Hot spraying metal ceramic powder for stove roller surface coatings

A technology of ceramic powder and cermet, which is applied in the field of surface coating of furnace rollers, can solve the problems of anti-pilling effect and weakened wear resistance of coatings, and achieve the effect of high temperature resistance and improved compactness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

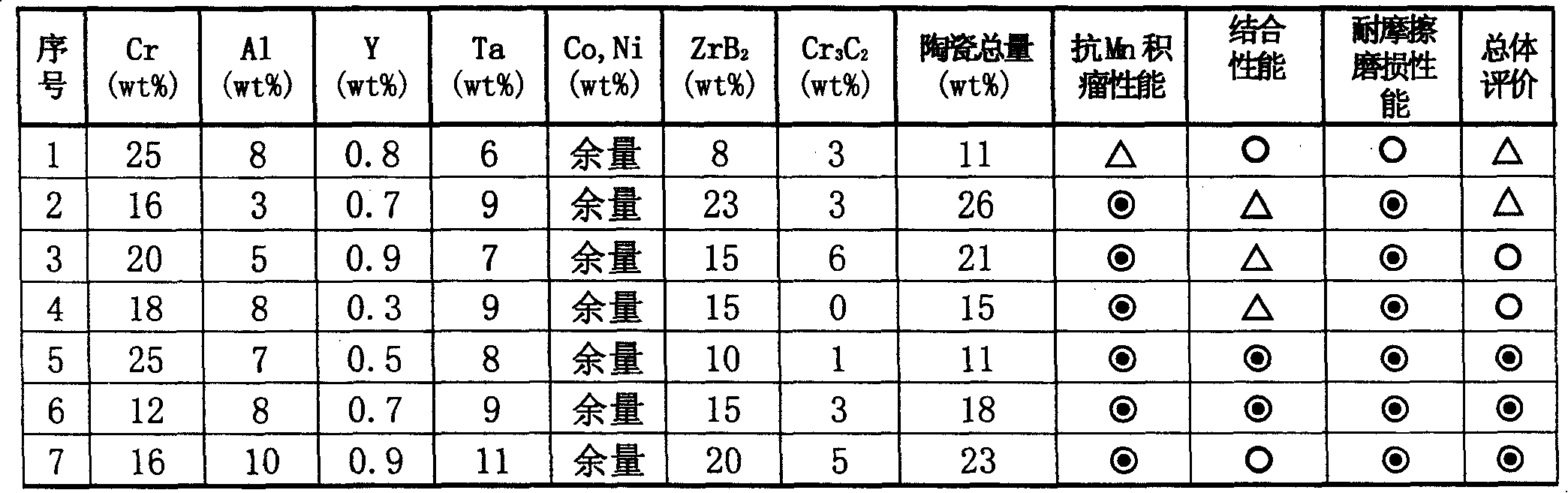

[0013] The protective coating on the surface of the cermet furnace roller is prepared by supersonic flame spraying method, and the thickness of the coating is about 0.15mm. The size of the anti-buildup sample is 50×50×10mm, and the material is 304 stainless steel. The specific method of the anti-build-up test: add a layer of MnO powder with a particle size of less than 44 μm on the surface of the coating. 2 -3%H 2 Atmosphere and 950°C for 48 hours, then take it out and analyze the tumor accumulation. The size of the coating friction and wear resistance sample is 12.32×12.32×19.05mm, and the material is 304 stainless steel; the size of the grinding pair is φ49.22×13.06mm, and the material is 45 quenched and tempered steel. The results are shown in the table below.

[0014]

[0015] Note: Symbol ○, △ respectively indicate the effect: good, average, slightly worse.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com