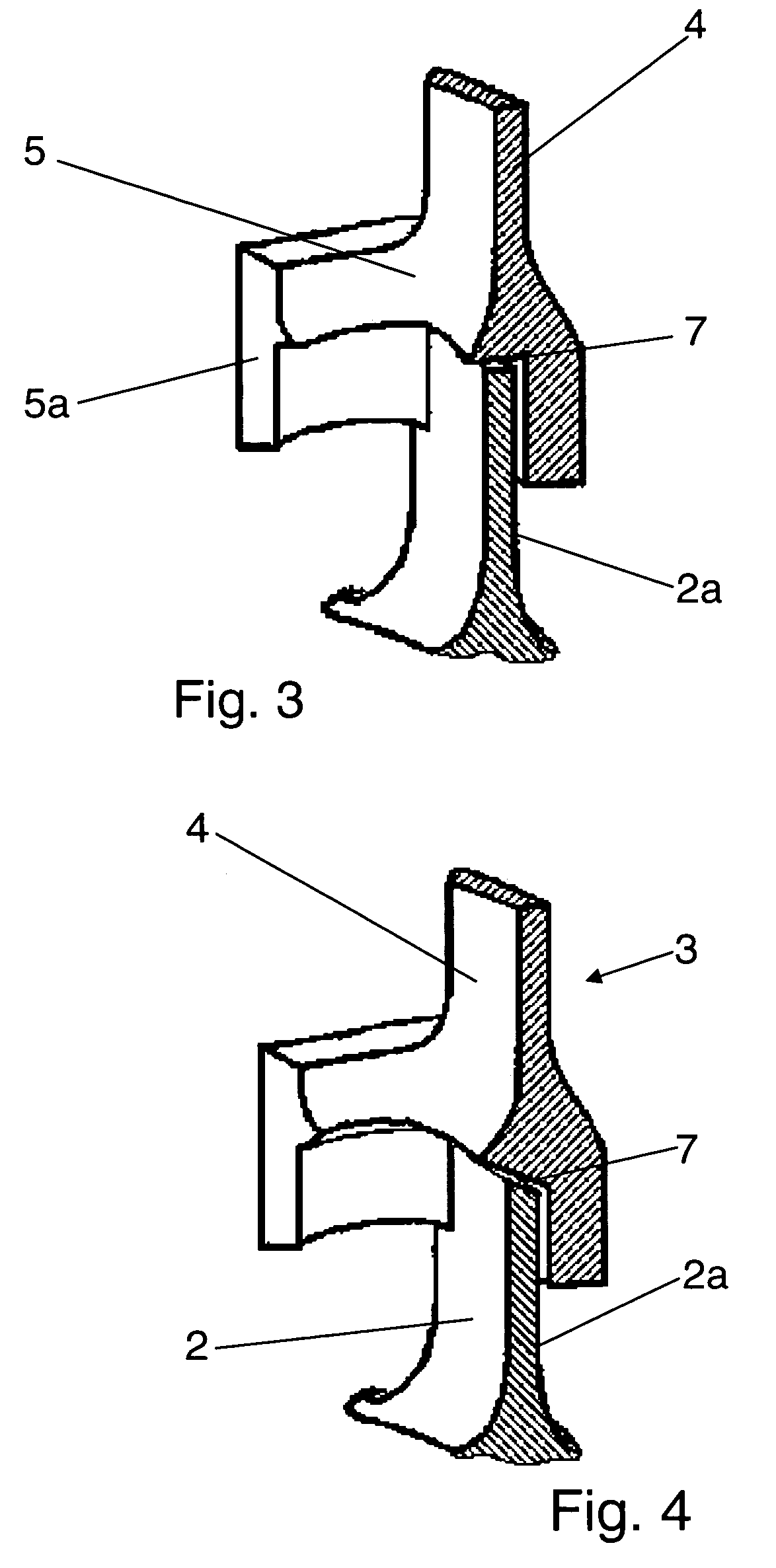

Method and apparatus for coating or heat treatment of blisks for aircraft gas turbines

InactiveUS20050271512A1Service life is not affectedEasy to usePropellersVacuum evaporation coatingGas turbinesFlange

A method for hard-material coating or heat treatment of the blade airfoils of blisks for gas turbines provides for partial heat-insulation and cooling of the other blisk parts during the respective process to prevent their properties from being changed by the high temperatures. The apparatus required for this method comprises two or more cooling plates (5 to 7) which are thermally insulated on their outer surfaces and include supporting flanges (20) which heat-conductively locate the blade platforms (3) of the blisks (1). Radially extending cooling medium channels (16) are provided in the cooling plates connected to a cooling medium source to continually apply cooling medium to the inner surfaces of the supporting flanges and the blade platforms.

