Crane box end anti-sway device

A technology of anti-rolling device and crane, which is applied in the direction of transportation and packaging, load hanging components, etc. It can solve the problems of reduced site utilization, hidden safety hazards, and difficulties in container stacking, and achieve the effect of promoting stability and slowing down swings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

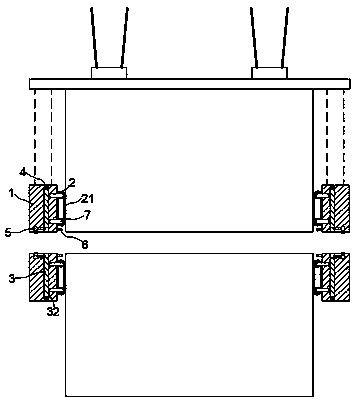

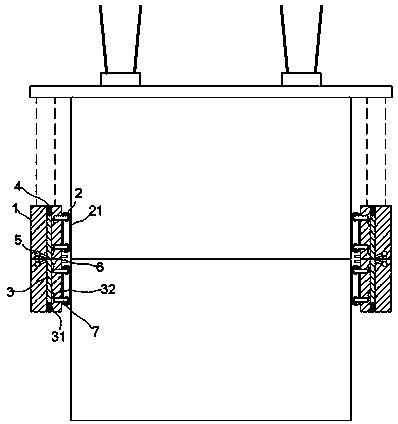

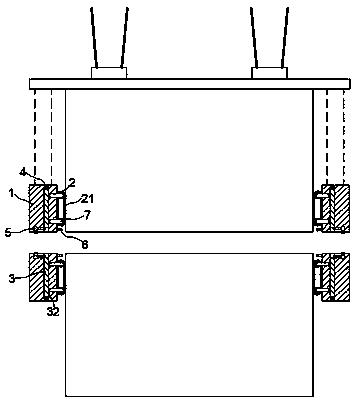

[0019] exist figure 1 , figure 2 In the shown embodiment, the anti-sway device at the end of the crane box includes a housing 1 made of permanent magnetic material, and the magnetic pole connection line of the permanent magnetic material is parallel to the front and rear connection lines of the housing 1;

[0020] A group of driving rollers 2 are installed on the bottom of the housing 1, and the driving rollers 2 can freely rotate around their own shafts; between the driving rollers 2, a driving crawler 21 is set, and the driving crawler 21 is composed of permanent magnets. joined together;

[0021] An adjustment slot is provided inside the housing 1, and an adjustment column 3 is slidably arranged in the adjustment slot, and one end of the adjustment column 3 is connected with the rear part of the housing 1 through a tension spring 31; An electronically controlled telescopic rod 4 is installed between the rear end of 3 and the housing 1, and the electrically controlled tel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com