A metal forming release agent

A technology of metal forming and mold release agent, which is applied in casting molding equipment, metal processing equipment, cores, etc. It can solve the problems of poor lubrication performance, poor separation and demolding ability, and failure to meet environmental protection standards, and achieve good cooling performance. Thermal insulation, strong separation and demoulding ability, beneficial to automatic production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

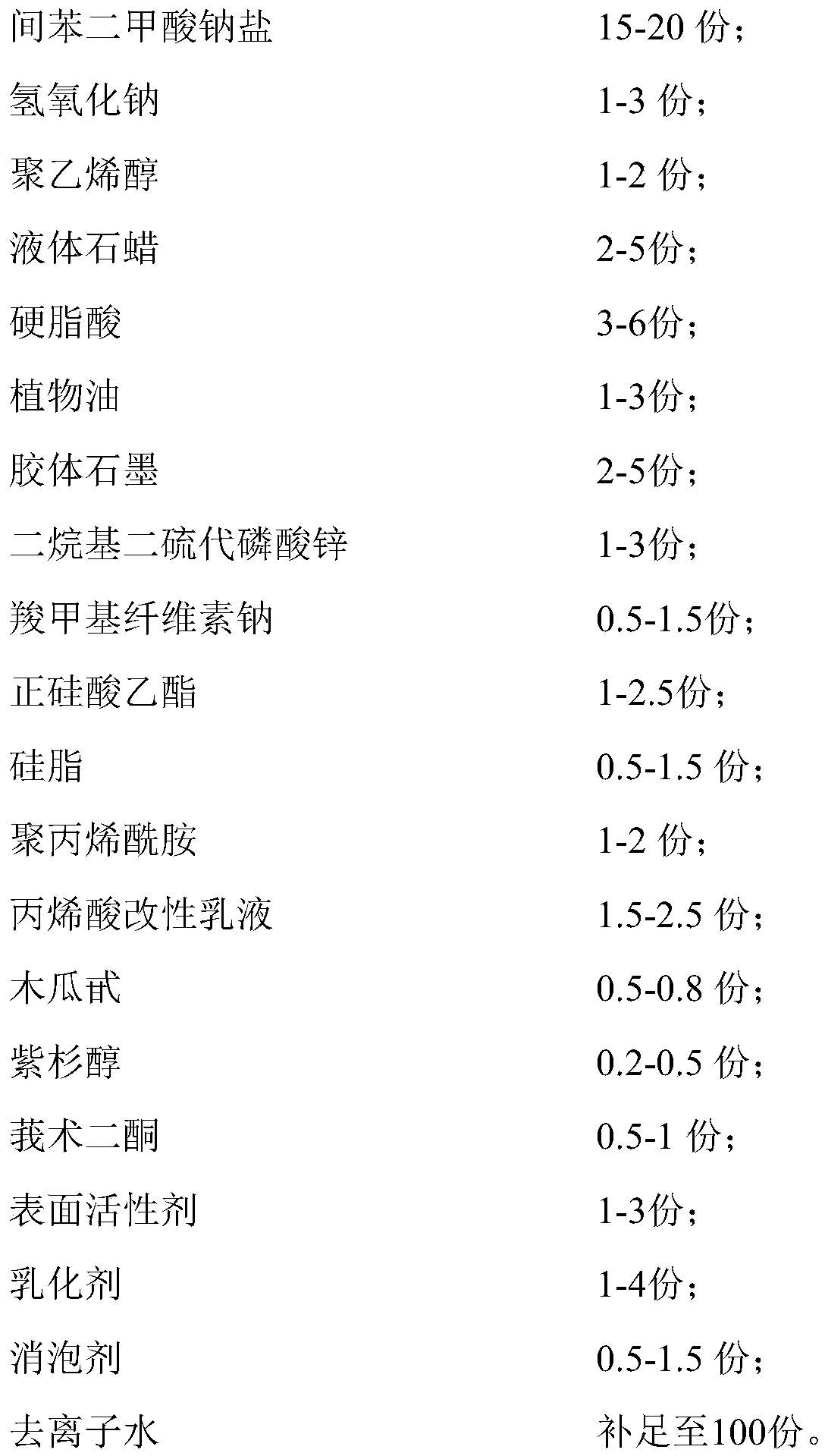

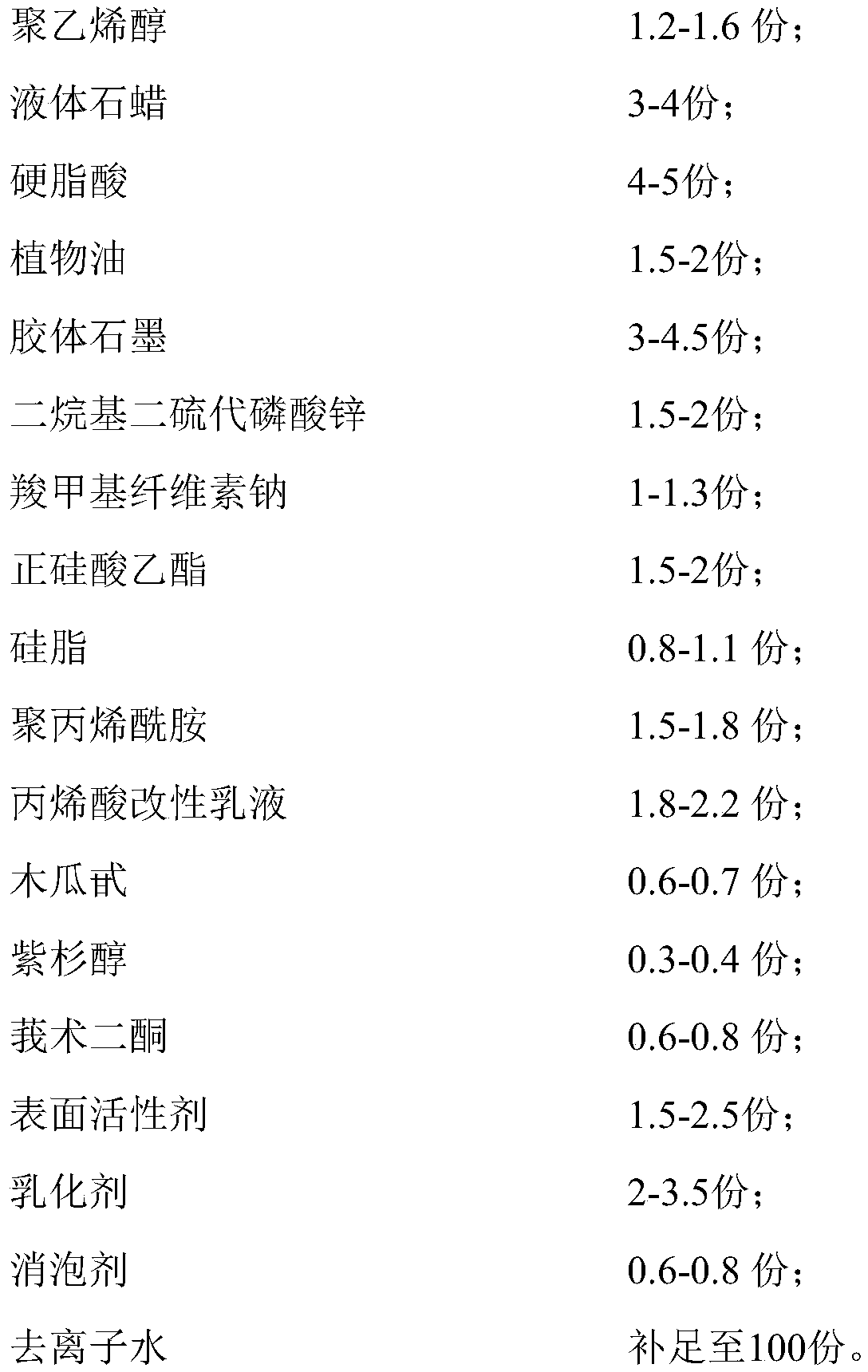

[0037] Metal forming release agent components: 17.5 parts of sodium isophthalate, 2 parts of sodium hydroxide, 1.4 parts of polyvinyl alcohol, 3.5 parts of liquid paraffin, 4.5 parts of stearic acid, 1.8 parts of vegetable oil, 4 parts of colloidal graphite, dioxane Zinc dithiophosphate 1.6 parts, sodium carboxymethyl cellulose 1.2 parts, ethyl orthosilicate 1.7 parts, silicone grease 1 part, polyacrylamide 1.65 parts, acrylic modified emulsion 2.1 parts, papain 0.63 parts, paclitaxel 0.38 parts, 0.75 parts of curedione, 2.2 parts of surfactants, 2.8 parts of emulsifiers, 0.65 parts of defoamers, and deionized water to make up to 100 parts.

[0038] The preparation method of metal forming release agent, the steps are as follows:

[0039] (1) Add 30 parts of deionized water to the preparation tank, then add isophthalic acid sodium salt, polyvinyl alcohol, liquid paraffin, stearic acid, vegetable oil, colloid in the manner of stirring for 5 minutes for each material added Graph...