Owner:ROLLS ROYCE DEUT LTD & CO KG

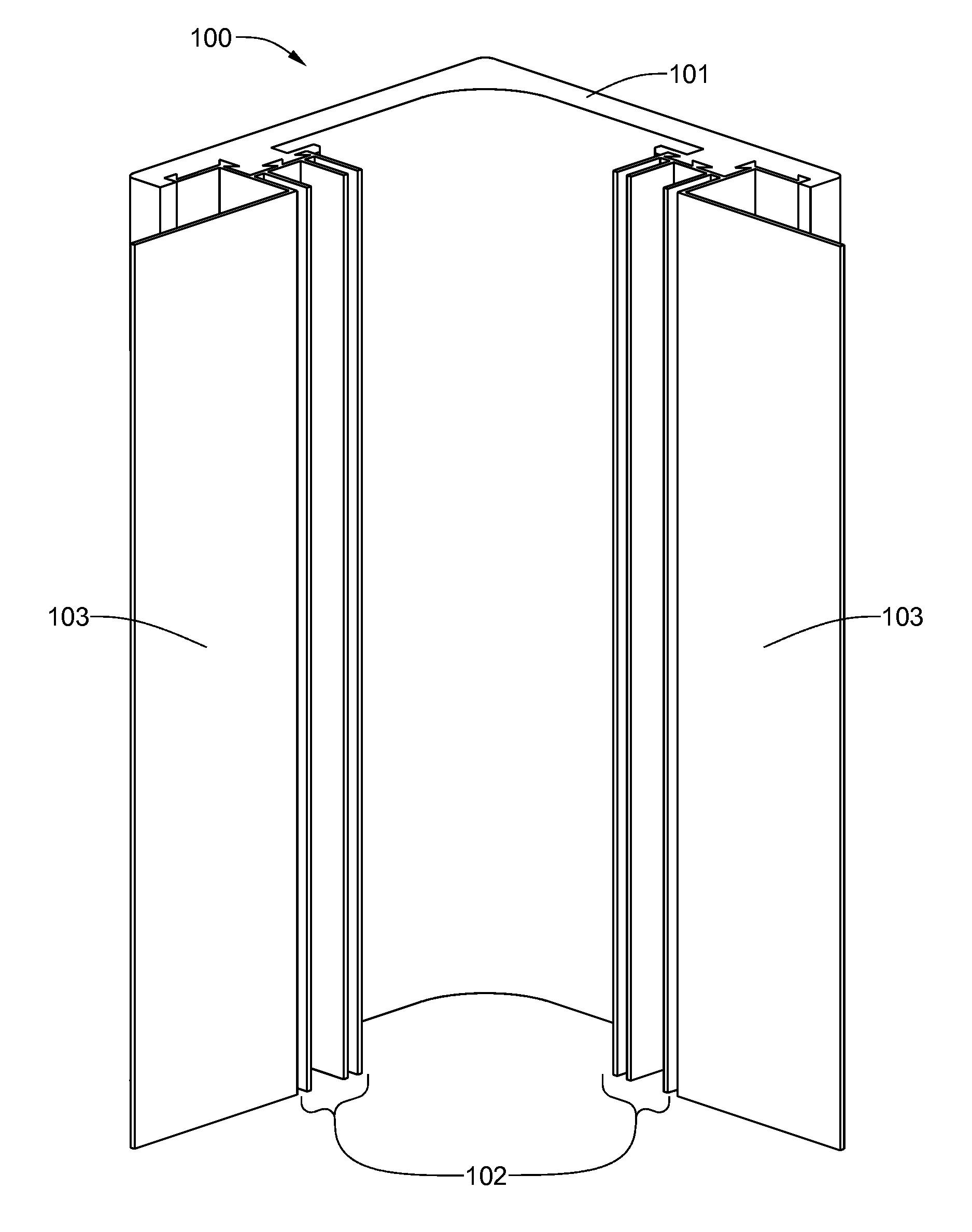

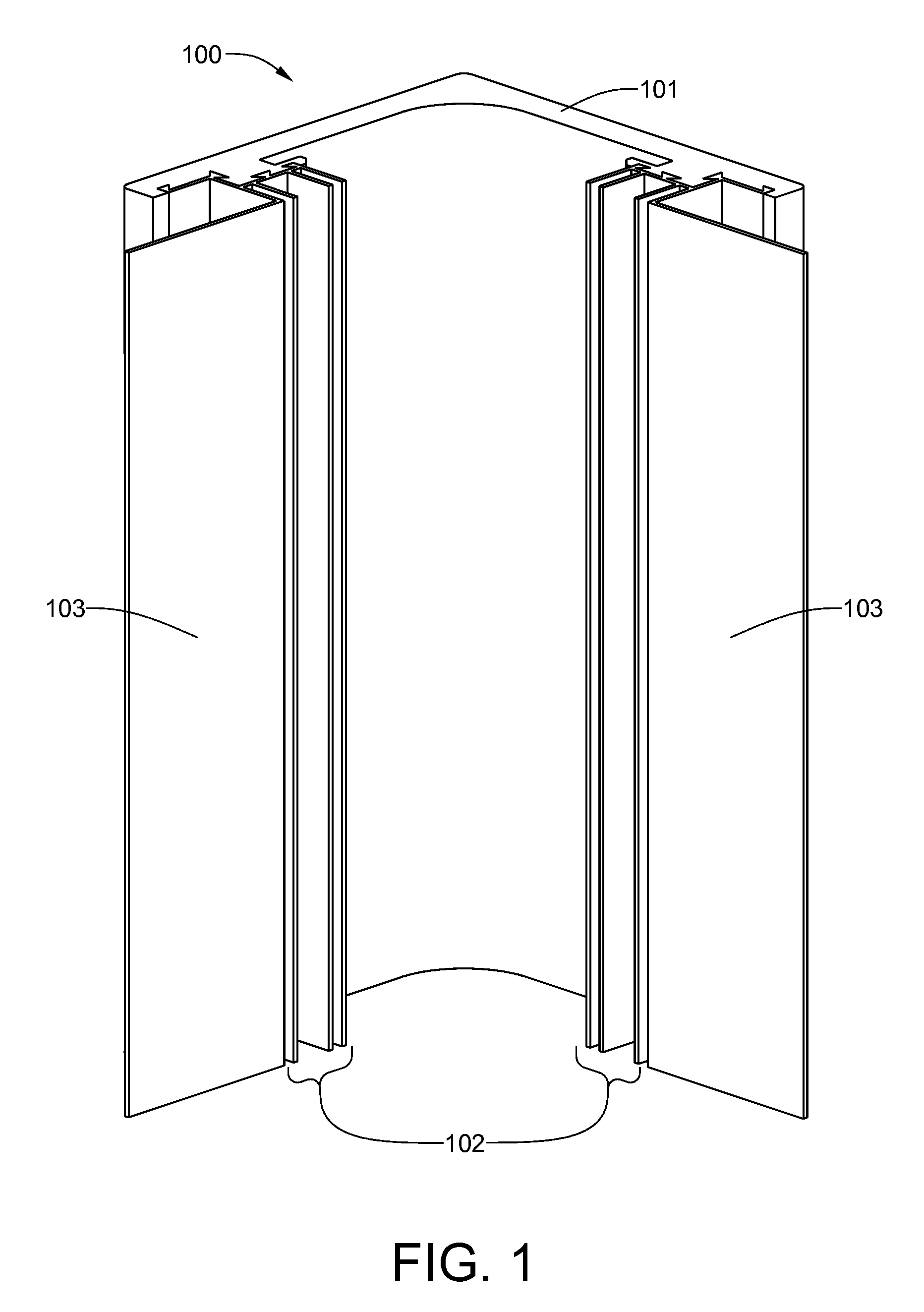

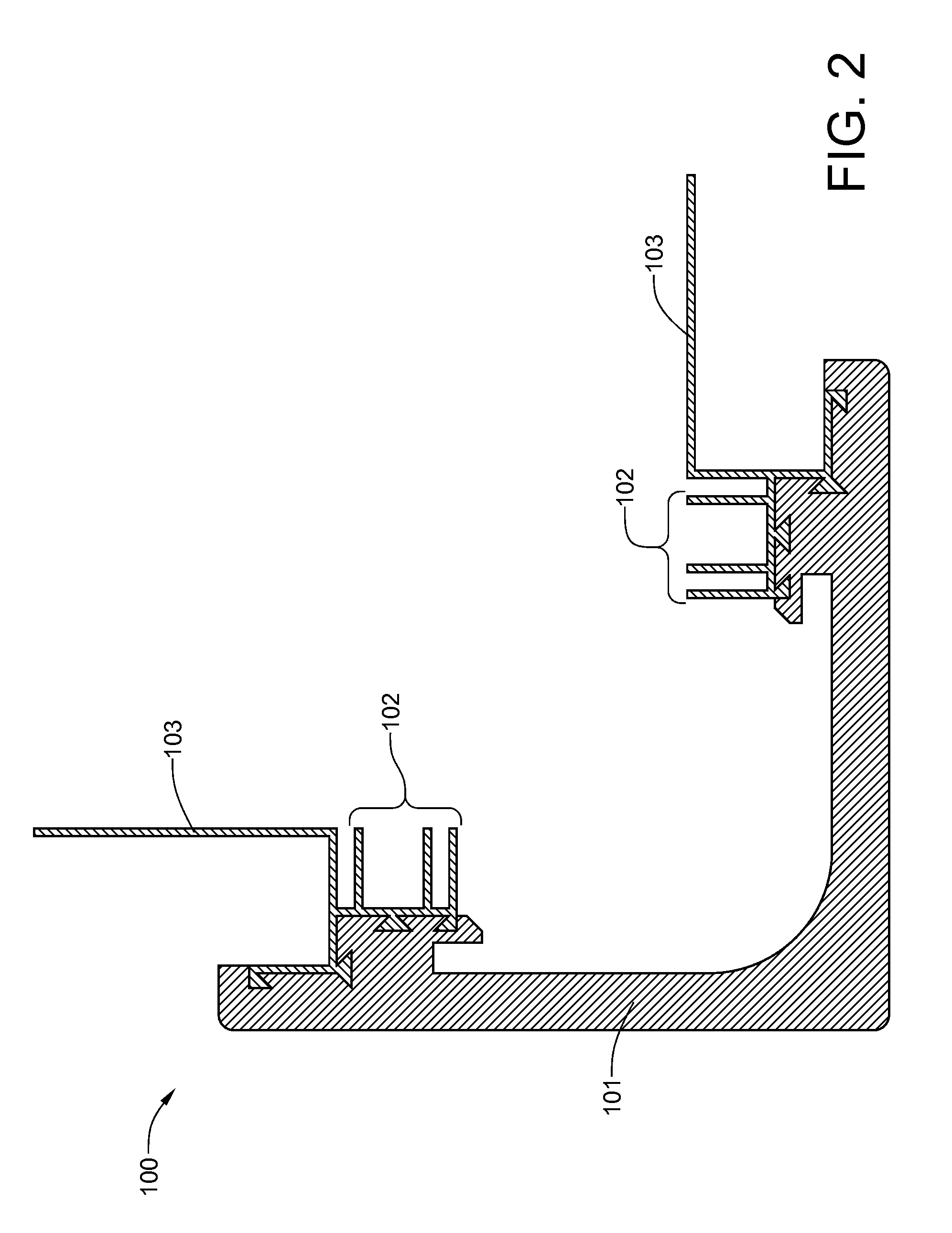

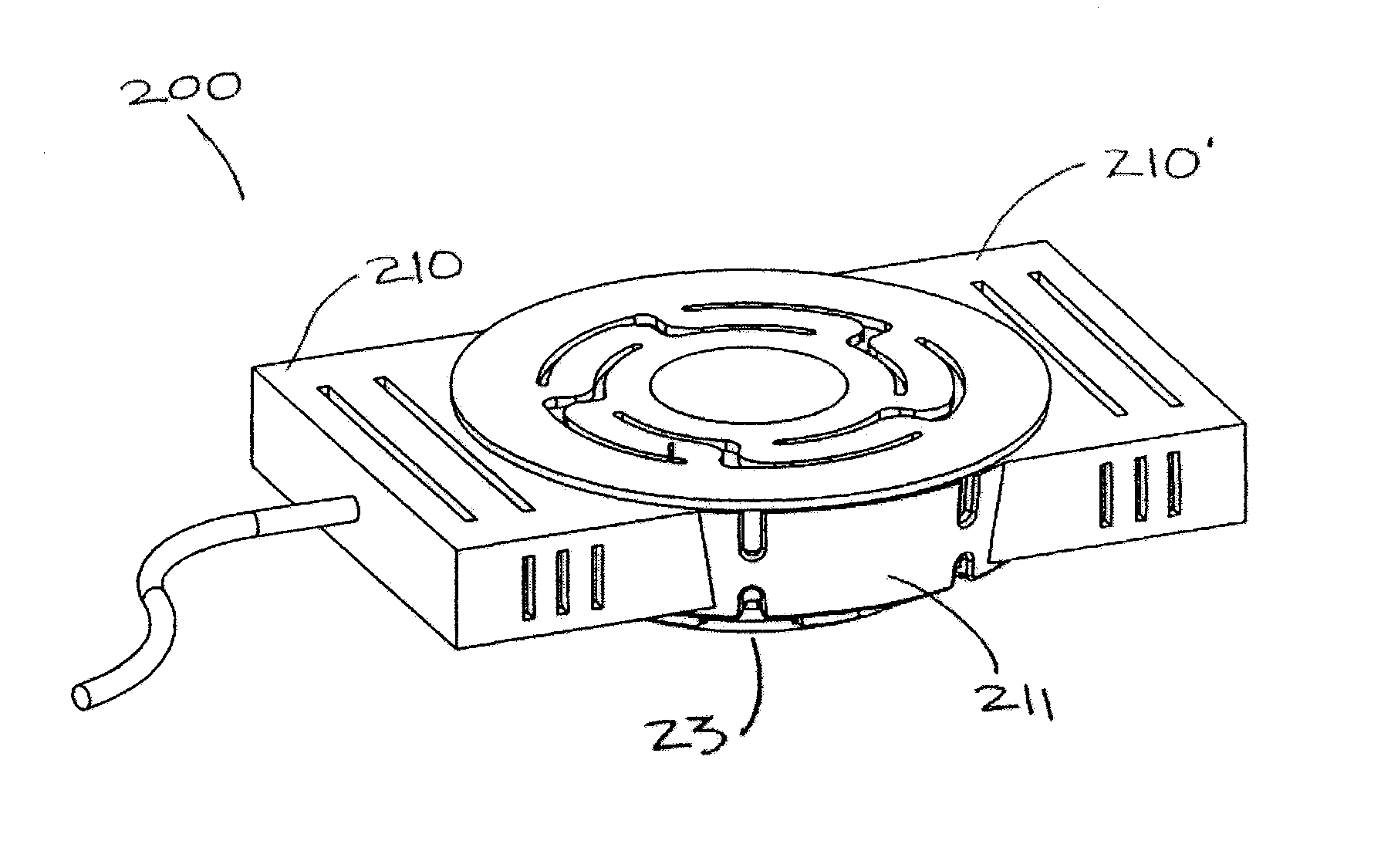

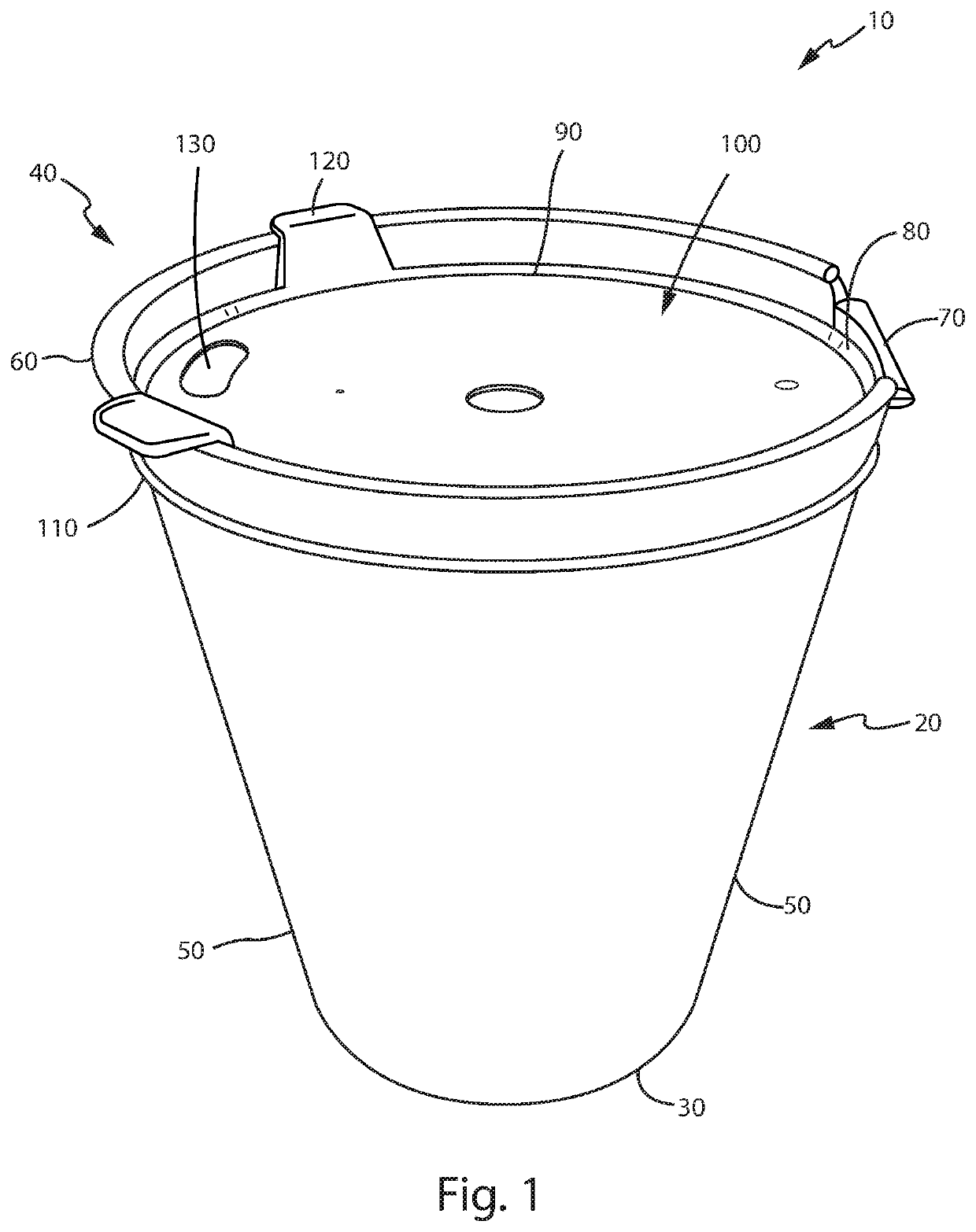

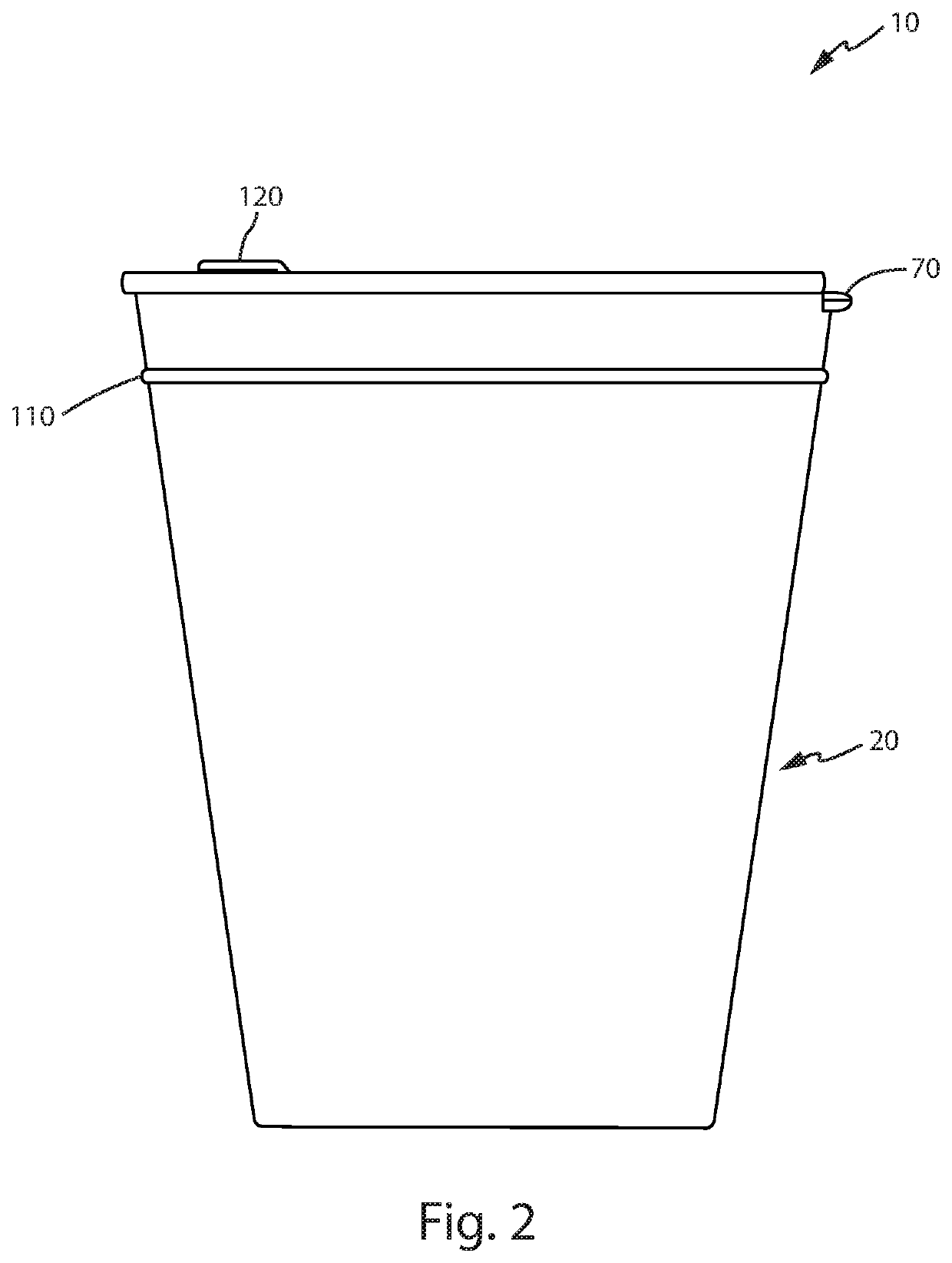

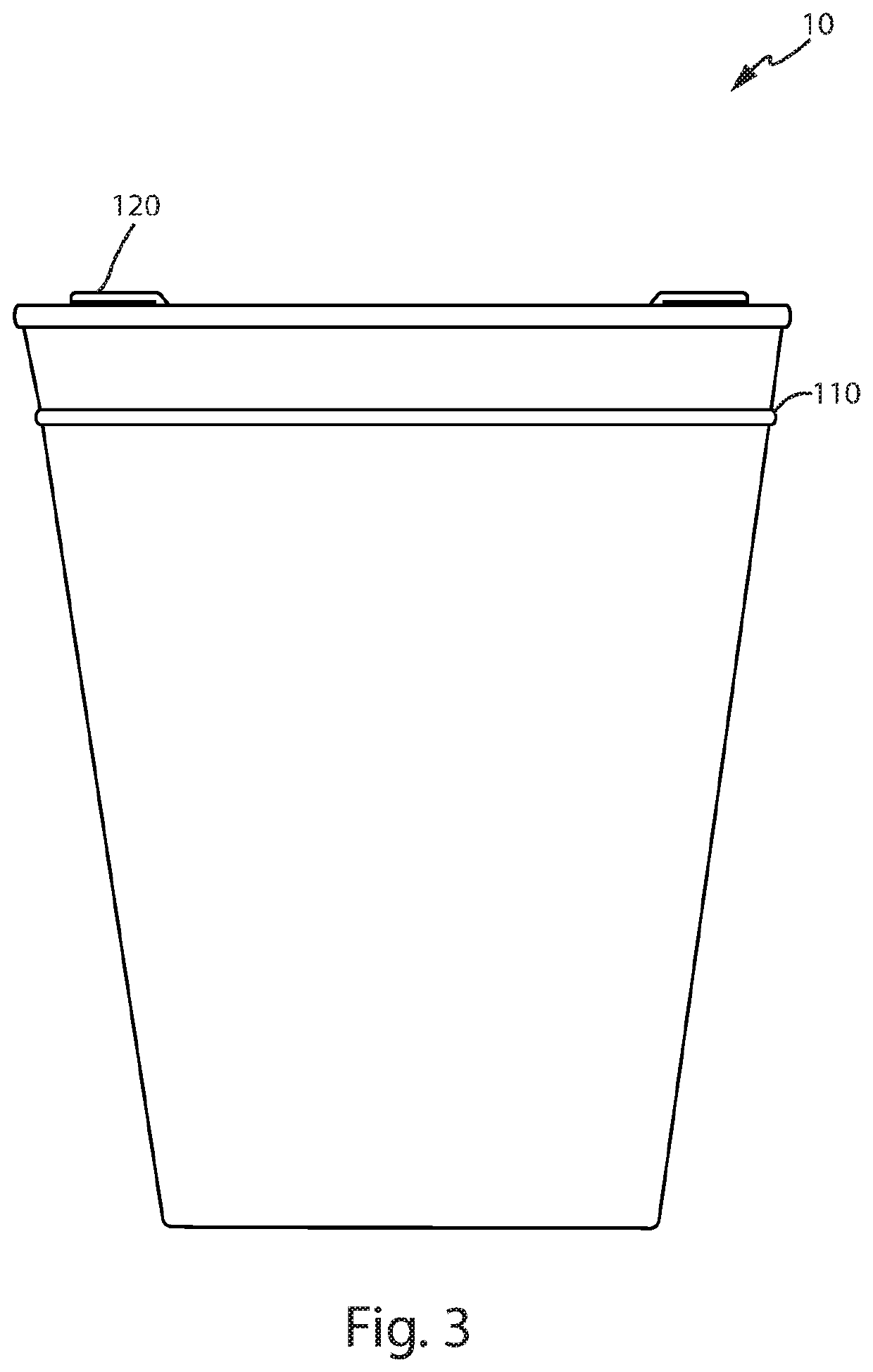

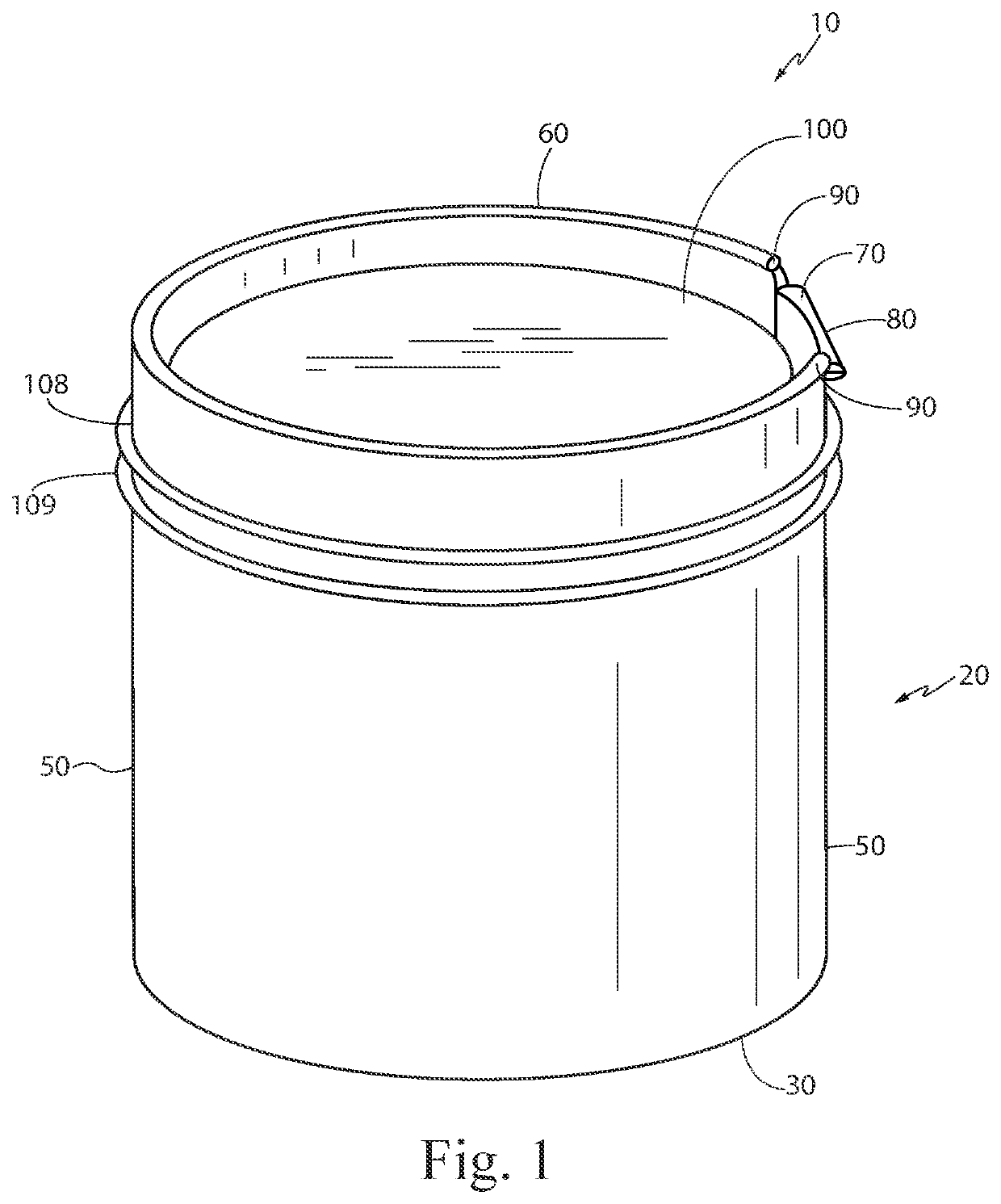

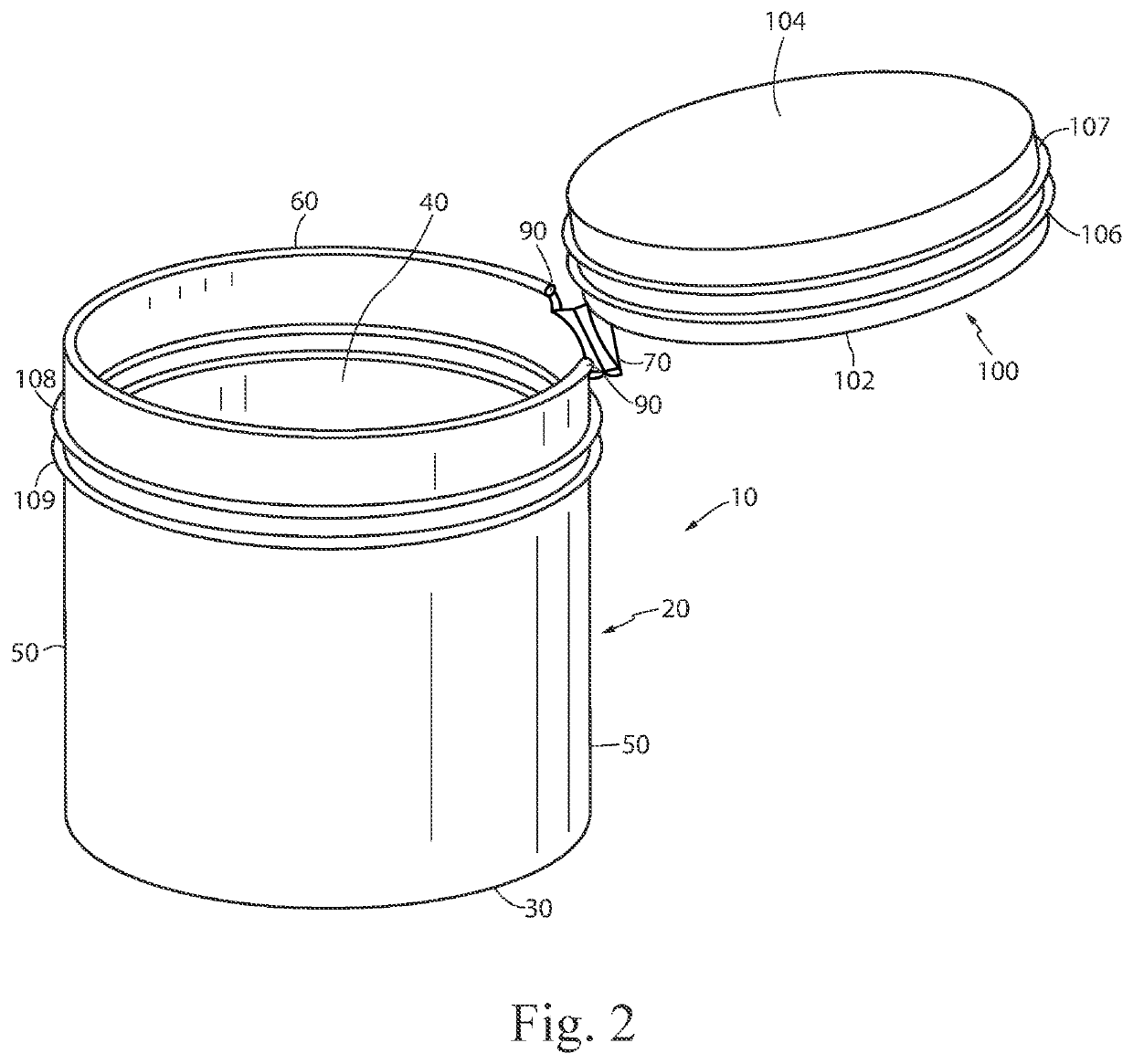

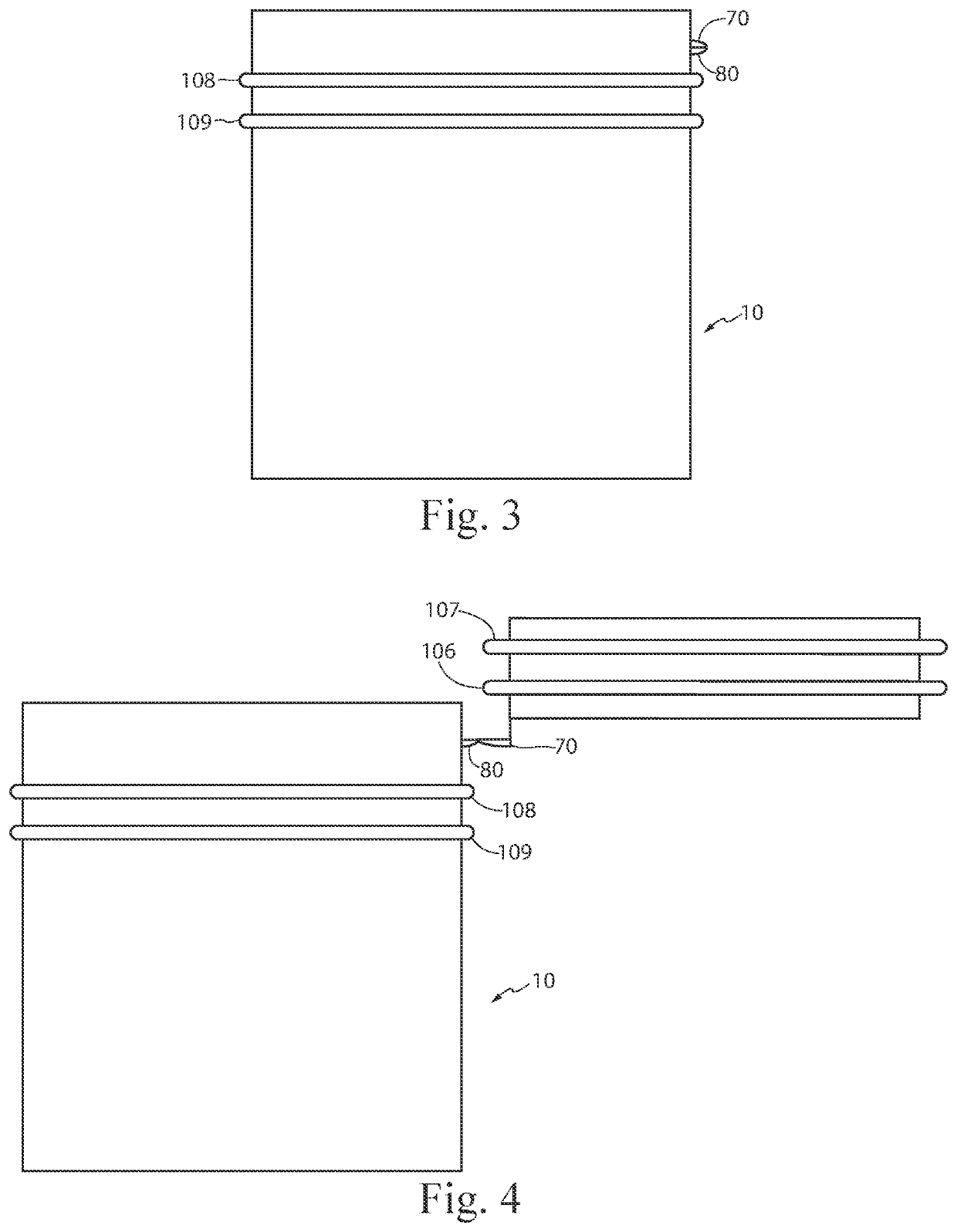

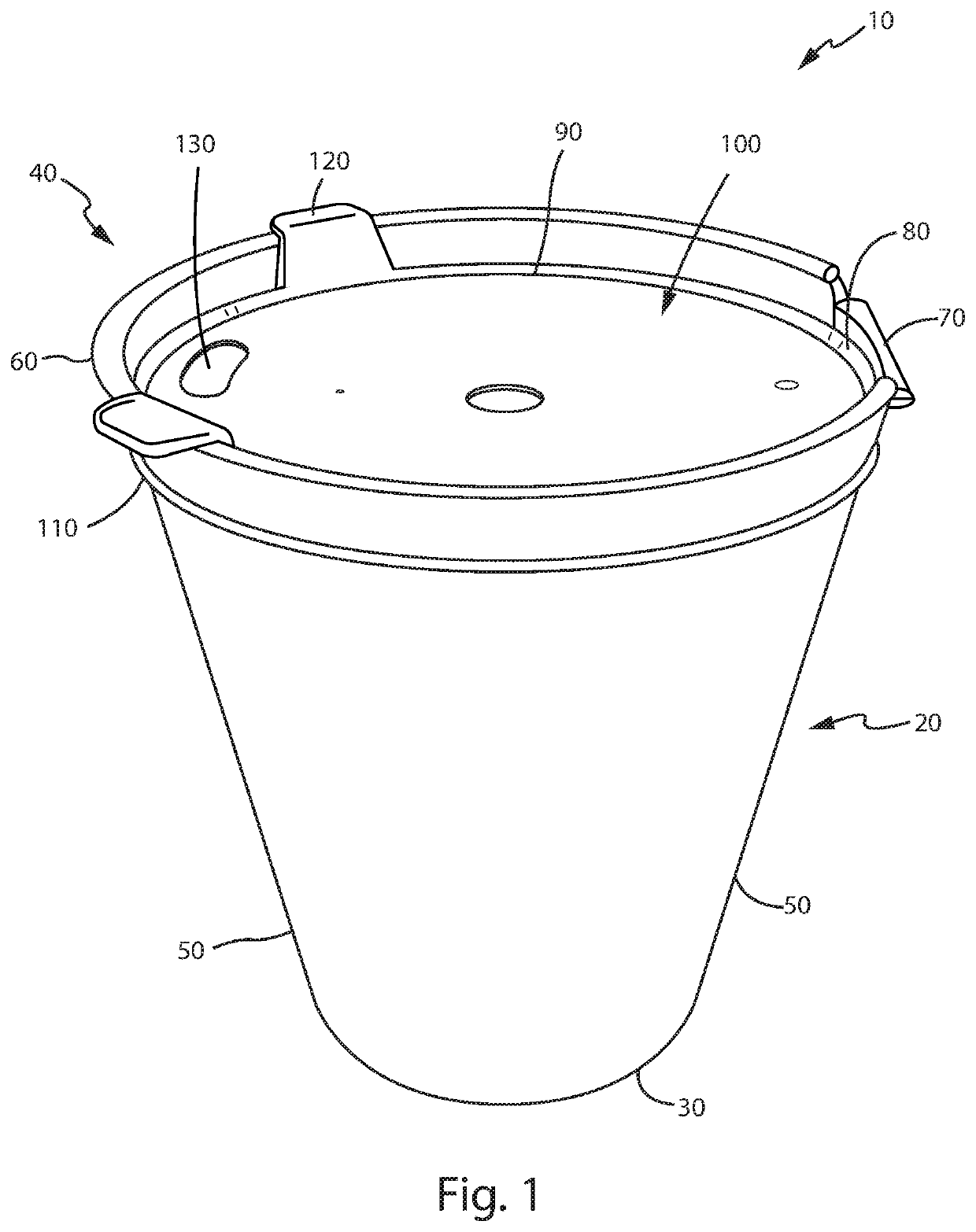

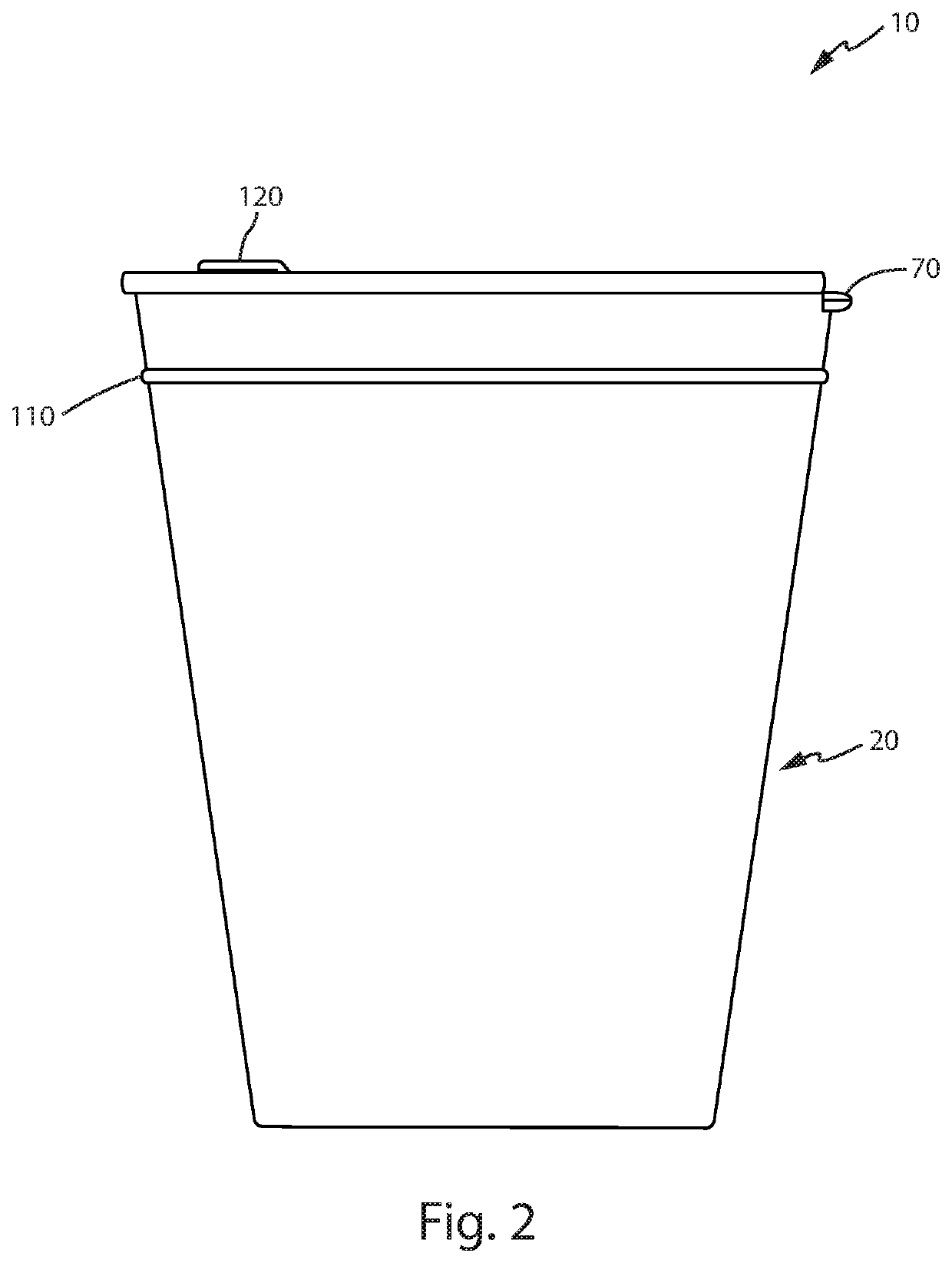

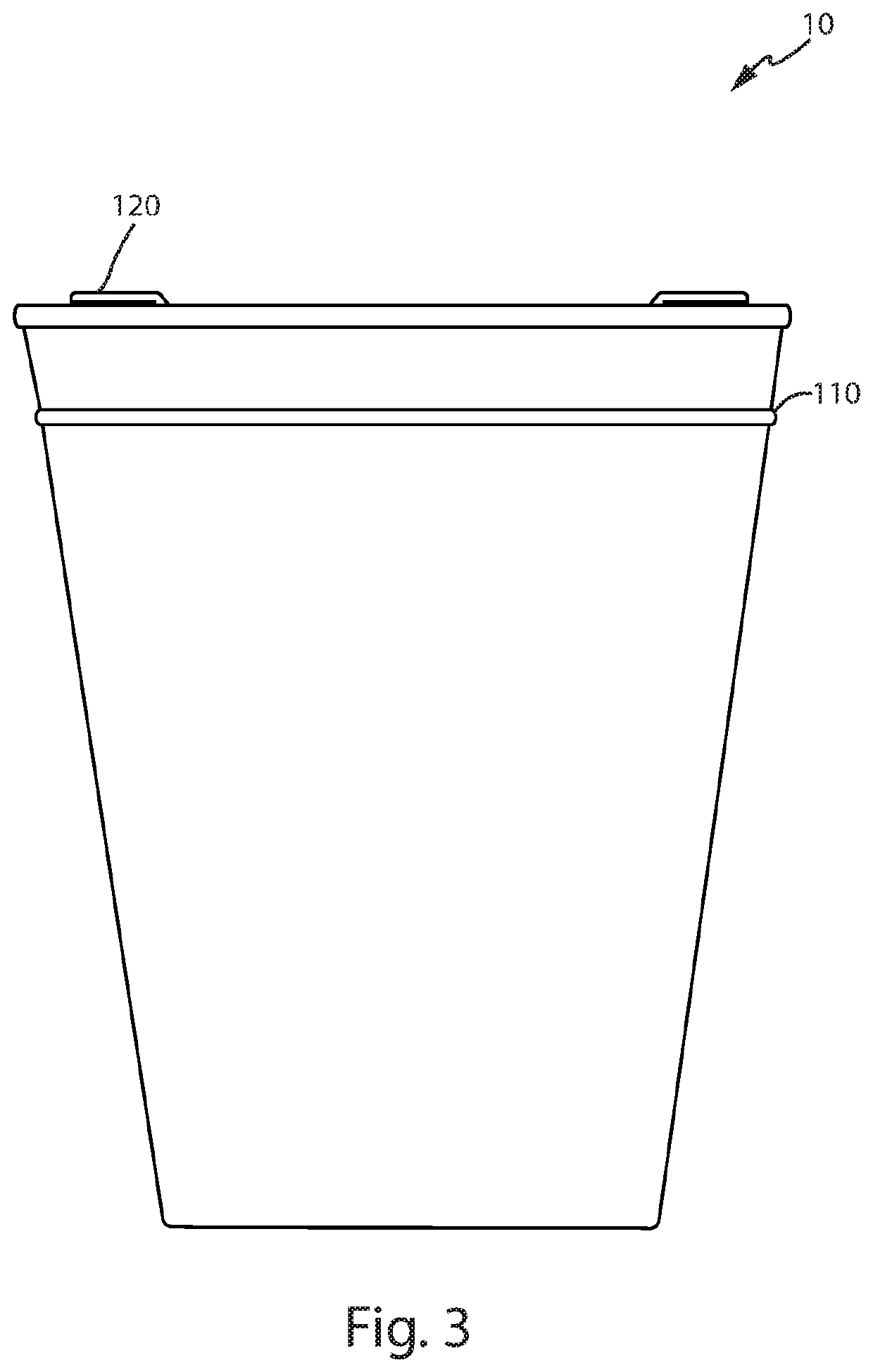

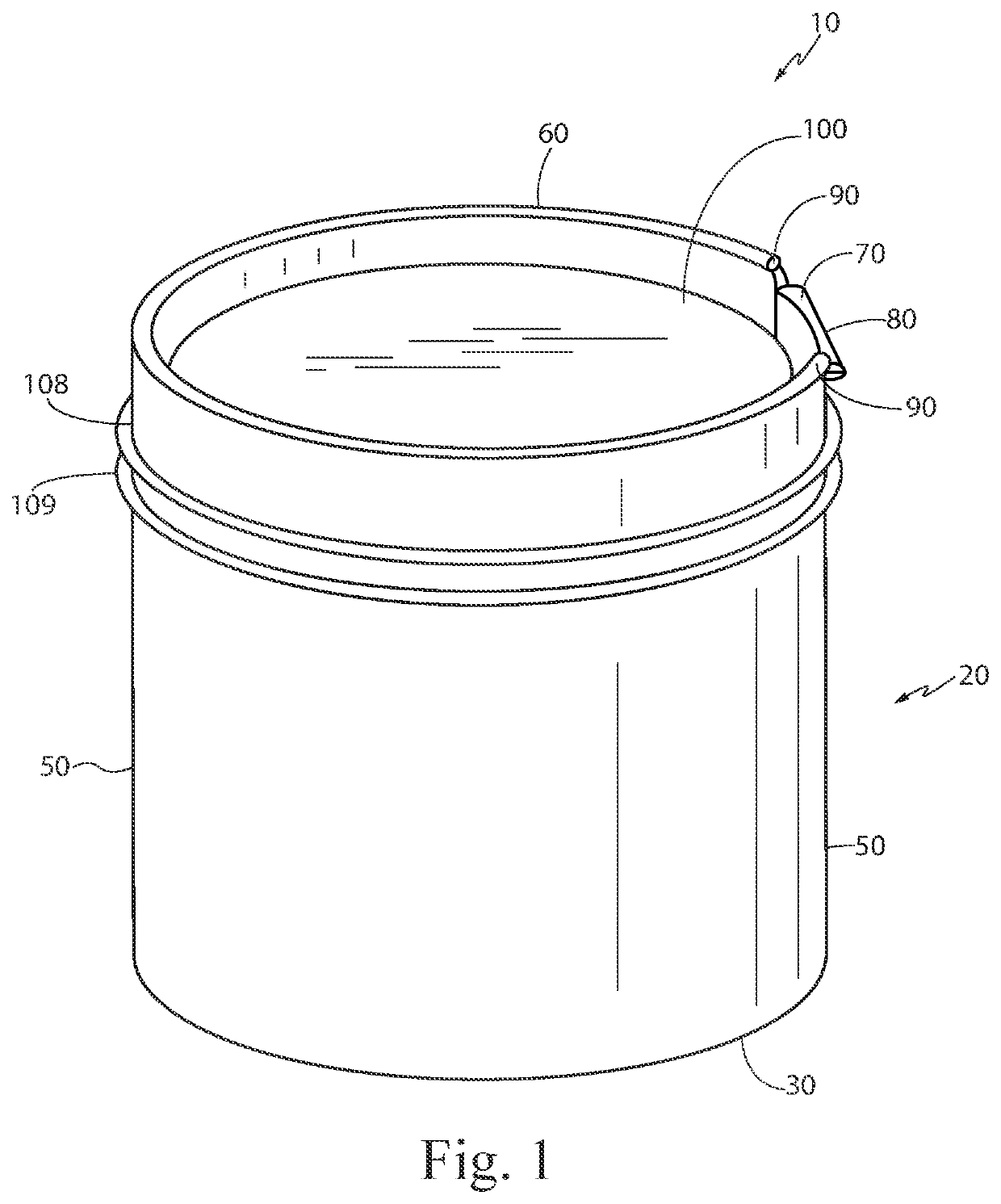

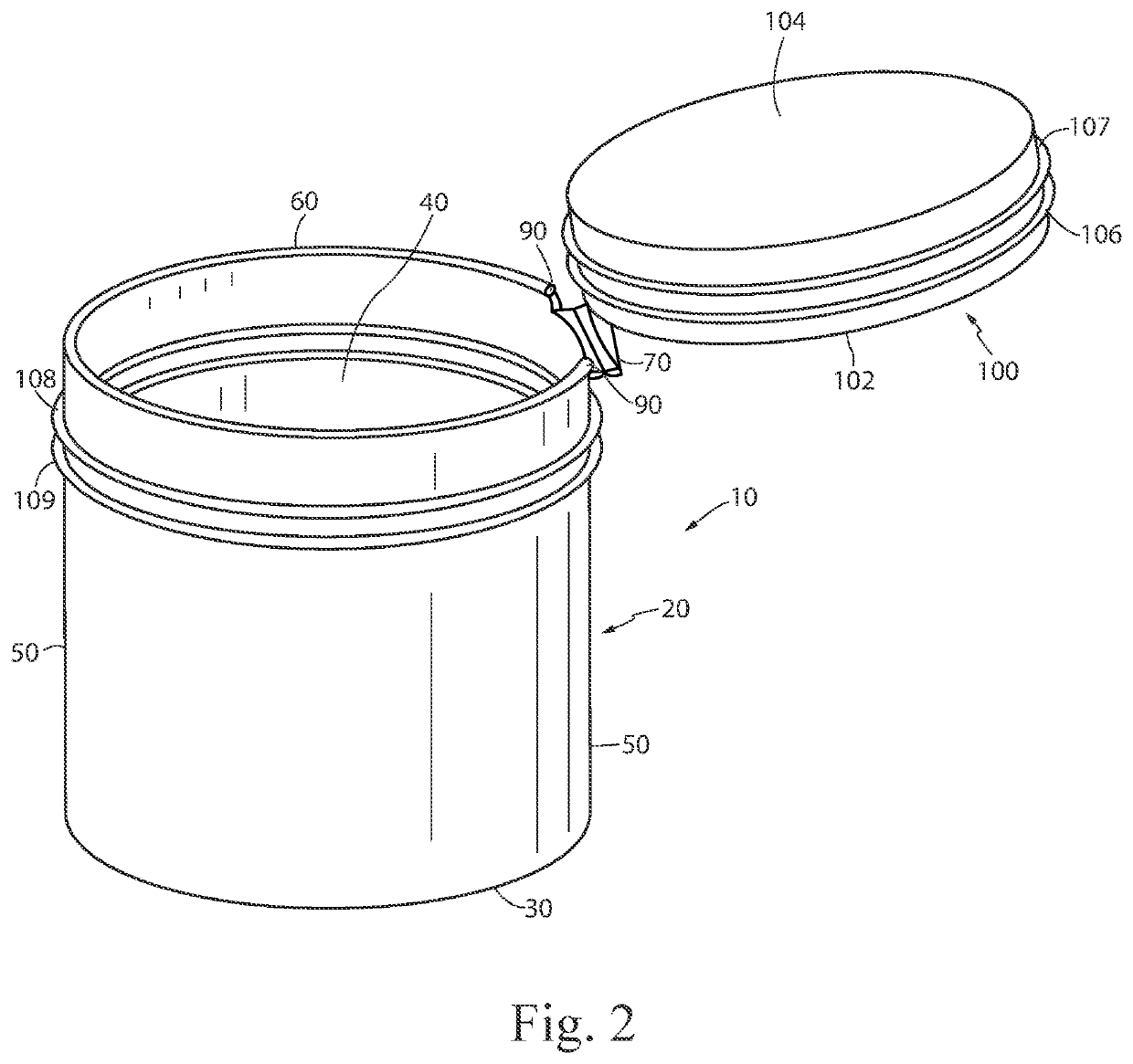

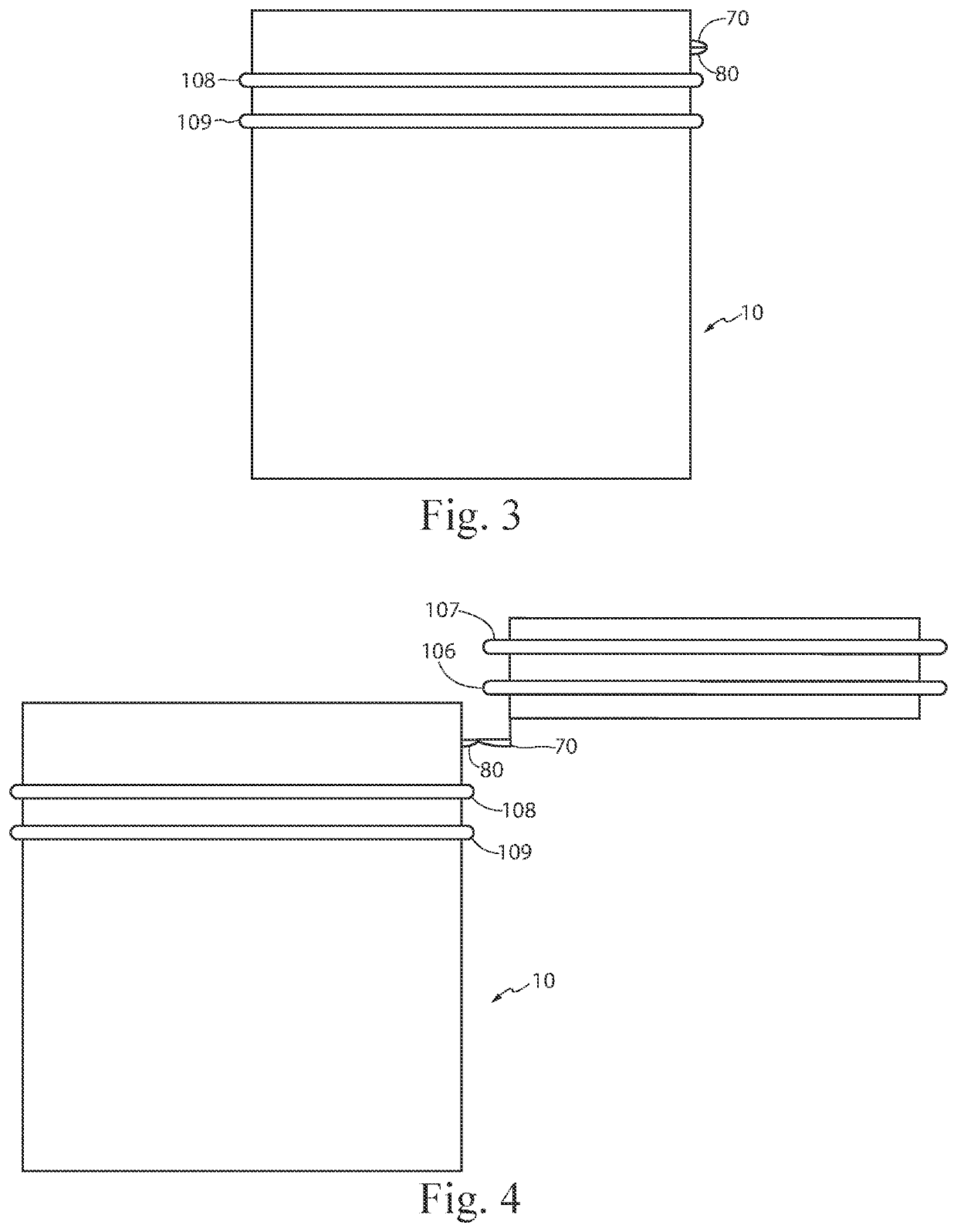

Cups and Containers with a Living Hinge and Sleeves

ActiveUS20190375560A1Improve functionalityImprove utilizationPackage recyclingVenting meansMechanical engineeringLiving hinge

The present invention is directed to cups, containers, and sleeves therefore having a living hinge and a dual seal structure on the lid such that the seal created by the contact of the lid with the inside of the cup or container ensures a secure, friction fit orientation to prevent spillage or leakage of the contents therein. The dual seal is created by a first component on the lip of the lid that extends down from the top of the lid and is substantial in shape with a rib on the bottom edge of the lip and the circumference of the lip that is of the same size and shape as the inner circumference of the cup or container such that a secure seal is created when closed. The cups and containers also have an inner concentric structure that follows the shape of the cup or container just above the base to offer stabilization, and ease of stacking, removal, and manufacture.

