Assembled steel frame greenhouse design method and structure thereof

A prefabricated, shed structure technology, applied in the field of agricultural greenhouses, can solve the problems of increasing construction costs, reducing building safety, poor thermal insulation and summer shading and cooling capabilities, etc., to enhance support, improve shading and cooling effects, and stabilize strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

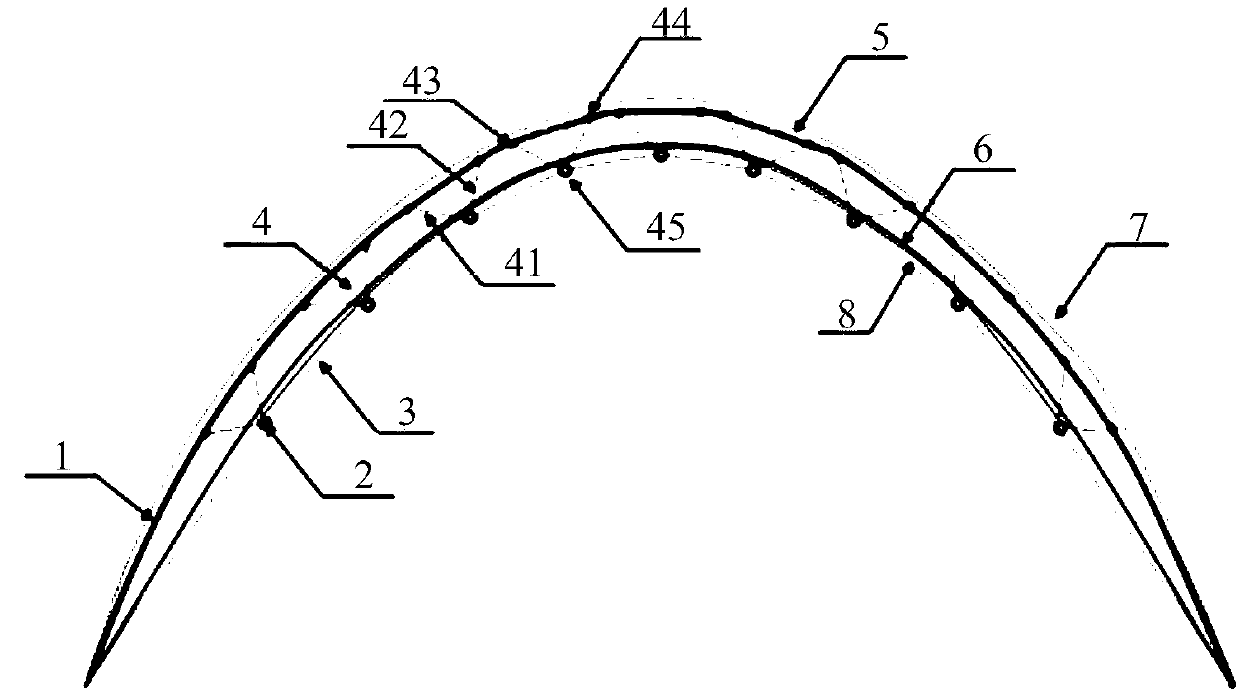

[0032] The embodiments will be described in detail below in conjunction with the accompanying drawings.

[0033] A method for designing a prefabricated steel-frame greenhouse, illustrated by taking a greenhouse with a span of 8 meters as an example, includes the following steps:

[0034] S1: Determine that the ceiling height of the greenhouse is 4 meters, the shoulder height is 2 meters, and (top height-shoulder height) / span=0.25 of the entire greenhouse.

[0035] S2: Reasonable axis streamline design between the high arc points of the two shoulders

[0036] The reasonable axis calculation formula is: Y=4(B-X)HX / B 2 , where Y is the height of each arc point, H is the top height, B is the span, and X is the horizontal distance. According to different X values, the height of each arc point on the reasonable axis between the two shoulder high arc points is calculated.

[0037] Here, the reasonable axis span between the high arc points of the two shoulders is 6 meters (minus the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com