Milk powder mixing device for obstetrics department

A mixing device and milk powder technology, applied in applications, home appliances, kitchen utensils, etc., can solve the problems of slow mixing speed, easy splashing of milk powder, waste, etc., and achieve the effect of increasing the mixing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

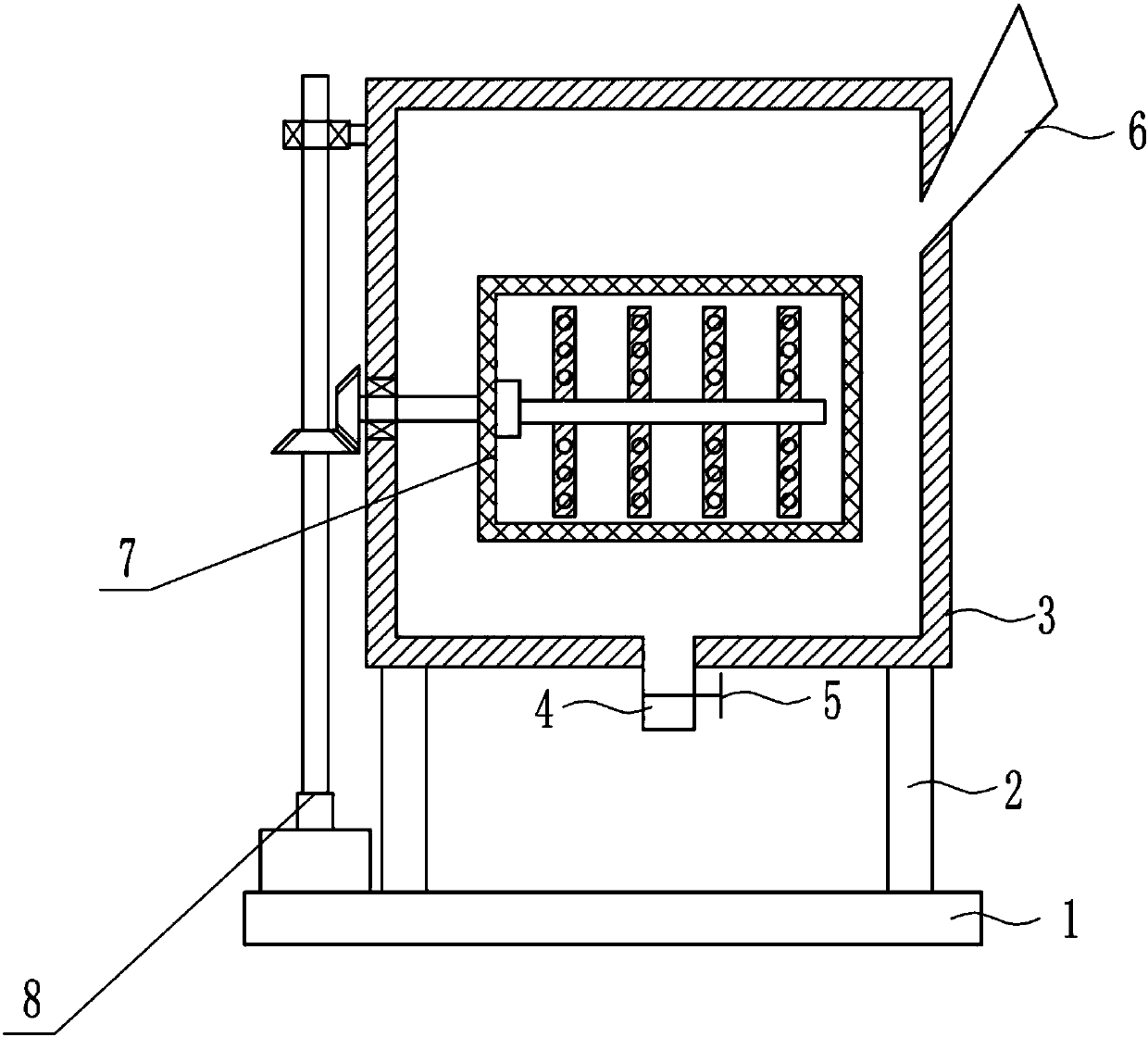

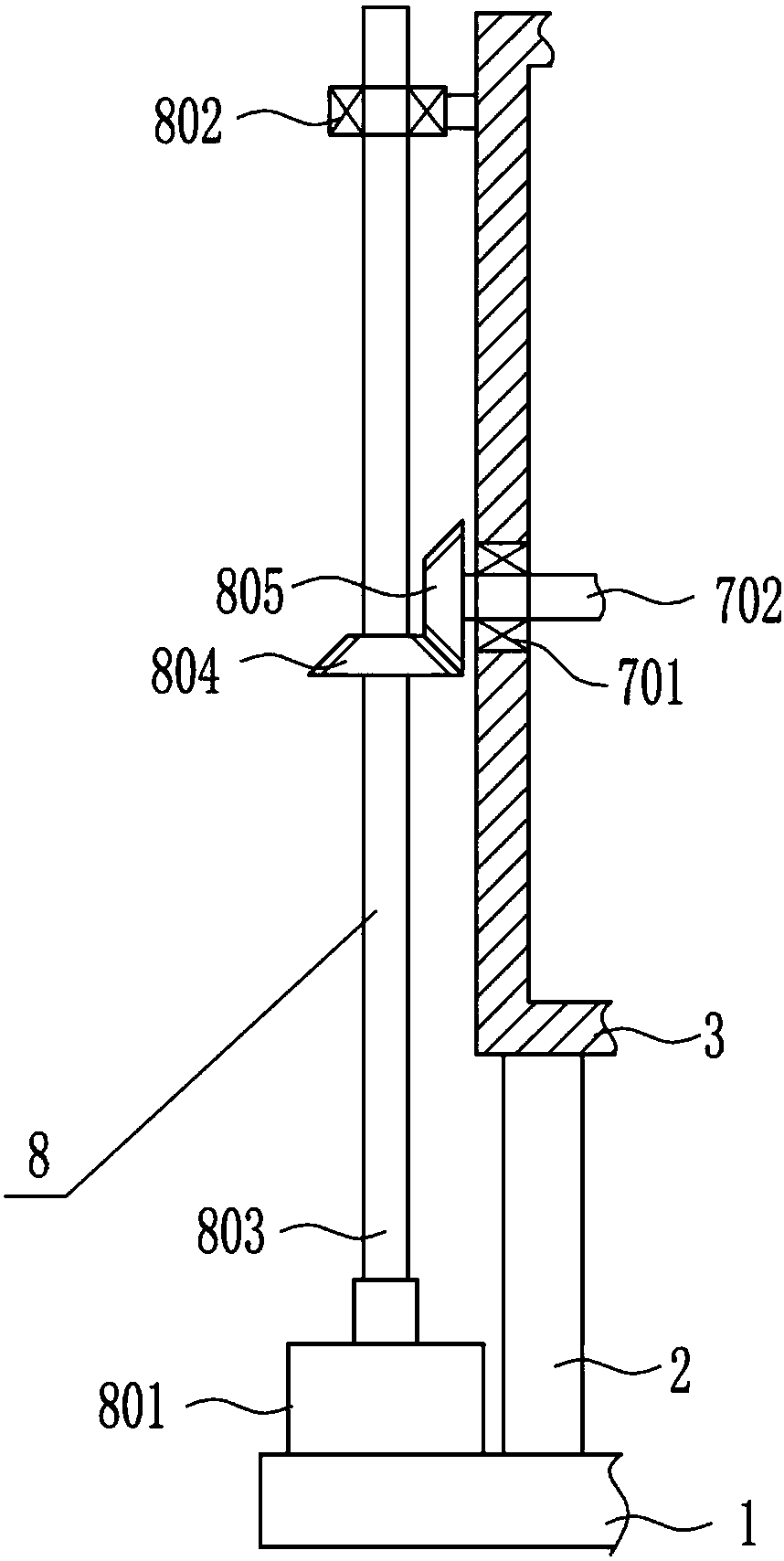

[0036] An obstetric milk powder mixing device, such as Figure 1-6 As shown, it includes a base plate 1, a pole 2, a mixing box 3, a liquid outlet pipe 4, a valve 5, a hopper 6, a mixing device 7 and a driving device 8, and the left and right sides of the top of the base plate 1 are vertically connected by bolts. Rod 2, a mixing box 3 is connected by bolts between the tops of the two poles 2, a liquid outlet pipe 4 is connected in the middle of the bottom of the mixing box 3, and a valve 5 is arranged on the liquid outlet pipe 4, and the upper right side of the mixing box 3 A hopper 6 is installed, a mixing device 7 is arranged in the mixing box 3 , and a driving device 8 is arranged on the top of the bottom plate 1 on the left side of the left pole 2 .

Embodiment 2

[0038] An obstetric milk powder mixing device, such as Figure 1-6 As shown, it includes a base plate 1, a pole 2, a mixing box 3, a liquid outlet pipe 4, a valve 5, a hopper 6, a mixing device 7 and a driving device 8, and the left and right sides of the top of the base plate 1 are vertically connected by bolts. Rod 2, a mixing box 3 is connected by bolts between the tops of the two poles 2, a liquid outlet pipe 4 is connected in the middle of the bottom of the mixing box 3, and a valve 5 is arranged on the liquid outlet pipe 4, and the upper right side of the mixing box 3 A hopper 6 is installed, a mixing device 7 is arranged in the mixing box 3 , and a driving device 8 is arranged on the top of the bottom plate 1 on the left side of the left pole 2 .