Owner:CLARITY INC

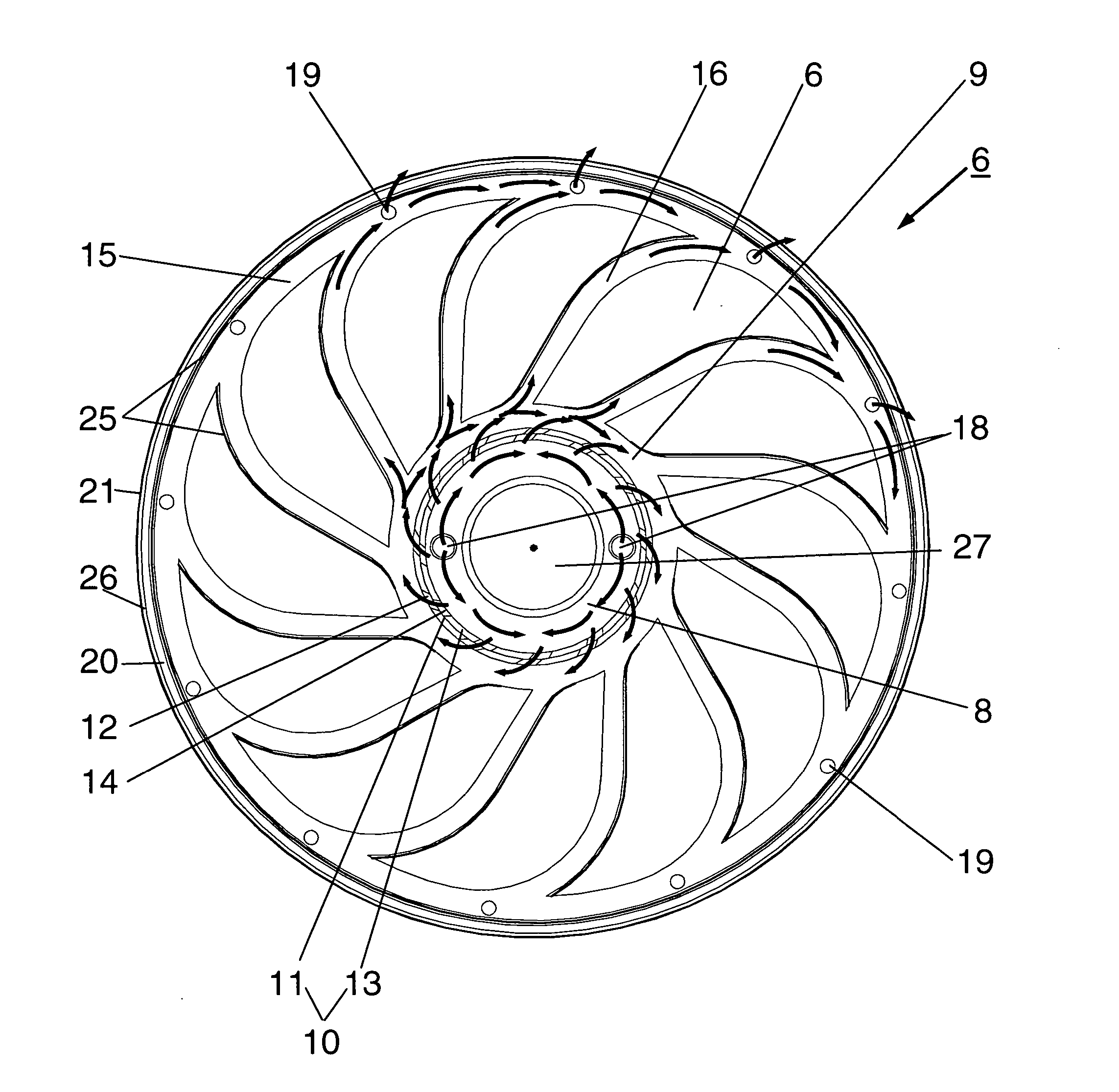

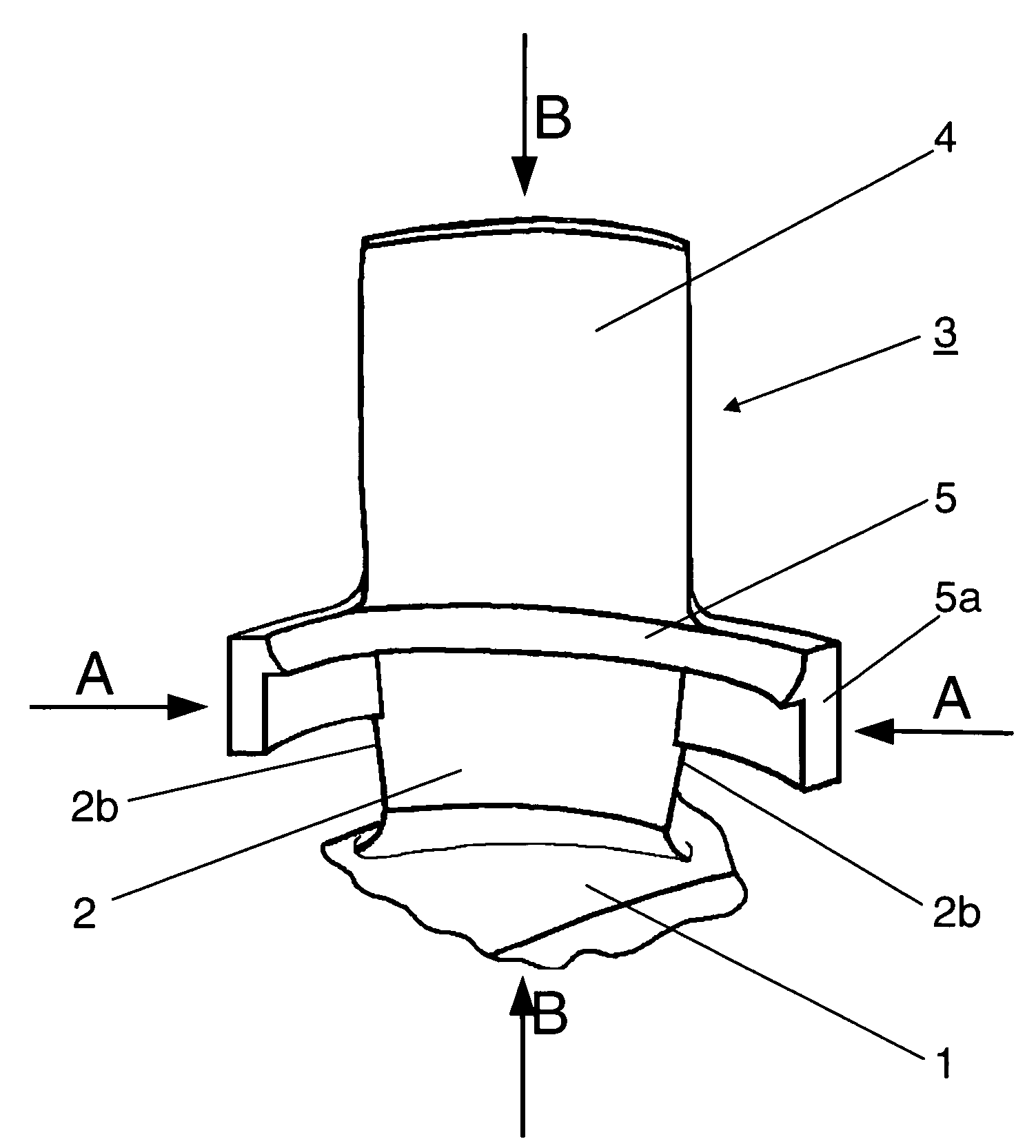

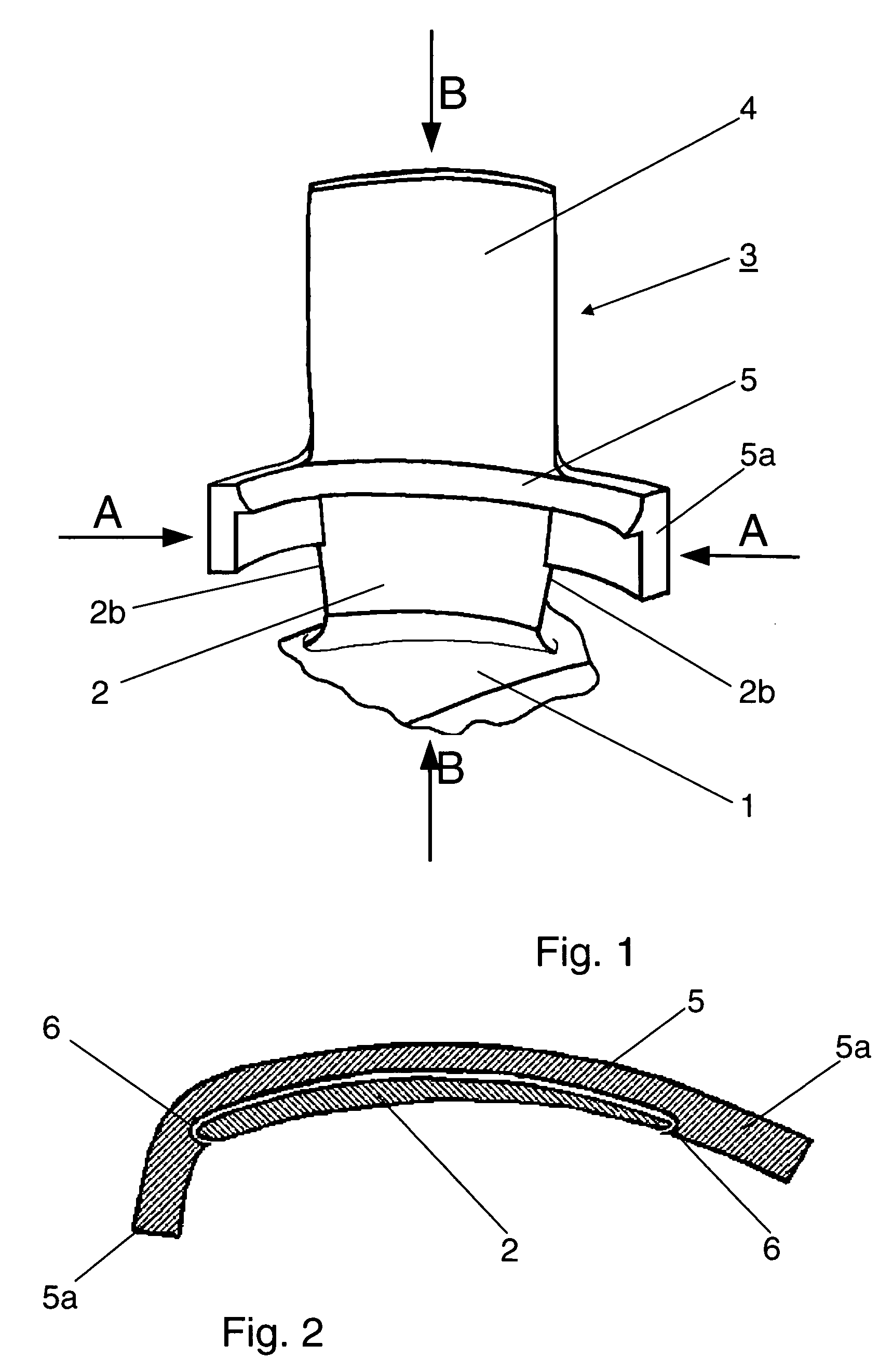

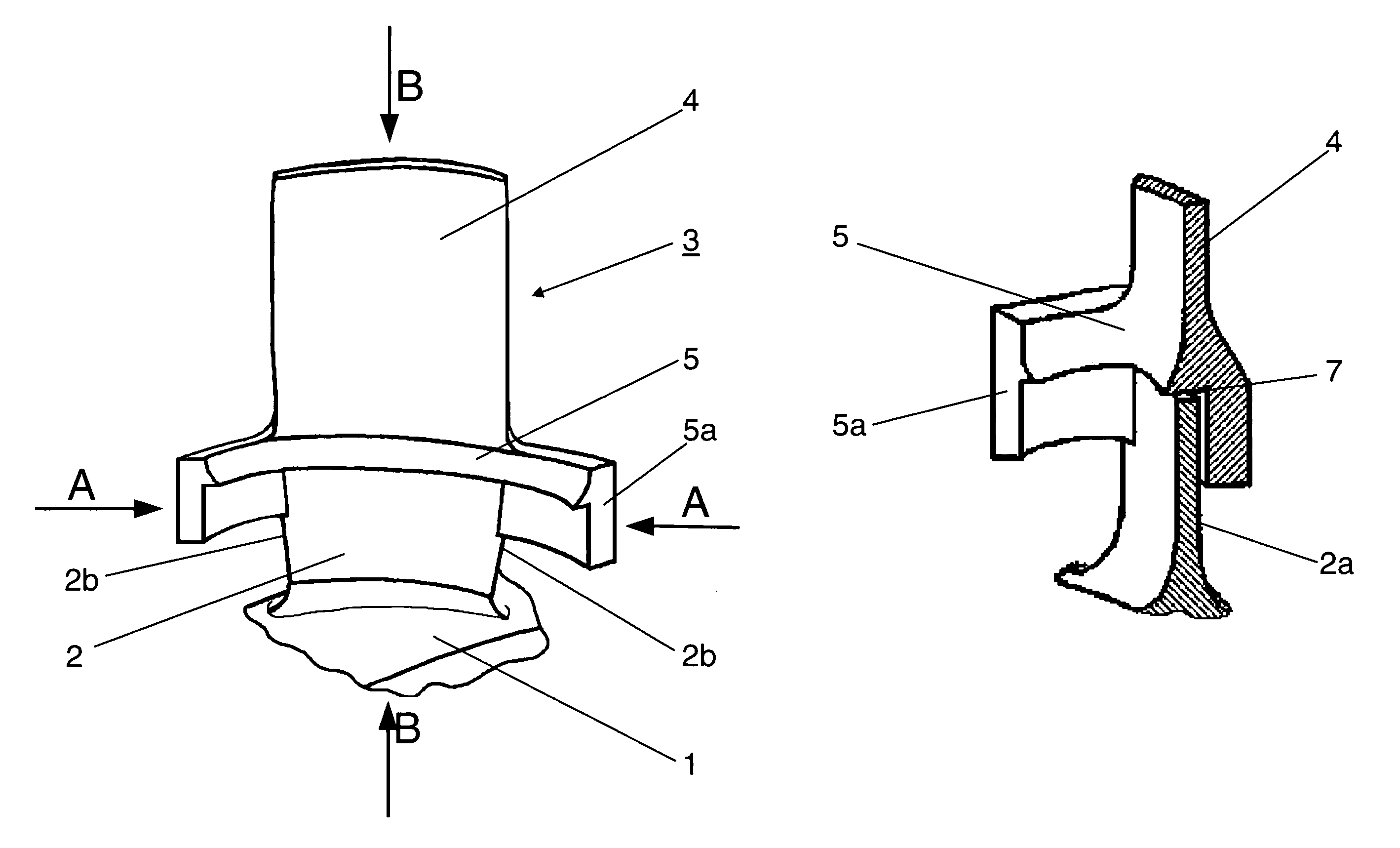

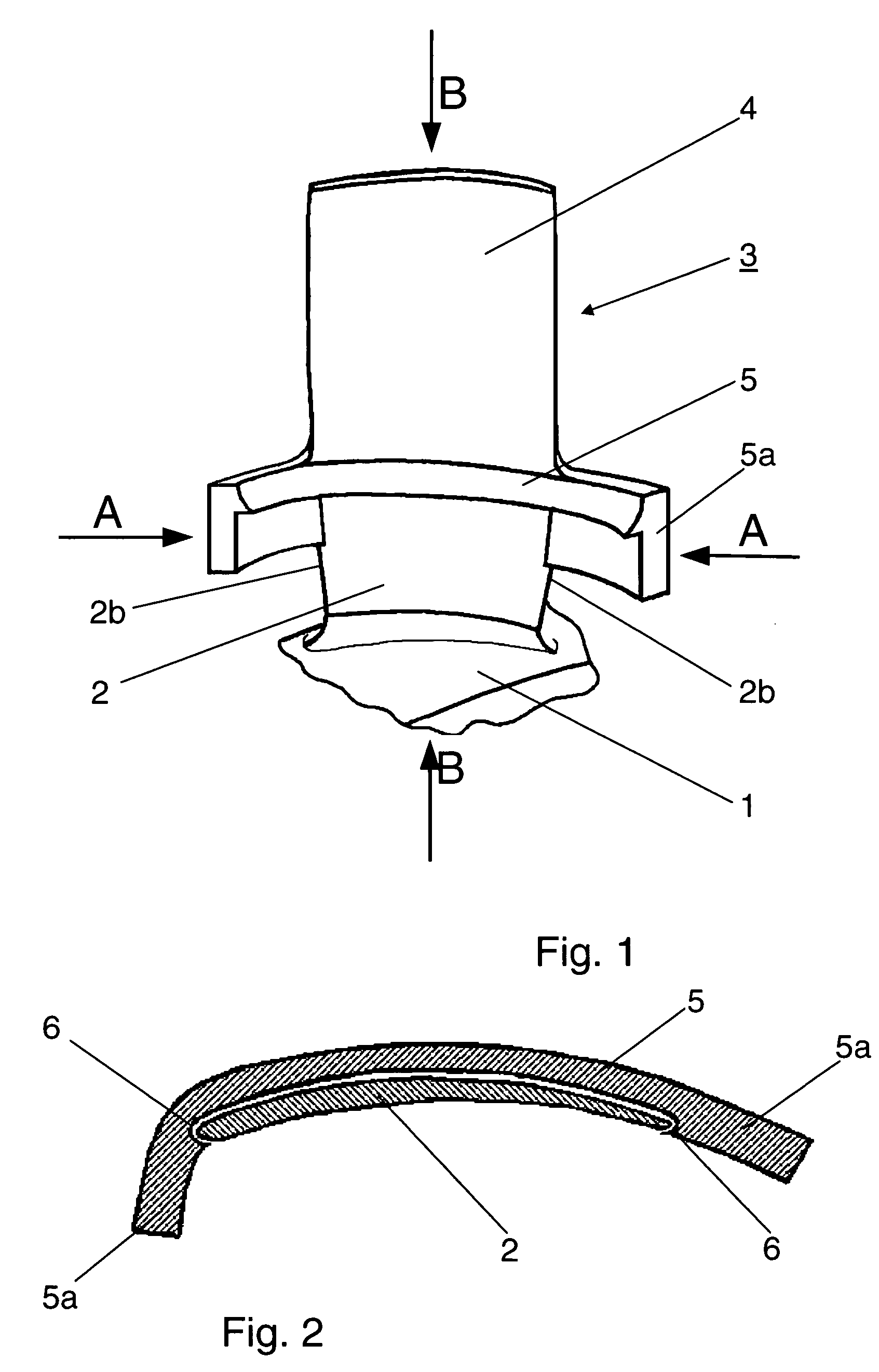

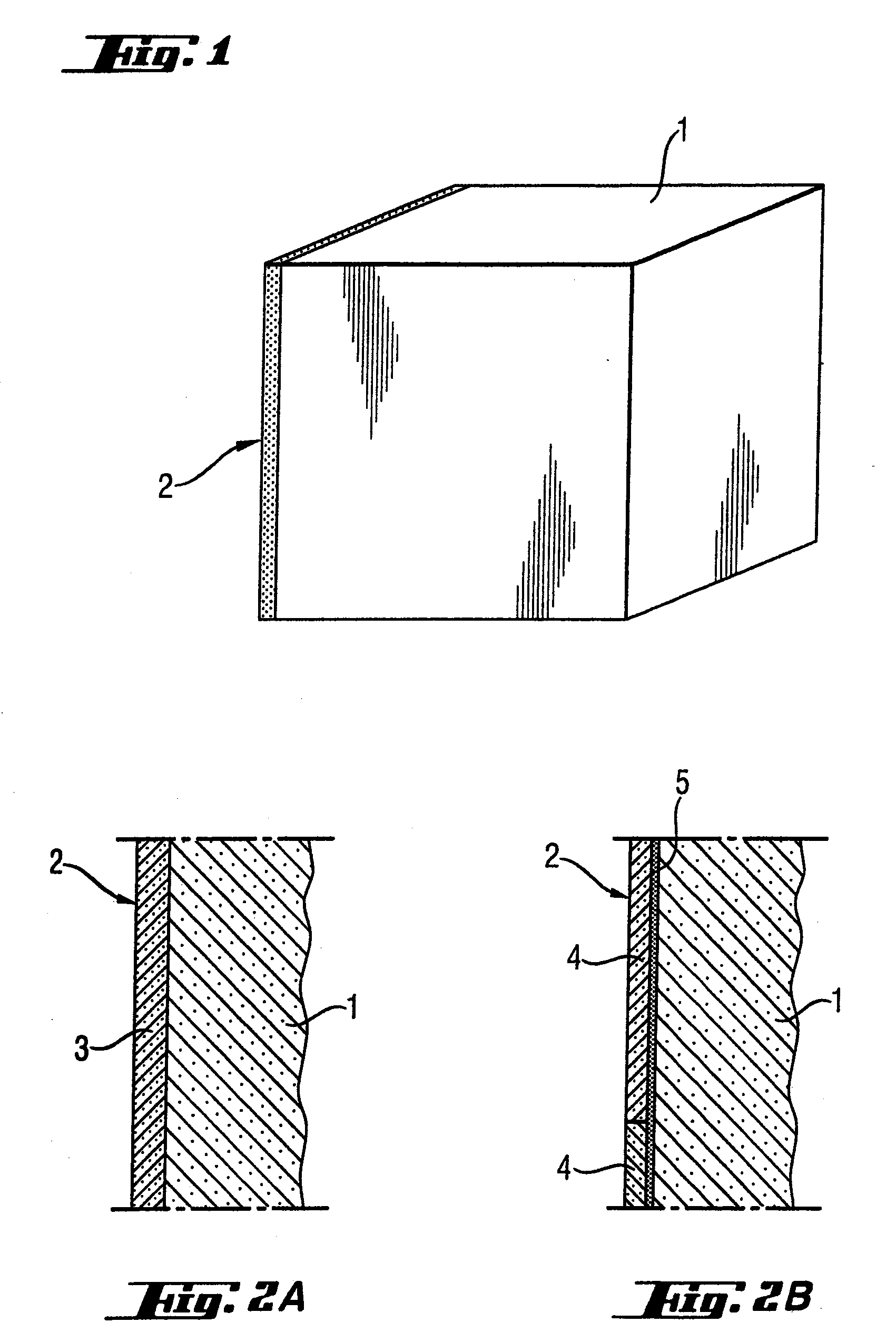

Method and blade repair element for blisk repair or blisk new manufacture

InactiveUS20060239823A1Reduction of work effort and costPrecise positioningBlade accessoriesReaction enginesEngineeringMechanical engineering

In the repair of a blisk or blisk drum, the damaged airfoils are completely cut off at the same low-stress nodal line peculiar to the respective blade type, except for a blade stump (2), and are each replaced by a new blade repair element (3) of a same shape and size which is accurately clamped onto the blade root by a ledge (5) formed onto its mating end, with this ledge (5) also serving for fixation of the processing fixtures and stabilization of the thin airfoil, and is then welded to the blade root and subsequently subjected to a cutting or non-cutting operation for removal of the ledge (5). This highly efficient repair method can similarly also be applied to the new manufacture of blisks.

Owner:ROLLS ROYCE DEUT LTD & CO KG

Combustion chamber of a combustion system

InactiveUS8006498B2Ensure longevityLongevityContinuous combustion chamberGas turbine plantsCombustion systemCombustion chamber

A combustion chamber of a combustion system comprises a combustion space, a support structure, a heat shield, and at least one through-opening. The heat shield has at least two segments, and each segment has an edge region, a gap communicating with the combustion space being formed between edge regions of adjacent segments, and a retaining device. The adjacent segments include a support element disposed in a bottom region of the gap. The retaining device fixes the respective liner element on the support structure via the respective support element. The at least one through-opening communicates with the gap so as to enable a cooling gas to flow through the through-opening. The at least one through-opening is disposed in at least one of the respective edge region and the support element at the bottom region of the gap.

Owner:ANSALDO ENERGIA IP UK LTD

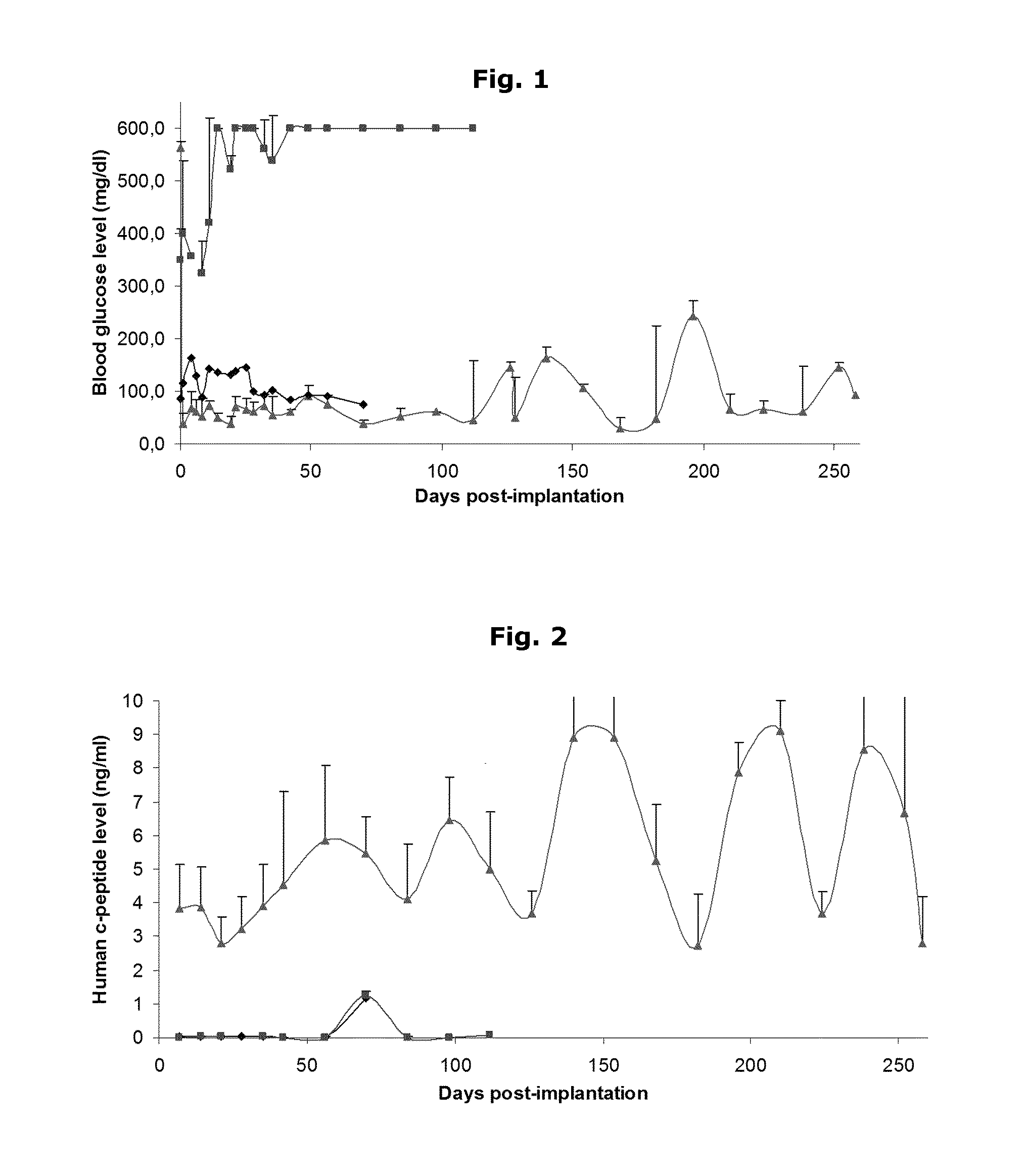

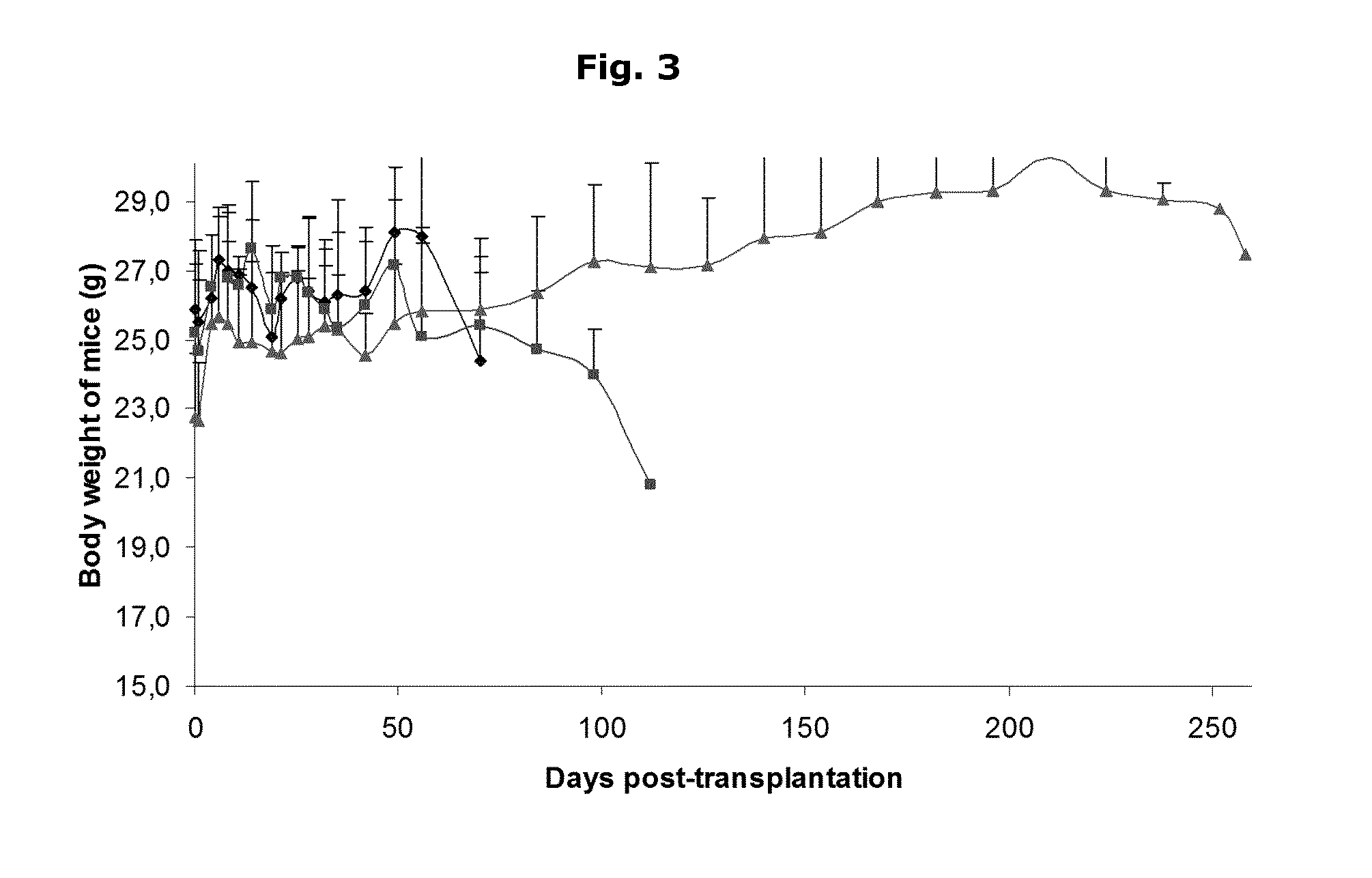

Method for encapsulated therapeutic products and uses thereof

InactiveUS20140017304A1Improve stabilityIncreased durabilityBiocidePeptide/protein ingredientsBiological materialsCell therapy

The current invention relates to encapsulation methods comprising alginate-based microencapsulation for the immune-protection and long-term functioning of biological material or therapeutics. The biological material or the therapeutics are encompassed by a membrane formed by jellifying an alginate polymer. Specifically, although by no means exclusively, the encapsulation system is intended for use in allo-or xenotransplantation. The membrane provides for a protective barrier of the encapsulated material, ensuring the longevity and preventing unwanted influences from outside the barrier, such as inflammatory reactions or immune-responses. The invention is furthermore directed to methods of producing and providing the encapsulated products for use in cell therapies. The therapeutic products obtained by the encapsulation method may provide a method for ameliorating of treating a range of conditions.

