A kind of manufacturing method of stainless steel rectangular tube support beam

A manufacturing method, stainless steel technology, applied in the direction of load-bearing elongated structural components, buildings, building components, etc., can solve the problem of large workpieces that cannot meet the precision requirements, complex process of steel structure support beams, and heavy weight of steel structure support beams And other problems, to achieve the effect of beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

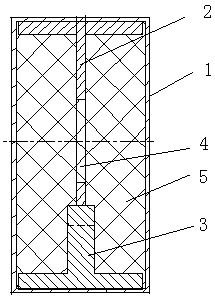

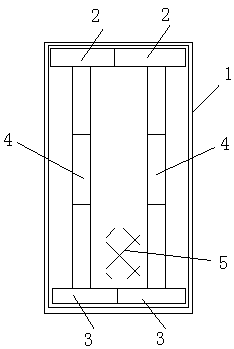

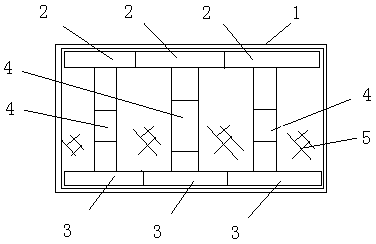

[0028] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0029] A stainless steel rectangular tube support beam, including a stainless steel rectangular tube, a skeleton, and expanded cement, the stainless steel rectangular tube is provided with a tightly bonded skeleton, and the two opposite planes in the stainless steel rectangular tube are seamlessly connected with the two planes of the skeleton, the The frame described above is an I-beam whose top and bottom sides are equal, and the cavity of the I-beam in the stainless steel rectangular tube is provided with a filler of expansive cement. The I-beam is composed of two T-shaped steels, and each T-shaped steel is evenly distributed with filler plate holes, and the plate holes are round holes, elliptical holes, or rectangular holes.

[0030] A method for manufacturing a stainless steel rectangular tube support beam, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com