Method for calculating blast momentum in blast furnace production process

A technology of blasting kinetic energy and production process, which is applied in the field of ironmaking, can solve the problems of failure to achieve major technological breakthroughs, failure to realize the determination method of blast kinetic energy, etc., and achieve the effect of ensuring longevity and production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

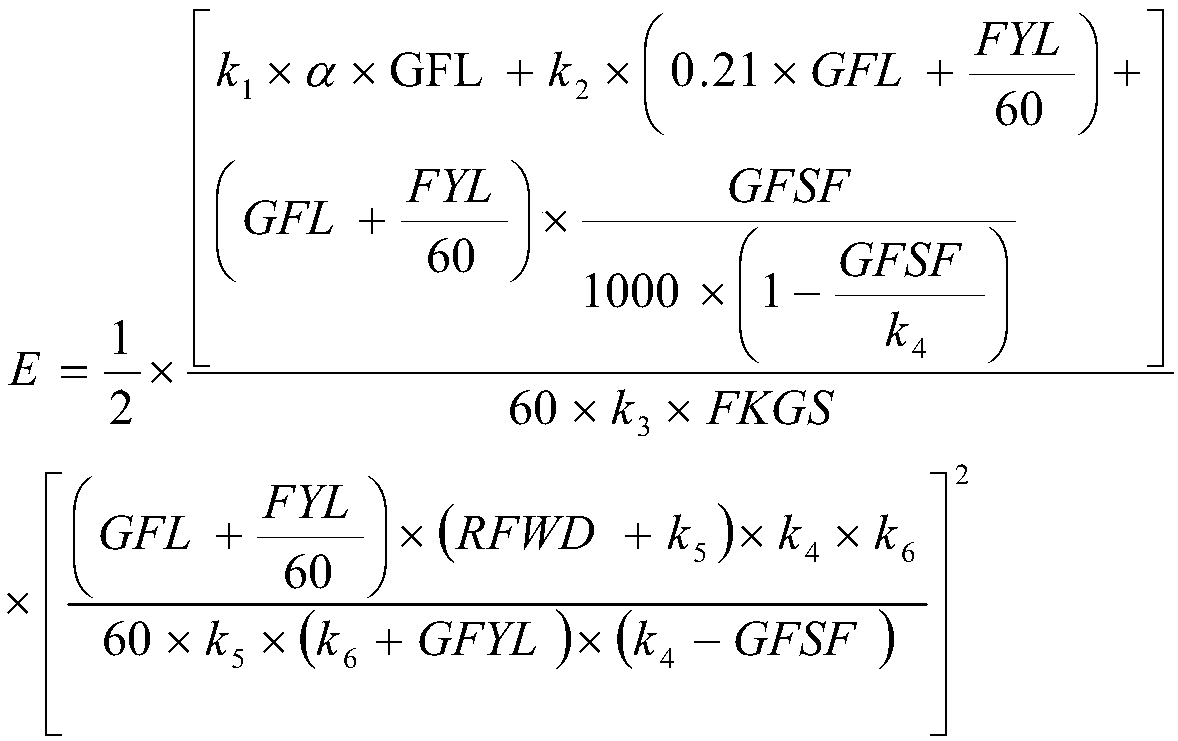

Method used

Image

Examples

Embodiment 1

[0016] Blast furnace effective furnace capacity 450m 3 .

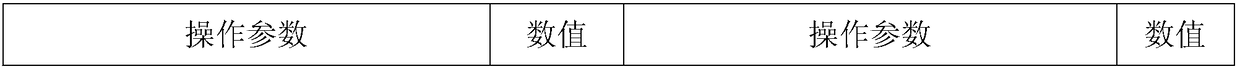

[0017] Operating parameters of blast furnace original production process:

[0018] The operating parameters of the blast furnace original production process and the calculation results of blast kinetic energy are shown in Table 1.

[0019] Table 1 Blast furnace original operating parameters and blast kinetic energy calculation results

[0020]

[0021]

[0022] Optimal adjustment of operating parameters:

[0023] Through the analysis of the blast kinetic energy in the original production process of the blast furnace, the blast kinetic energy under the initial operating conditions is 54200J / s, which is relatively small. , should increase the kinetic energy of the blower, and adjust the relevant operating parameters. The adjusted operating parameters of the blast furnace and the calculated results of blast kinetic energy are shown in Table 2.

[0024] Table 2 Calculation results of optimized blast furnace oper...

Embodiment 2

[0031] Blast furnace effective furnace capacity 1280m 3 .

[0032] Operating parameters of the original blast furnace production process: see Table 4 for the operating parameters of the original blast furnace production process and the calculation results of blast kinetic energy.

[0033] Table 4 Calculation results of original blast furnace operating parameters and blast kinetic energy

[0034]

[0035]

[0036] Optimal adjustment of operating parameters:

[0037] Through the analysis of the blast kinetic energy in the original production process of the blast furnace, the blast kinetic energy under the initial operating conditions is 68750J / s, which is relatively small, and the blast kinetic energy standard of the same volume blast furnace in the industry is maintained above 70000J / s. , the blast kinetic energy should be increased, and related operating parameters should be adjusted. The adjusted blast furnace operating parameters and blast kinetic energy calculation re...

Embodiment 3

[0045] Blast furnace effective furnace capacity 2580m 3 .

[0046] Operating parameters of the original blast furnace production process: see Table 7 for the operating parameters of the original blast furnace production process and the calculation results of blast kinetic energy.

[0047] Table 7 Calculation results of original blast furnace operating parameters and blast kinetic energy

[0048]

[0049]

[0050] Optimize operation parameter adjustment:

[0051] Through the analysis of the blast kinetic energy in the original production process of the blast furnace, the blast kinetic energy under the initial operating conditions is 82170J / s, which is relatively small, and the blast kinetic energy standard of the same volume blast furnace in the industry is maintained above 83000J / s, so , the blast kinetic energy should be increased, and related operating parameters should be adjusted. The adjusted blast furnace operating parameters and blast kinetic energy calculation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com