Owner:BETA CELL

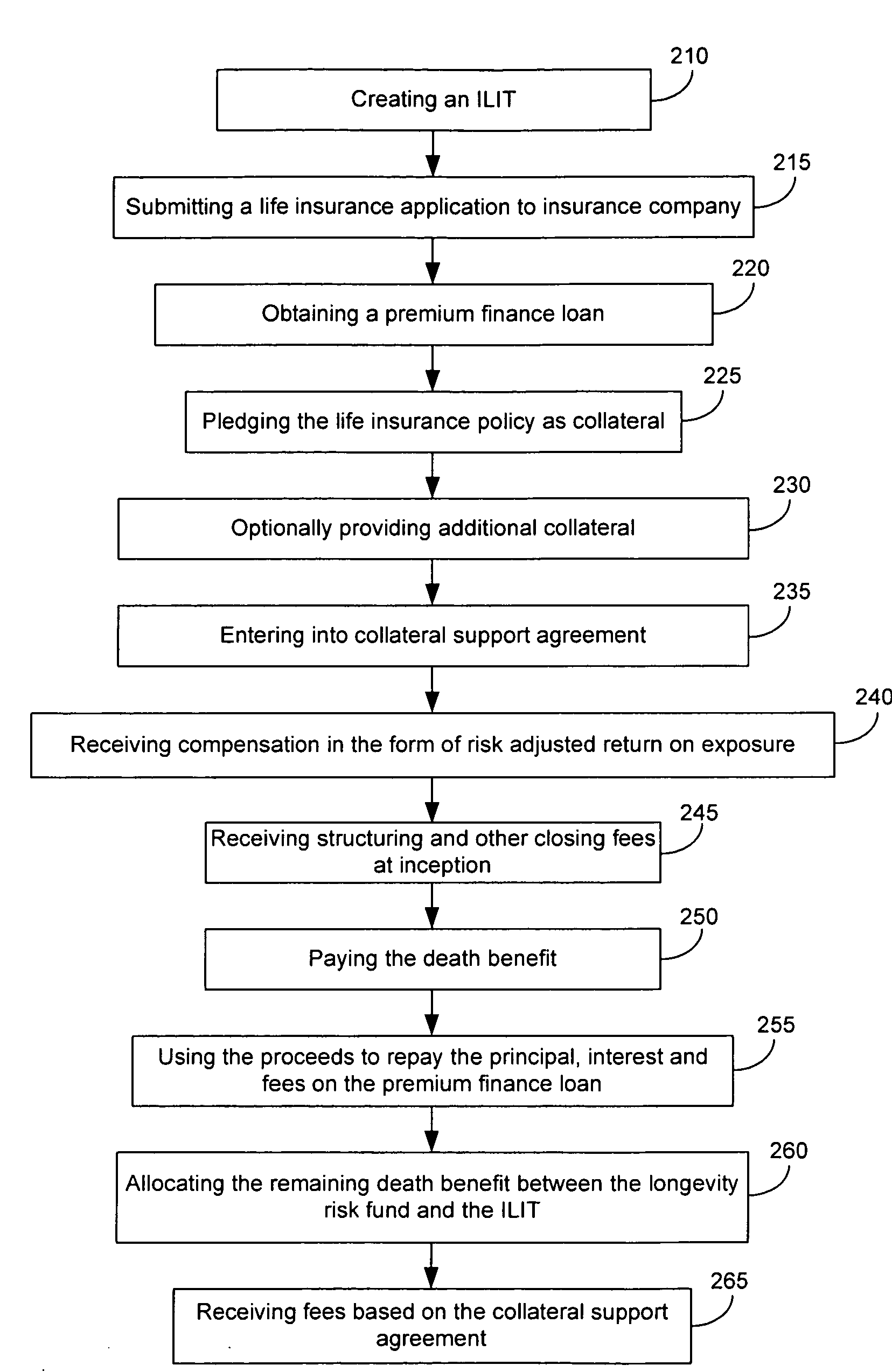

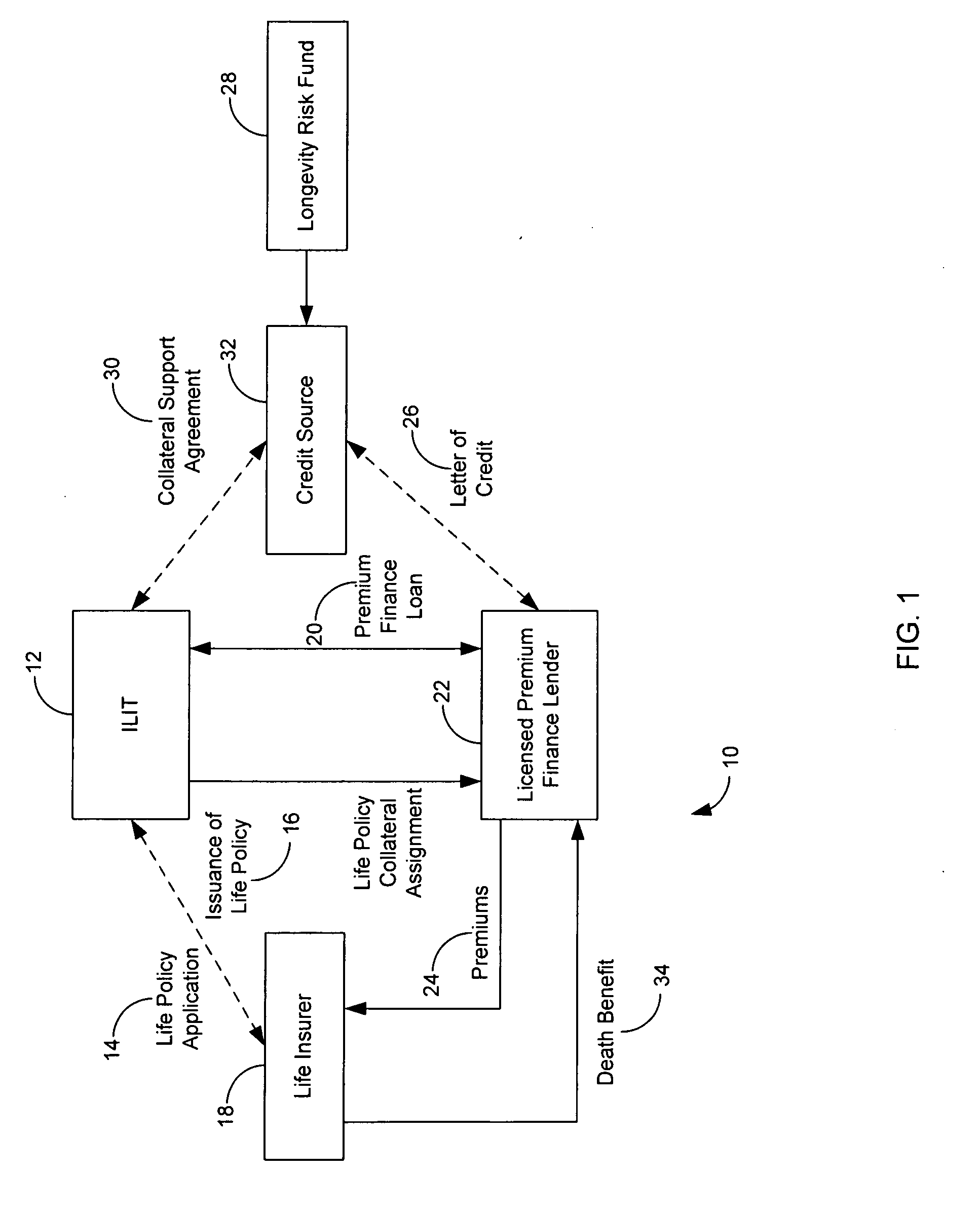

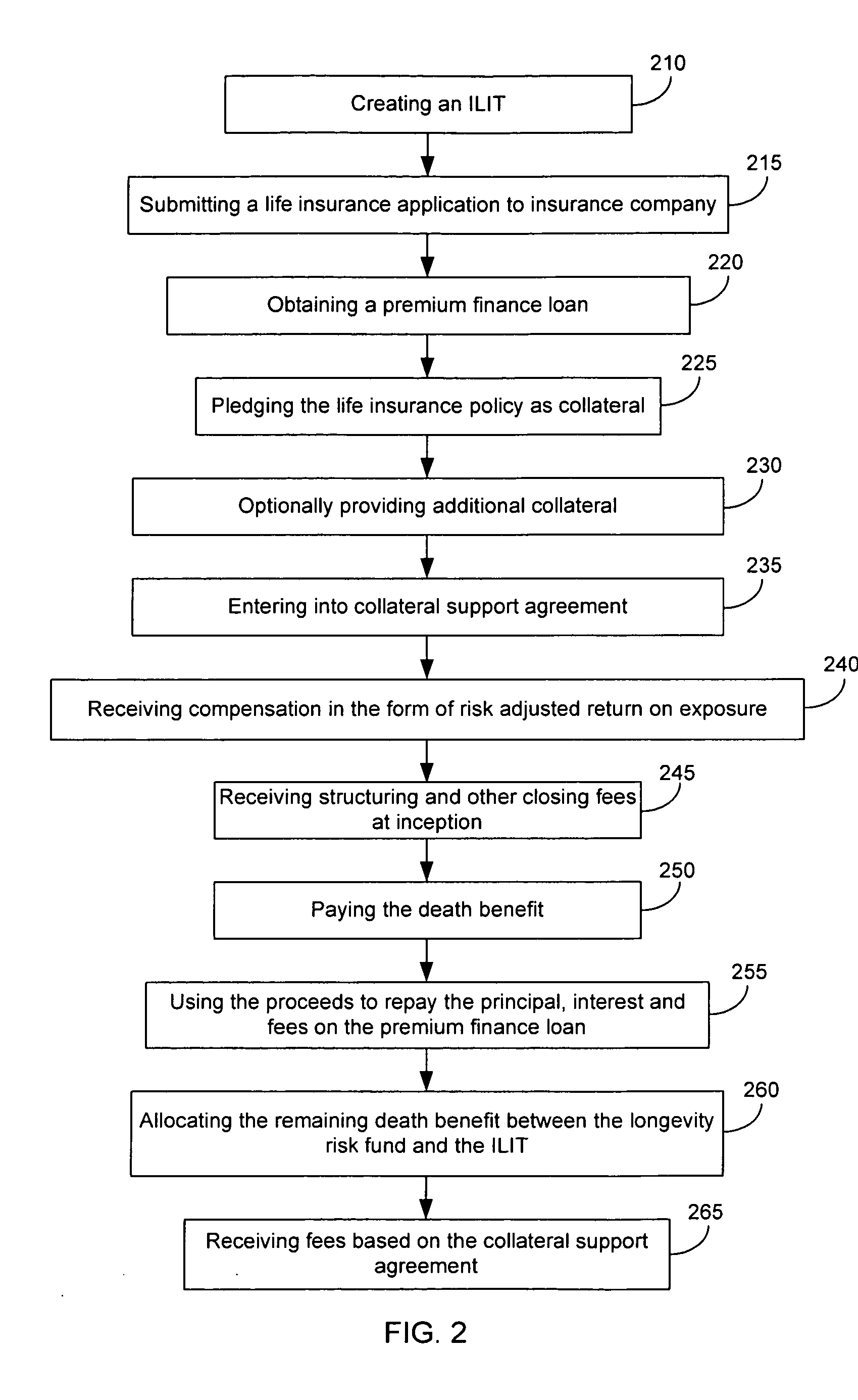

Systems and methods for securitizing longevity risk

A system for structuring credit support in connection with life insurance premium finance loans and securitizing longevity risk includes a trust having a life insurance policy and a premium finance loan from a lender that finances the cost of the premiums of the life insurance policy. The life insurance policy is used as collateral for the premium finance loan. The trust provides to the lender additional collateral in the form of a letter of credit or other forms of collateral to cover any shortfall between the balance and the policy cash surrender value. A longevity risk fund provides the credit support by entering into a collateral support agreement with the trust through a credit source. The longevity risk fund receives compensation in the form of risk adjusted return on exposure, in exchange for providing the additional collateral. The cash flows received from the credit support obligations are then securitized through the transfer of the related collateral support agreements (either by legal transfer or economic participation) to a special purpose vehicle that issues securities (either equity or debt) to the capital markets.

