Codirectional variable-speed transmission coupler and use method

A variable speed transmission and coupling technology, which is applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of no buffering and shock absorption, and cannot change the direction of rotation, etc., and achieve the effect of compact structure and high transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

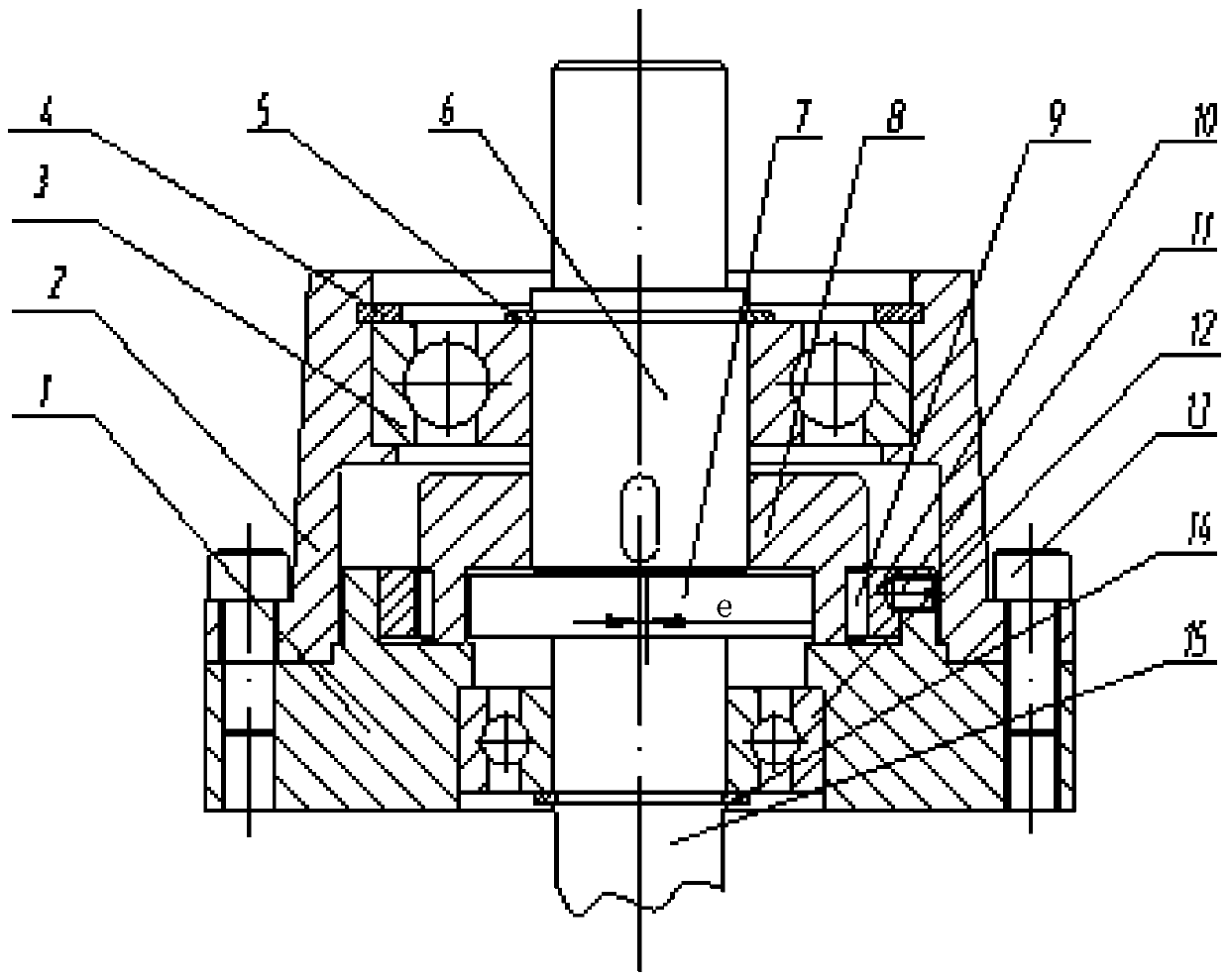

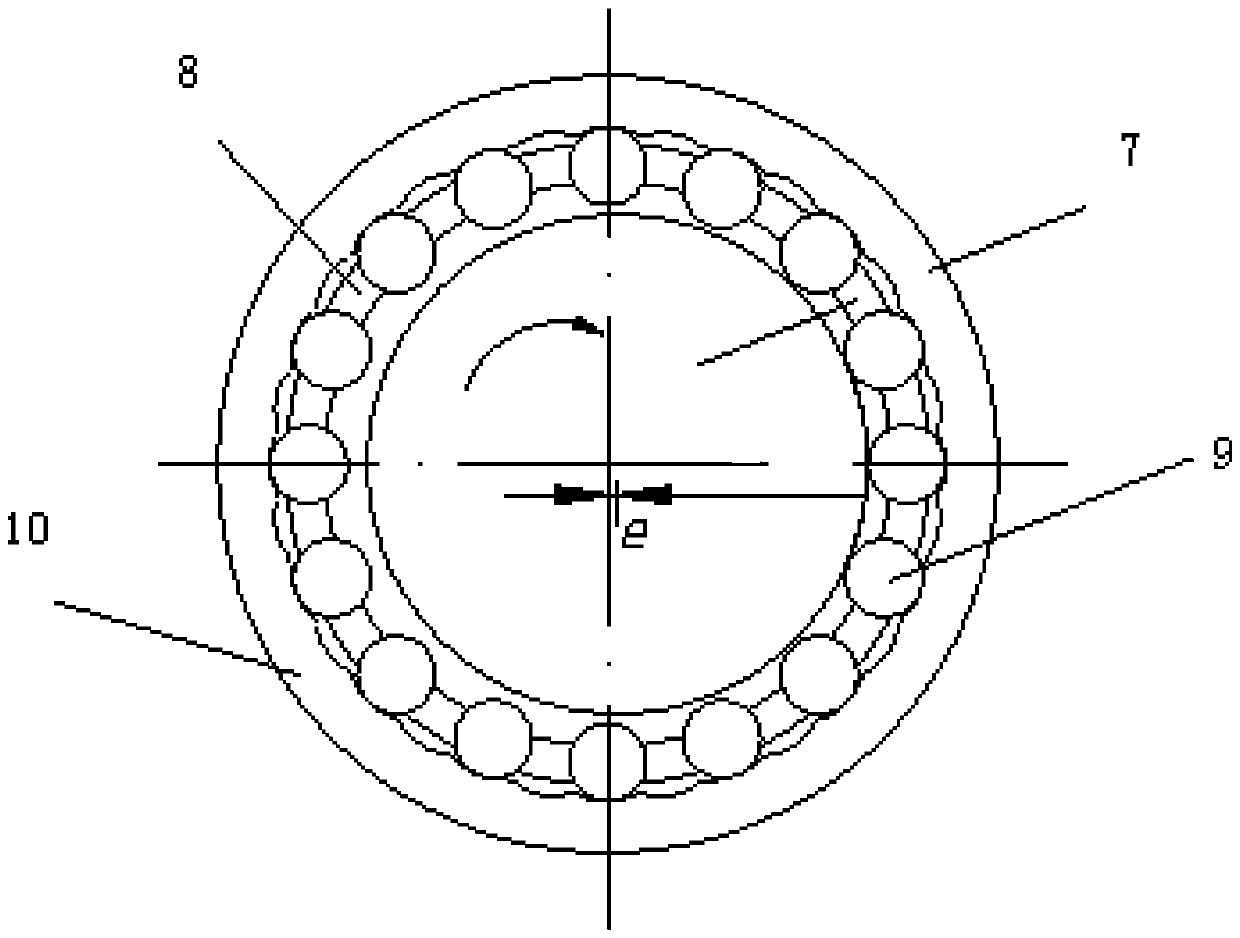

[0021] Such as Figure 1-2 , a transmission coupling with variable speed in the same direction, which includes an input shaft 15, a second rolling bearing 12 is set on the input shaft 15, and an outer ring fastener 1 is set on the outside of the second rolling bearing 12; One end of the ring fastener 1 is provided with a cycloidal tooth 10, and the two are fixed by a locking screw 11; the inner ring of the cycloidal tooth 10 is provided with a middle ring 8, and the middle ring 8 and the cycloidal tooth 10 Cylindrical rollers 9 are installed between them; the eccentric wheel 7 is arranged inside the middle ring 8, and the eccentric wheel 7 is installed on the input shaft 15; the middle ring 8 is installed on the output shaft 6; the output shaft 6 The outer edge of the outer shell 2 is fixedly connected with the middle ring 1 through the hexagonal bolt 13 through the first rolling bearing 3 .

[0022] Further, the output shaft 6 is provided with a first clip spring 5 outside t...

Embodiment 2

[0027] A method of using a co-directional variable speed transmission coupling, using hexagonal bolts 13 to fix the outer ring fastener 1 and the housing 2, and the outer ring fastener 1 fixes the cycloidal teeth 10 through locking screws 11, and finally Fix the cycloid ring gear;

[0028] When the main motion is transmitted from the input shaft 15 to the middle eccentric wheel for input rotation, the cylindrical roller is pushed outward due to the effect of eccentricity. At this time, since the outer cycloidal teeth of the cylindrical roller are fixed, the Under extrusion, the cylindrical roller can only release the interference of this radial movement obstruction by squeezing the fixed cycloidal ring gear to produce a circumferential movement, so that the cylindrical roller has a circular movement, thereby driving The middle ring 8 transmits the circular motion to the output shaft;

[0029] When the shaft of the middle eccentric wheel rotates a circle, the eccentric wheel s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com