Ship anti-capsizing system

A ship and system connection technology, applied in ship safety, ship, transportation and packaging, etc., can solve the problems of difficult ship capsizing, high cost, bulky volume, etc., and achieve the effect of preventing capsizing and slowing down the sinking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

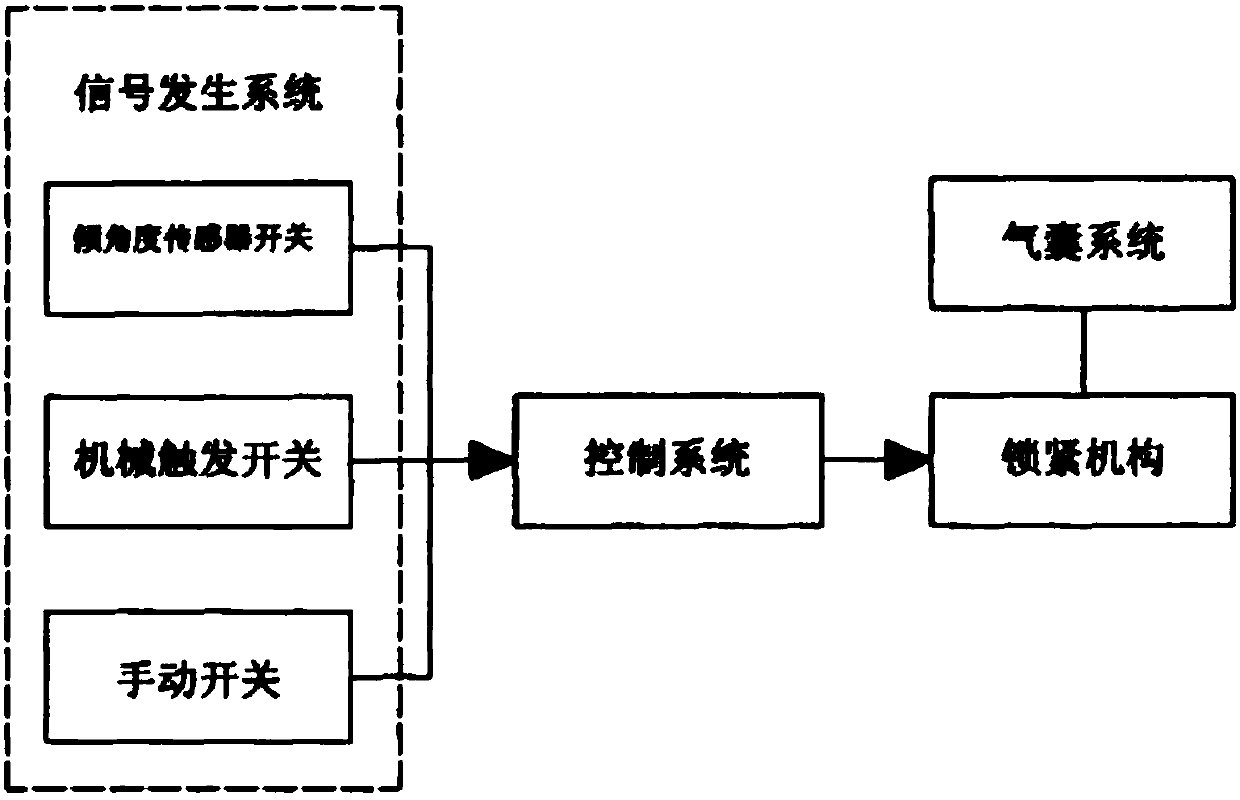

[0008] The principle of a ship anti-rolling system of the present invention is as follows: figure 1 As shown, it includes a signal generating system, a control system, an opening mechanism and a locking mechanism connected in sequence, and the locking mechanism is connected with the airbag system. The signal generating system is an inclination sensor switch, a mechanical trigger switch or a manual switch. The airbag system is arranged on the ship side bulwarks 3 on both sides of the hull 1 . The locking mechanism is arranged in the side deck of the hull. The airbag system is composed of an airbag with 6-7 atmospheric pressure gas inside and an airbag shell. The airbag shell is an outwardly convex arc panel, and the airbag shell is made of Q235 carbon steel; the lower side of the airbag shell is connected to the side of the ship through a joint The outer wall of the side plate is collated, the upper side of the airbag shell is connected with the hull through the locking mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com