Owner:RAGHAVAN HARISH +2

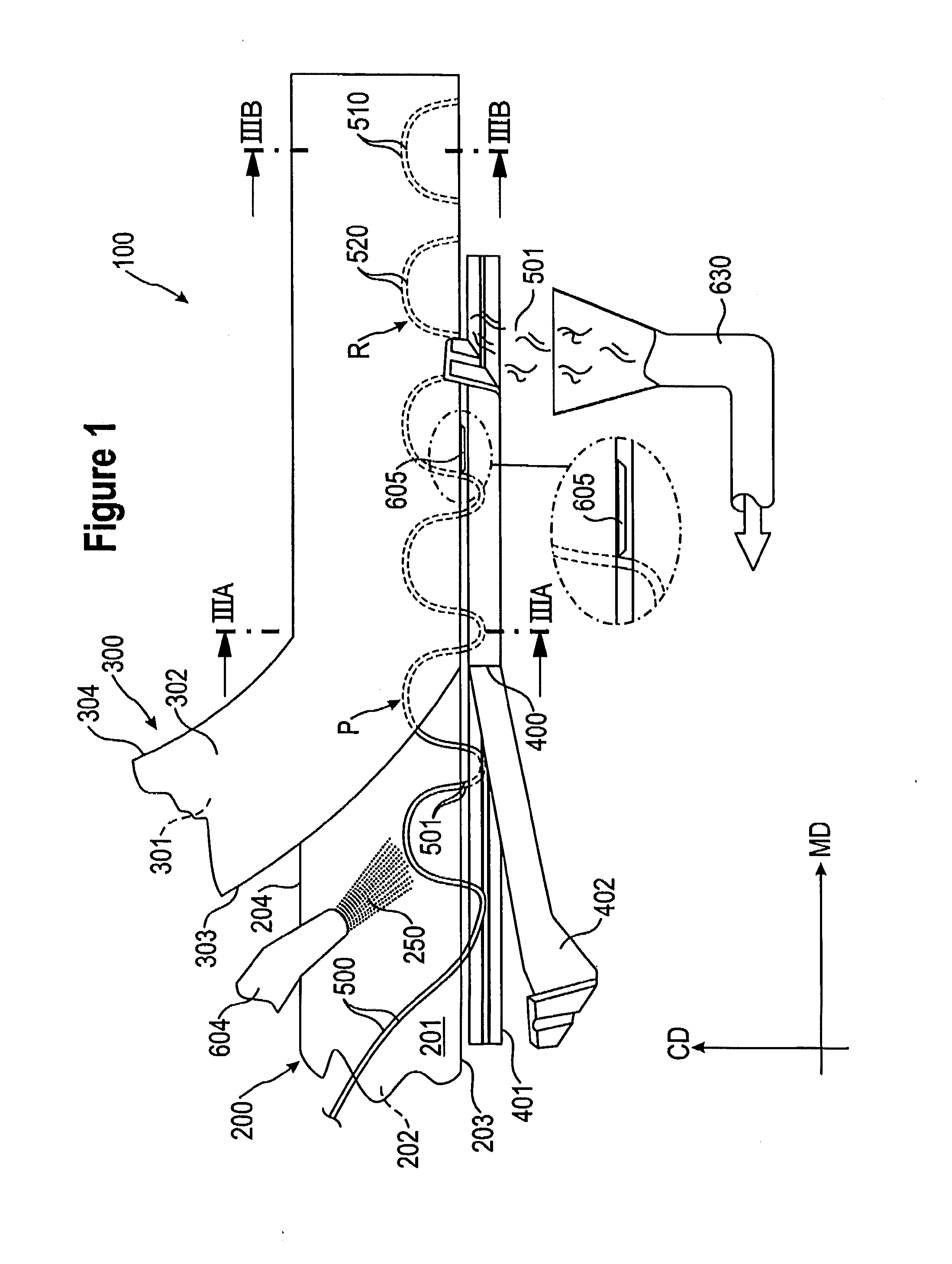

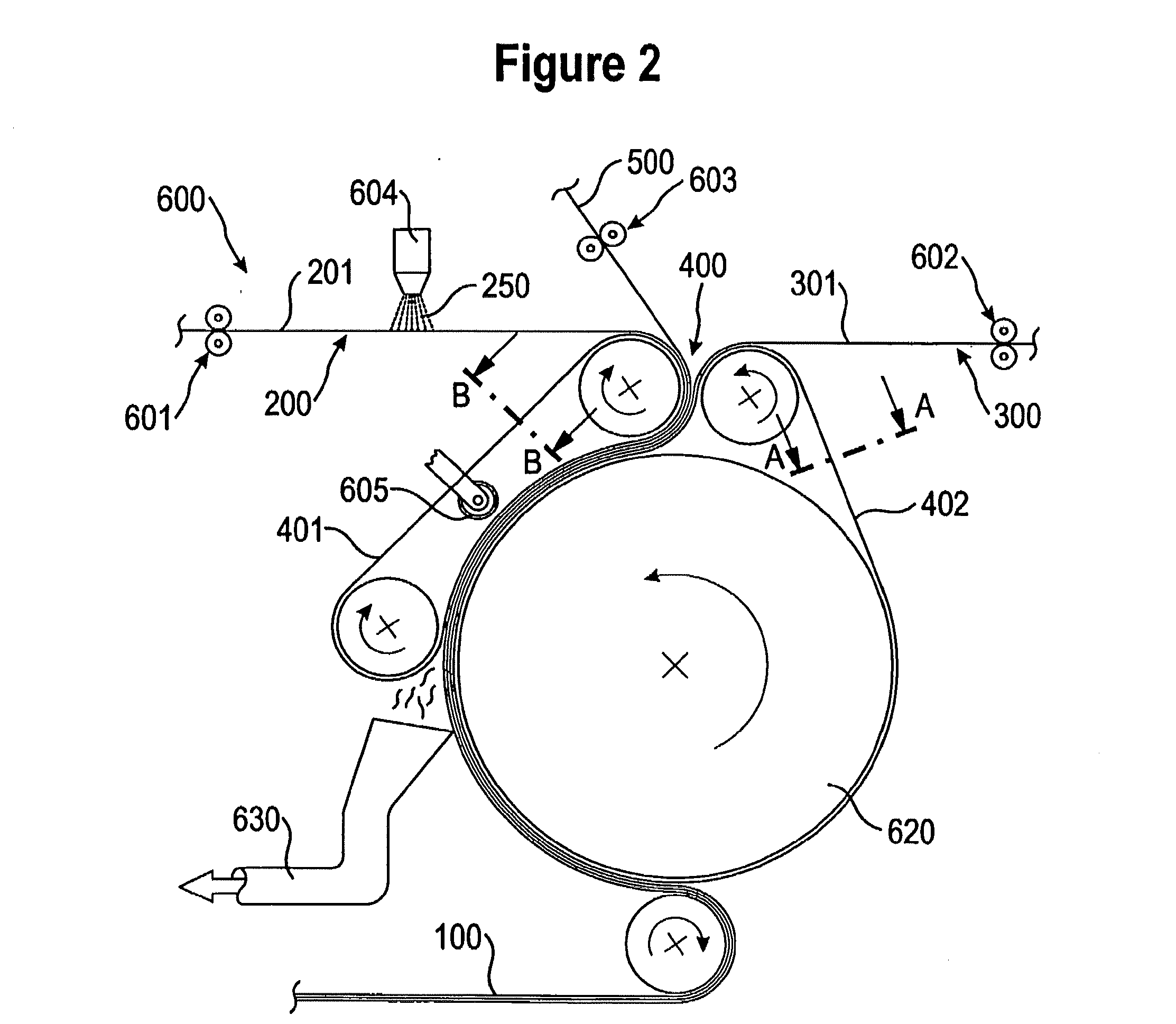

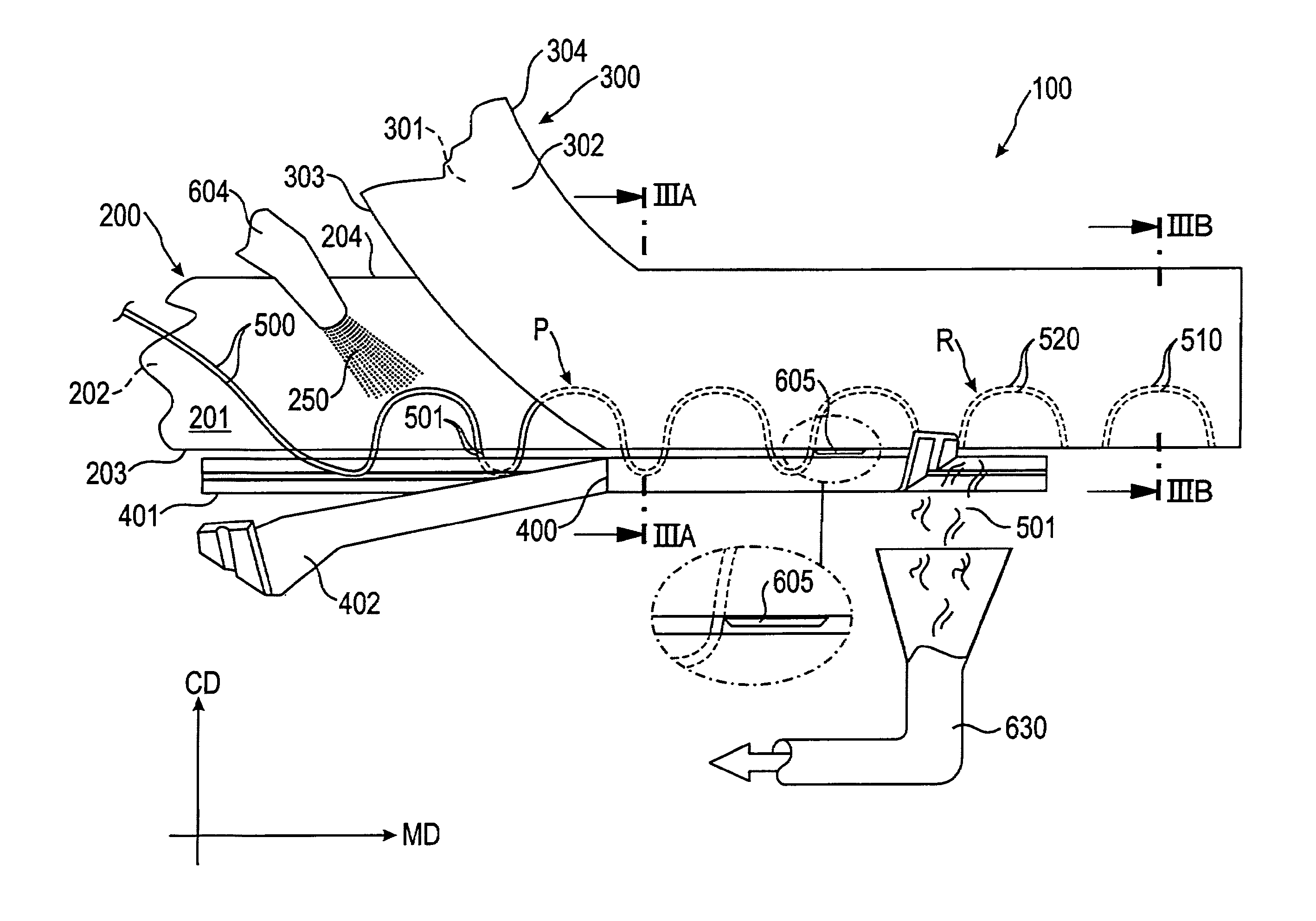

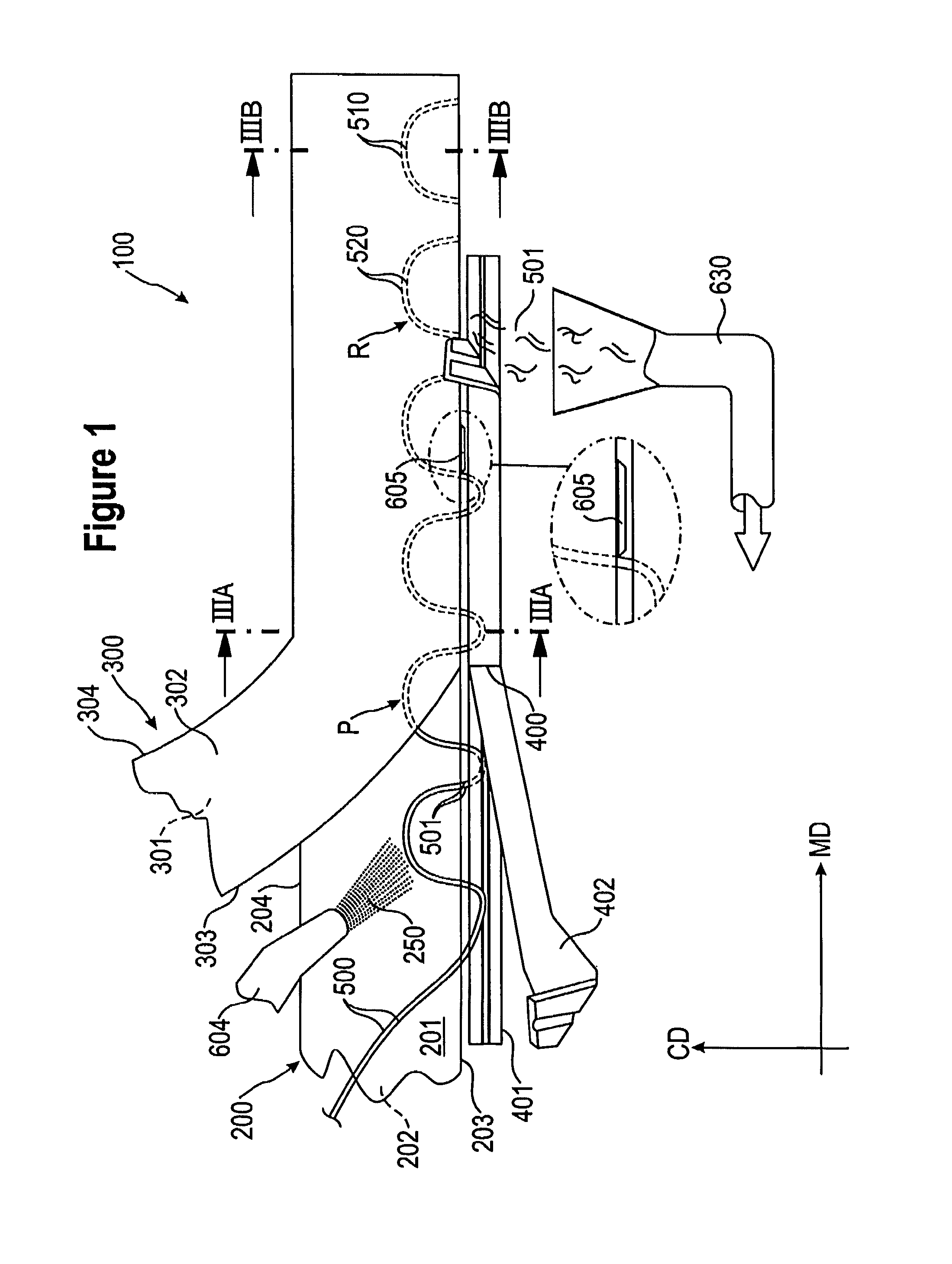

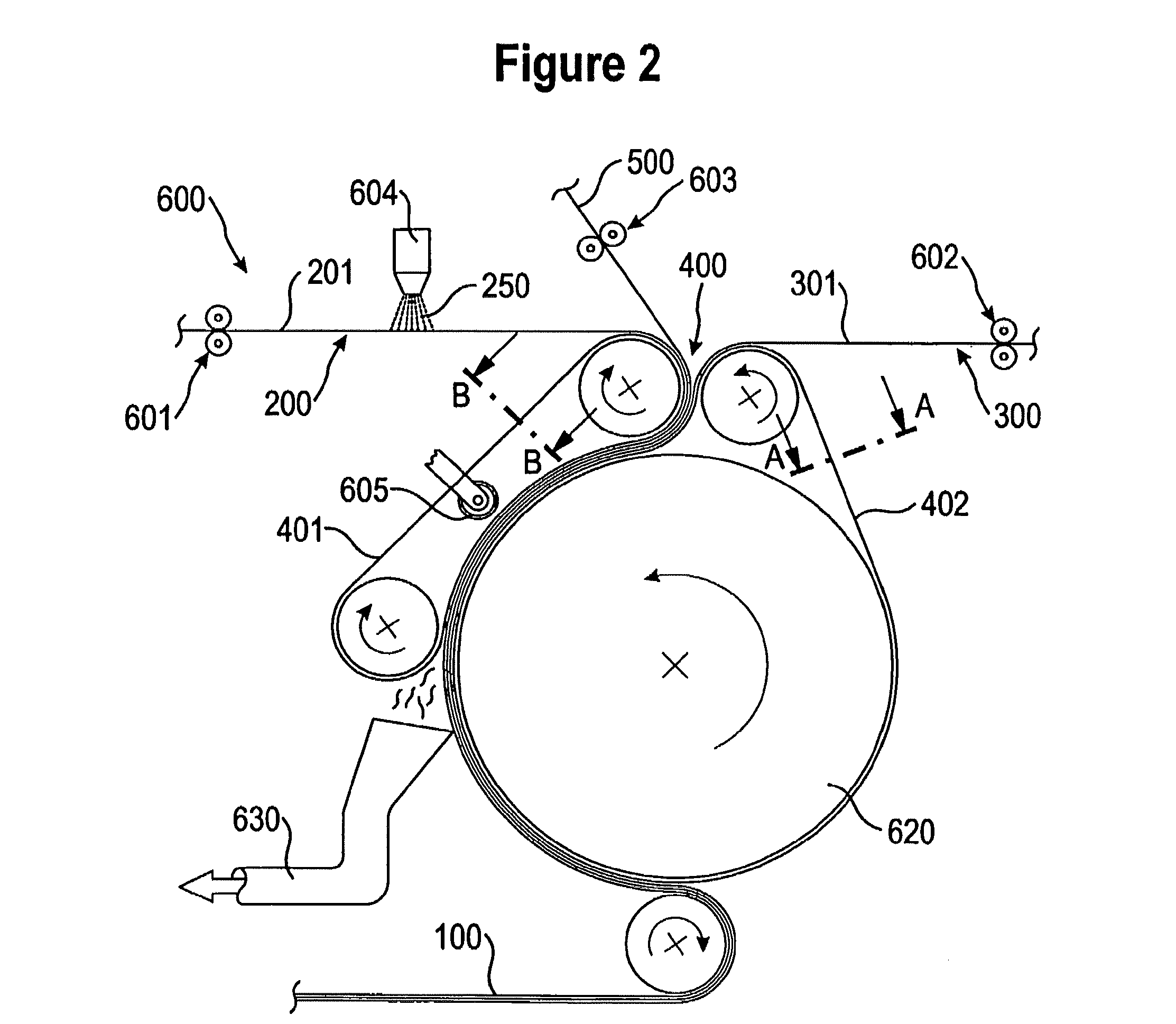

Method and apparatus for trimming material from a web

ActiveUS20130331250A1Avoid excessive wearIncrease opportunitiesMechanical working/deformationGang saw millsEngineeringKnife blades

Unattached elastic portions of an elasticised web are grasped and raised above a support surface for feeding the elasticised web. The raised portions are brought into contact with a knife blade that is positioned to protrude through the thickness of the raised elastic layer into free space so as to remain spaced from the support surface that is moving beneath the blade in a direction normal to the support surface. The raised elastic layer is held raised during trimming with the knife blade by an elevation element over which the elastic layer runs. A grasping device holds the unattached portion being cut in a taut state in the cross machine direction. The elastic layer thus spans across the elevation element and the grasping device. The knife blade extends through the thickness of the elastic layer along the spanned part of the elastic layer into free space.

Owner:ESSITY HYGIENE & HEALTH AB

Cups and Containers with a Living Hinge and Sleeves

ActiveUS20210086958A1Improve utilizationImprove functionalityPackage recyclingDomestic cooling apparatusClassical mechanicsStructural engineering

The present invention is directed to containers for holding non-food items having a living hinge and a quad or multi seal structure on the lid such that the seal created by the contact of the lid with the inside of the cup or container ensures a secure, friction fit orientation to prevent spillage or leakage of the contents therein. The quad or multi directional seal is created by multiple ribs on the lid that securably fit within the base of the container and indentations oriented in the bases, or by multiple ribs on the lid that securably fit within a channel structure in the top of the base of the container, the channel structure having the indentations in order to create a secure fit.

