Teaching type outer circle and plane dual-purpose grinding machine tool

A grinding and plane technology, which is applied to the parts of grinding machine tools, grinding frame, grinding bed, etc., can solve the problem of not being able to intuitively and clearly observe the operation of surface grinders and cylindrical grinders, and the operation of surface grinders and cylindrical grinders. The grinding machine is bulky and reduces the enthusiasm of students to learn, etc., so as to improve the processing effect, control the manufacturing cost and improve the teaching effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

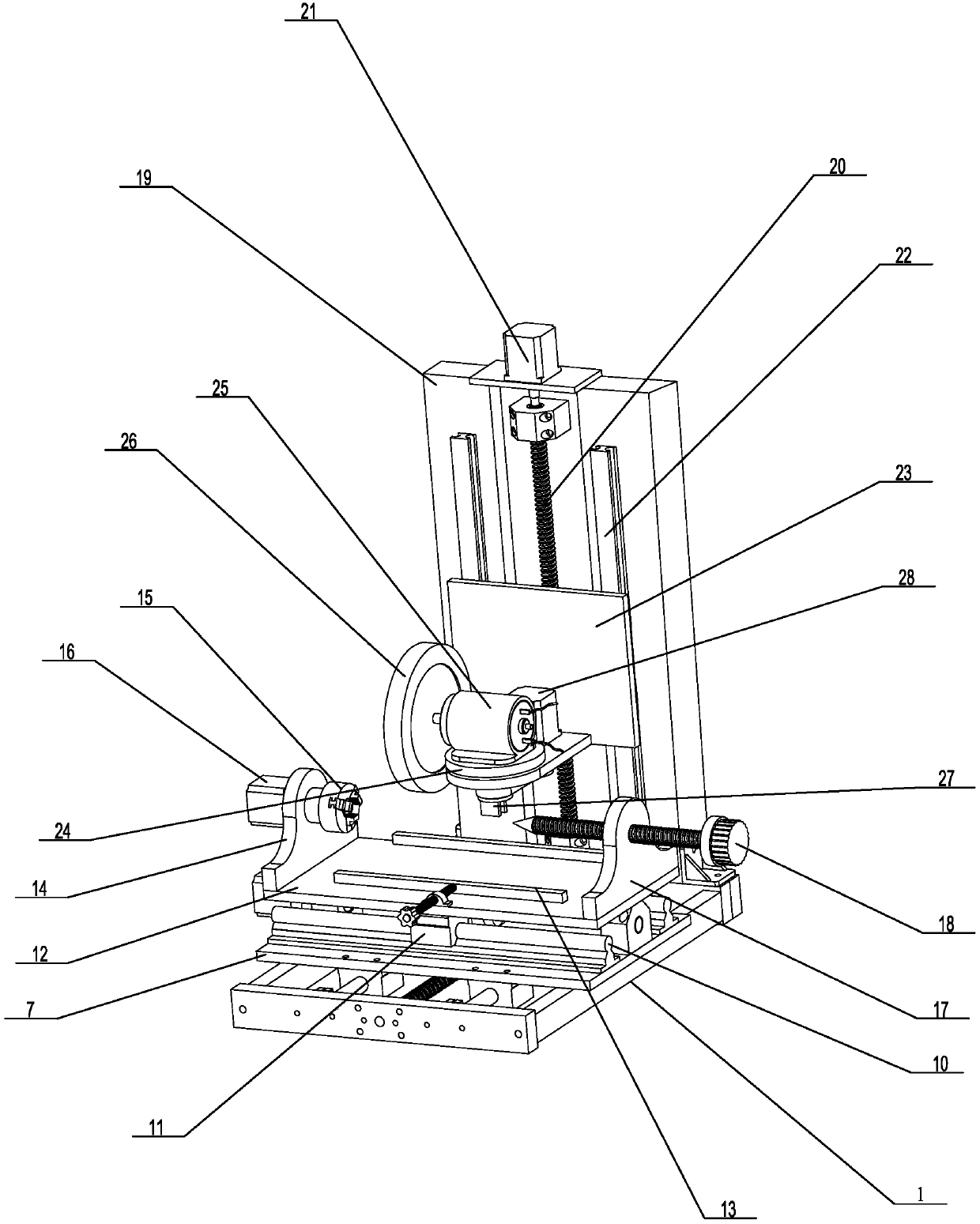

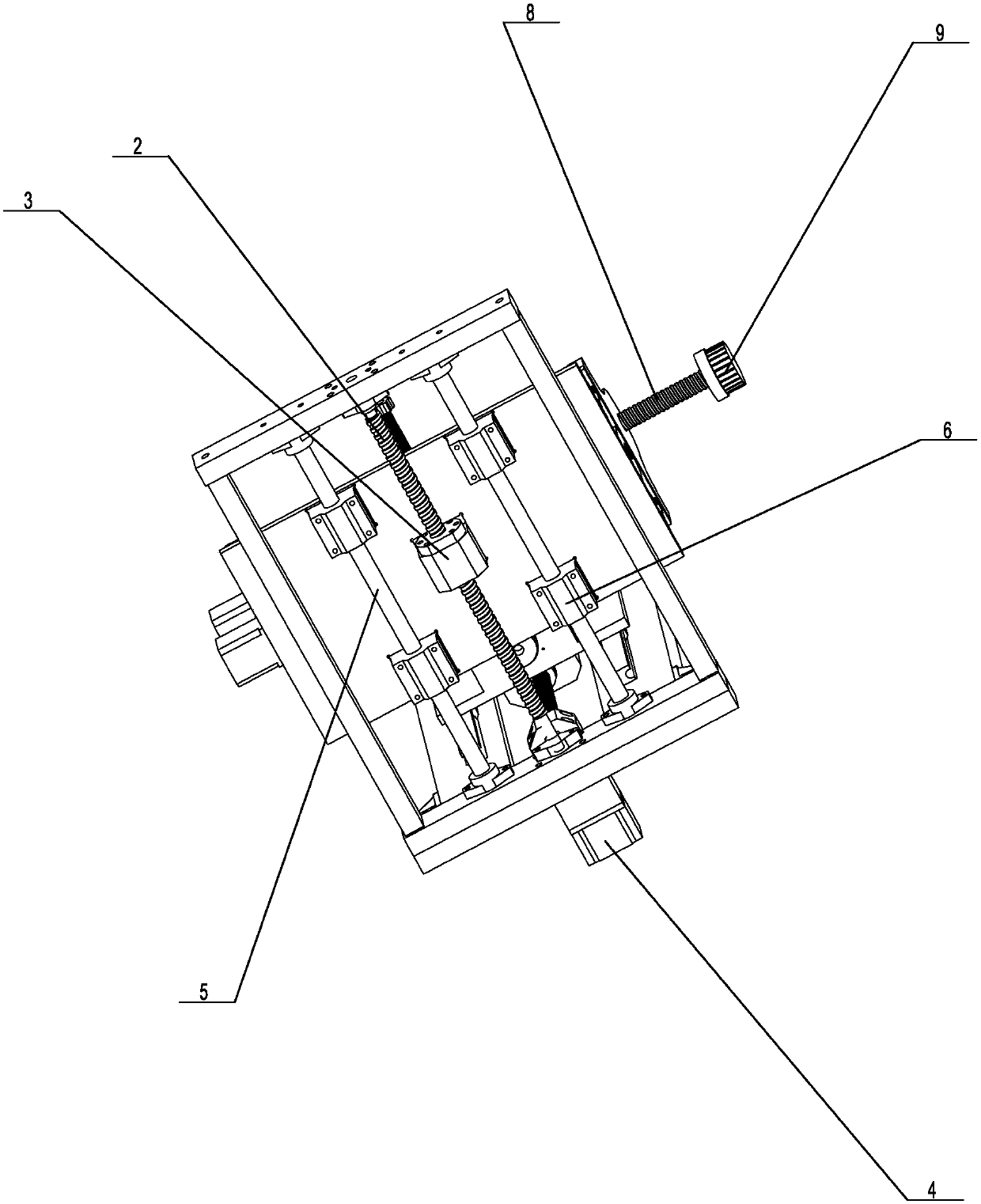

[0017] like figure 1 A specific embodiment of the present invention is proposed as shown, a teaching-type cylindrical and plane dual-purpose grinding machine tool, including a square underframe frame 1, a Y-axis ball screw 2 is arranged inside the underframe frame 1, and the The Y-axis ball screw 3 is provided with its matching Y-axis ball 3, and its end is provided with a Y-axis motor 4, and both sides of the Y-axis ball screw 2 are provided with 1 fixed in the chassis frame. Y-axis linear slides 5, two Y-axis linear slides 5 are provided with Y-axis sliders 6, and in this implementation, two Y-axis linear slides 5 are provided with two Y-axis slides 6; the Y-axis The balls 3 and all the Y-axis sliders 6 are connected to the bottom surface of the workbench support plate 7, then the workbench support plate 7 moves along the Y-axis direction along with the Y-axis balls 3 and the four Y-axis sliders 6, An X-axis ball screw 8 is provided on the workbench support plate 7, and an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com