A kind of packaging film processing technology

A technology of packaging film and processing technology, which is applied in the field of self-adhesive film processing, can solve problems such as self-adhesive film tearing, and achieve the effect of high-quality processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

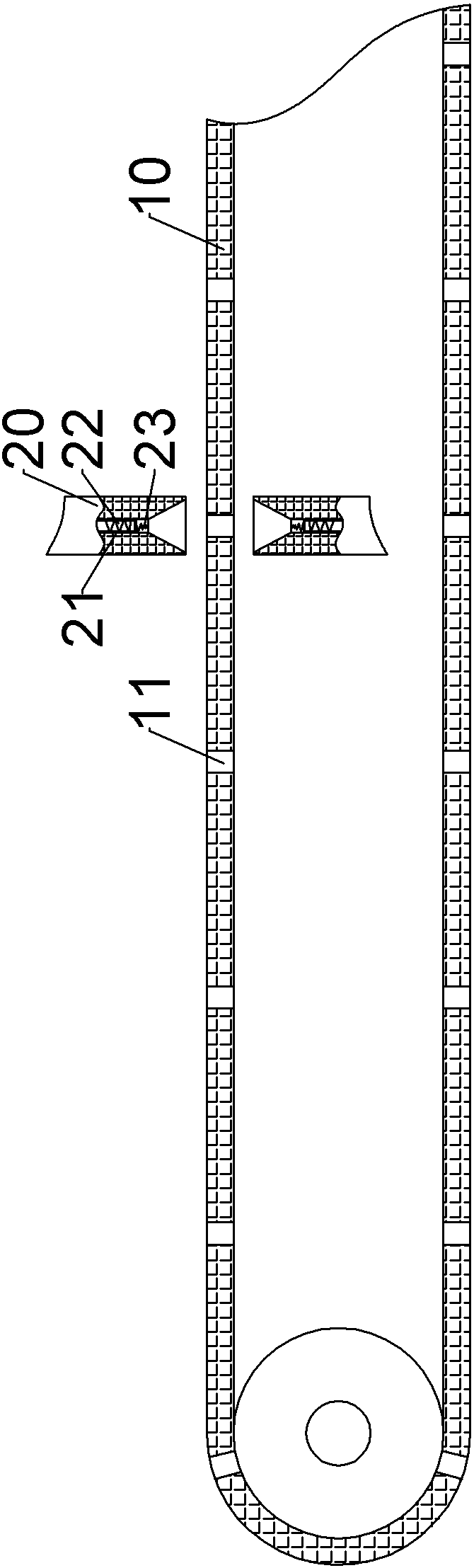

[0026] The packaging film processing technology in this scheme comprises the following steps:

[0027] Step 1, film attachment: attach the film to the conveyor belt body and advance with the belt body;