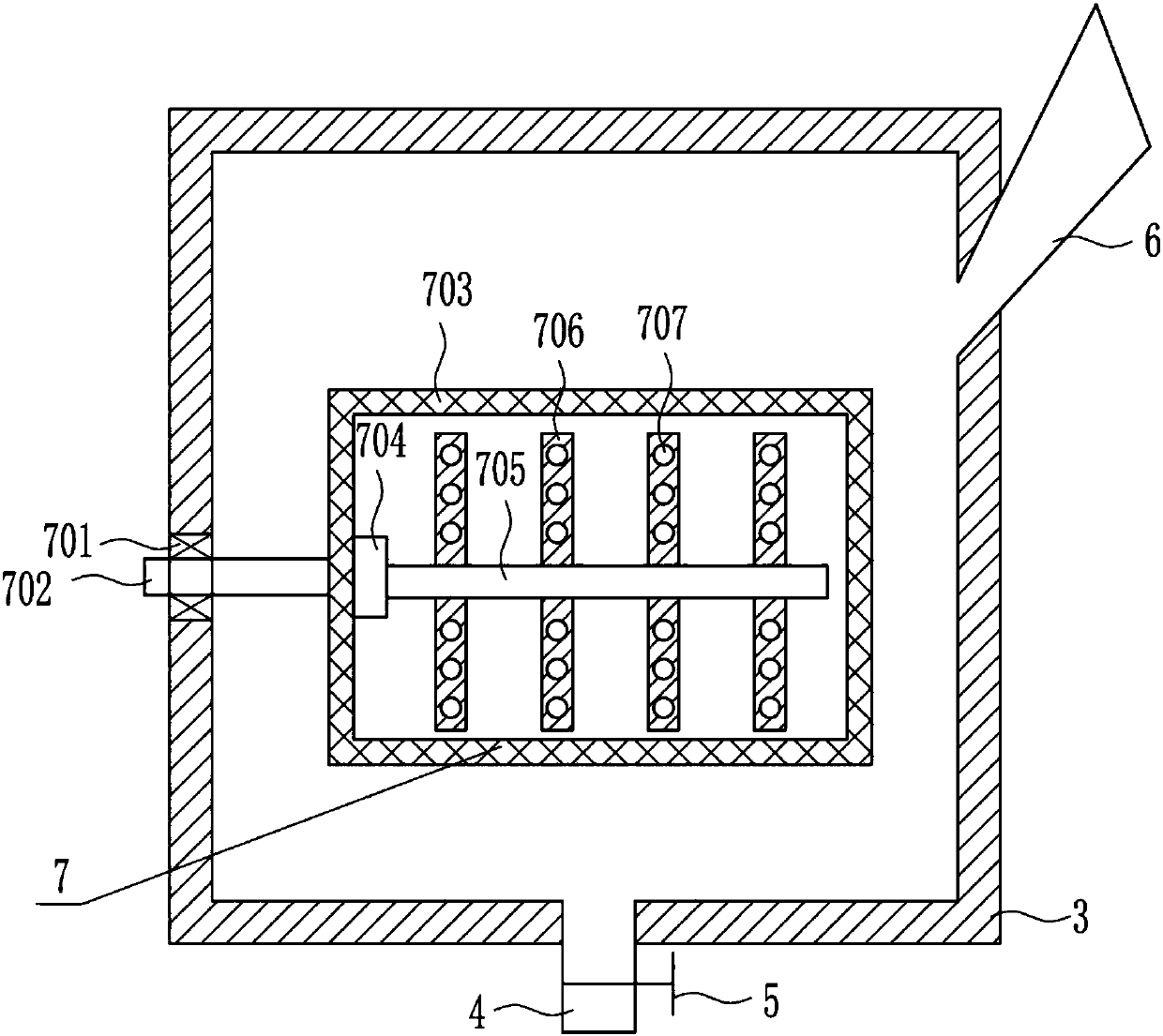

[0039] The mixing device 7 includes a first bearing seat 701, a first rotating shaft 702, a screen frame 703, a second bearing seat 704, a second rotating shaft 705 and a stirring blade 706, and the first bearing seat 701 is ...

Embodiment 3

[0041] An obstetric milk powder mixing device, such as Figure 1-6 As shown, it includes a base plate 1, a pole 2, a mixing box 3, a liquid outlet pipe 4, a valve 5, a hopper 6, a mixing device 7 and a driving device 8, and the left and right sides of the top of the base plate 1 are vertically connected by bolts. Rod 2, a mixing box 3 is connected by bolts between the tops of the two poles 2, a liquid outlet pipe 4 is connected in the middle of the bottom of the mixing box 3, and a valve 5 is arranged on the liquid outlet pipe 4, and the upper right side of the mixing box 3 A hopper 6 is installed, a mixing device 7 is arranged in the mixing box 3 , and a driving device 8 is arranged on the top of the bottom plate 1 on the left side of the left pole 2 .

[0042] The mixing device 7 includes a first bearing seat 701, a first rotating shaft 702, a screen frame 703, a second bearing seat 704, a second rotating shaft 705 and a stirring blade 706, and the first bearing seat 701 is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap