Filter tip with upgrading ring and cigarette

A filter tip and quality improvement technology, applied in tobacco, e-liquid filter, application and other directions, can solve the problems of breaking, cigarette taste fade, reduce cigarette tar, etc., to avoid the effect of punching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

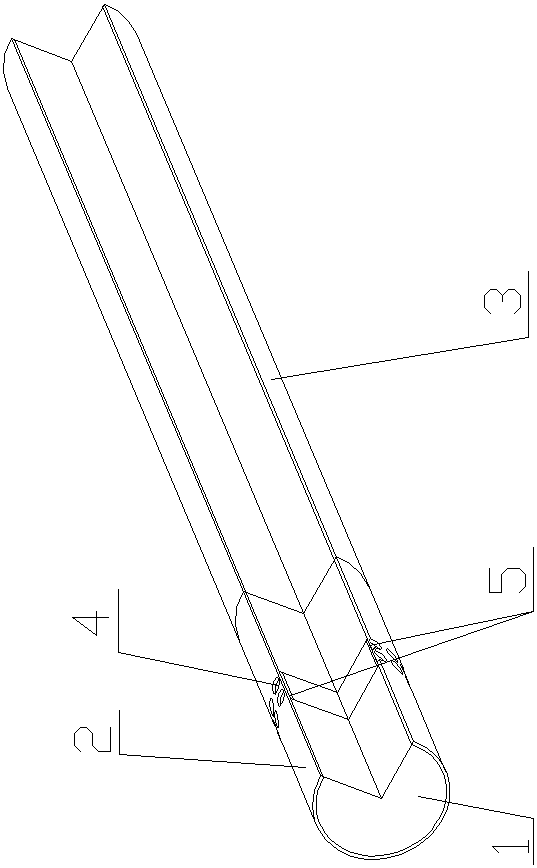

[0022] Such as figure 1 As shown, a filter tip with a quality-enhancing ring of the present invention includes a filter rod 1 and a tipping paper 2 wrapped outside the filter rod 1 and connecting the filter rod 1 with a cigarette 3. The tipping paper 2. There are more than one row of holes at intervals. 4. The rows are distributed in parallel, and the holes between the rows are aligned or staggered. One or more rows of holes are provided with holes that completely seal the row of holes. Blocked upgrading ring 5.

[0023] The quality-improving ring can be made of brittle materials such as gelatin, which is convenient for crushing.

[0024] The quality-improving ring 5 is located between the tipping paper 2 and the filter rod 1 and is fixedly sleeved on the filter rod 1 . The thickness of the upgrading ring is 0.2mm, and the wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com