Assembly method for camera system suitable for mobile terminal

A technology of a camera system and an assembly method, which is applied in the parts, installation, image communication and other directions of a TV system, can solve problems such as working distance, stray light, and increase the design difficulty of the imaging lens group after the imaging lens group is long, so as to improve the complexity of the imaging lens group. Astigmatism problem, improved optical performance, effect of short back focus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

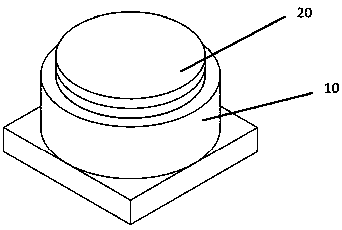

[0028] figure 1 It is a schematic diagram of the three-dimensional structure of the camera system according to the present invention.

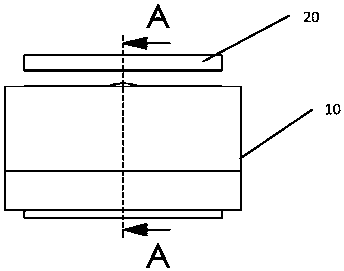

[0029] Figure 2a is a schematic side view of the camera system according to the first embodiment of the present invention.

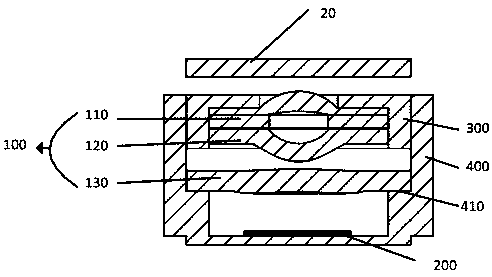

[0030] Figure 2b yes Figure 2a A side sectional view along the A-A direction;

[0031] image 3 It is a schematic cross-sectional view of the imaging lens group and the lens group sleeve in the imaging system of the first embodiment of the present invention;

[0032] Figure 4 It is a schematic cross-sectional view of the image sensor packaging module in the camera system of the first embodiment of the present invention;

[0033] Please refer to figure 1 , the camera system includes a camera module 10 and a protective cover 20 of the camera system, please refer to Figure 2a , Figure 2b , The camera module 10 includes: a lens group 100, an image sensor chip 200, the camera module 10 can be a fixed-focus cam...

no. 2 example

[0035] Figure 5a It is a schematic side view of the camera system according to the second embodiment of the present invention.

[0036] Figure 5b yes Figure 5a A side sectional view along the A-A direction;

[0037] Figure 6 It is a schematic cross-sectional view of the imaging lens group and the lens group sleeve in the camera system of the second embodiment of the present invention;

[0038] Figure 7 is a schematic cross-sectional view of the image sensor packaging module in the camera system according to the second embodiment of the present invention.

[0039] Please refer to Figure 5a , Figure 5b, the camera system includes a camera module 10' and a protective cover 20' of the camera system. The camera module includes: a lens group 100', an image sensor chip 200', a VCM module 600 located inside a frame 400' around the lens group 100', The VCM module 600 is provided with a VCM motor, and the camera module can be a fixed-focus camera module or an auto-focus c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com