Owner:CLARITY INC

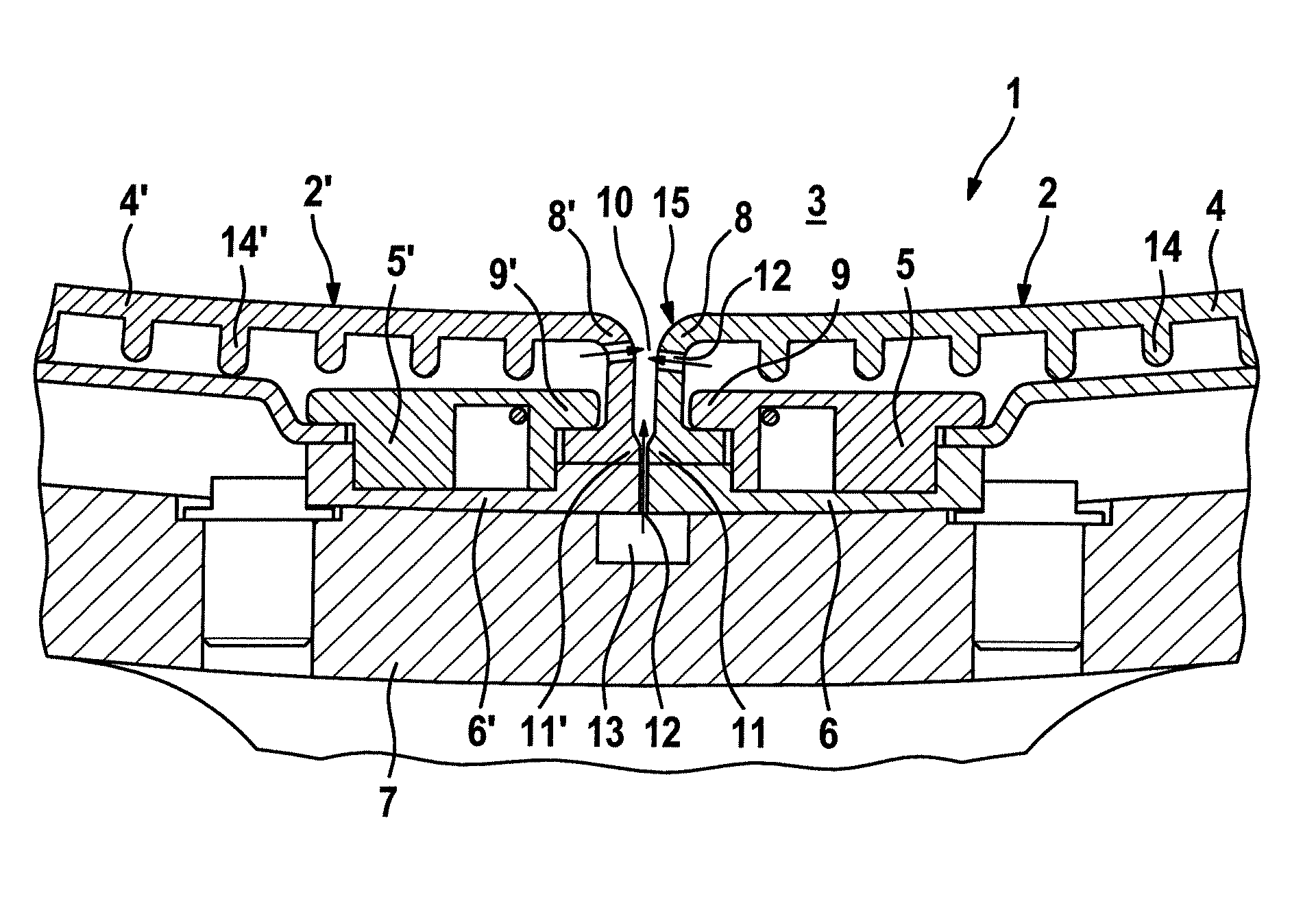

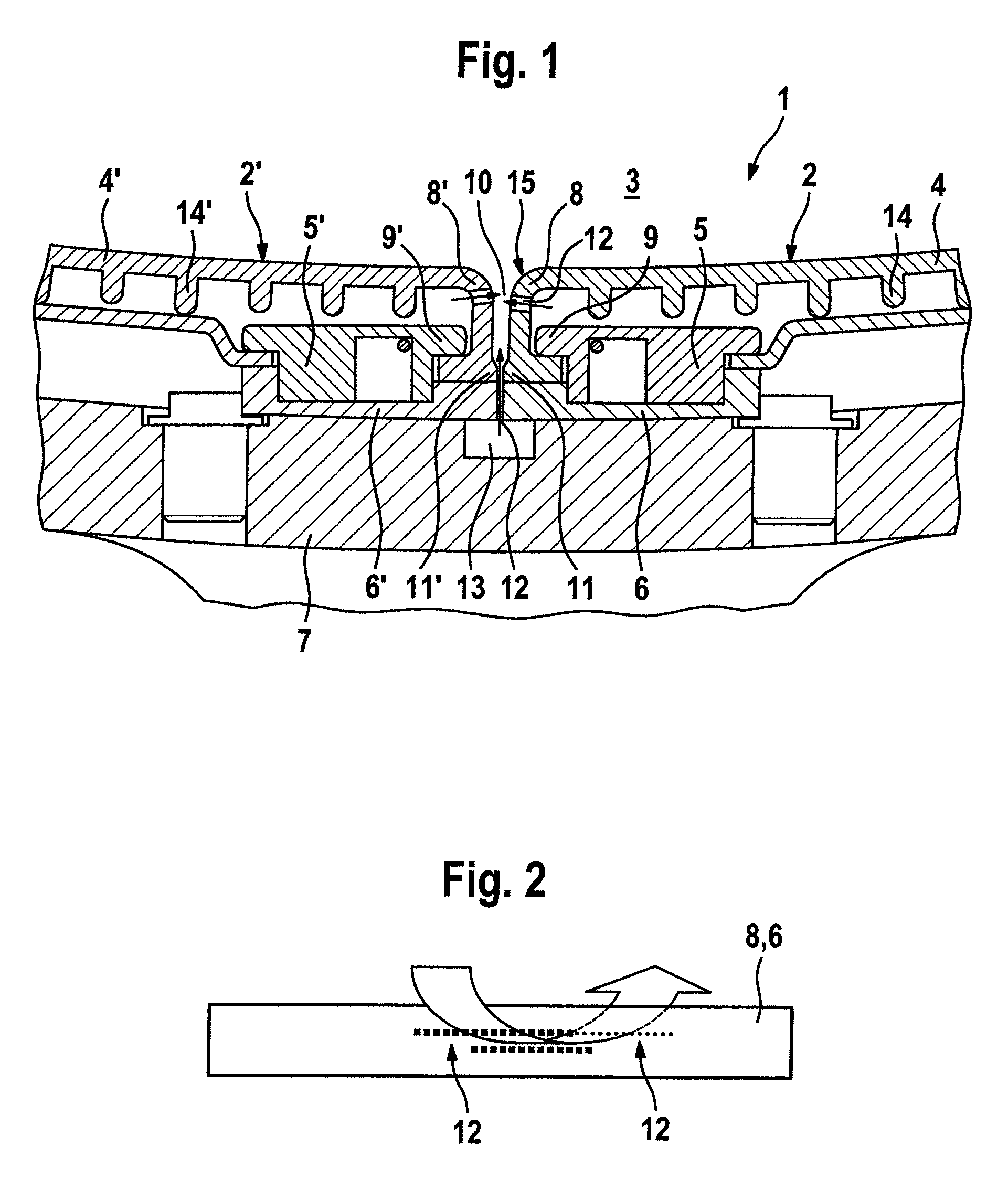

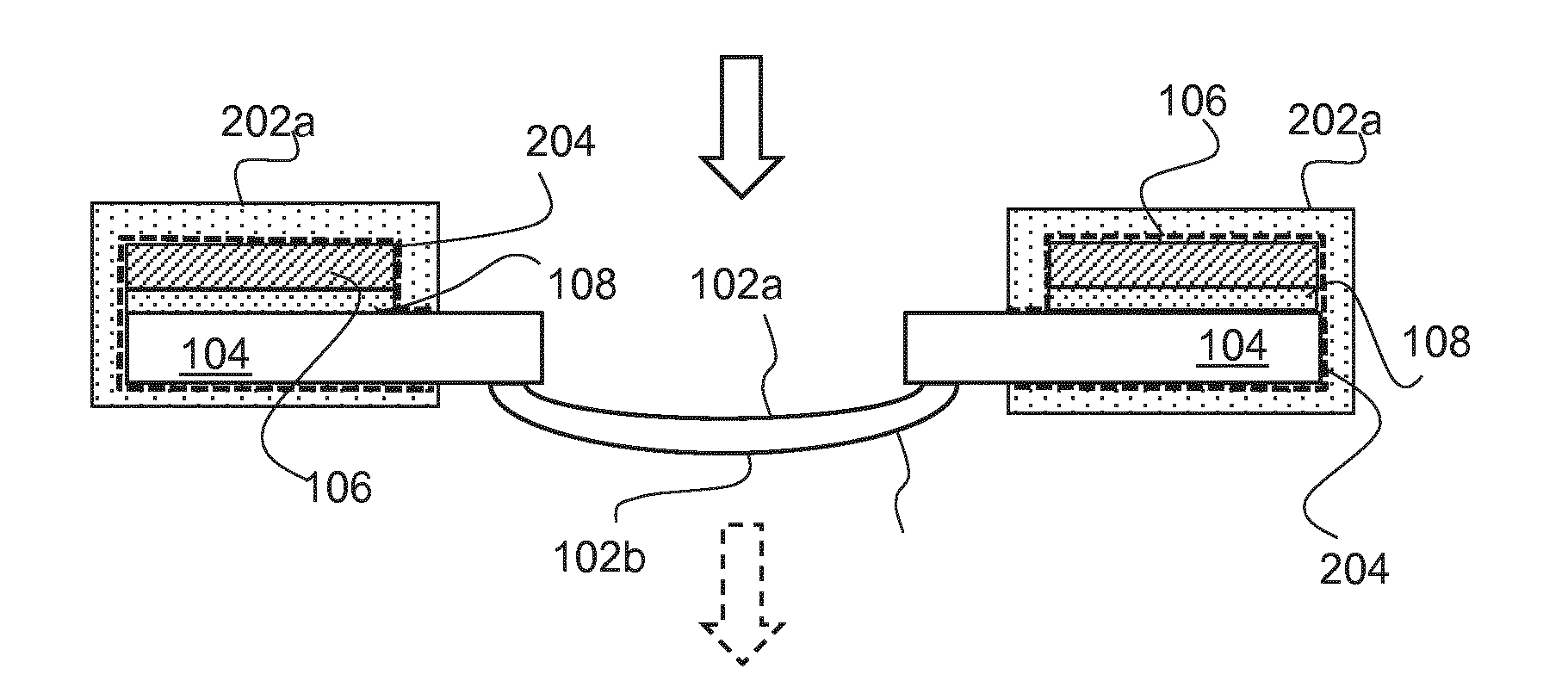

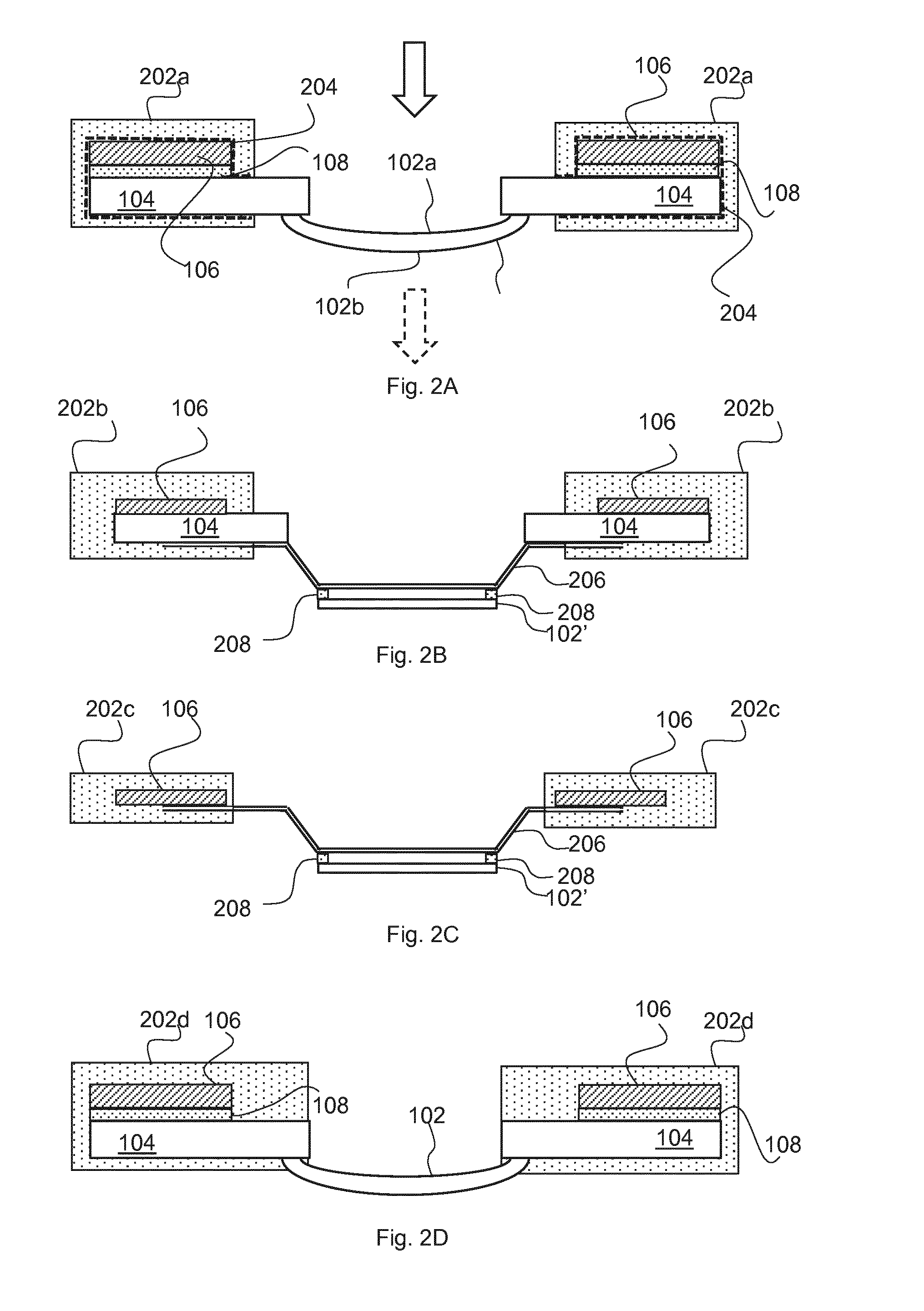

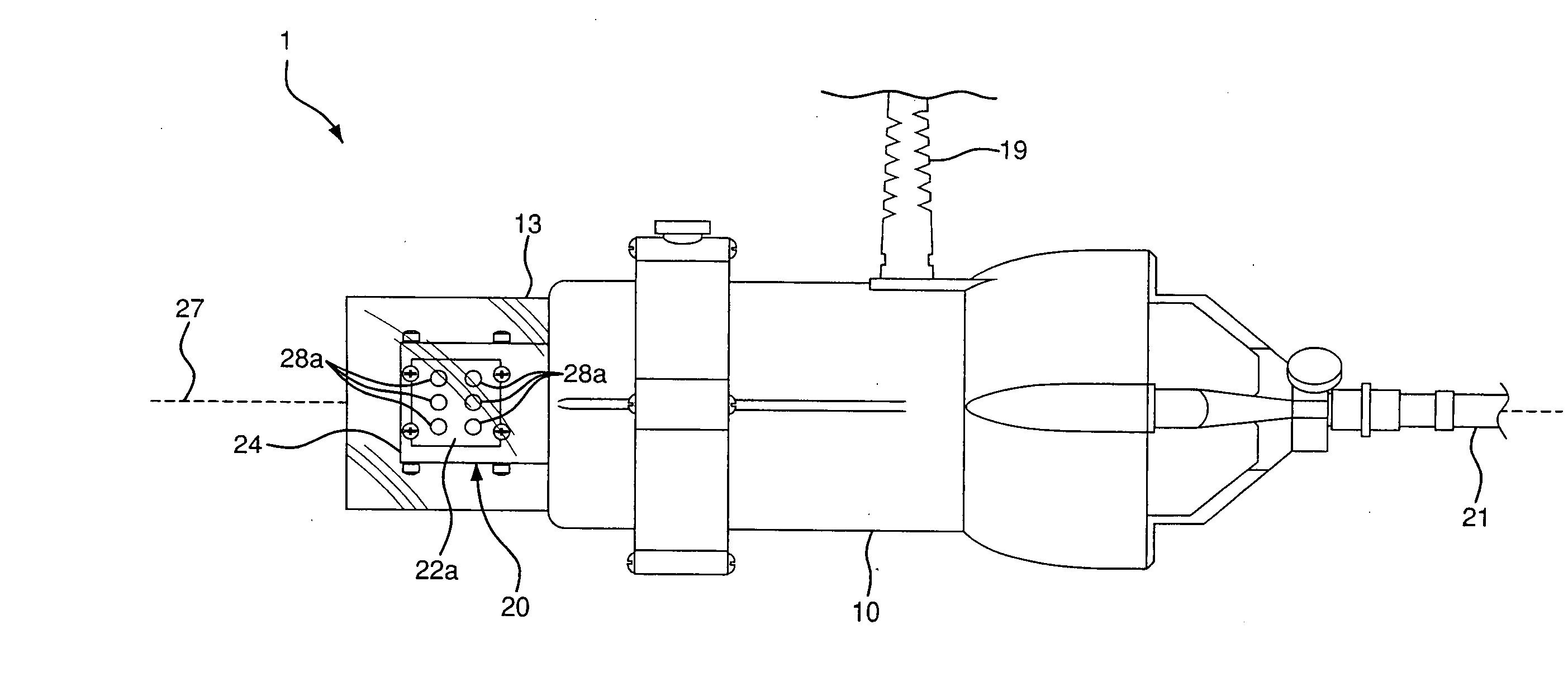

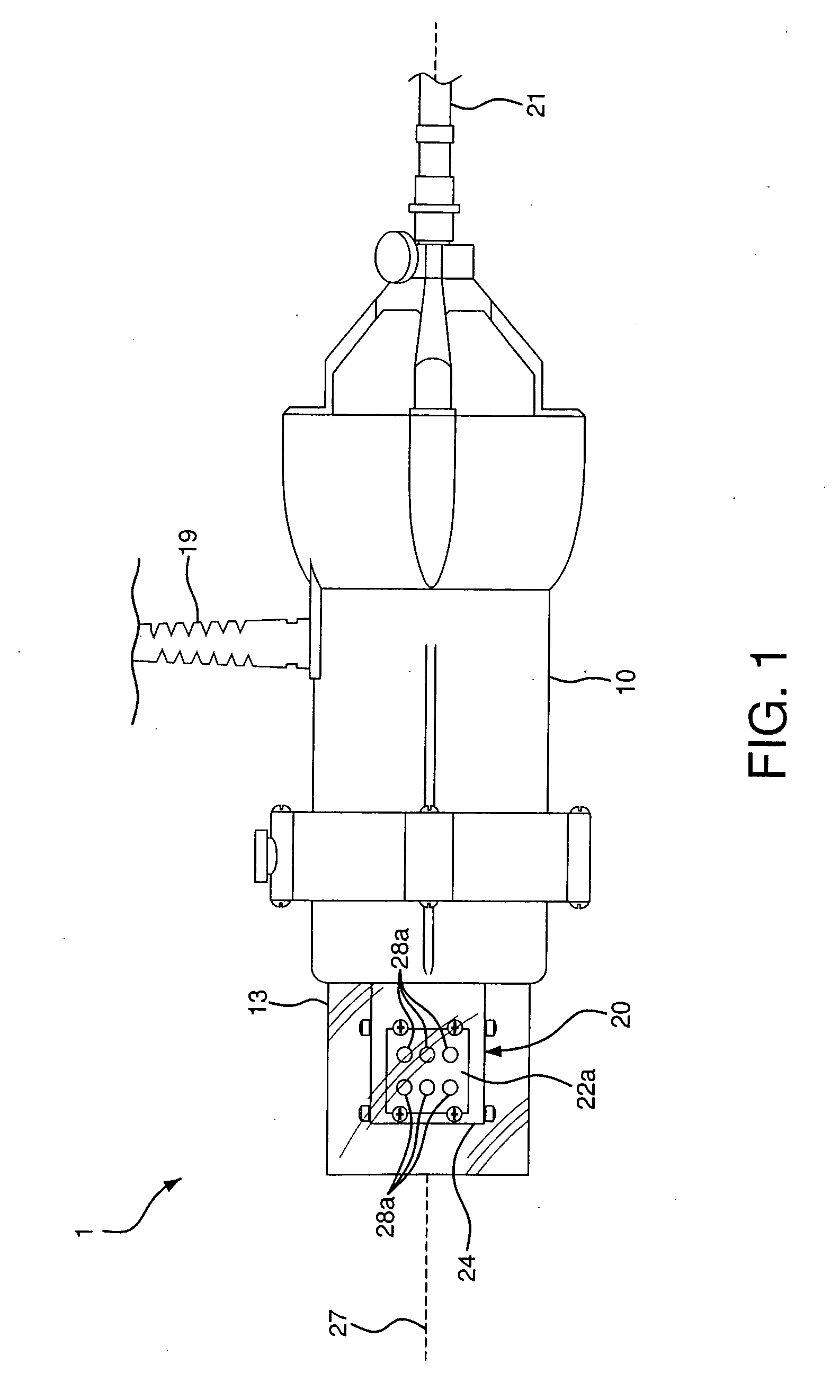

Liquid droplet apparatus

InactiveUS20160310981A1Enhance bondingEffective compressibility be lowRespiratorsLiquid spraying apparatusPhysicsEngineering

Apparatus for producing liquid droplets (for example an aerosol) is described. The apparatus comprises a vibratory element (106) arranged, in use of the apparatus, to vibrate an aperture plate (102) having at least one aperture therein. Also provided is a sealing element (202), which is arranged to provide a liquid tight seal over at least a portion of the vibratory element (106). The sealing element (202) comprises a closed cell foam material. In some embodiments, sealing element (202) may be molded over other elements of the apparatus, including the vibratory element (106).

Owner:KONINKLJIJKE PHILIPS NV

Cups and containers with a living hinge and sleeves

ActiveUS10947018B2Improve functionalityImprove utilizationPackage recyclingVenting meansEngineeringMechanical engineering

The present invention is directed to cups, containers, and sleeves therefore having a living hinge and a dual seal structure on the lid such that the seal created by the contact of the lid with the inside of the cup or container ensures a secure, friction fit orientation to prevent spillage or leakage of the contents therein. The dual seal is created by a first component on the lip of the lid that extends down from the top of the lid and is substantial in shape with a rib on the bottom edge of the lip and the circumference of the lip that is of the same size and shape as the inner circumference of the cup or container such that a secure seal is created when closed. The cups and containers also have an inner concentric structure that follows the shape of the cup or container just above the base to offer stabilization, and ease of stacking, removal, and manufacture.

Owner:CLARITY INC

Cups and containers with a living hinge and sleeves

ActiveUS11254473B2Minimal impactEnsure longevityPackage recyclingDomestic cooling apparatusStructural engineeringMechanical engineering

The present invention is directed to containers for holding non-food items having a living hinge and a quad or multi seal structure on the lid such that the seal created by the contact of the lid with the inside of the cup or container ensures a secure, friction fit orientation to prevent spillage or leakage of the contents therein. The quad or multi directional seal is created by multiple ribs on the lid that securably fit within the base of the container and indentations oriented in the bases, or by multiple ribs on the lid that securably fit within a channel structure in the top of the base of the container, the channel structure having the indentations in order to create a secure fit.

Owner:CLARITY INC

Method and blade repair element for blisk repair or new blisk manufacture

InactiveUS7784180B2Reduction of work effort and costPrecise positioningBlade accessoriesReaction enginesEngineeringMechanical engineering

In the repair of a blisk or blisk drum, the damaged airfoils are completely cut off a low-stress nodal line of the respective blade, except for a blade stump (2), and are each replaced by a new blade repair element (3) of a same shape and size which is accurately clamped onto the blade root by a ledge (5) formed onto its mating end, with this ledge (5) also serving for fixation of the processing fixtures and stabilization of the thin airfoil, and is then welded to the blade root and subsequently subjected to a cutting or non-cutting operation for removal of the ledge (5). This highly efficient repair method can similarly also be applied to the new manufacture of blisks.

Owner:ROLLS ROYCE DEUT LTD & CO KG

Lighting systems

InactiveUS20080074874A1Ensure longevityConvenient lightingNon-electric lightingLighting support devicesControl powerEffect light

A lighting system, and method for using same, including a light source with one or more LEDs and a controller in communication with and adapted to control power flow to the light source. The LEDs may be overdriven by the controller in a flash setting so as to achieve a luminosity of approximately 1000% of their rated output for a short duration, and in another setting overdriven in a continuous mode so as to achieve a luminosity of approximately 250% their rated output.

Owner:HIGH LIGHTING

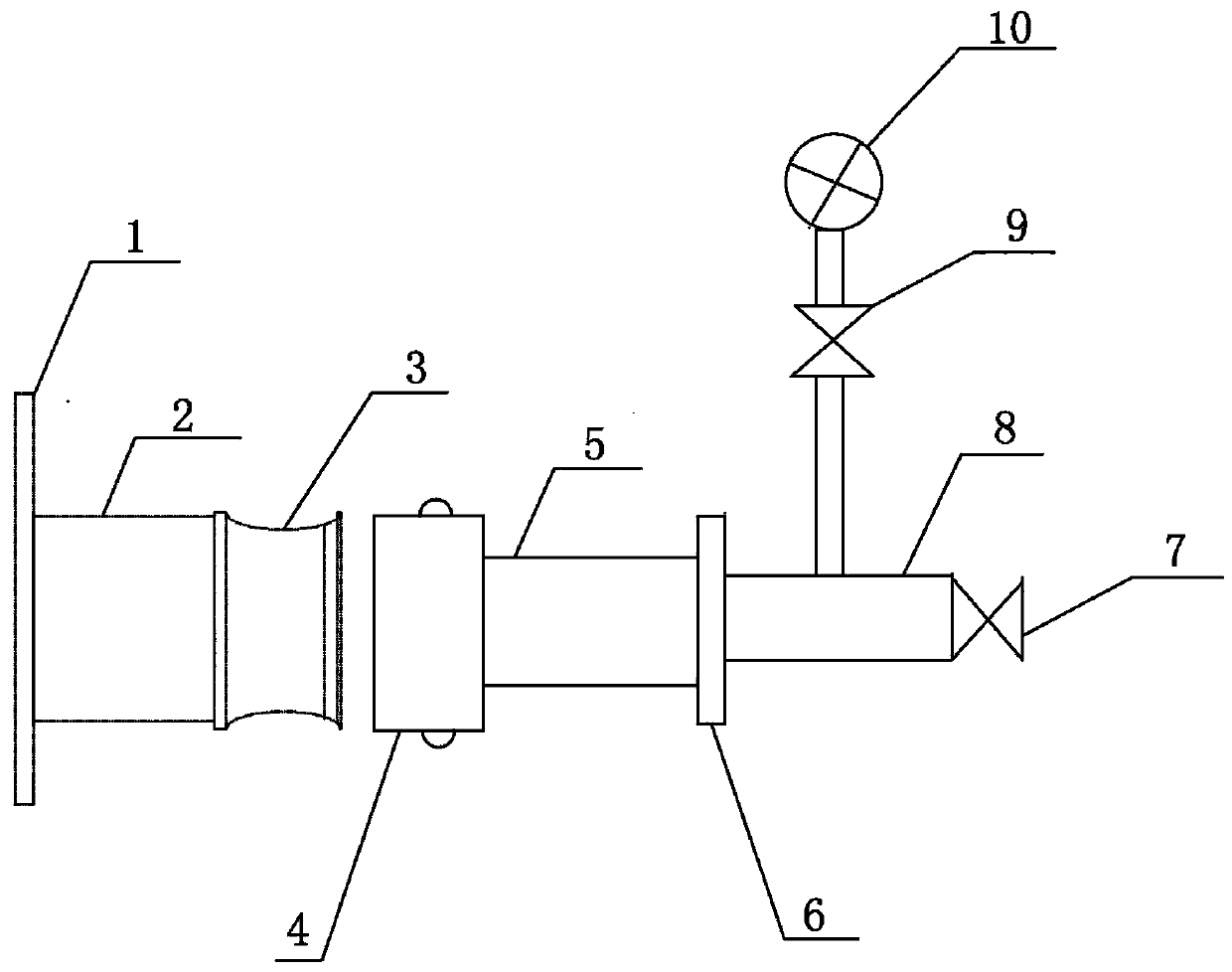

Method for detecting leakage of cooing walls by using self-made pressurization leakage detector

InactiveCN107586906AExtended service lifeAvoid Shearing HazardsCooling devicesEngineeringIndustrial water

The invention discloses a method for detecting the leakage of cooing walls by using a self-made pressurization leakage detector. The method comprises the following steps: changing the hard connectionof a U-shaped steel pipe of a cooling wall water inlet and outlet tube between a tenth-stage cooling wall and a sixteenth-stage cooling wall of a blast furnace into connection using the flexible connection structure of a quick connector, carrying out pressurization leakage detection layer by layer, using a metal flexible tube quick connector and continuing normal circulation cooling if the leakagedetection result is good in order to carry out connection, carrying out grouting sealing if a leakage detection result is severe damage, and carrying out industrial water poling maintenance if the damage degree is small. The cooling wall pressurization leakage detector comprises a quick connector female buckle, the outside end of the quick connector female buckle is connected with a flange through a flexible tube, the center of the flange is connected with a steel tube with the diameter being 32 mm and the length being 200 mm, a ball valve is arranged at the tail end of the steel tube, the tube body of the middle part of the steel tube is connected with a steel tube with the diameter being 15 mm and the length being 100 mm, and the steel tube is sequentially provided with a ball valve anda pressure gauge from bottom to top.

Owner:XINJIANG BAYI IRON & STEEL

Lining for Carbothermic Reduction Furnace

InactiveUS20080317085A1Effective coolingOvercome disadvantagesLinings repairFurnace typesRefractoryMolten salt

An inner lining for the steel shell of a carbothermic reduction furnace for the production of alumina has a base layer of graphite and a coating layer of refractory material. The refractory material is corundum (Al2O3) bound by Sialon (Si.Al.O.N). The lining structure provides protection against the molten slag and it is not attacked by the CO-rich melt furnace atmosphere. Further, the lining does not contaminate the melt and it provides an effective heat dissipation system in case of a power shut-off.

Owner:SGL CARBON SE

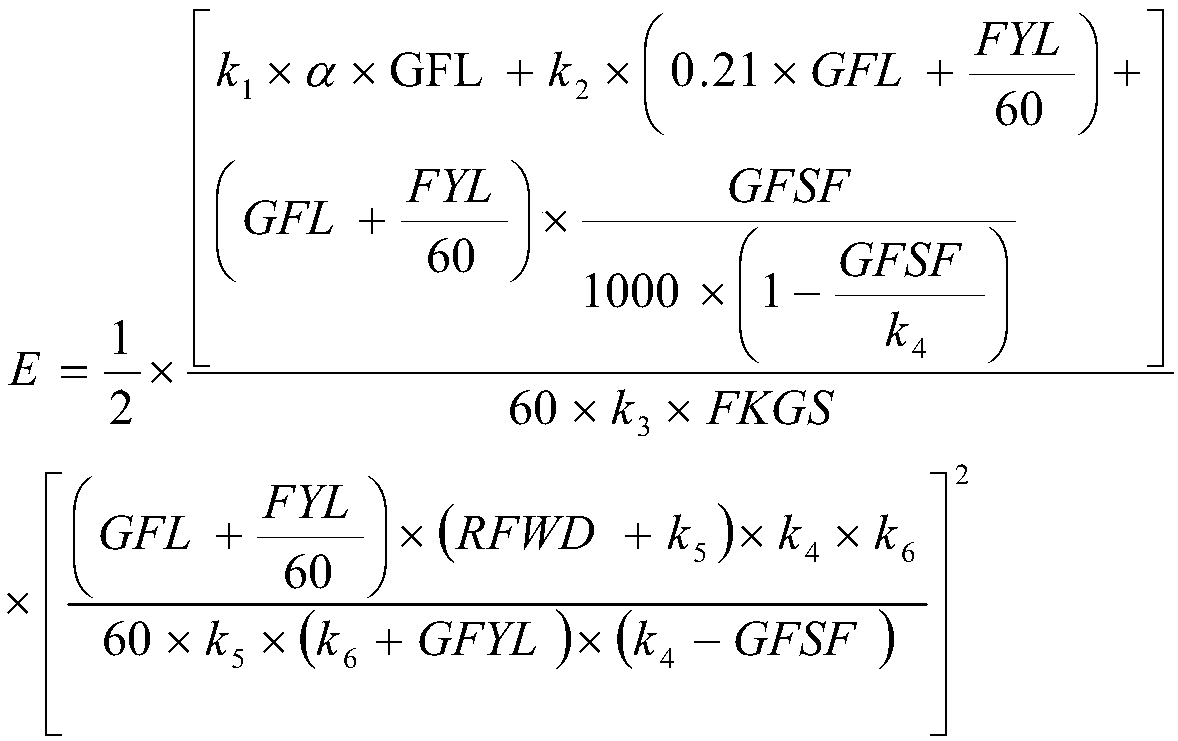

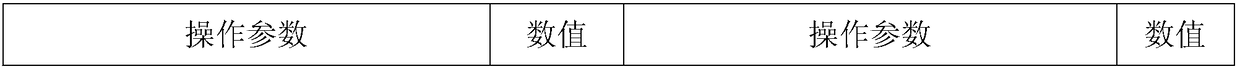

Method for calculating blast momentum in blast furnace production process

InactiveCN108396084AEnsuring Longevity and ProductionEnsure longevityBlast furnace detailsKinetic energyWater vapor

The invention provides a method for calculating the blast momentum in a blast furnace production process, wherein the real-time blast momentum in the blast furnace production process is calculated according to the controllable operation parameters of blast furnaces with different converter capacities during the daily production process, and the controllable operation parameters comprise the coefficient, the blast furnace blast volume GFL, the rich oxygen content FYL in the blast, the blast humidity GFSF, the hot air temperature RFWD, the blast pressure GFYL, the working air port number FKGS, the nitrogen density k1, the oxygen density k2, the gravity acceleration k3, the water vapor density, the Kelvin temperature k5 at the temperature of 0 DEG C, and the atmospheric pressure k6 under thestandard state. According to the present invention, with the method, the reasonable blast momentum can be onlinely and real-timely controlled during the blast furnace production, such that the reasonable daily blast furnace production operation is performed from the formation and control angle of the reasonable coal gas flow inside the furnace hearth so as to ensure the long service life of the blast furnace and the low consumption, stability and smooth operation of the production.