Embodiment 2

[0044] Metal forming release agent components: 15 parts of sodium isophthalate, 3 parts of sodium hydroxide, 1 part of polyvinyl alcohol, 5 parts of liquid paraffin, 3 parts of stearic acid, 3 parts of vegetable oil, 2 parts of colloidal graphite, dioxane 3 parts of zinc dithiophosphate, 0.5 parts of sodium carboxymethyl cellulose, 2.5 parts of ethyl orthosilicate, 0.5 parts of silicone grease, 2 parts of polyacrylamide, 1.5 parts of acrylic modified emulsion, 0.8 parts of papain, paclitaxel 0.2 parts, 1 part of curedione, 1 part of surfactant, 4 parts of emulsifier, 0.5 part of defoamer, and deionized water to make up to 100 parts.

[0045] The preparation method is the same as in Example 1.

Embodiment 3

[0047] Metal forming release agent components: 20 parts of sodium isophthalate, 1 part of sodium hydroxide, 2 parts of polyvinyl alcohol, 2 parts of liquid paraffin, 6 parts of stearic acid, 1 part of vegetable oil, 5 parts of colloidal graphite, dioxane 1 part of zinc dithiophosphate, 1.5 parts of sodium carboxymethyl cellulose, 1 part of ethyl orthosilicate, 1.5 parts of silicone grease, 1 part of polyacrylamide, 2.5 parts of acrylic modified emulsion, 0.5 parts of papain, paclitaxel 0.5 parts, 0.5 parts of curedione, 3 parts of surfactant, 1 part of emulsifier, 1.5 parts of defoamer, and deionized water to make up to 100 parts.

[0048] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com