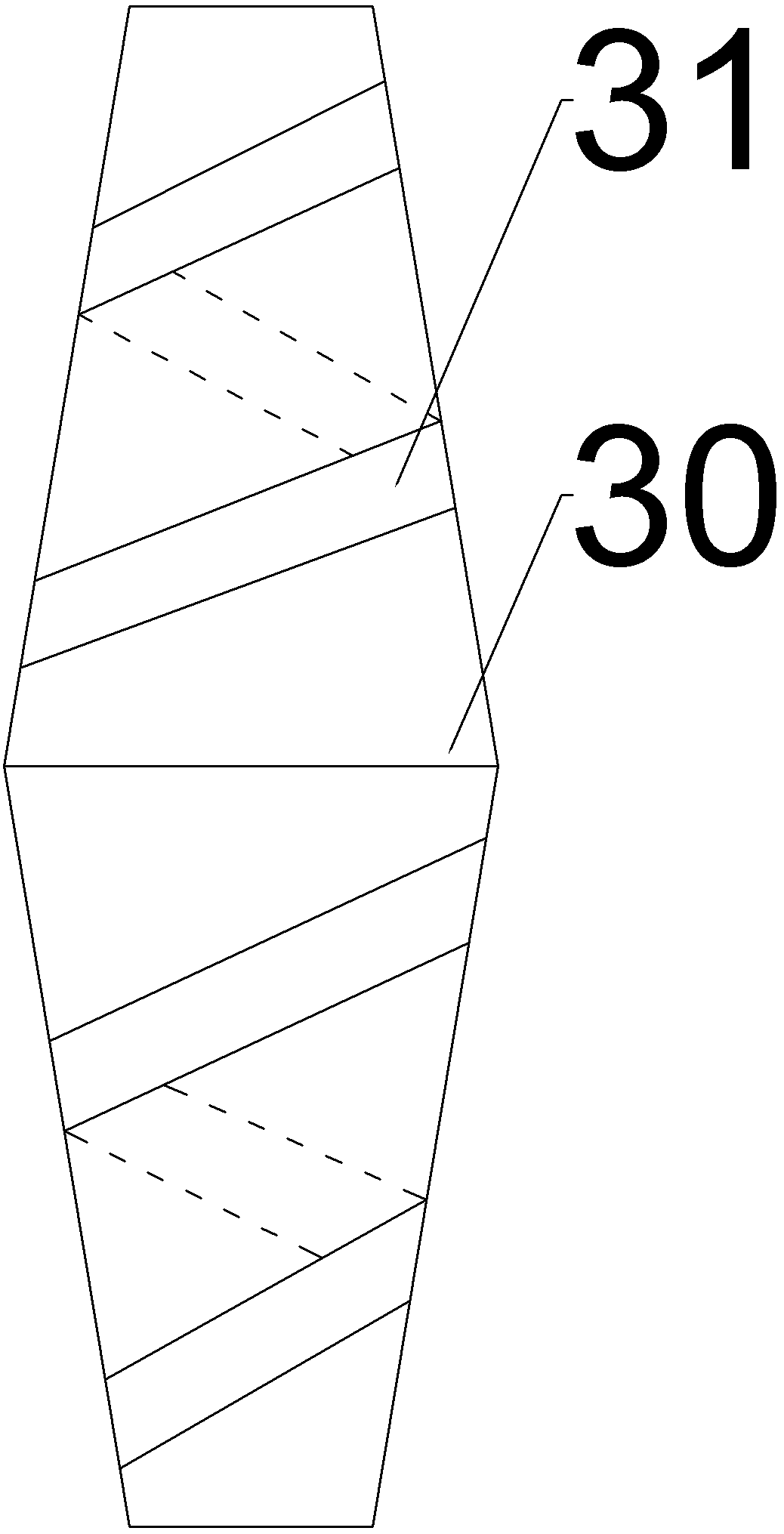

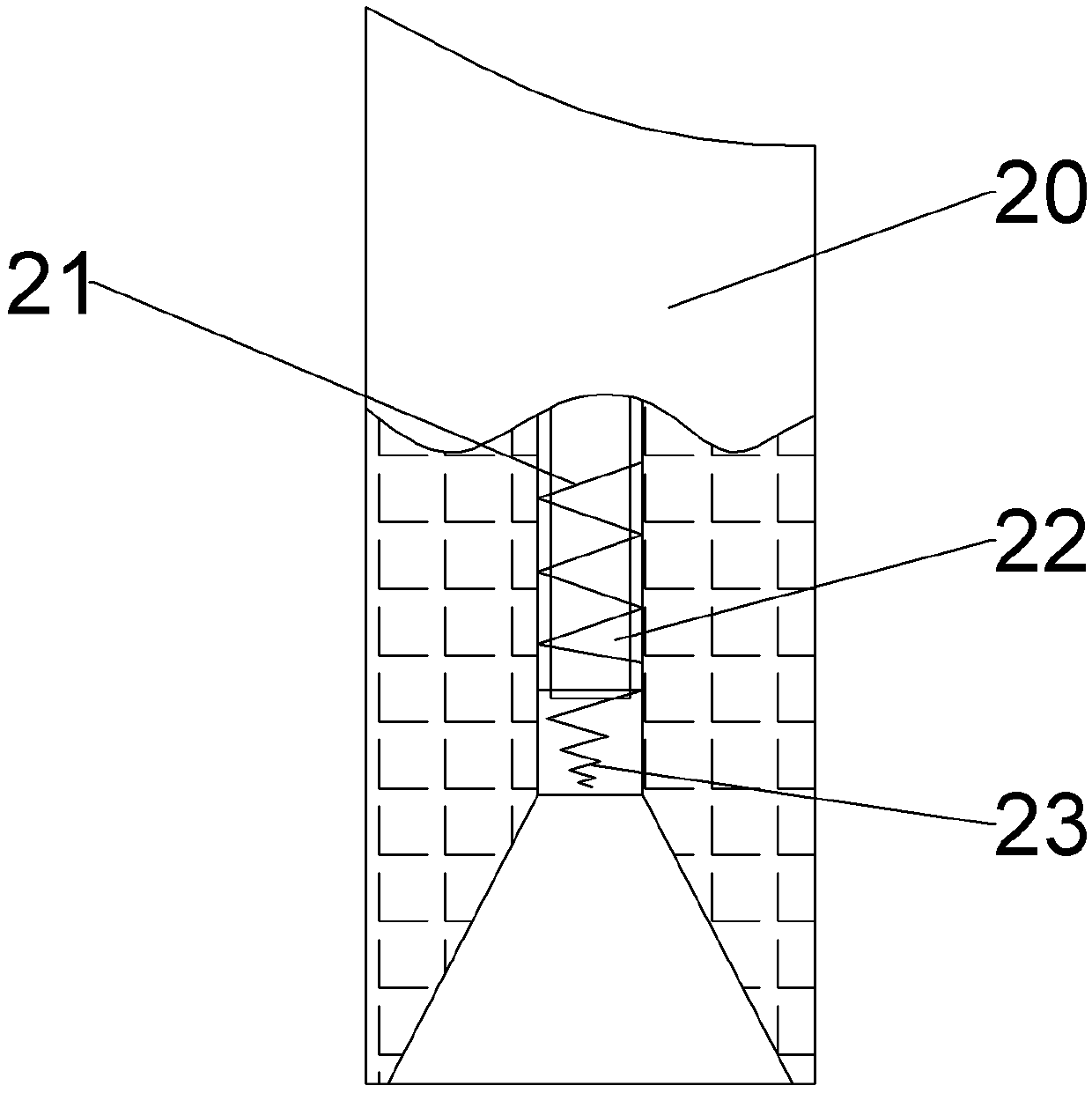

[0028] Step 2, punching: when the film passes through the drive unit, the spiral coil in the upper drive unit is energized and forms an electromagnet with the iron core, which generates a repulsive force that drives the flying knife downward. Through the through hole of the film and the conveyor belt body, a self-adhesive film processing is completed, and the flying knife enters the lower driving unit. At this time, the spiral coil of the lower driving unit is energized to generate a repulsive force that drives the flying knife upward, and the flying knife overcomes its own gravity. Pass through the through hole and film of the conveyor belt body at high speed, so as to complete another self-adhesive film processing;

[0029] Step 3, repeat steps 1-2 until the self-adhesive f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com