Machining clamp for lower shell of HUD

A head-up display and housing technology, applied in the direction of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of poor adaptability, poor clamping stability, cumbersome operation, etc., to simplify the clamping operation, improve the accuracy, improve the installation The effect of clip stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

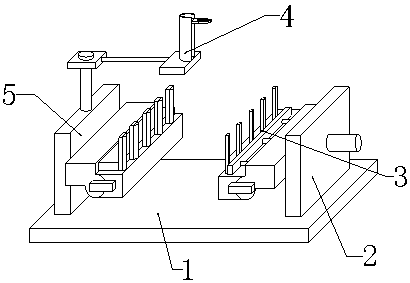

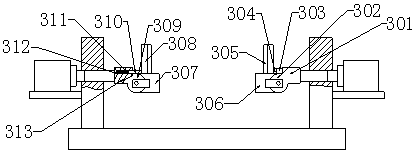

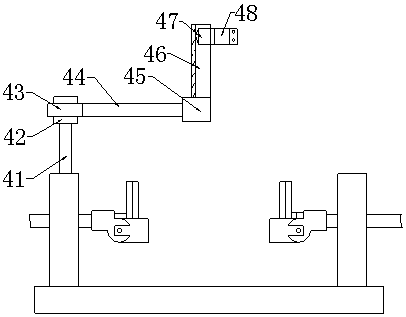

[0022] see Figure 1-Figure 3, the present invention provides a technical solution: a HUD head-up display lower housing processing fixture, including a base plate 1, a support plate 2, a clamping assembly 3, a hole depth monitoring assembly 4, and a support plate 2 5, and the support plate 2 is fixed On the upper end surface of the base plate 1, the support plate 2 5 is arranged on the left side of the support plate 2, and the support plate 2 5 is fixed on the upper end surface of the base plate 1, and the clamping assembly 3 is installed on the support plate 2 and the support plate 2 5, clamping Component 3 includes a fixed carrier 301, a cylinder 302, an electric telescopic column 303, a connecting bar 304, a clamping bar 305, a rotating carrier...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap