Hole spacing measuring method and apparatus of hole etching morphology

A measurement method and hole spacing technology, applied in the direction of measuring devices, instruments, and using wave/particle radiation, can solve the problems of time-consuming, poor precision and accuracy, etc., and achieve the goal of improving measurement efficiency, measurement precision and accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to make the above objects, features and advantages of the present application more obvious and understandable, the embodiments of the present application will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods.

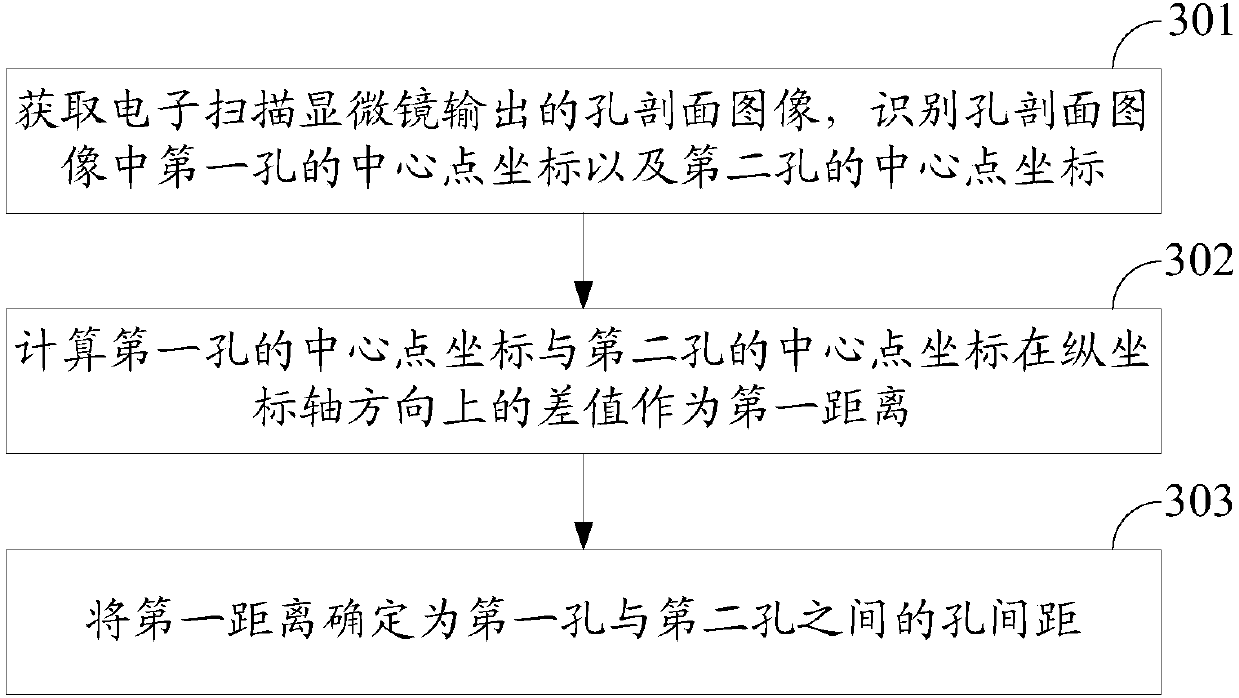

[0047] In practical applications, in the deep hole etching process, deep hole etching can be performed on the wafer, and multiple rows of deep holes are etched to process some electronic devices. The hole spacing between different horizontal rows of deep holes will affect Subsequent filling process will ultimately affect the electrical performance of the device. In order to solve the technical problems of poor accuracy and time-consuming manual measurement of hole spacing in the prior art, an embodiment of the present application provides a method and device for measuring hole spacing of hole etching topography, based on image capture and The computer software quantitatively characteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com