Device and method for pressing label of electric energy meter qualification certificate on electric energy meter verification assembly line

A technology of electric energy meter verification and pressing device, which is applied in the direction of labeling, packaging, labeling machines, etc., can solve the problems of low efficiency, poor certification, and human resources consumption, so as to prolong life, reduce clamping times, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

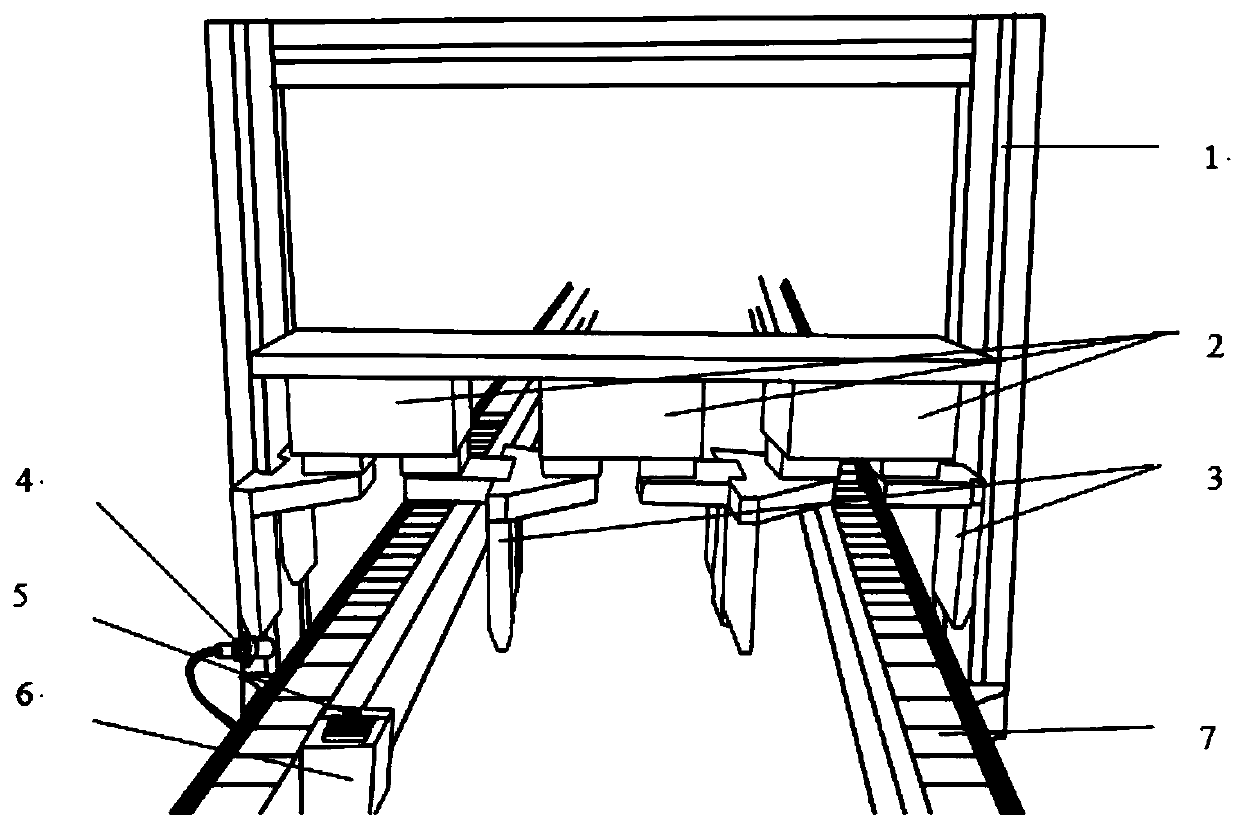

[0032] Such as figure 1 As shown, the electric energy meter certification label pressing device on the electric energy meter verification line is provided with a door-shaped bracket 1 above the electric energy meter automatic assembly line conveyor belt 7, and the door-shaped bracket 1 is provided with at least one for detecting whether the electric energy meter passes through the bracket. There are three clamping cylinders 2 on the door bracket 1, each clamping cylinder has a pair of grippers 3, and a stopper with a proximity switch 5 is provided on the conveyor belt at the set position below the door bracket 1. device6.

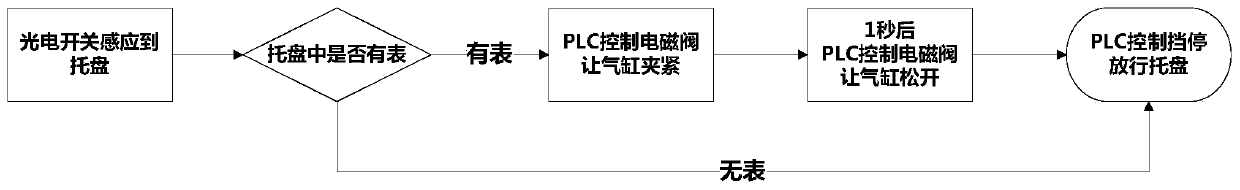

[0033] Such as figure 2 As shown, on the automatic verification line of the electric energy meter, the electric energy meter is placed side by side on the tray and is conveyed by the conveyor belt. During the process of being conv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com