Pin puller used for maintenance

A technology for pin pullers and placement slots, applied in tool storage devices, hand-held tools, manufacturing tools, etc., can solve problems such as lack of functions, inconvenient pin pullers to replace pin pullers of different sizes, poor protection effect, etc. Achieve the effect of improving the protection effect, reducing the occupied space, and being convenient to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

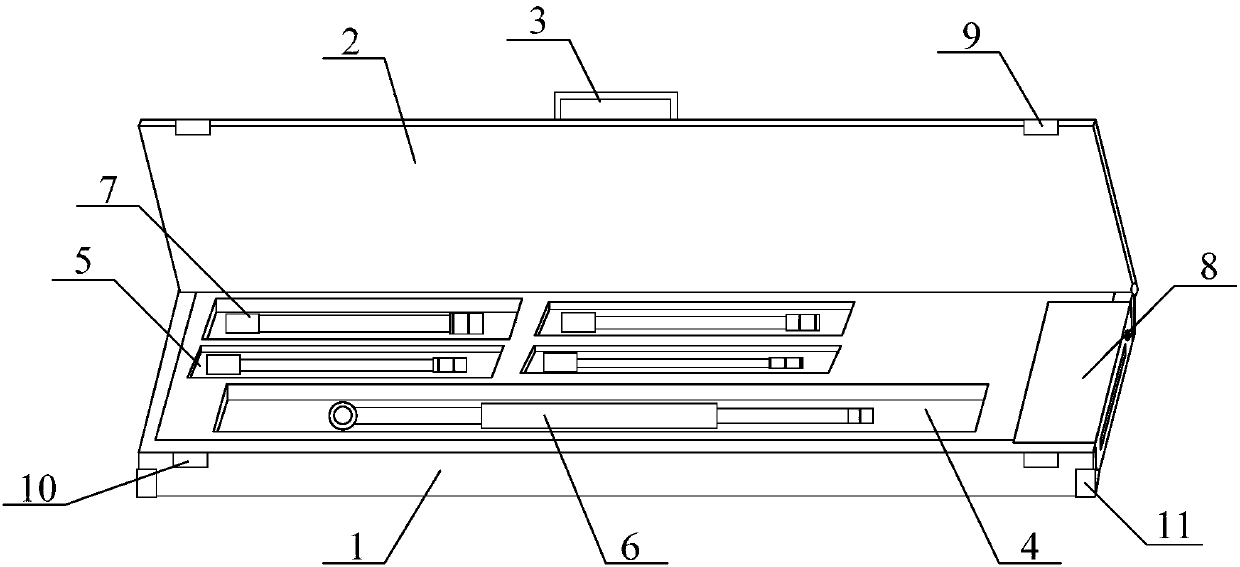

[0029] as attached figure 1 to attach Figure 4 shown

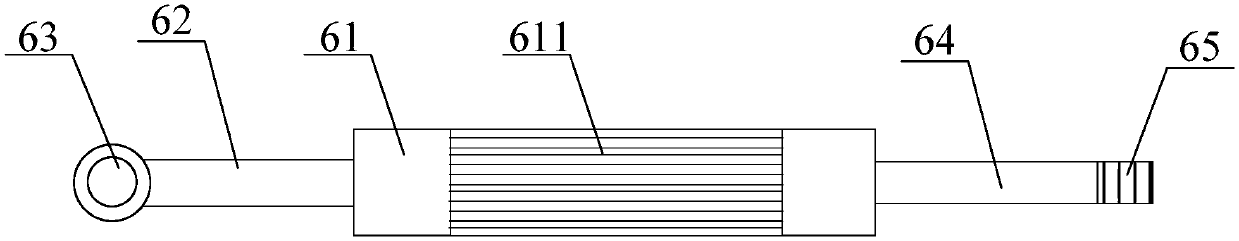

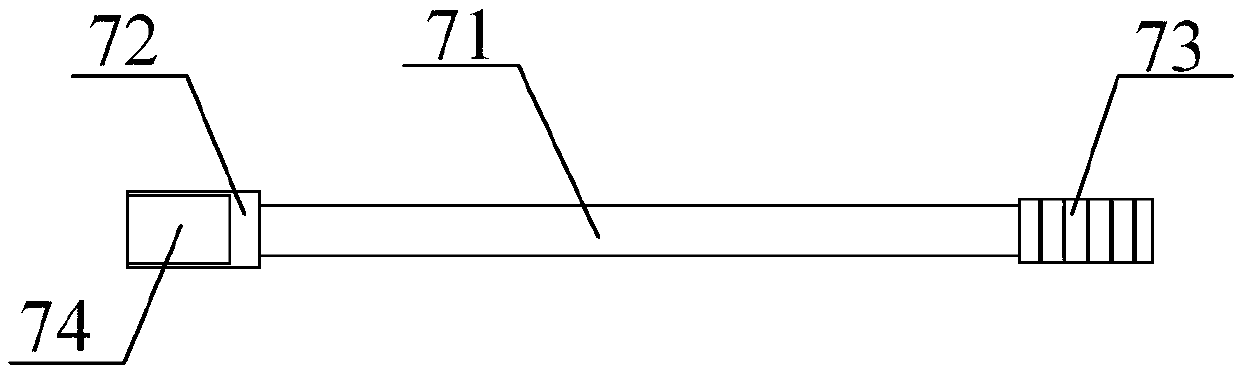

[0030] The invention provides a pin puller for maintenance, which includes a storage box 1, a box cover 2, a handle 3, a pin puller placement slot 4, a pin puller placement slot 5, a pin puller knot 6, a pin puller The device adjustment head structure 7, the lighting structure 8, the upper lock 9 and the lower lock 10, the box cover 2 is pivotally connected to the upper part of the storage box 1; the handle 3 is injection molded on the middle and upper part of the box cover 2 The pin puller placement groove 4 and the pin puller placement groove 5 are also horizontally arranged on the top of the storage box 1 respectively; the pin puller knot 6 is placed in the pin puller placement groove 4; The pin puller adjustment head structure 7 is placed in the pin puller placement groove 5; the lighting structure 8 is installed on the right side of the storage box 1; the upper lock 9 is respectively installed on the upper part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com