Owner:ANGANG STEEL CO LTD

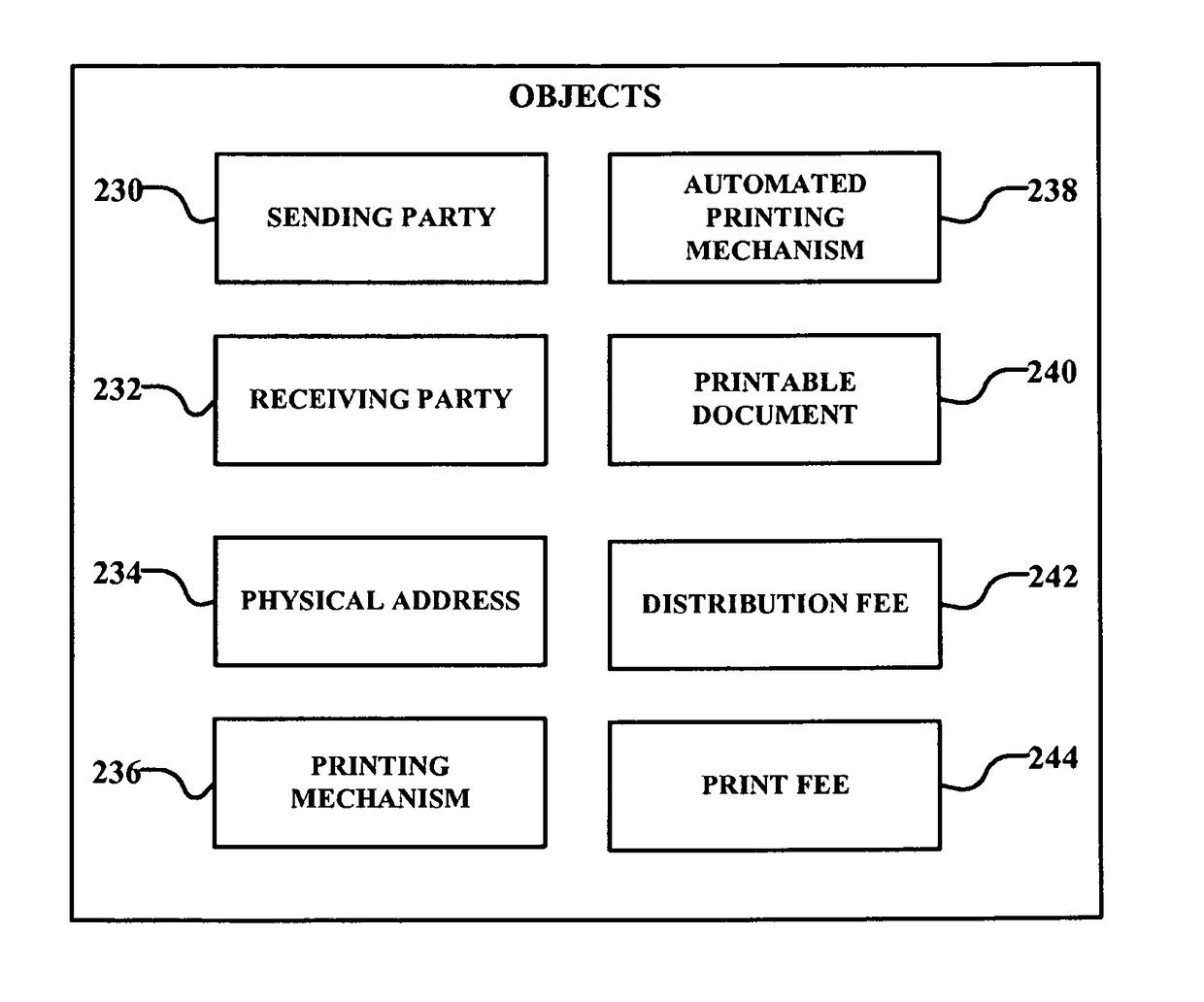

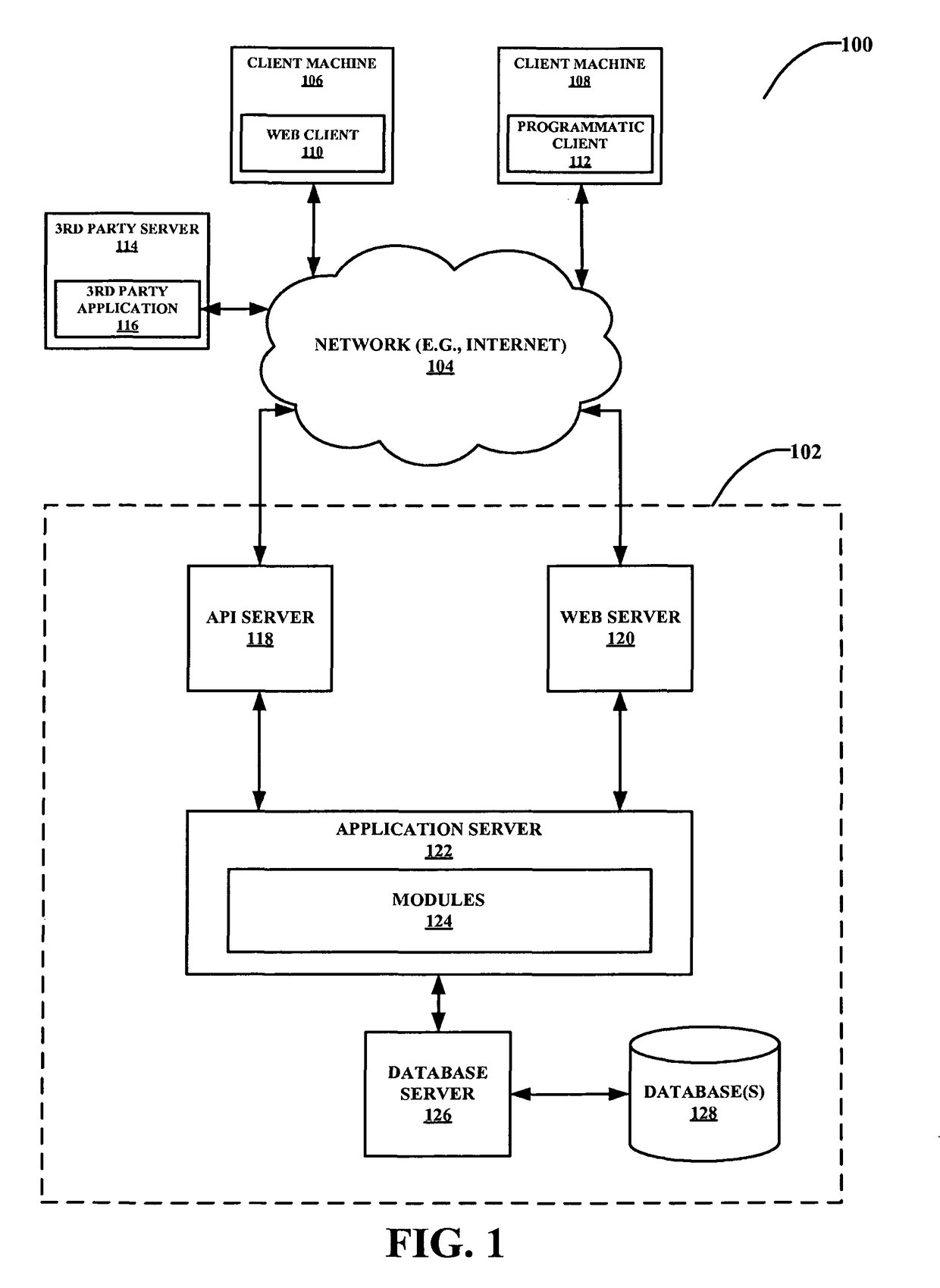

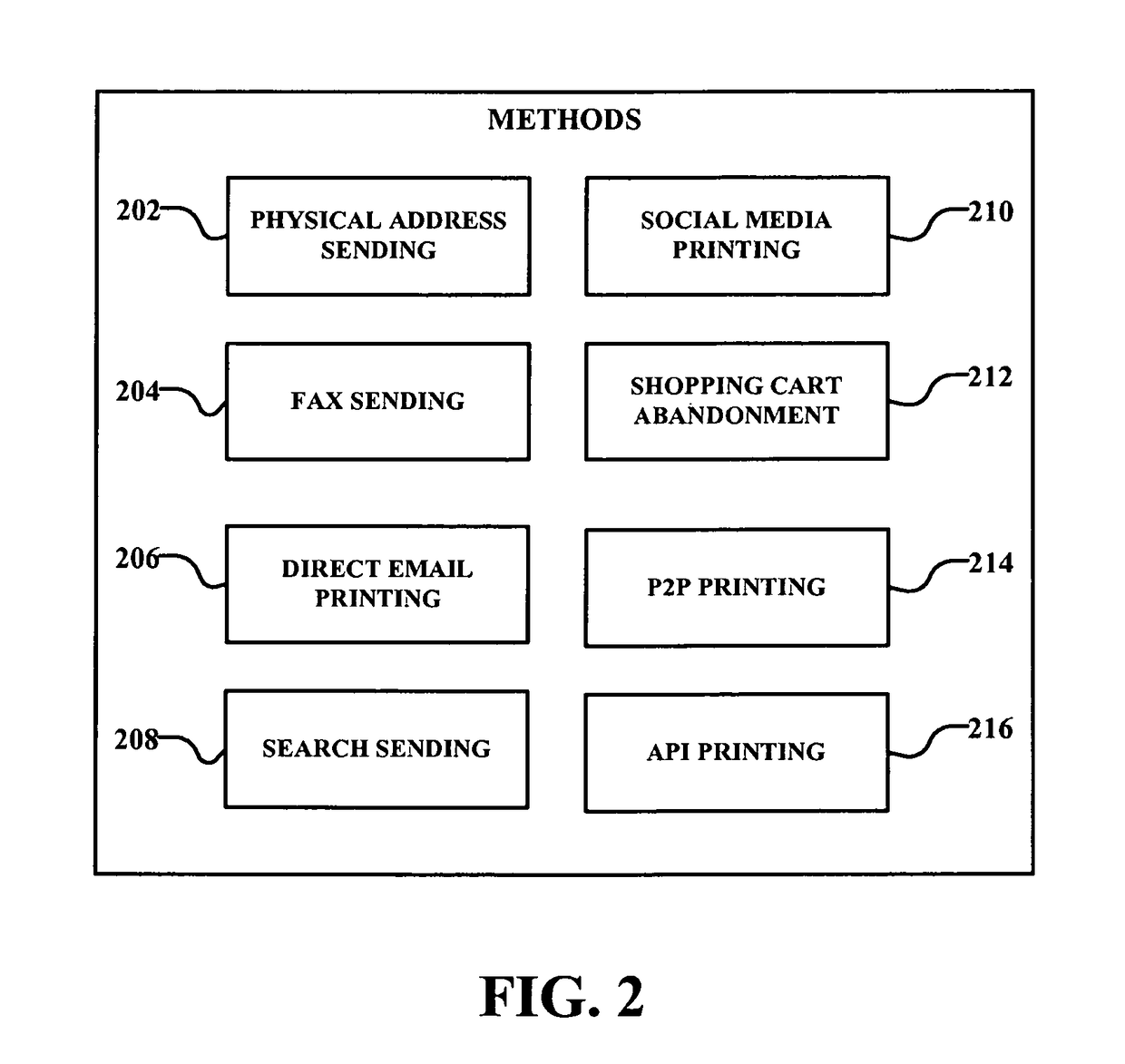

System and method for document delivery

InactiveUS9772808B1Low costReduce environmental impactApparatus for meter-controlled dispensingVisual presentationEngineeringDocumentation

The direct marketing system and method is disclosed that receives information from two parties, referred to as the sending party and the receiving party, and delivers a message or advertisement between the two. The message is then immediately printed on the receiving party's printer, and a small fee is paid by the sending party. A portion of this fee is sent to the receiving party as reimbursement for paper costs, ink costs, and printer maintenance.

Owner:NASHBAR ERIC

Method and apparatus for trimming material from a web

ActiveUS8739670B2Avoid excessive wearIncrease opportunitiesMechanical working/deformationGang saw millsKnife bladesSupport surface

Unattached elastic portions of an elasticised web are grasped and raised above a support surface for feeding the elasticised web. The raised portions are brought into contact with a knife blade that is positioned to protrude through the thickness of the raised elastic layer into free space so as to remain spaced from the support surface that is moving beneath the blade in a direction normal to the support surface. The raised elastic layer is held raised during trimming with the knife blade by an elevation element over which the elastic layer runs. A grasping device holds the unattached portion being cut in a taut state in the cross machine direction. The elastic layer thus spans across the elevation element and the grasping device. The knife blade extends through the thickness of the elastic layer along the spanned part of the elastic layer into free space.

Owner:ESSITY HYGIENE & HEALTH AB

Method and apparatus for coating or heat treatment of blisks for aircraft gas turbines

InactiveUS7413610B2Service life is not affectedEasy to usePropellersVacuum evaporation coatingGas turbinesFuel gas

A method for hard-material coating or heat treatment of the blade airfoils of blisks for gas turbines provides for partial heat-insulation and cooling of the other blisk parts during the respective process to prevent their properties from being changed by the high temperatures. The apparatus required for this method comprises two or more cooling plates (5 to 7) which are thermally insulated on their outer surfaces and include supporting flanges (20) which heat-conductively locate the blade platforms (3) of the blisks (1). Radially extending cooling medium channels (16) are provided in the cooling plates connected to a cooling medium source to continually apply cooling medium to the inner surfaces of the supporting flanges and the blade platforms.

Owner:ROLLS ROYCE DEUT LTD & CO KG

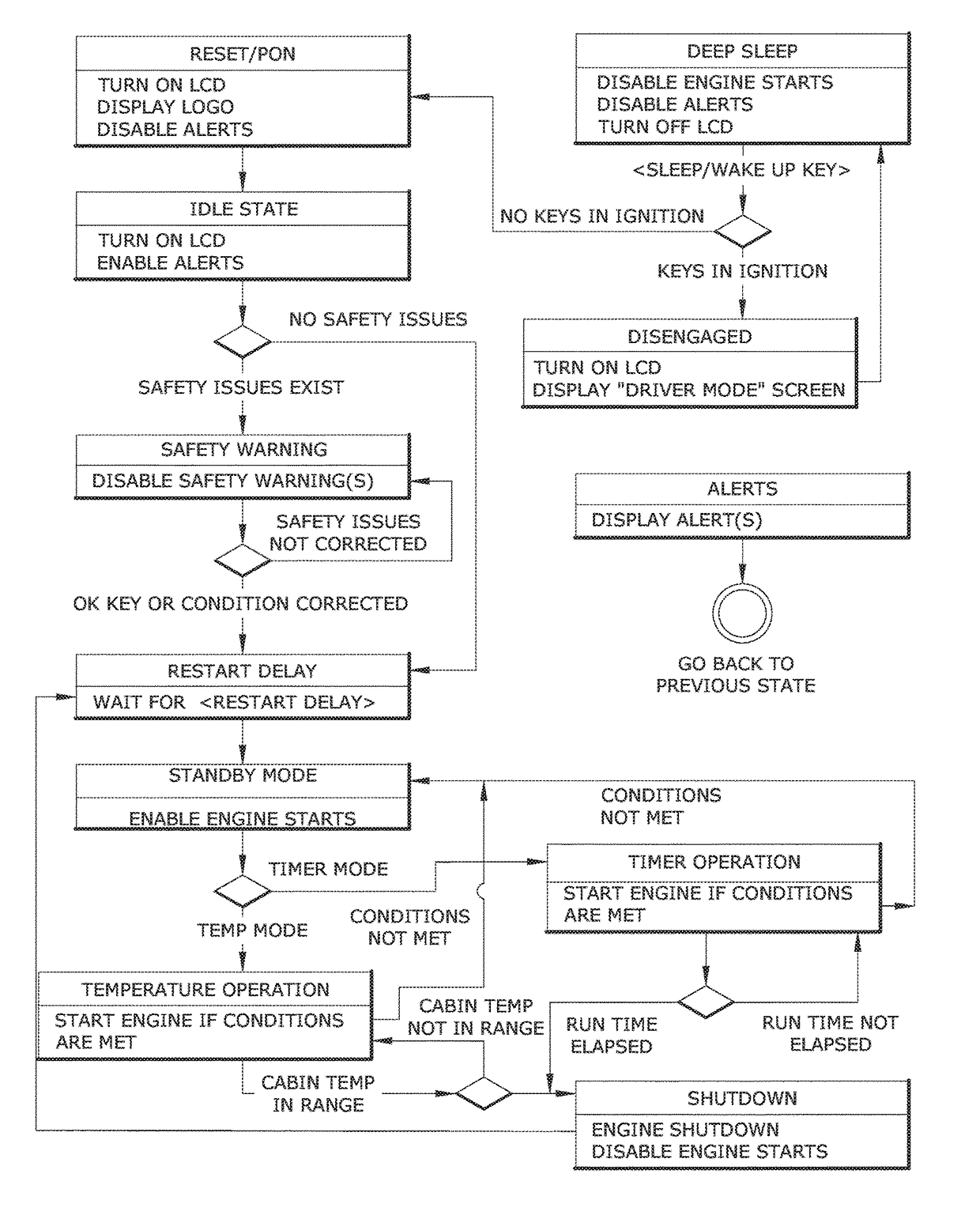

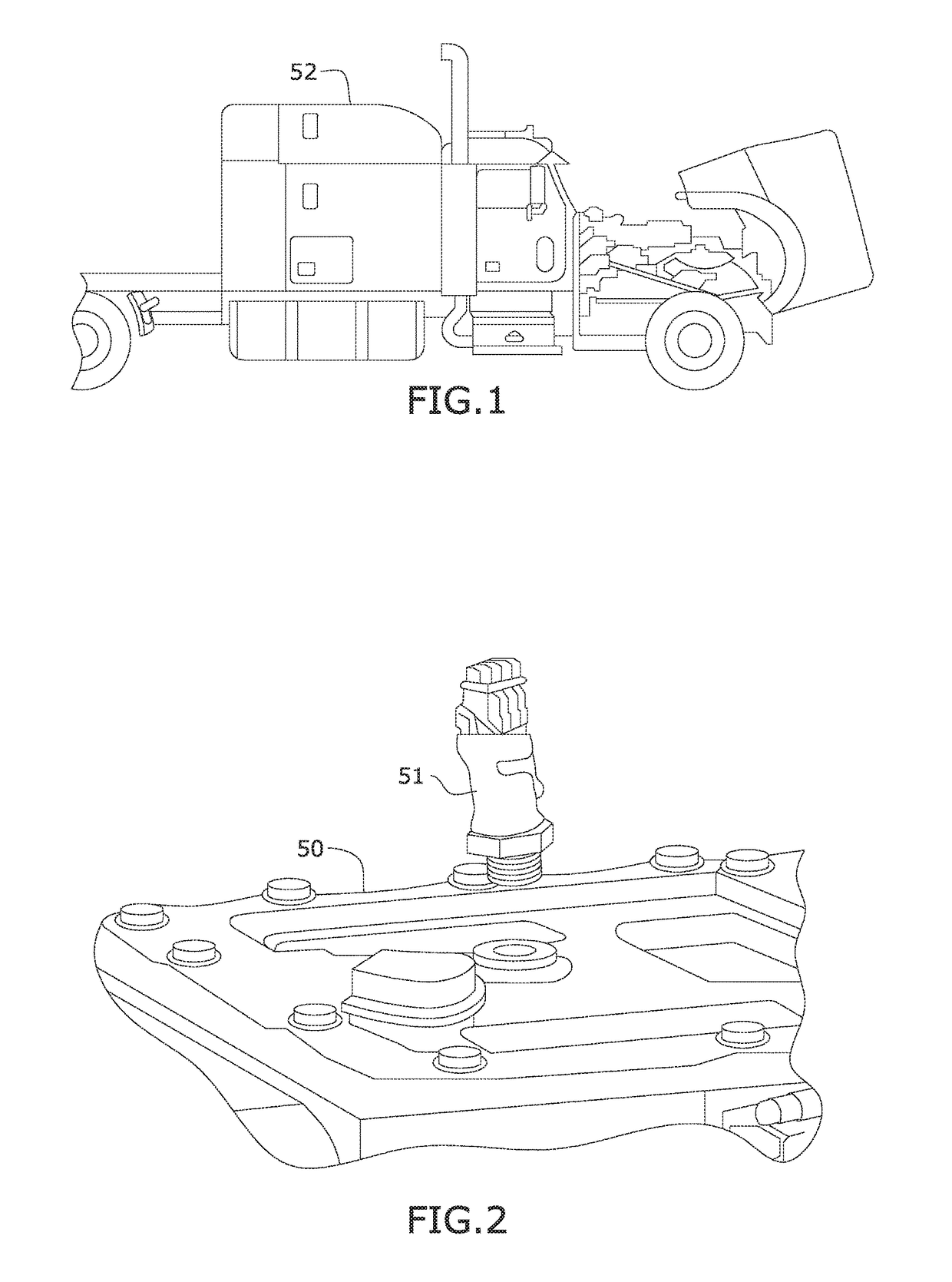

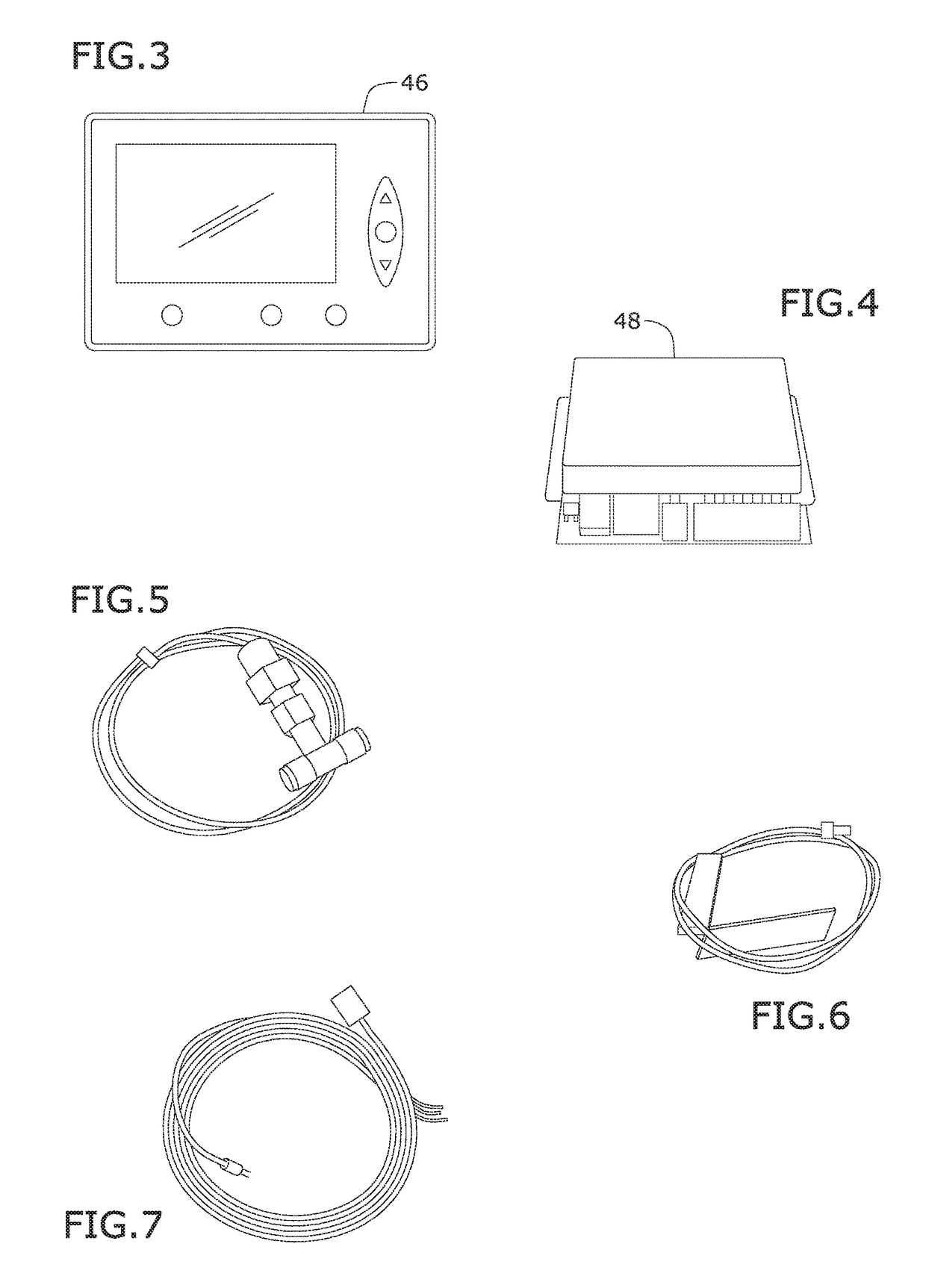

Engine start stop system based on programmable battery voltage levels

ActiveUS20170159633A1Enhance operational characteristic and performanceEnsure longevityInternal combustion piston enginesElectrical testingMobile vehicleBattery charge

A motor vehicle, such as a truck, battery charge monitoring and recharging system. The truck engine start / stop system initiates a battery recharge cycle based on programmable battery voltage levels. The system allows the user to individually program the appropriate voltage recharge levels dynamically to meet optimal standards based on location, environment, and other vehicle settings.

Owner:IDLE SMART LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com